Method for manufacturing hollow sodium inflating valve with closed disc end

A manufacturing method and valve technology, which are applied to lift valves, mechanical equipment, valve devices, etc., can solve the problems of complicated processing procedures, small space in the bottom cavity, and small amount of sodium filling, so as to reduce welding defects, reduce manufacturing costs, and reduce costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

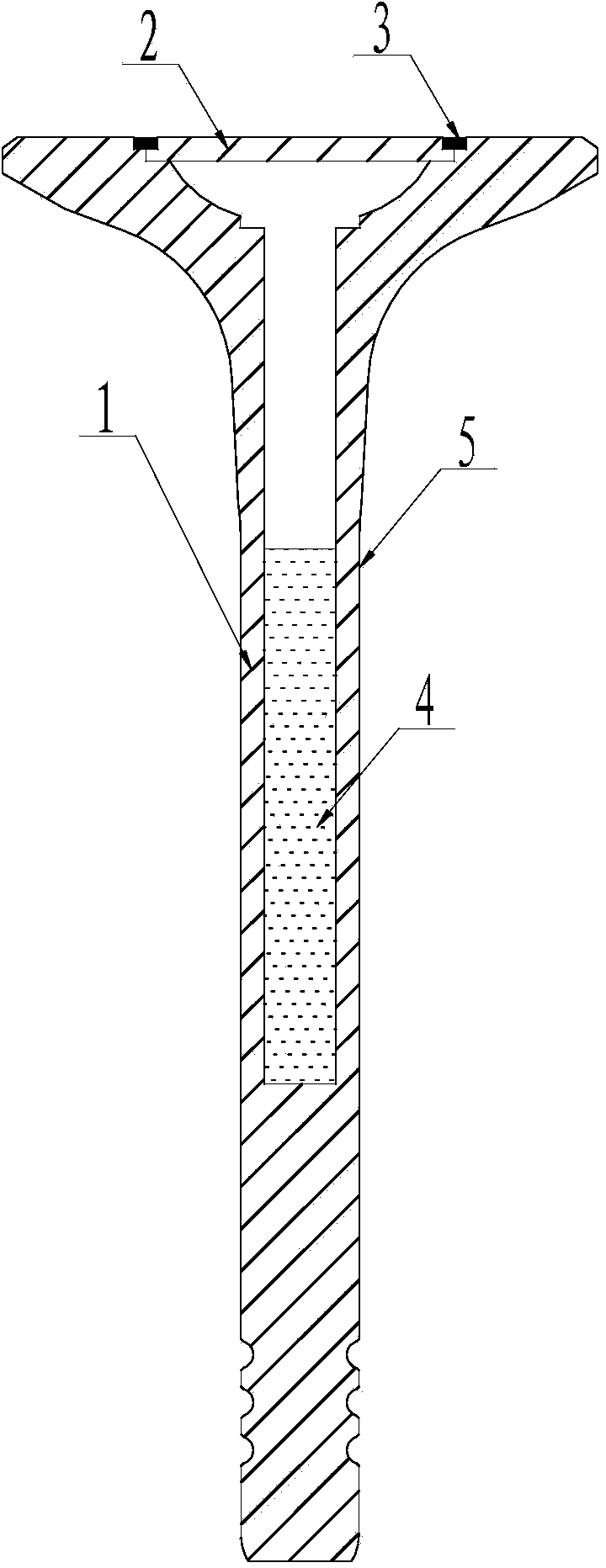

