Induction ring tracking device of rotary lathe

A technology of tracking device and induction ring, which is applied in the direction of feeding device, automatic control device, metal processing machinery parts, etc., can solve the problem of low milling flatness, inability to ensure the shape and dimensional accuracy of the milling surface, affecting the performance and life of the machine tool, etc. problem, to achieve the effect of ensuring shape and size accuracy and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

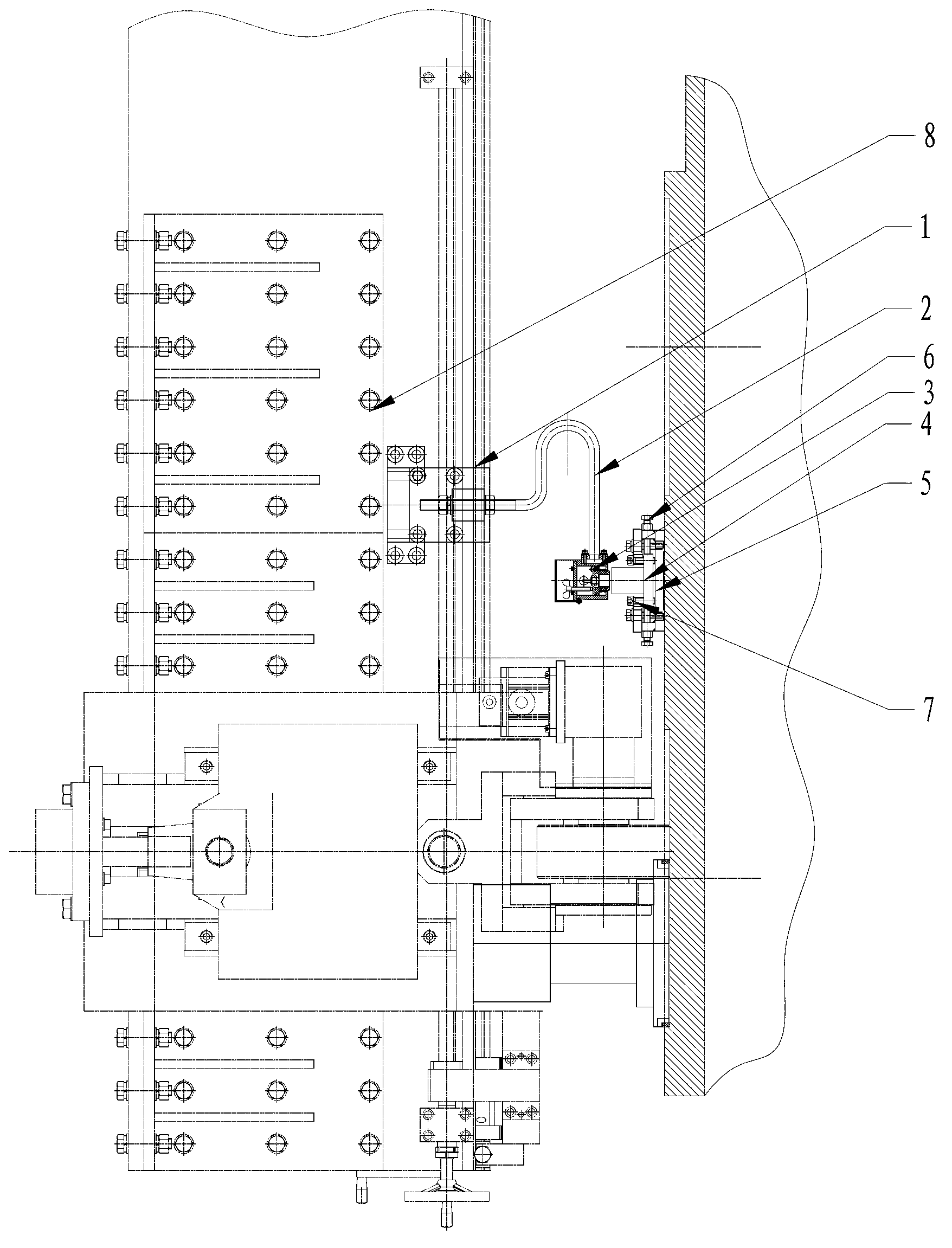

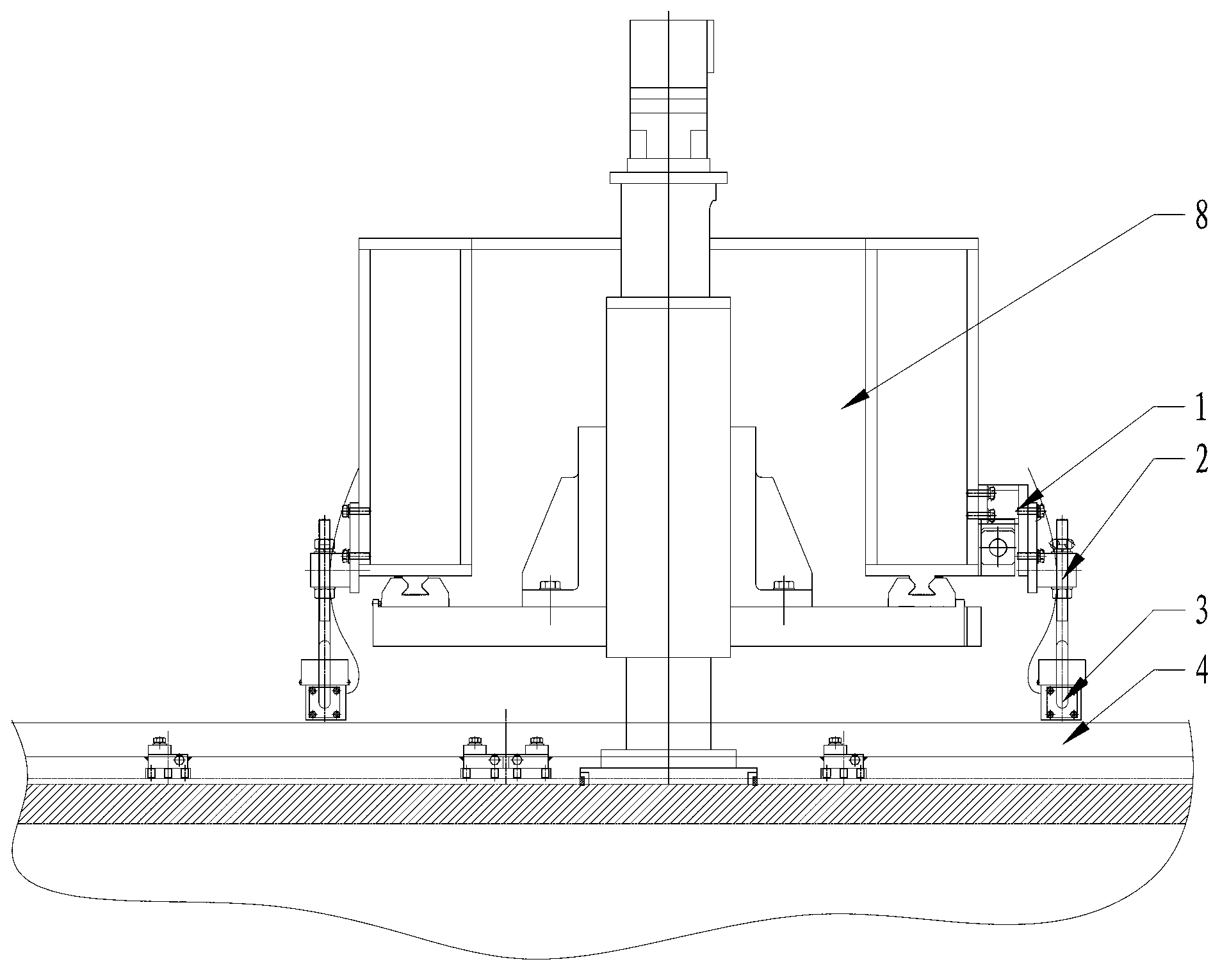

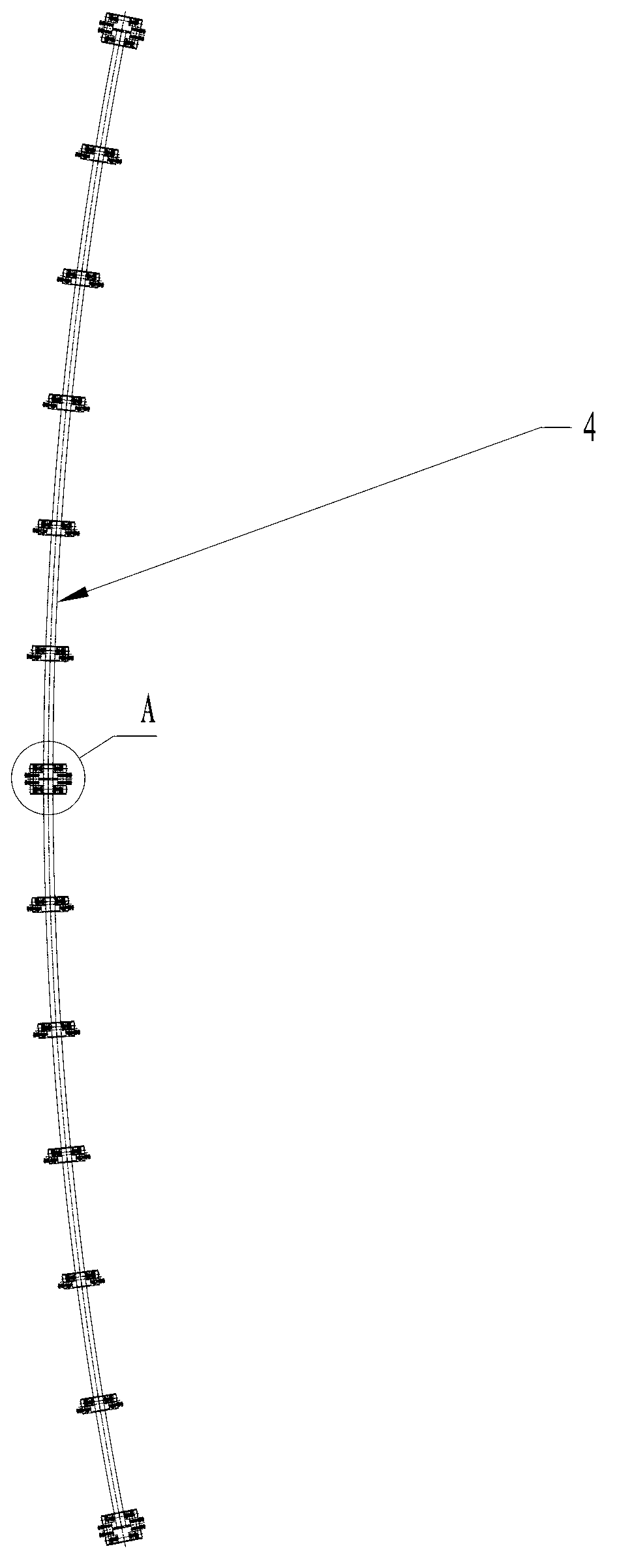

[0015] Such as Figure 1~4 As shown, the present invention mainly includes two bases 1 respectively fixed on both sides of the milling power head of the frame 8 , and each base 1 is connected with an eddy current sensor 3 through a sensor bracket 2 . An arc-shaped reference ring 4 is provided directly in front of the two eddy current sensors 3 .

[0016] Every other end of the reference ring 4 is connected with a backing plate 5, and a magnet is installed in each backing plate 5, and is adsorbed on the surface of the workpiece through the magnet. Each backing plate 5 is respectively connected with a first adjusting bolt 6 up and down, and the reference ring 4 is pressed vertically by the upper and lower first adjusting bolts 6 . Two second adjusting bolts 7 are connected to the side of each backing plate 5 , and the reference ring 4 is pressed horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com