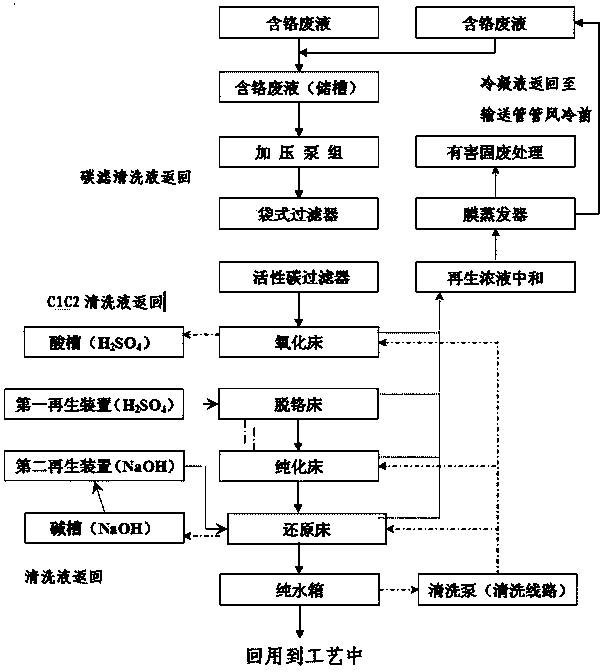

Comprehensive harmless treatment and recycling method for chromium-containing wastewater on electrolytic tinplate production line

A technology of harmless treatment and electroplating of tin plates, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Superior performance, high degree of automation, easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the figures and specific embodiments.

[0024] Principle Description

[0025] Ion exchange is carried out by a substance called an ion exchanger. The ions in the solid ion exchanger are exchanged with the ions in the dilute solution to achieve the purpose of extracting or removing some ions in the solution. A unit operation belonging to the mass transfer separation process; ion exchange is a reversible equivalent exchange reaction.

