Method for preparing ultra-thin highly-pure europium oxide by europium-rich sulfuric acid rare earth

A technology of rare earth sulfuric acid and europium-rich sulfuric acid, which is applied in the field of hydrometallurgy and can solve problems such as low efficiency, environmental pollution, and uneven particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

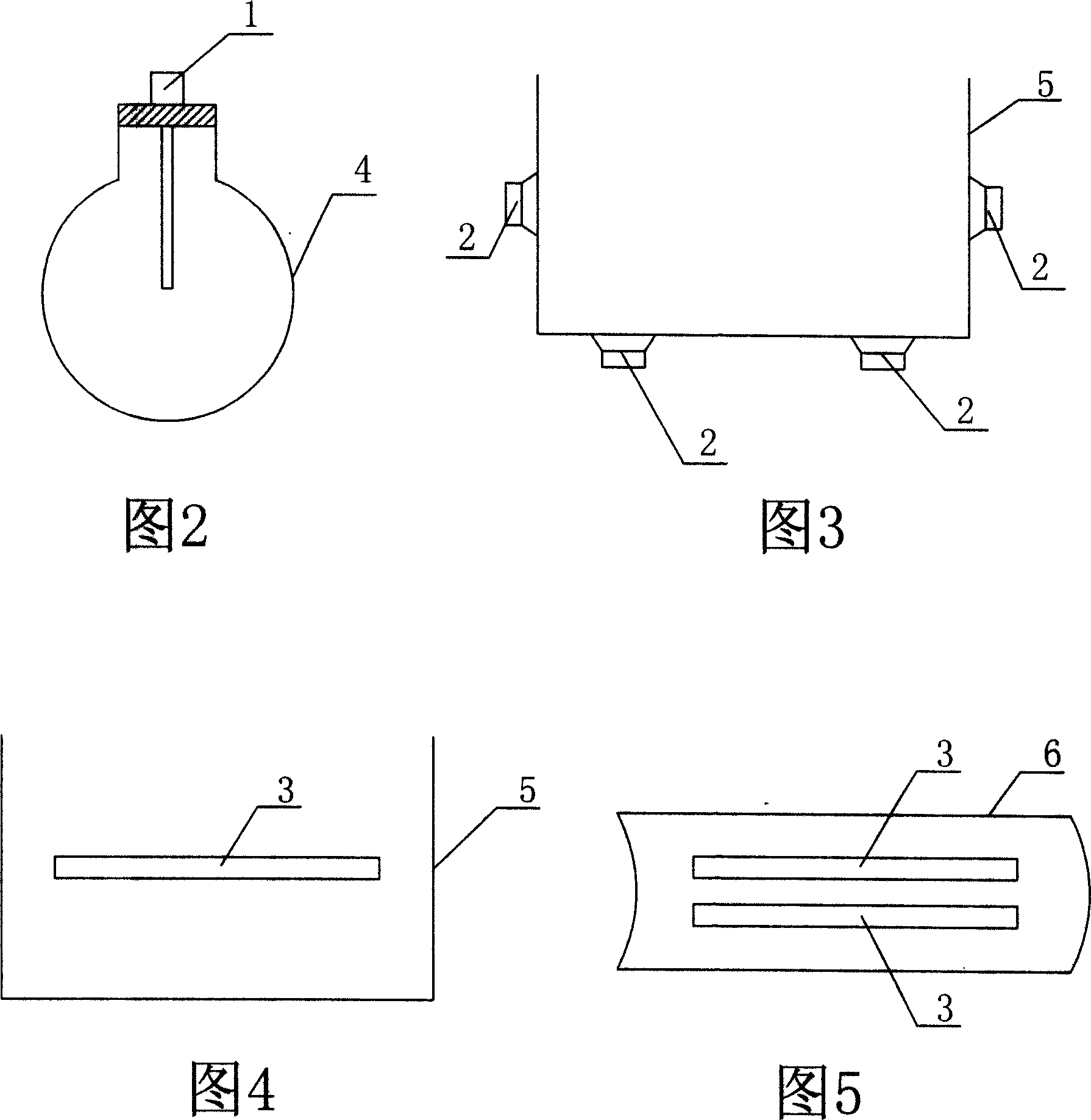

[0037] Main equipment: extraction kettle with probe-type ultrasonic generator, crystallization kettle with probe-type ultrasonic generator, fixed-bed electrochemical reactor.

[0038] Main raw materials: Europium-rich rare earth sulfate, H 2 SO 4 、HNO 3 ,P 2 0 4 Extractant, kerosene, NH 4 HCO 3 .

