Horizontal MBR membrane sanitary sewage processor

A domestic sewage, horizontal technology, applied in the field of horizontal MBR membrane domestic sewage processor, can solve the problems of lack of pretreatment and impact resistance, small transverse area of MBR components, difficulty in ensuring sewage treatment effect, etc. Water efficiency, wide applicability, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

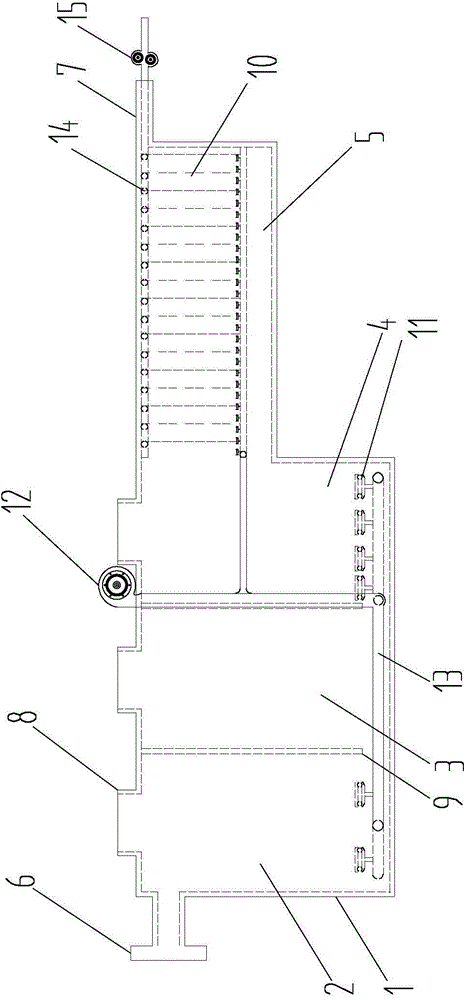

[0016] Such as figure 1 As shown, the present invention comprises box body 1, hydrolytic acidification pool 2, anaerobic pool 3, aerobic pool 4 and MBR membrane pool 5, and box body 1 is provided with water inlet 6 and water outlet 7 respectively on the left and right sides upper side, enters Water port 6 is connected with hydrolytic acidification pool 2, and the right side of hydrolysis acidification pool 2 is provided with anaerobic pool 3, aerobic pool 4 and MBR membrane pool 5 successively, and MBR membrane pool 5 is placed horizontally and vertically with aerobic pool 4, and the water There is a manhole 8 above the decomposition acidification pool, the anaerobic pool 3, and the aerobic pool 4, and the MBR membrane pool 5 is provided with an upper MBR membrane module 10 with a gap at the bottom, and the hydrolytic acidification pool 2, the aerobic pool 4, and the MBR membrane module A diffuser 11 is provided at the bottom of the housing 1, and a fan 12 is provided above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com