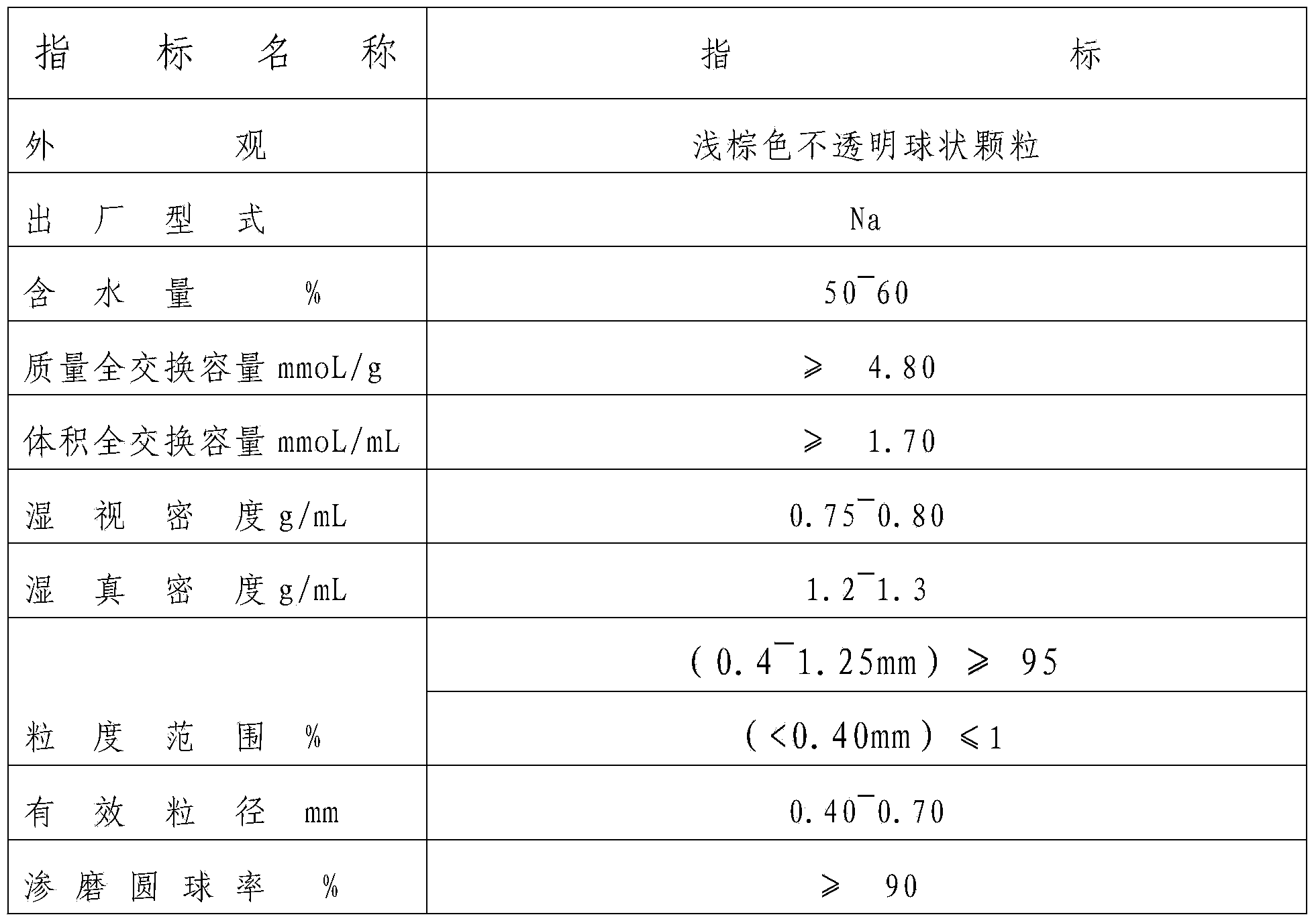

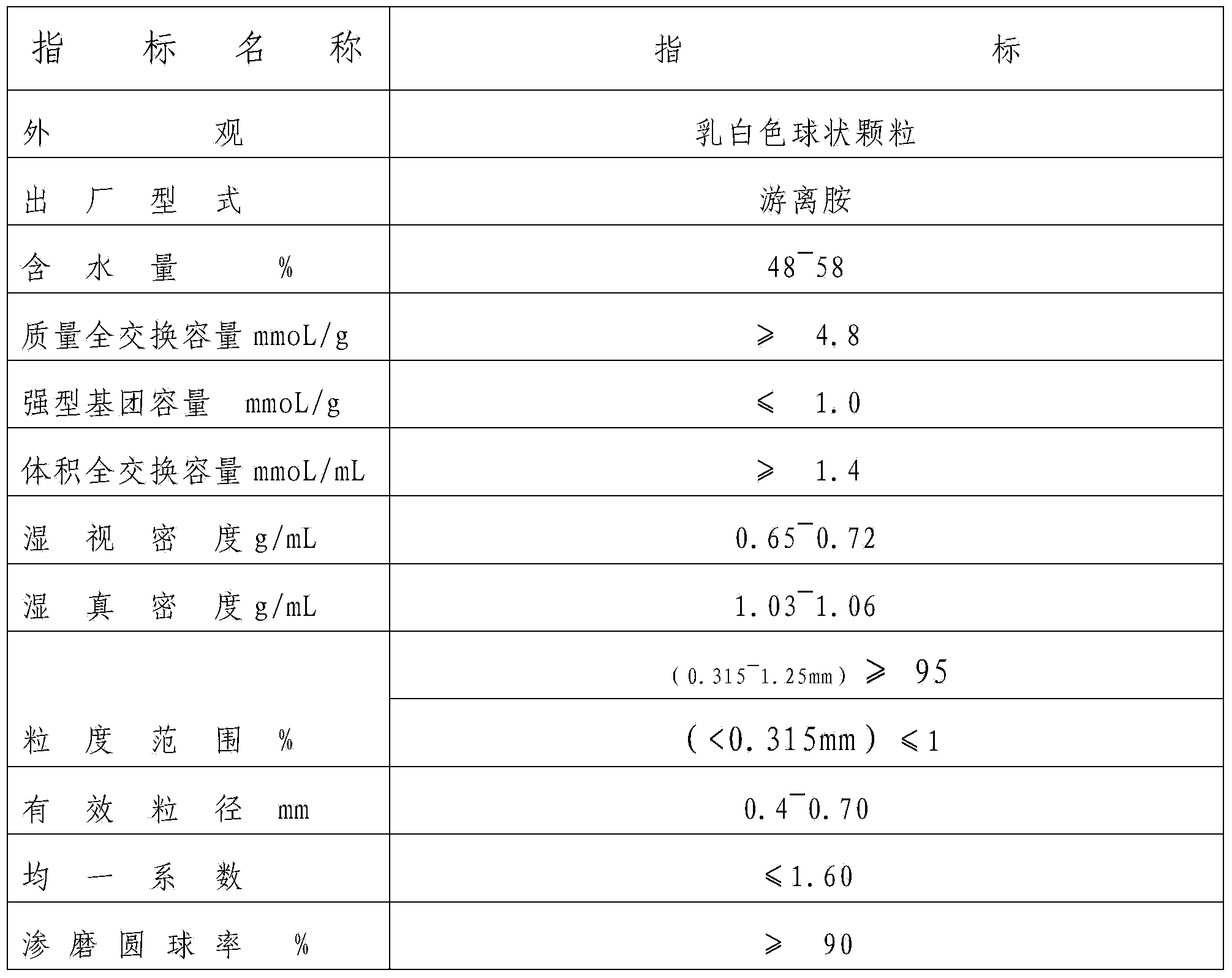

[0026] Ion exchange resin is a high molecular polymer with high exchange capacity, mostly spherical particles, low water flow resistance, high mechanical strength and good chemical stability.

[0027] The chromium-containing waste liquid to be treated in this case is mainly composed of sodium dichromate and a small amount of trivalent chromium, and has the following chemical equilibrium characteristics (partially):

[0028] Na 2 Cr 2 o 7 +2H + ==H 2 Cr 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com