Zero-energy-consumption sewage treatment system and method for constructed wetlands

A sewage treatment system and constructed wetland technology, applied in the field of constructed wetland sewage treatment system, can solve problems such as improper sludge suction treatment and disposal, low operation and maintenance level, and unstable equipment operation, and achieve stable and reliable treatment process, Good water quality and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention is based on the three-compartment septic tanks in scattered residential areas, and carries out the deep purification treatment process of continuous sewage.

[0025] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

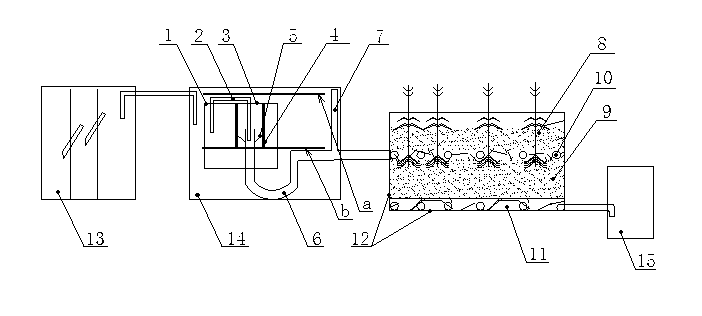

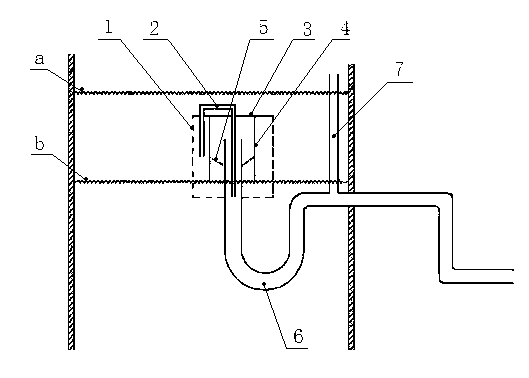

[0026] figure 1 Shown is the sectional structure schematic diagram of the present invention;

[0027] The invention provides a zero-energy constructed wetland sewage treatment system, which is composed of four parts: a sewage pretreatment system, an automatic siphon system, a constructed wetland purification system and a water collection system. The sewage pretreatment system includes a three-compartment septic tank 13 The sewage siphon pool 14 is connected to it through pipelines, the automatic siphon system is placed in the sewage siphon pool 14, the artificial wetland purification system is connected to the automatic siphon system, and the water collection system is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com