Novel supercritical carbon dioxide extraction technology for continuously carrying out fine extraction on liquid raw materials

A carbon dioxide and liquid raw material technology, applied in liquid solution solvent extraction, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the constraints on the development of supercritical extraction technology, low space-time yield of the device, difficulty in obtaining high purity and high added value Products and other issues, to achieve the effect of shortening the production cycle, reducing production costs, selective acquisition or removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

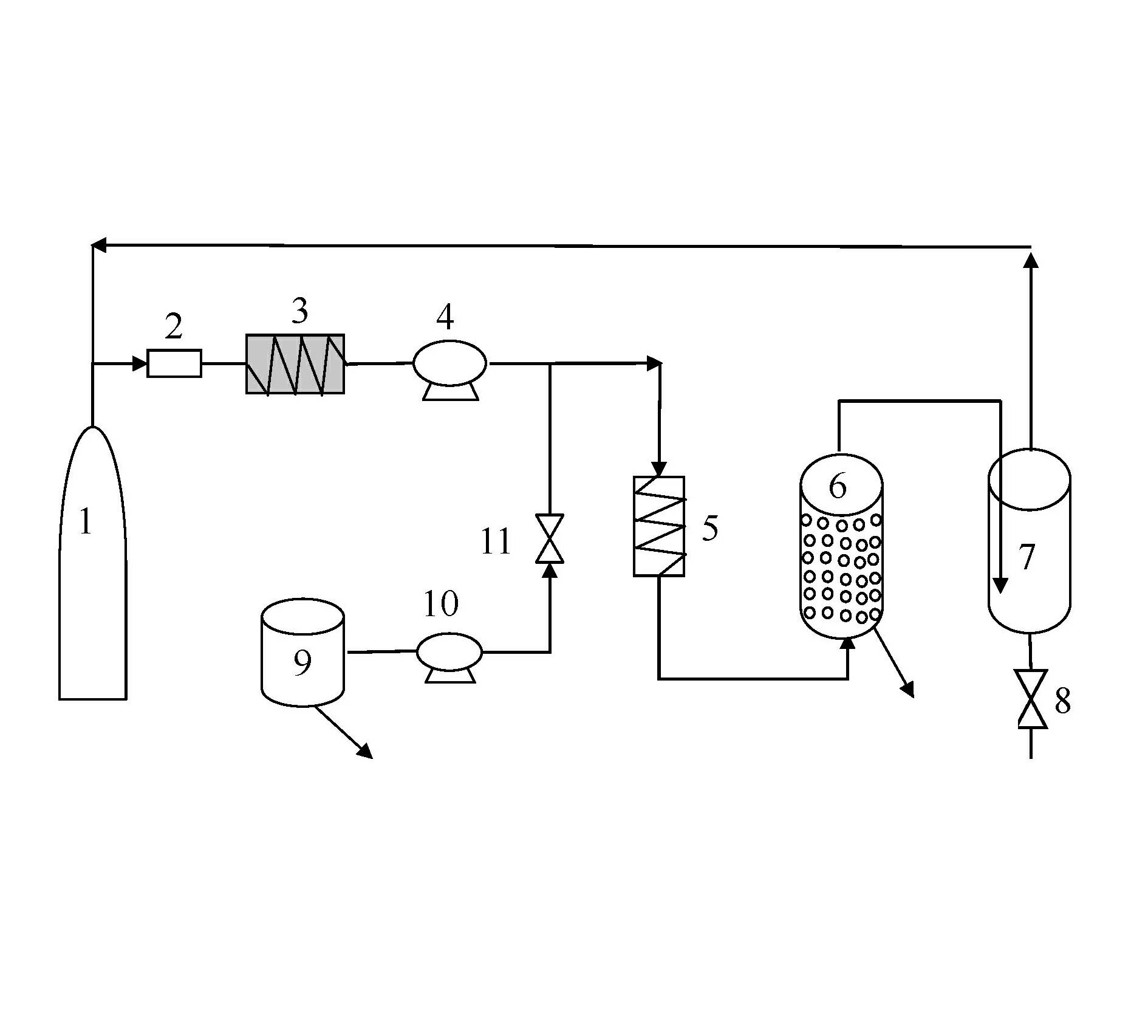

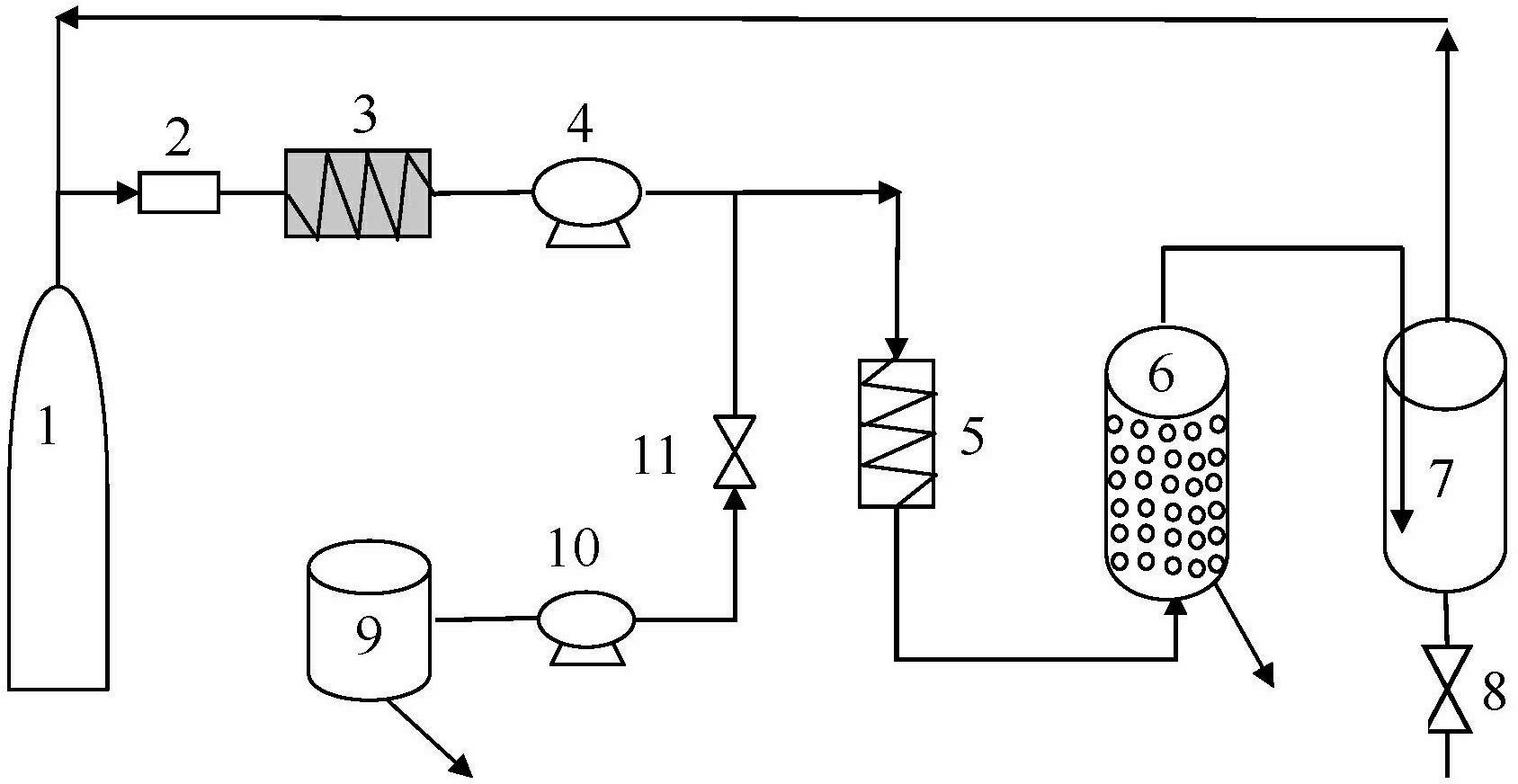

Method used

Image

Examples

example 1

[0025] The free fatty acid and wax in rice bran oil seriously affect the quality of rice bran oil, so dewaxing and free fatty acid treatment are required for rice bran oil. Put the crudely squeezed rice bran oil into a container connected to the extraction kettle, fill the extraction kettle with zeolite and compact it. The supercritical fluid is carbon dioxide, the extraction pressure is set at 50MPa, the extraction temperature is 70°C, the pressure of the separation tank is 4.5~7MPa, the temperature of the separation tank is 75°C, and continuous extraction is performed to obtain dewaxed and low-free fatty acid rice bran oil , Improve the application value of rice bran oil.

[0026] About the rice bran oil utilization technique of the present invention and the extraction comparison of normal hexane method technique.

[0027] Crude rice bran oil contains 2-4% waxes, 1-2% phospholipids and 5-25% free fatty acids, pigments, etc., which makes crude rice bran oil difficult to puri...

example 2

