Numerical control inverted double-station deep hole drilling machine

A deep-hole drilling machine and dual-station technology, applied in the direction of boring/drilling, drilling/drilling equipment, components of boring machine/drilling machine, etc., can solve the problem that the surface quality requirements cannot be met, the drill bit is broken, and the waiting time is not sufficient. Use and other issues to achieve the effect of ensuring dimensional accuracy and inner surface finish, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

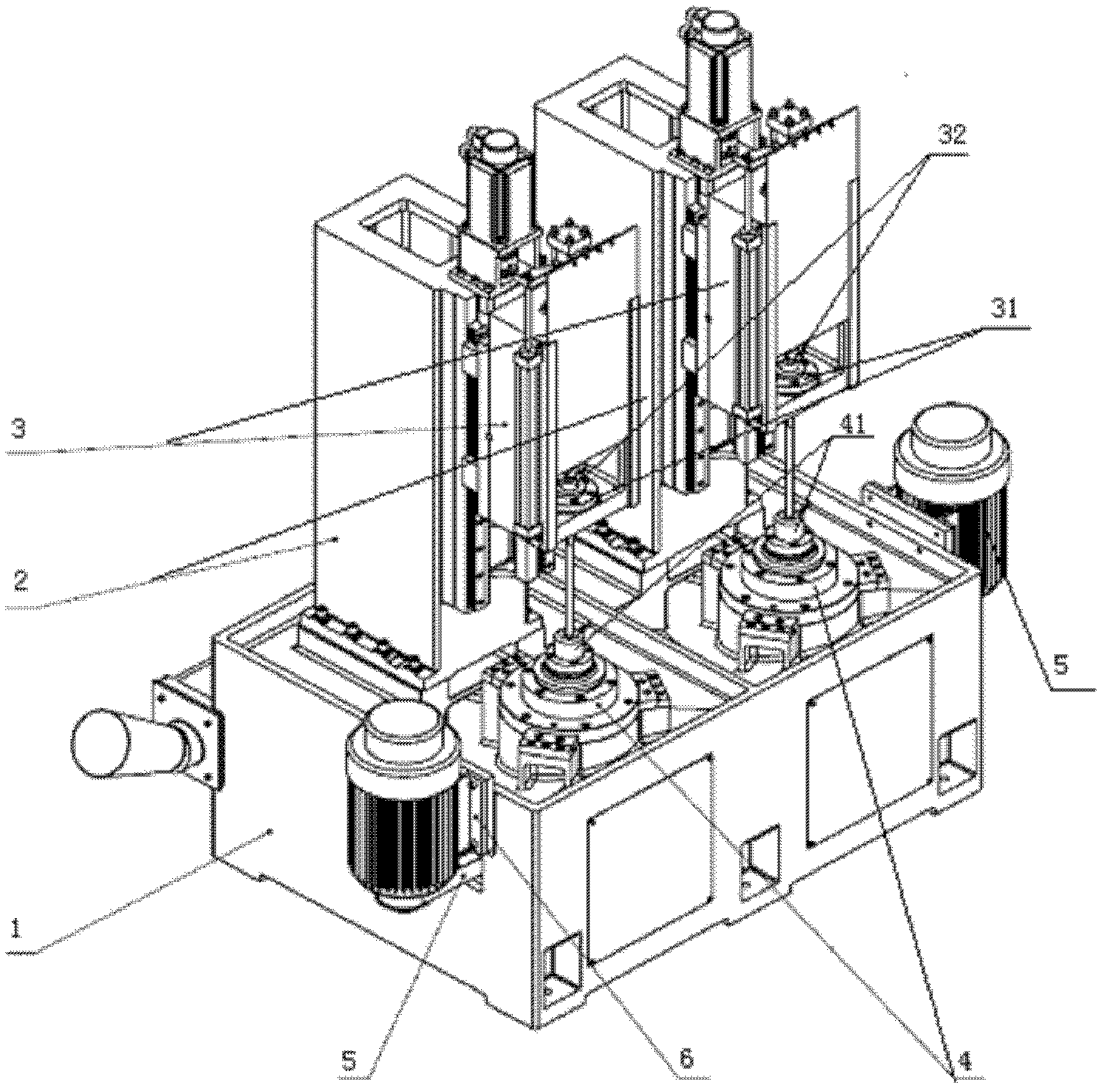

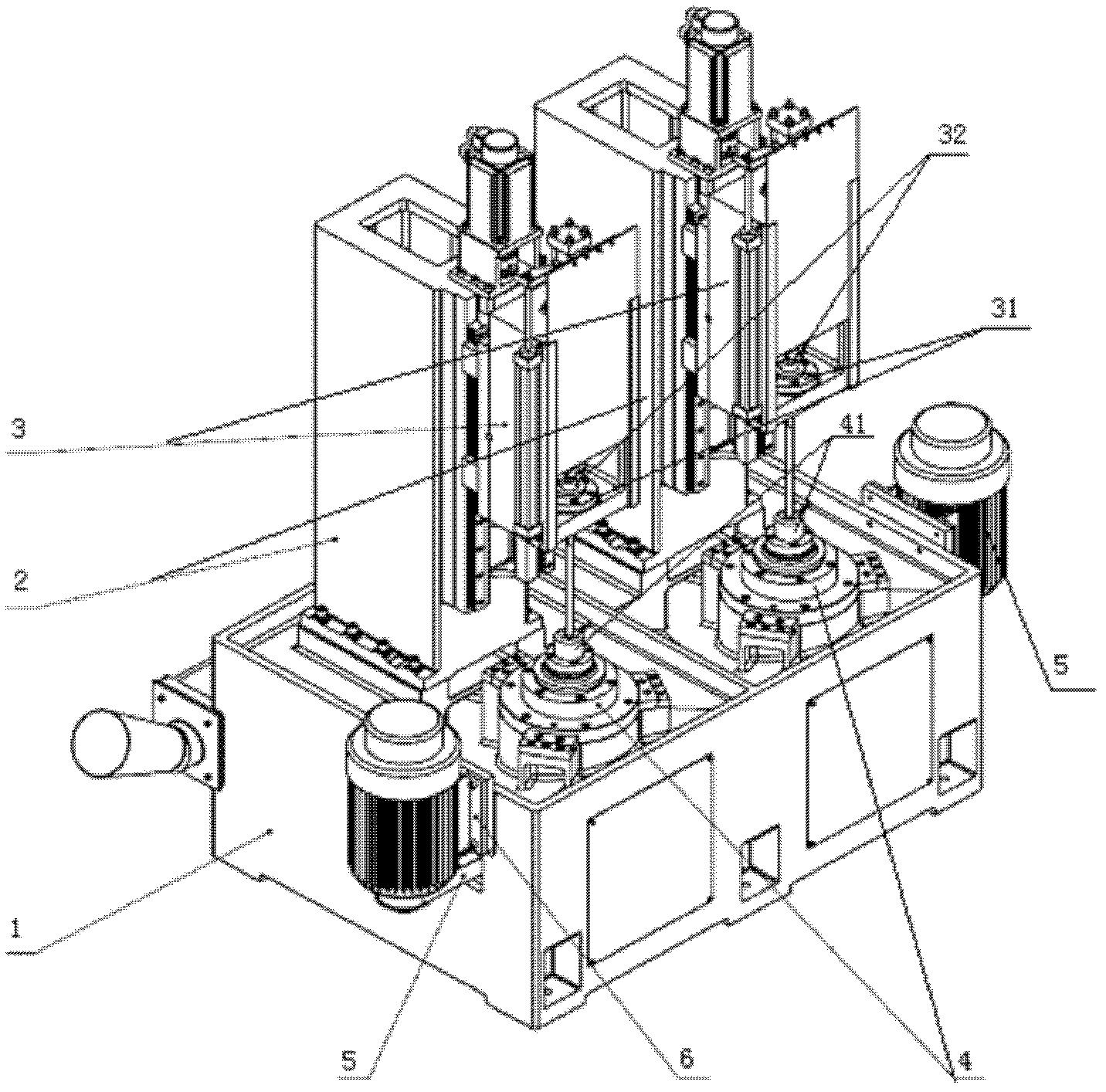

[0013] Such as figure 1 As shown, the CNC inverted double-station deep hole drilling machine includes a double-station funnel-shaped bed part 1, and a left and right frame-shaped column part 2 is fixed and vertically installed on the table at the rear of the bed part 1. , the two frame-shaped pressing parts 3 are respectively connected to the left and right column parts 2 by sliding along the up and down direction with the slide rail as the guide. (not shown in the figure) to realize workpiece positioning, clamping and oil cooling; two left and right main shaft parts 4 are fixedly installed on the table at the front part of the bed part 1, and a special deep Hole drilling tool, bed part 1 both sides are fixedly installed with variable frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com