Arc welding system and method with low energy input

An arc welding, low-energy technology, applied in the field of low-energy input arc welding systems, can solve the problems of difficult promotion of welding wire, complicated control, and difficult realization, etc., to achieve improved arc stability, simple overall control, and strong arc stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

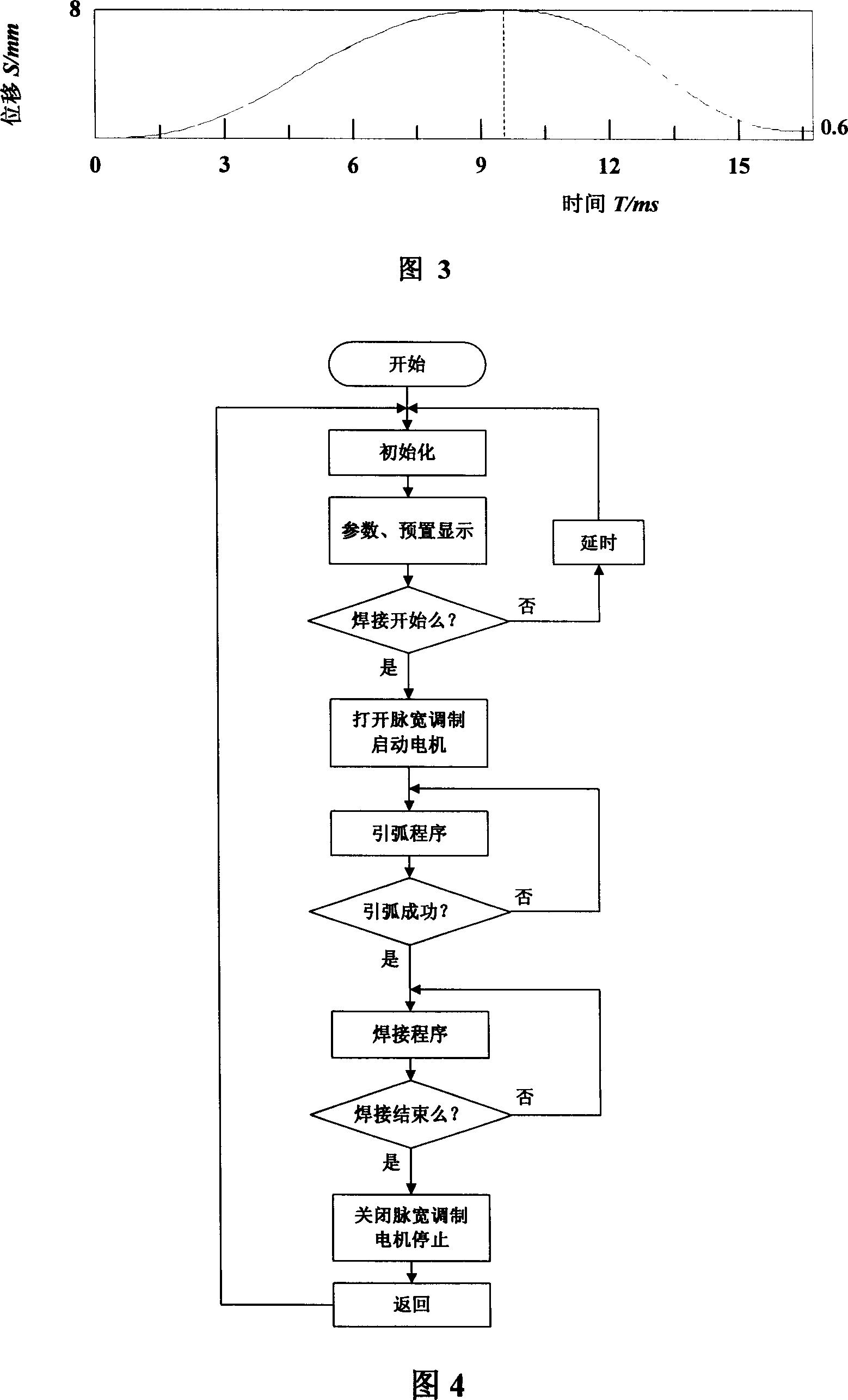

[0031] The present embodiment will now be described with reference to the drawings. (embodiment carries out the welding of butt weld seam at the 3A21 aluminum alloy plate of 1mm thickness)

