Water supplier for firecracker paper roll

A paper water dispenser and water dispenser technology, which is applied in the field of firecracker roll paper dispensers, can solve problems such as unstable water quality, low production efficiency, and waste of water resources, and achieve environmental protection, increase production efficiency, and reduce labor costs. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

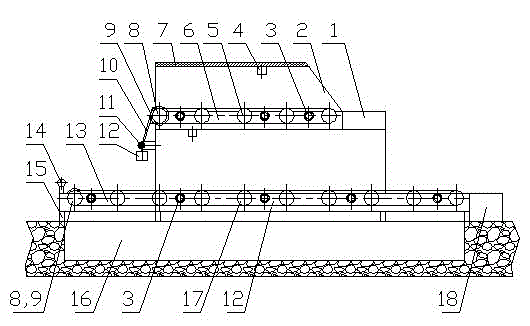

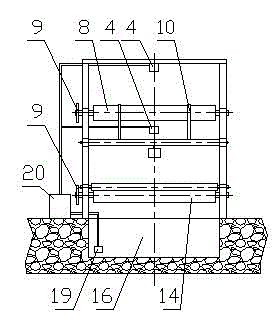

[0023] The frame 15 of the water generator is mainly composed of side wall panels 2, small beams 3, upper side beams 6, roof 7, and lower side beams 13. It is a box-type structure without end plates and bottom plates. The upper-level conveying mechanism is installed in parallel in the box-type structure. 5 and the lower conveying mechanism 17, the upper conveying mechanism 5 is located above the lower conveying mechanism 17; the upper conveying mechanism 5 is installed between the two upper side beams 6; the lower conveying mechanism 17 is installed between the two lower side beams 13; the upper conveying mechanism The length of conveying mechanism 5 is shorter than the length of lower conveying mechanism 17, and both are all connected with power and transmission mechanism, during work, the direction of motion of upper conveying mechanism 5 is opposite to the running direction of lower conveying mechanism 17; A flanging mechanism 11 is installed at the end of the top; a high-pr...

Embodiment 2

[0026] It is basically the same as Embodiment 1, except that the upper conveying mechanism 5 and the lower conveying mechanism 17 are composed of rollers, and the upper planes of the same group of rollers are all on the same horizontal plane; sprockets are installed at the ends of each roller, and each Each sprocket is connected with the power and transmission mechanism through a chain.

[0027] In this embodiment, the water source is tap water, and the flanging mechanism 11 is designed and manufactured using known prior art, and manual or simple devices are used for loading and unloading, and the roller bodies of all rollers are made of stainless steel, plastic or other non-rusting materials. The material is made, and the diameters of the roller bodies of all the rollers can be equal or unequal, and the diameters are preferably equal.

Embodiment 3

[0029] It is basically the same as Embodiment 1, except that the upper conveying mechanism 5 and the lower conveying mechanism 17 are all composed of a driving roller 8 and several driven rollers 5, and the same group of driving rollers 8 and driven rollers 5 The upper plane is on the same level; the driving roller 8 and all the driven rollers 5 of the same group are equipped with an annular conveyor belt with holes, and the two ends of the roller body of the driving roller 8 are set to drive the conveyor belt. For the running driving gear, the conveyor belt is provided with a matching through hole corresponding to the position of the driving gear, and the driving gear meshes with the through hole, and the driving roller 8 drives the conveyor belt to run when it rotates; a sprocket 9 is installed on one end of the driving roller 8, Sprocket 9 is connected with power and speed change mechanism.

[0030] In this embodiment, the water source is tap water, and the flanging mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com