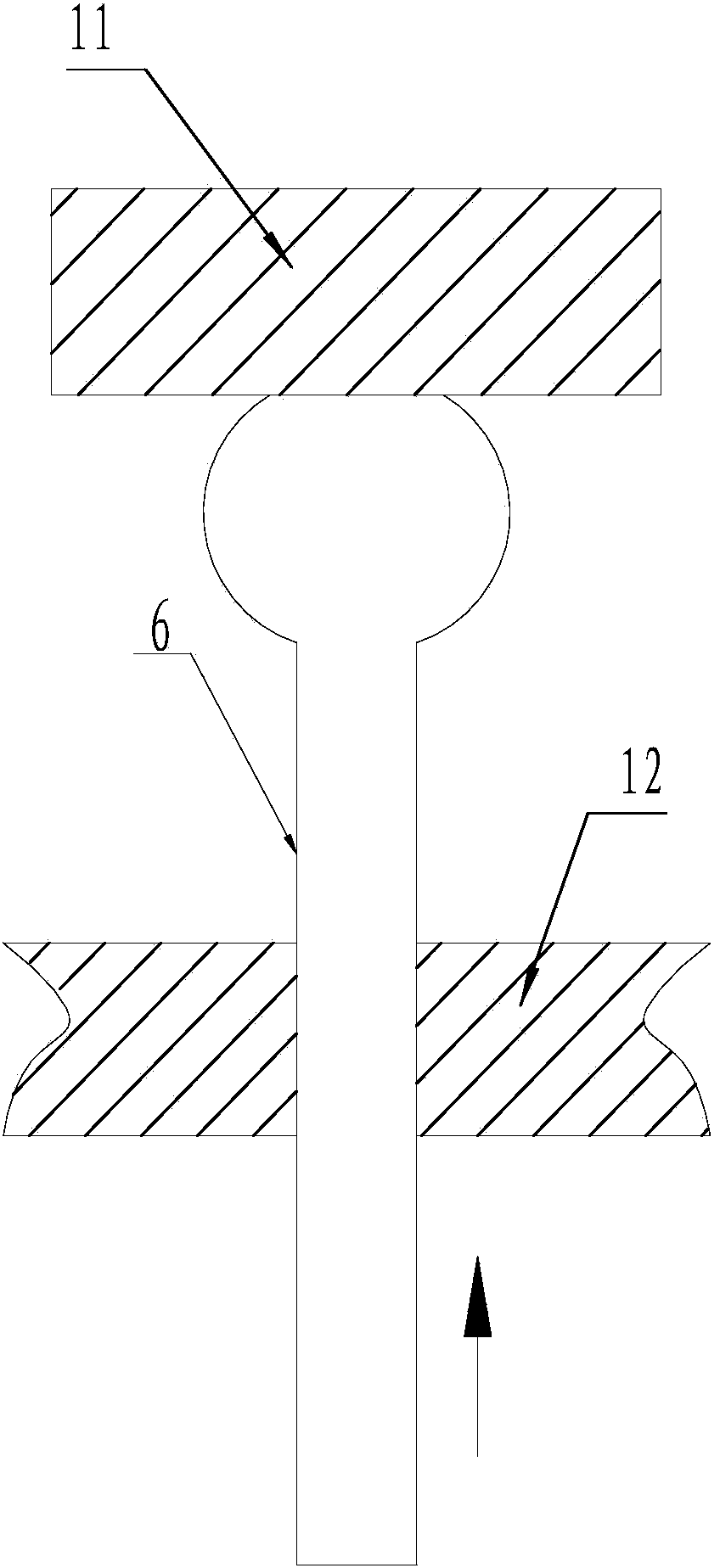

[0025] Embodiment 1, a kind of manufacturing method of disk end airtight hollow sodium-filled valve is characterized in that: comprise the following steps: A. electric pier, will intercept slender bar stock 6 according to the rod portion diameter of valve finished product and gross weight, use The electric pier machine heats one end of the bar to about 1100±50°C, and at the same time is pushed by the cylinder to form a pre-blank with a spherical end, that is, a garlic shape.

