Process for preparing superfine high-purity europium oxide by using europium riched material

A technology of europium-enriched hydrochloric acid and europium oxide, applied in the fields of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high toxicity of oxalic acid, difficulty in increasing production capacity, and slow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

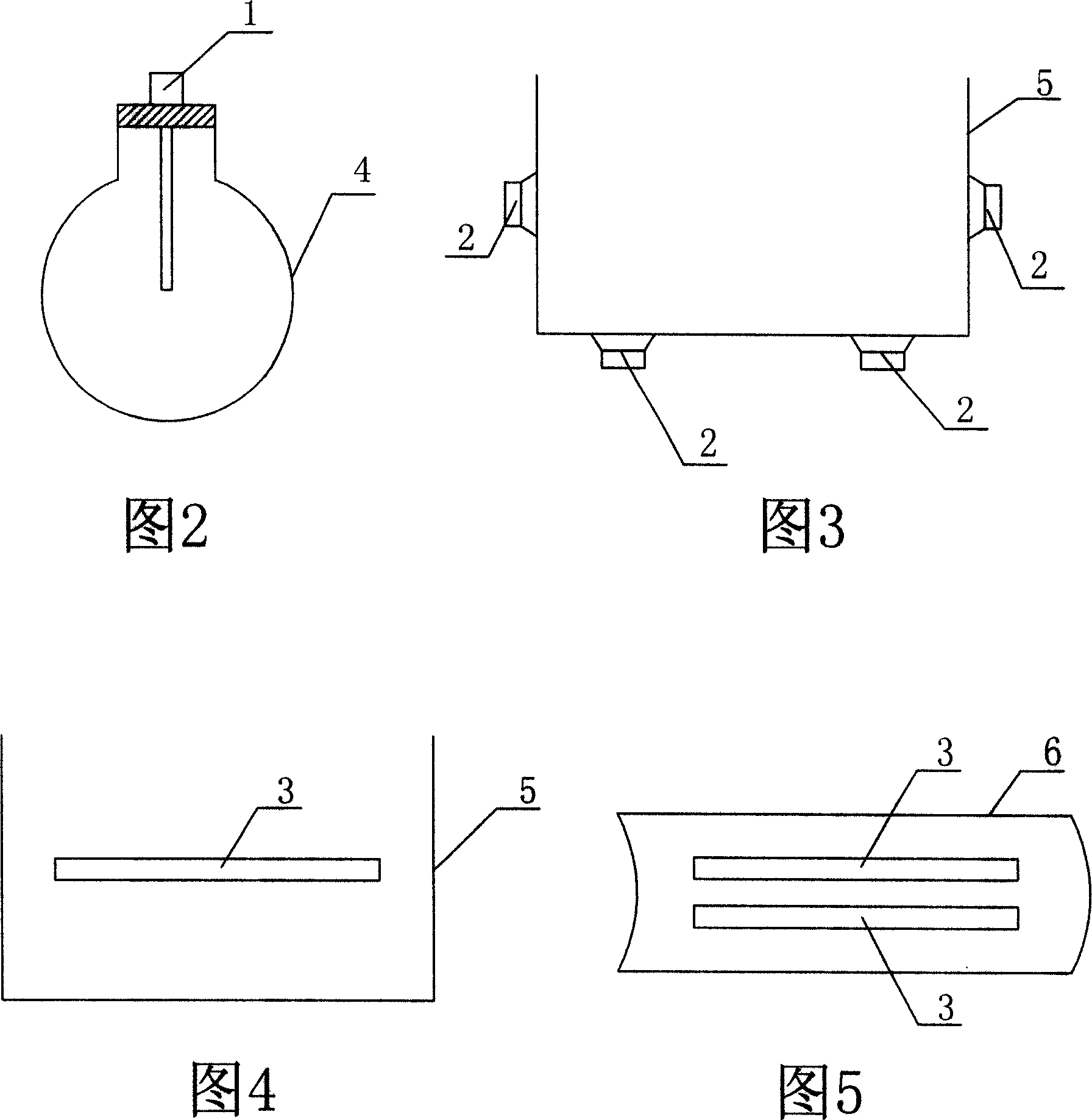

[0035] Main equipment: extraction kettle with probe-type ultrasonic generator, crystallization kettle with probe-type ultrasonic generator, fixed-bed electrochemical reactor.

[0036] Main raw materials: Europium-rich rare earth hydrochloride, HCl, P204 extractant, kerosene, NH 4 HCO 3 .

