Bender and method thereof

A flat laying and flipping technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as defects, product side deformation, product surface damage, etc., to achieve high bending height, ensure dimensional accuracy, The effect of ensuring structural quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

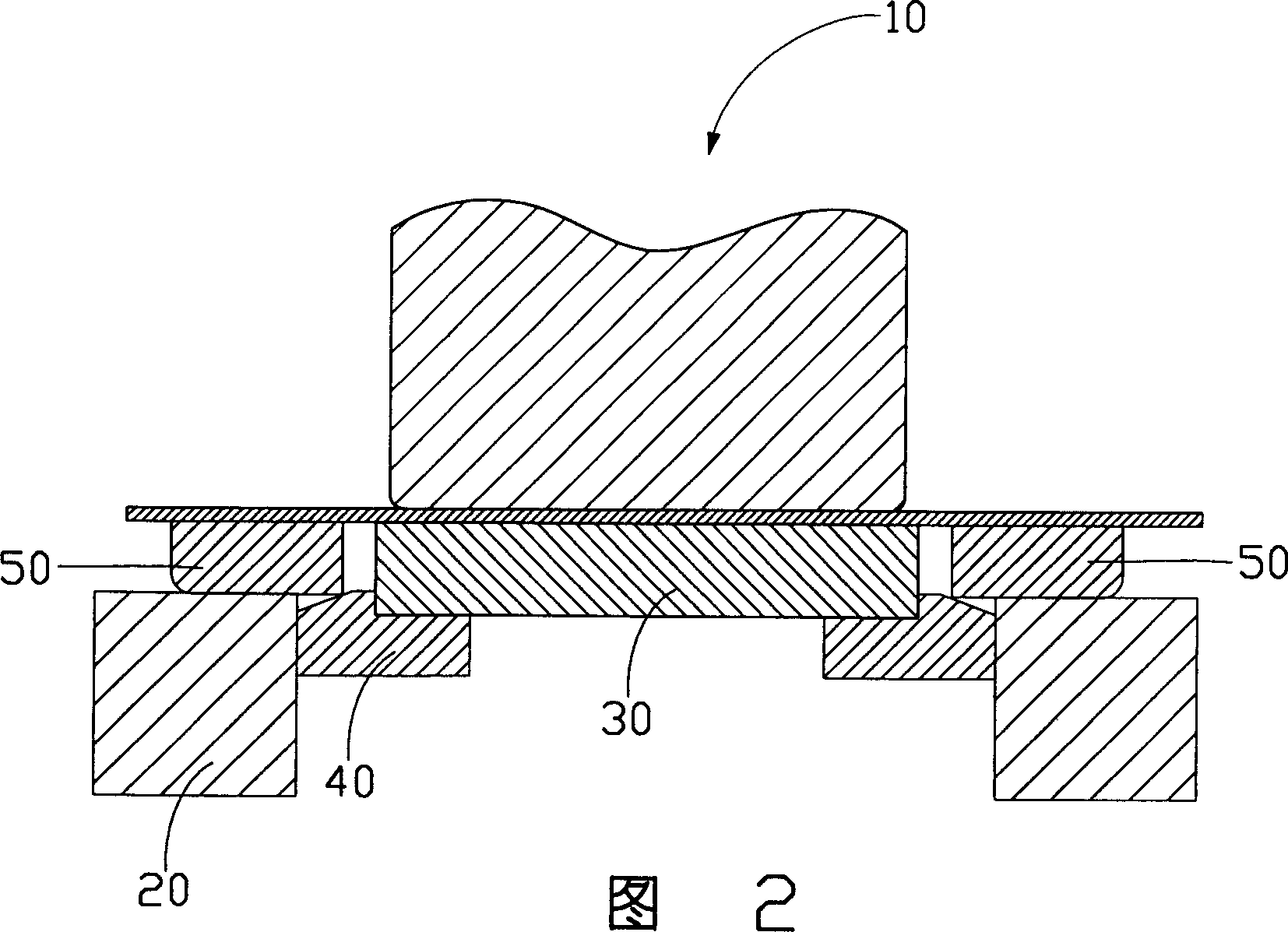

[0016] Please refer to FIG. 2 , the bending forming device 10 of the present invention is mainly composed of a folding knife 20 , a punching plate 30 , a supporting plate 40 and a turning plate 50 .

[0017] The beating plate 30 is approximately in the shape of a cuboid and is located inside the jackknife 20. There is a certain distance between the beating plate 30 and the jackknife 20, which is roughly equal to the thickness of the turning plate 50 and can be adjusted and controlled by the supporting plate 40 to be suitable for different applications. thickness of the flap 50.

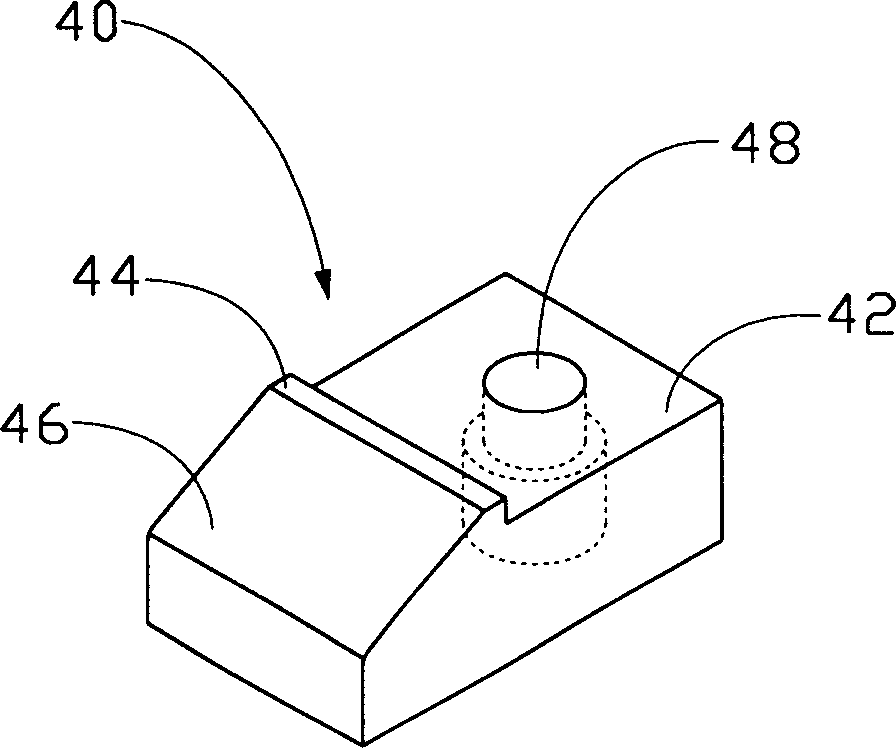

[0018] Please refer to image 3 A supporting section 42 , an abutting section 44 and a slope section 46 are sequentially formed on the top of the supporting plate 40 from inside to outside. A countersunk screw hole 48 is formed on the supporting section 42 , and a screw (not marked on the figure) can pass through the screw hole 48 to fix the supporting plate 40 and the punching plate 30 together. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com