Chlopyrifos pesticides waste water treatment process

A chlorpyrifos pesticide and wastewater treatment technology, which is applied in water/sewage multi-stage treatment, extraction water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of lack of mature and effective industrialized treatment methods, high concentration of wastewater pollutants, microbial Problems such as high toxicity, to achieve the effect of optimizing the structure of wastewater treatment, saving investment, and saving acid and alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

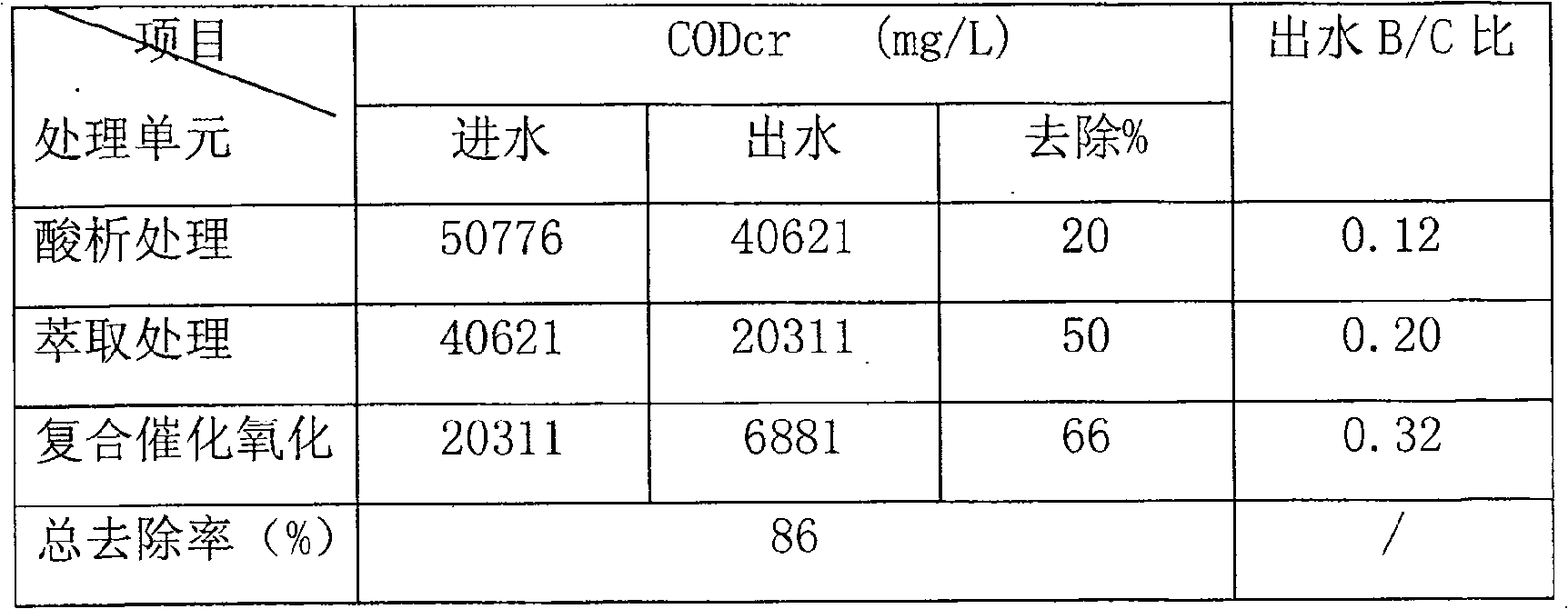

Embodiment 1

[0023] Chlorpyrifos wastewater from Shandong Huayang Technology Co., Ltd. was used as the water to be treated, and it was treated by acid analysis, complex extraction, Fenton oxidation and catalytic oxidation.

[0024] The specific process steps are as follows:

[0025] 1) Acid analysis: Use pendimethalin acidic wastewater to adjust the chlorpyrifos alkaline wastewater. After the chlorpyrifos wastewater is adjusted, the pH value is controlled at 3, and then filtered through a plate and frame filter press;

[0026] 2) Complex extraction: After acid analysis, the waste water and complex extractant enter into the extraction tower with stirring, and after stirring evenly, stand still for 2 hours to separate layers. The wastewater located in the lower layer of the extraction tower enters the Fenton pool, and the complexed extractant in the upper layer enters the extraction agent regeneration device for reuse;

[0027] 3) Fenton oxidation: Wastewater enters the Fenton pool for Fent...