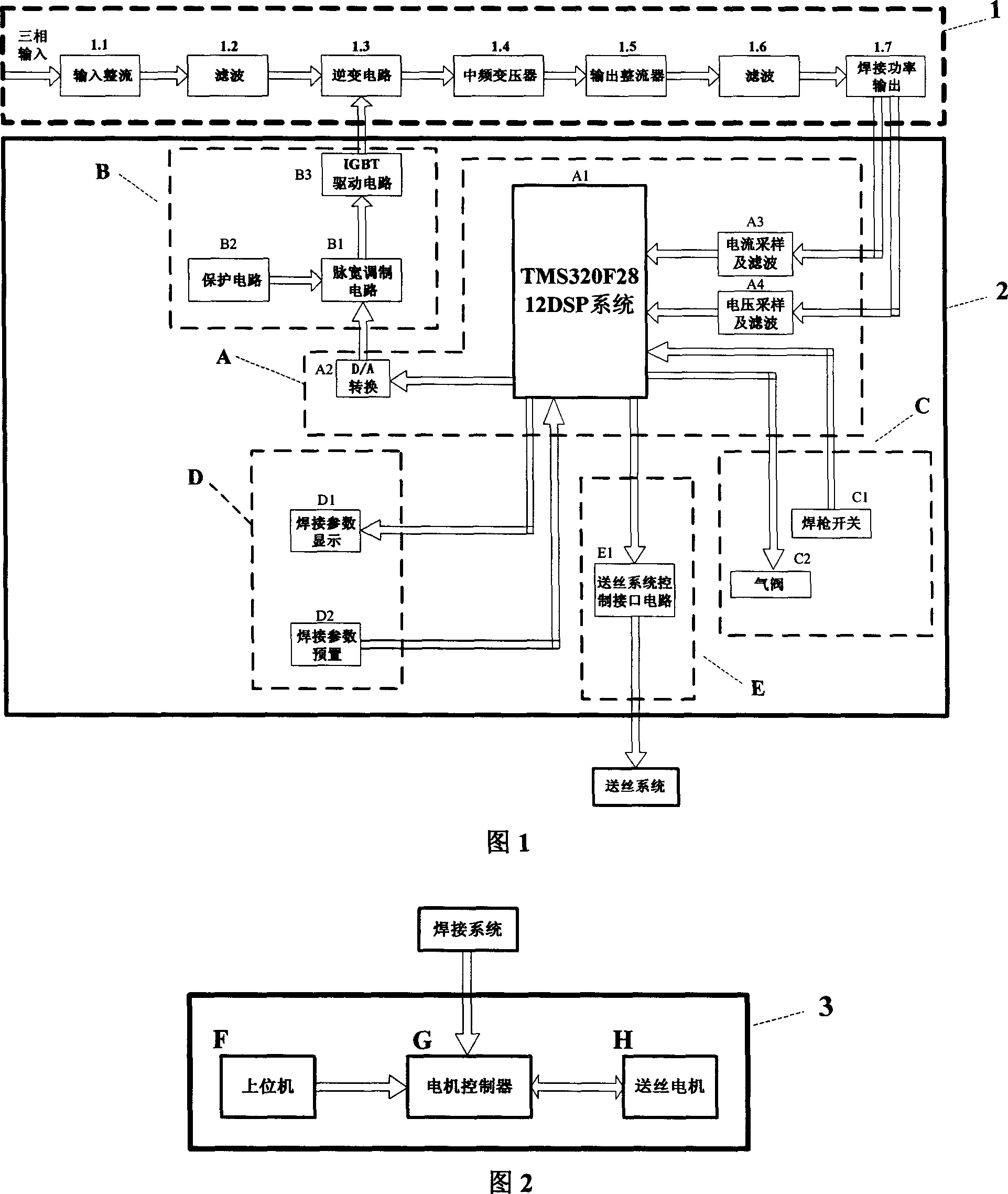

[0032] A concrete example of the present invention is a low-energy input arc welding system structure diagram shown in Figures 1 and 2, which generally includes two parts: a welding system and a wire feeding system 3 .