[0030] Crude lemon essential oil contains a large amount of terpenes, which are easily oxidized and affect the stability of lemon essential oil as a food additive. Therefore, deterpened lemon essential oil has better stability and market value. Put the crudely squeezed lemon essential oil into a container that can lead to the extraction kettle, fill the 2L extraction kettle with 40-60 mesh microsphere silica gel and compact it. The supercritical fluid is carbon dioxide, the extraction pressure is set at 9MPa, the extraction temperature is 40°C, the temperature of the separation tank is 45°C, and the pressure is 4.5MPa. Control the flow of the essential oil raw material pumped into the extraction kettle from the container leading to the extraction kettle, and adjust the flow rate of the liquid carbon dioxide pumped into the extraction kettle so that the flow rate ratio of the two is 4:1. This moment, what collected in the separation kettle was mainly the terpene components in t...

example 3

[0034] Bergamot essential oil contains furanocoumarins, which can cause skin allergies and even cancer, so the furanocoumarins should be removed. The furanocoumarin content is that the thick bergamot essential oil of 4541ppm is packed in the container leading to extraction kettle, and 60~80 order diatomites are loaded into 2L extraction kettle. The supercritical fluid is carbon dioxide. Set the extraction pressure to 20MPa, the extraction temperature to 40°C, the temperature of the separation tank to 45°C, and the pressure to 4.5MPa. Control the flow of essential oil raw materials pumped into the extraction tank from the container leading to the extraction tank to adjust the liquid state. The flow rate of the carbon dioxide pumped into the extraction tank is such that the flow rate ratio of the two is 6:1. Under this process, defuranocoumarin bergamot essential oil can be obtained.

[0035] The extraction comparison of defuranocoumarin using technique of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com