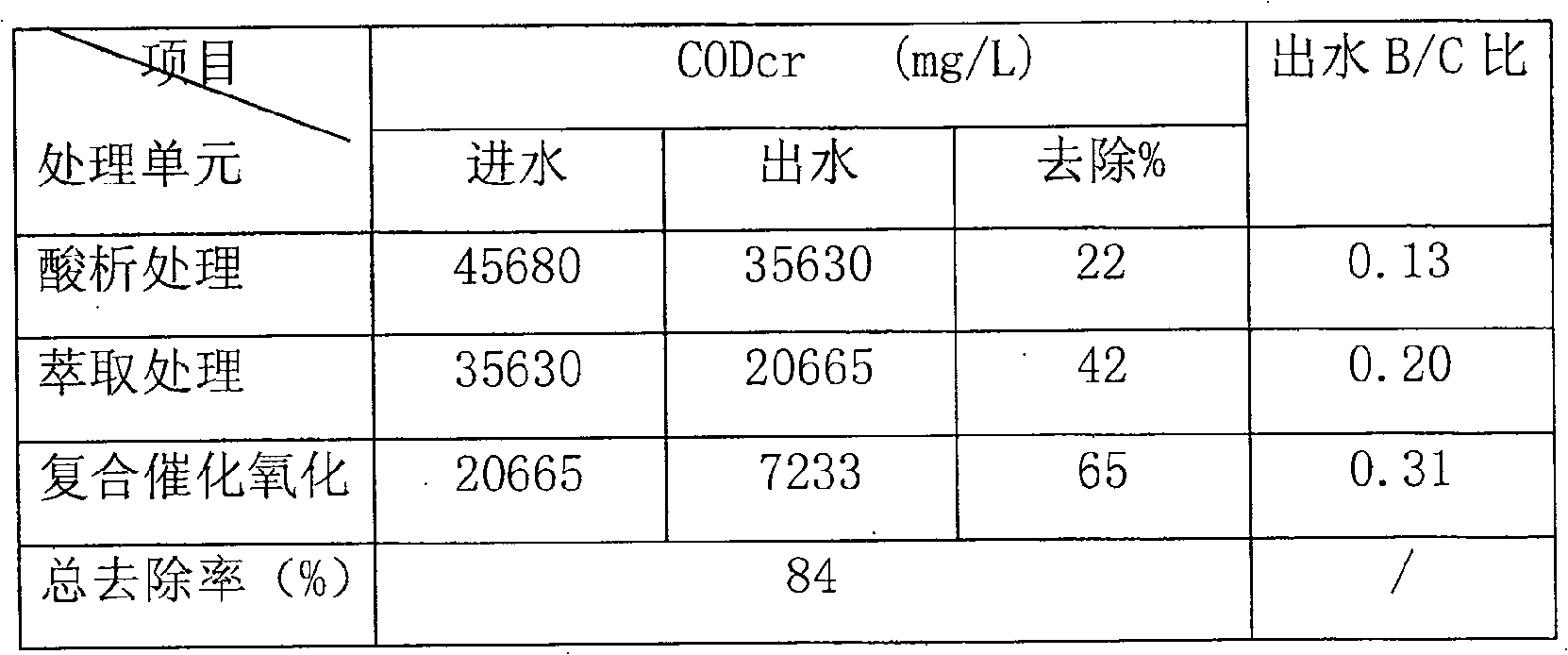

Embodiment 2

[0034] Chlorpyrifos wastewater from a pesticide factory was used as the untreated water, which was treated by acid analysis, complex extraction, Fenton oxidation and catalytic oxidation.

[0035] The specific process steps are as follows:

[0036] 1) Acid analysis: Use pendimethalin acidic wastewater to adjust chlorpyrifos alkaline wastewater. After the chlorpyrifos wastewater is adjusted, the pH value is controlled at 2, and then filtered through a plate and frame filter press;

[0037] 2) Complex extraction: After acid analysis, the waste water and complex extractant enter into the extraction tower with stirring, and after stirring evenly, stand still for 2 hours to separate layers. The wastewater located in the lower layer of the extraction tower enters the Fenton pool, and the complexed extractant in the upper layer enters the extraction agent regeneration device for reuse;

[0038] 3) Fenton oxidation: Wastewater enters the Fenton pool for Fenton oxidation, the pH value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com