Beam transmission structure for numerical control milling and drilling machine

A transmission structure, drilling and milling machine technology, applied in the direction of driving devices, metal processing machinery parts, metal processing equipment, etc., can solve the general aspects of rigidity, layout, adjustment method and manufacturability are not very reasonable, can not ensure the shape and shape of the drilling and milling surface. Dimensional accuracy, affecting the performance and life of machine tools, etc., achieve the effect of good running stability, ensuring shape and dimensional accuracy, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

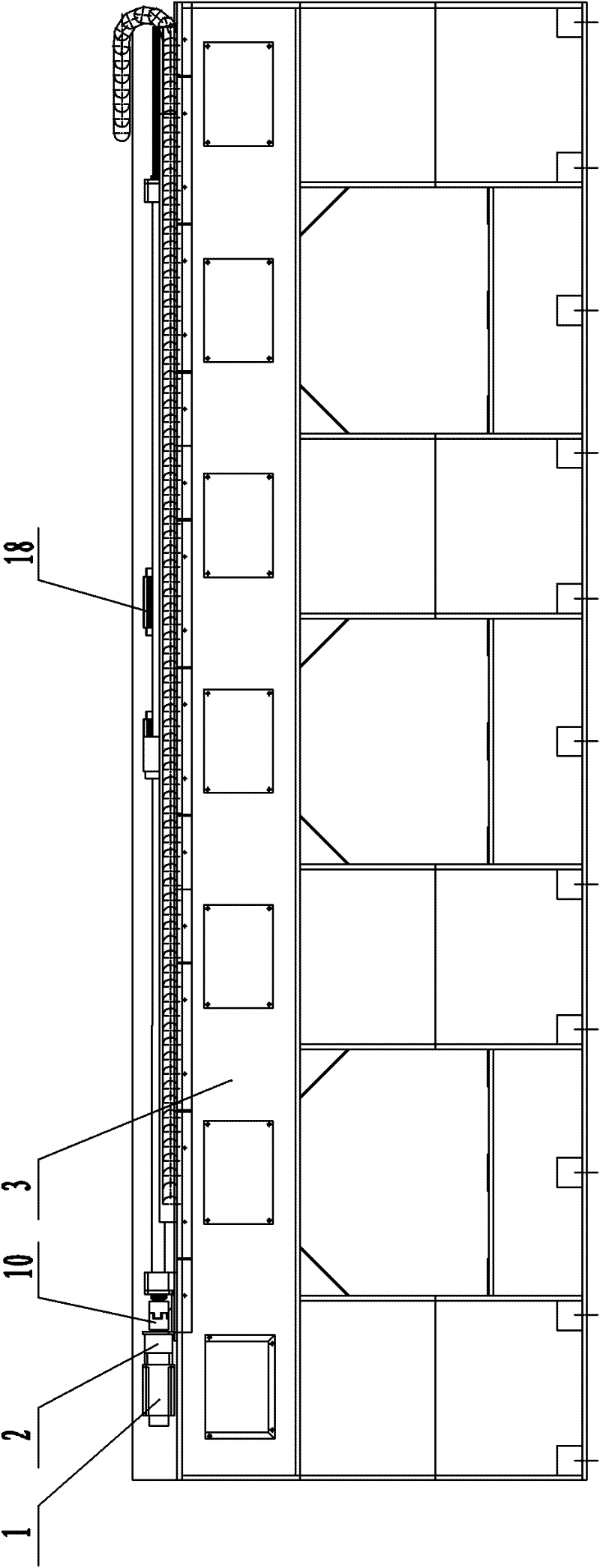

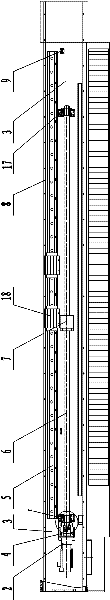

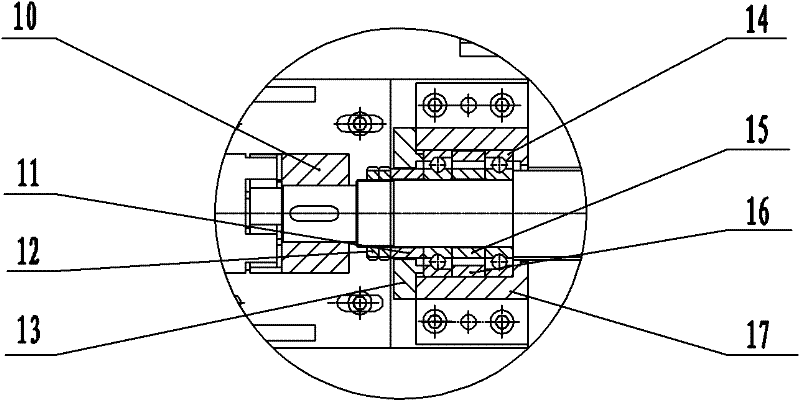

[0014] As shown in the figure, the present invention mainly consists of a servo motor 1, a reducer 2, a frame 3, a reducer mounting seat 4, a guiding linear guide 5, a ball screw 6, a screw nut seat 7, a guide groove 8, and a limit block 9 , Elastic coupling 10, spacer sleeve 11, round nut 12, bearing cover 13, corner ball bearing 14, inner spacer 15, outer spacer 16, bearing block 17 and guide slider 18 and other components.

[0015] The beam transmission structure of the CNC drilling and milling machine includes a servo motor 1 and a reducer mounting base 4 fixedly installed on the frame 3, a reducer 2 is fixedly installed on the reducer mounting base 4, and the servo motor 1 and the reducer 2 are in phase. Connection, bearing housings 17 are installed at fixed intervals on the frame 3, angular ball bearings 14 are installed in the bearing housings 17, ball s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com