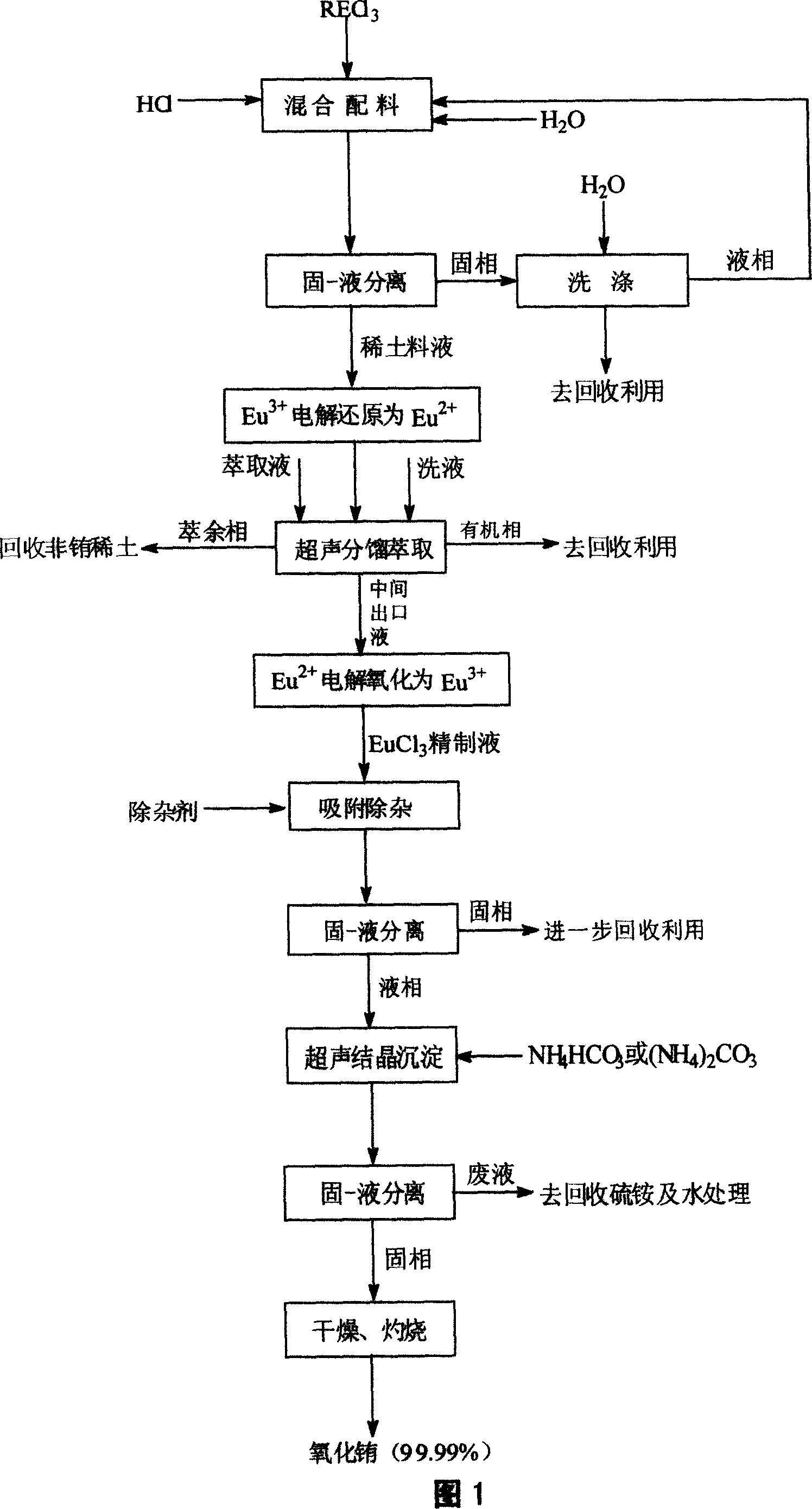

[0037]As shown in Fig. 1 and Fig. 2, a kind of method for preparing ultrafine high-purity europium oxide with rich europium hydrochloride rare earth is to take rich europium rich rare earth hydrochloride as raw material, and the method steps are as follows:

[0038] (1) batching mixing: the rare earth hydrochloride rich in europium, hydrochloric acid, water are mixed batching;

[0039] (2) Solid-liquid separation: After solid-liquid separation, insoluble impurities are removed to obtain a rare earth solution rich in europium hydrochloride, and the concentration of rare earth in the feed liquid is 0.1-1.2mol / L; the solid phase is recovered and recycled through washing;

[0040] (3) Electro...

Embodiment 2

[0048] Main equipment: extraction tank with vibrator-type ultrasonic generator, crystallization tank with vibrator-type ultrasonic generator, fluidized bed electrochemical reactor.

[0049] Main raw materials: europium-rich rare earth hydrochloride, HCl, P204 extractant, sulfonated kerosene, (NH 4 ) 2 CO 3 .

[0050] As shown in Fig. 1 and Fig. 3, a kind of method for preparing ultrafine high-purity europium oxide with rich europium hydrochloride rare earth is to take rich europium rich rare earth hydrochloride as raw material, and the method steps are as follows:

[0051] (1) batching mixing: the rare earth hydrochloride rich in europium, hydrochloric acid, water are mixed batching;

[0052] (2) Solid-liquid separation: After solid-liquid separation, insoluble impurities are removed to obtain a rare earth solution rich in europium hydrochloride, and the concentration of rare earth in the feed liquid is 0.1-1.2mol / L; the solid phase is recovered and recycled through washing...

Embodiment 3

[0061] Main equipment: extraction tube with vibrating plate ultrasonic generator, crystallization tube with vibrating plate ultrasonic generator, fixed bed electrochemical reactor.

[0062] Main raw materials: Europium-rich rare earth hydrochloride, HCl, P204 extractant, No. 200 gasoline, NH 4 HCO 3 .

[0063] As shown in Fig. 1 and Fig. 5, a kind of method for preparing ultrafine high-purity europium oxide with rich europium hydrochloride rare earth is to take rich europium rich rare earth hydrochloride as raw material, and described method step is as follows:

[0064] (1) batching mixing: the rare earth hydrochloride rich in europium, hydrochloric acid, water are mixed batching;

[0065] (2) Solid-liquid separation: After solid-liquid separation, insoluble impurities are removed to obtain a rare earth solution rich in europium hydrochloride, and the concentration of rare earth in the feed liquid is 0.1-1.2mol / L; the solid phase is recovered and recycled through washing;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com