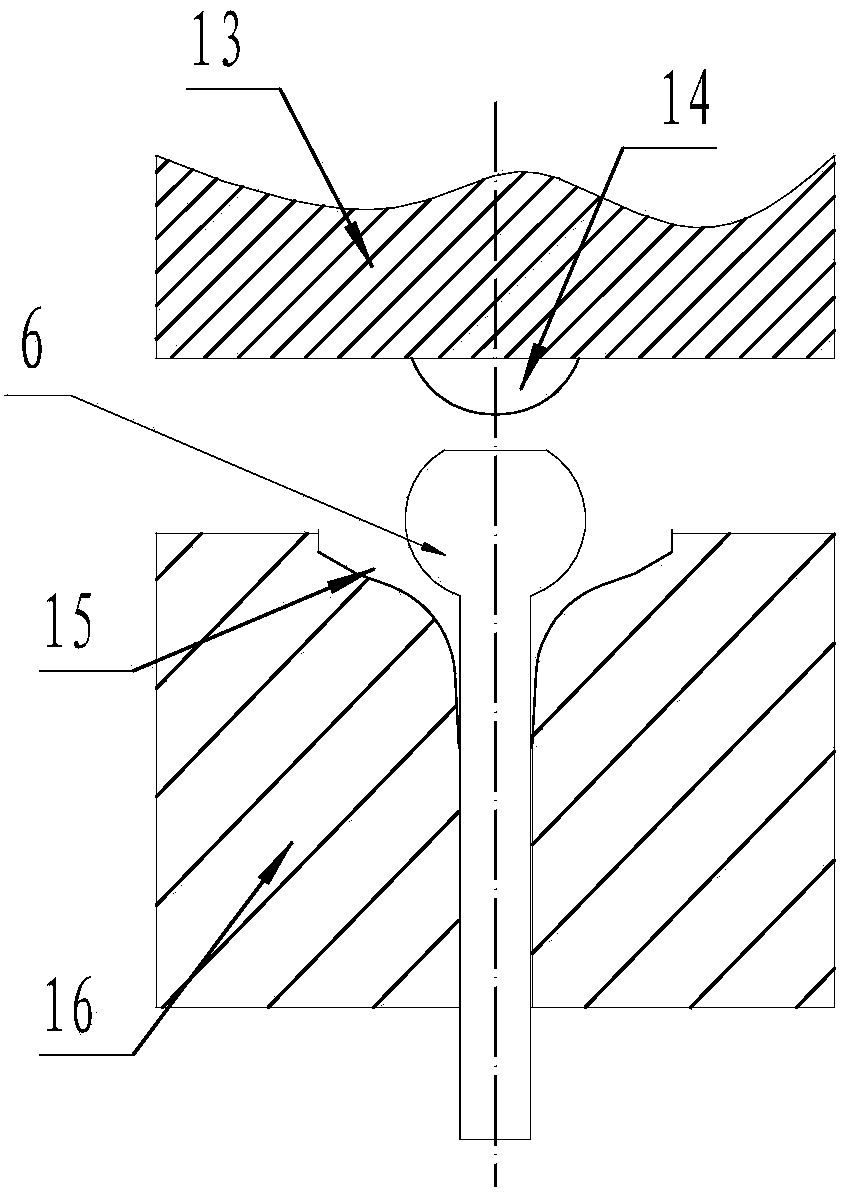

[0026] B. Use the die forging equipment to forge the pre-blank into the shape of the valve blank. The center of the bottom plane of the upper mold 13 of the die forging equipment has an upper mold ball head 14, and the lower mold cavity 15 is consistent with the outer contour of the valve. The upper mold used is provided with a mold ball head, which can forge the valve bottom socket 19 in the disc end of the valve blank,

[0027] C. Use turning equipment to process three steps in the bottom socket of the...

Embodiment 2

[0034]Example 2, a disk-end-closed hollow sodium-filled valve manufactured by a method for manufacturing a disk-end-closed hollow sodium-filled valve. Including the valve stem and the valve disc, the center hole of the valve stem and the bottom pocket of the valve disc are filled with metal sodium, and there are three steps in the bottom pocket of the valve disc, from bottom to top are drilling platform steps, installation The sealing cover step, the end face of the valve disc and the groove formed by the sealing cover of the disc end face are surfacing welded with superalloy, and the surface of the valve stem and valve disc is provided with a chrome-plated layer or a nitride layer. For the disc cone surface, there is a superalloy layer or The thickness of nitrided layer, nitrided layer or chromium plating layer is 0.01mm, and the thickness of surfacing layer is 0.5mm.

[0035] The diameter of the drilling platform step is 1.5-1.7 times the diameter of the central hole of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com