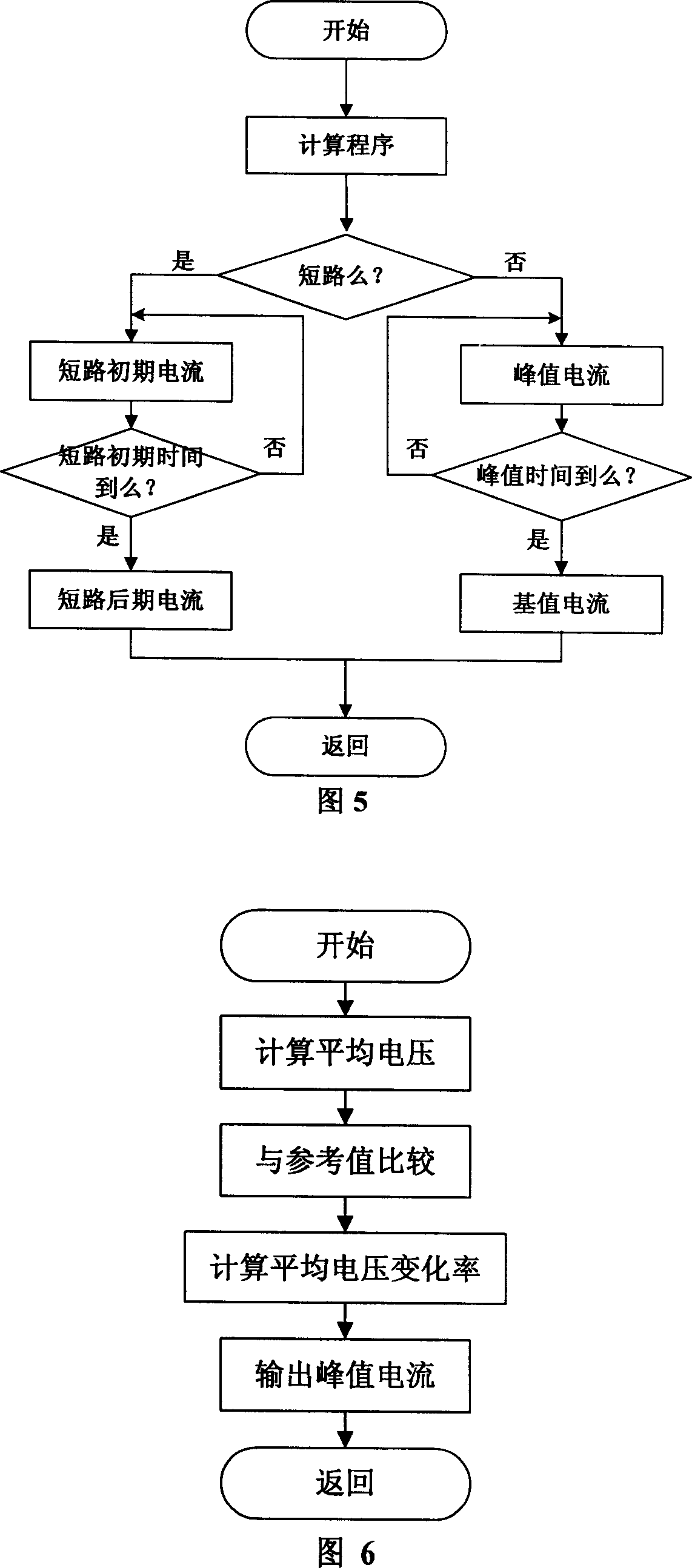

[0033]The welding system includes a main circuit part 1 and a control circuit part 2 with TMS320F2812DSP as the core. The input voltage of the main circuit is three-phase 380V; the input rectification 1.1 is rectified by Fuji rectifier bridge, the model is FUJ 6RI100G-160; Ultrafine crystal magnetic core, the transformation ratio is 15:2; filter 1.6 adopts magnetic core saturated inductance, the inductance is about 30μH. The control circuit part 2 adopts a control system based on TMS320F2812DSP, which mainly completes parameter calculation, proportional-integral adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com