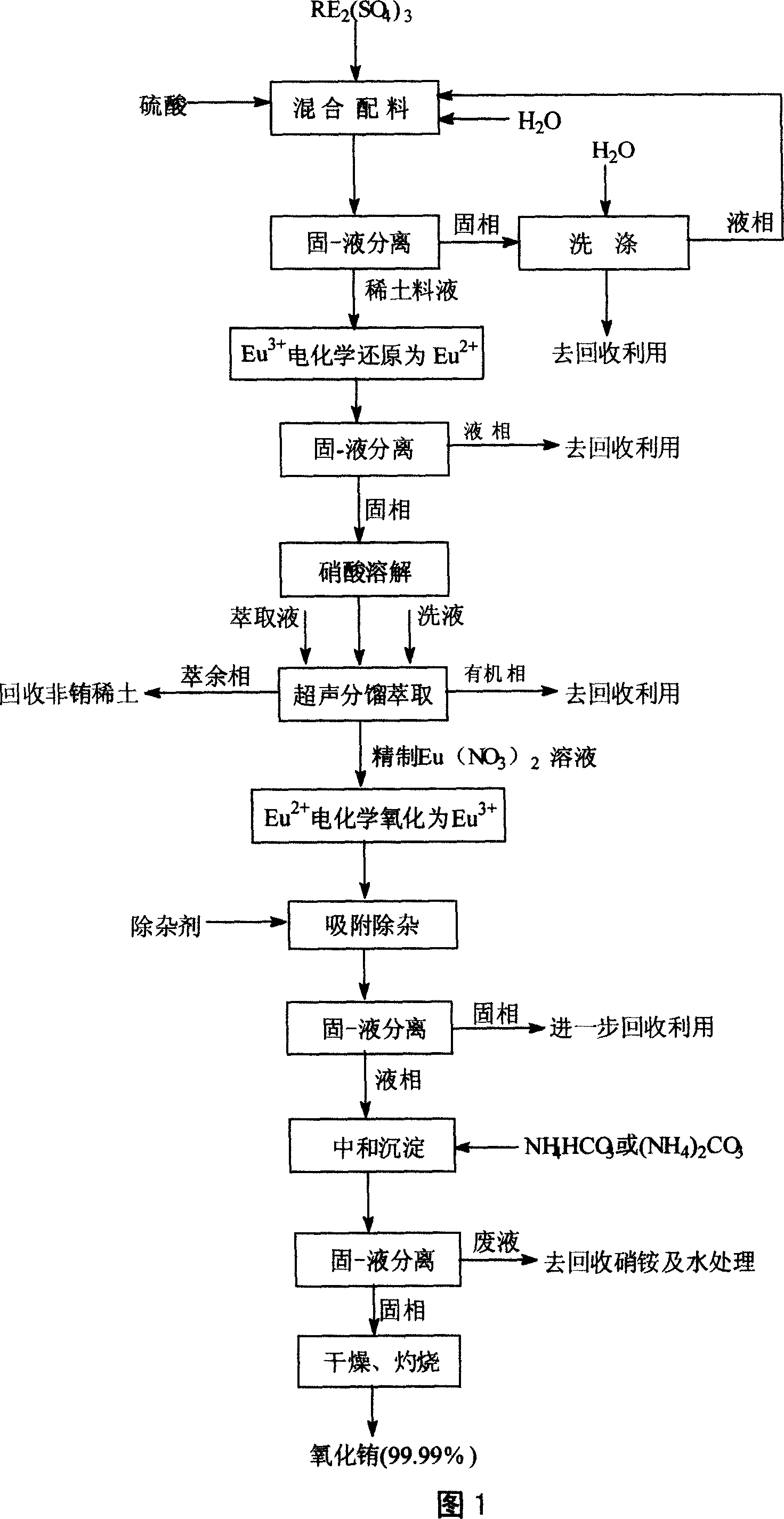

[0039]As shown in Figure 1 and Figure 2, a kind of method for preparing ultrafine high-purity europium oxide with rich europium sulfate rare earth is to be raw material with rich europium sulfate rare earth, and described method step is as follows:

[0040] (1) Mixing of ingredients: mixing ingredients of europium-rich rare earth sulfate, sulfuric acid, and water;

[0041] (2) Solid-liquid separation: through solid-liquid separation, insoluble impurities are removed to obtain a rare earth sulfate rich in europium sulfate solution feed liquid, the concentration of rare earth in the feed liquid is 0.1-0.2mol / L; the solid phase is recovered and recycled through washing;

[0042...

Embodiment 2

[0052] Main equipment: extraction tank with vibrator-type ultrasonic generator, crystallization tank with vibrator-type ultrasonic generator, fluidized bed electrochemical reactor.

[0053] Main raw materials: Europium-rich rare earth sulfate, H 2 SO 4 、HNO 3 , P204 extractant, sulfonated kerosene, (NH 4 ) 2 CO 3 .

[0054] As shown in Fig. 1 and Fig. 3, a kind of method for preparing ultrafine high-purity europium oxide with rich europium sulfate rare earth is to be raw material with rich europium sulfate rare earth, and described method step is as follows:

[0055] (1) Mixing of ingredients: mixing ingredients of europium-rich rare earth sulfate, sulfuric acid, and water;

[0056] (2) Solid-liquid separation: through solid-liquid separation, insoluble impurities are removed to obtain a rare earth sulfate rich in europium sulfate solution feed liquid, the concentration of rare earth in the feed liquid is 0.1-0.2mol / L; the solid phase is recovered and recycled through wa...

Embodiment 3

[0067] Main equipment: extraction tube with vibrating plate ultrasonic generator, crystallization tube with vibrating plate ultrasonic generator, fixed bed electrochemical reactor.

[0068] Main raw materials: Europium-rich rare earth sulfate, H 2 SO 4 、HNO 3 , P204 extractant, No. 200 gasoline, NH 4 HCO 3 .

[0069] As shown in Fig. 1 and Fig. 5, a kind of method for preparing ultrafine high-purity europium oxide with rich europium sulfate rare earth is to be raw material with rich europium sulfate rare earth, and described method step is as follows:

[0070] (1) Mixing of ingredients: mixing ingredients of europium-rich rare earth sulfate, sulfuric acid, and water;

[0071] (2) Solid-liquid separation: through solid-liquid separation, insoluble impurities are removed to obtain a rare earth sulfate rich in europium sulfate solution feed liquid, the concentration of rare earth in the feed liquid is 0.1-0.2mol / L; the solid phase is recovered and recycled through washing; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com