Adjusting mechanism capable of micro-controlling back lash of pinion and rack

A rack and gap technology, applied in the field of gap adjustment mechanism, can solve the problems of too large or too small gap, and it is difficult for adjustment mechanism and control method to accurately control and maintain the gap value, so as to achieve the improvement of process control ability and high-efficiency gap. effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

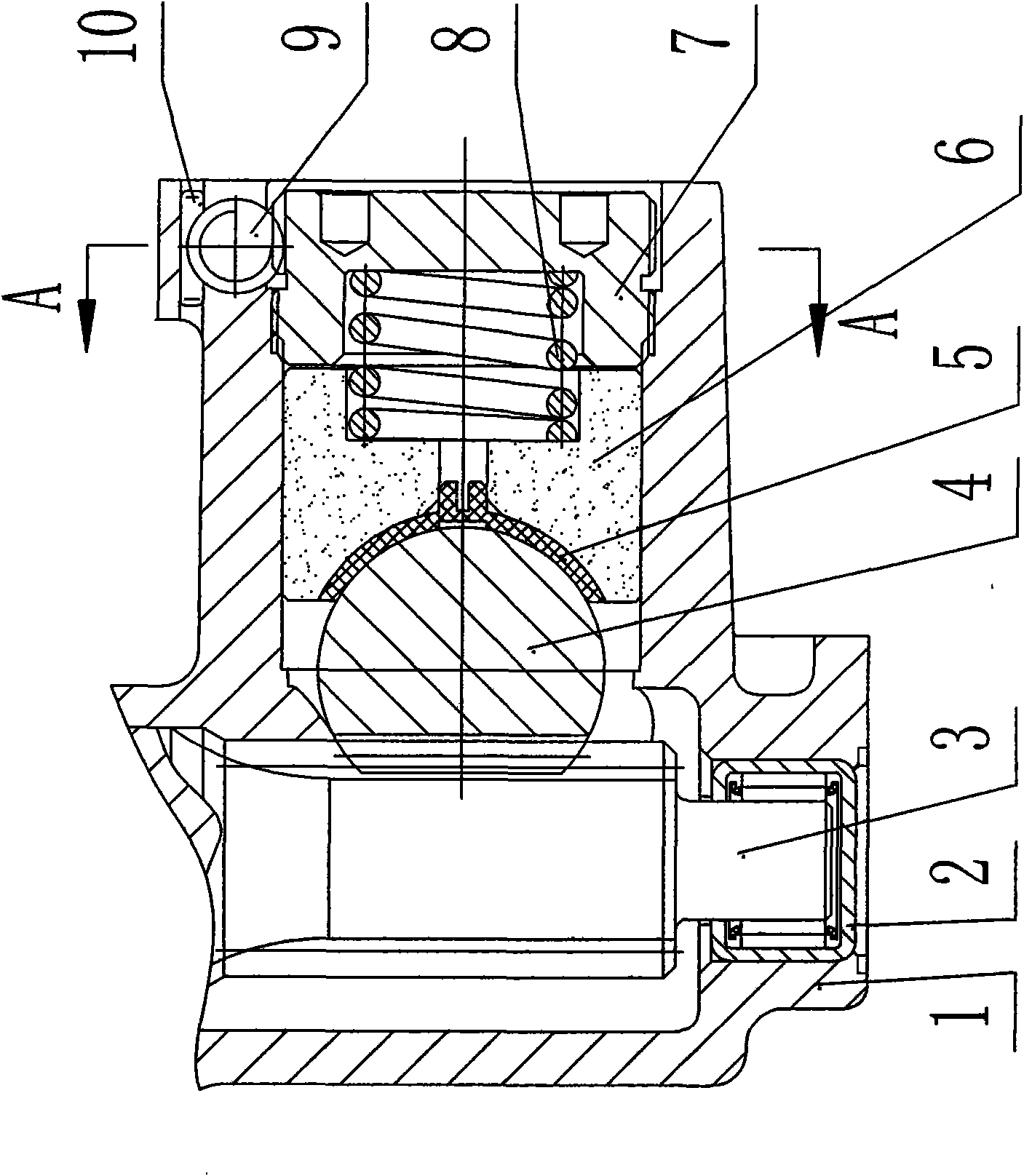

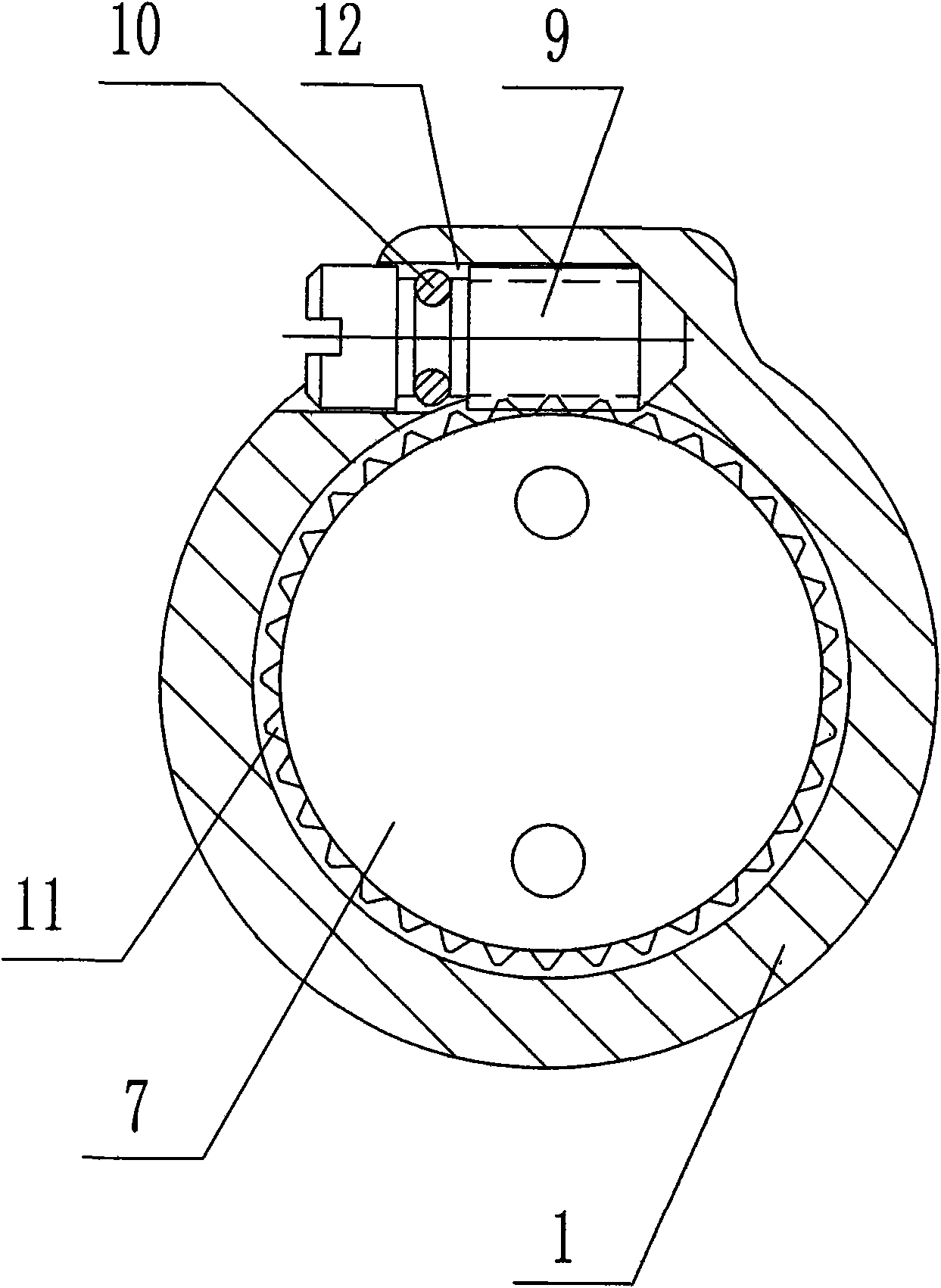

[0012] The adjustment mechanism capable of micro-controlling the meshing gap of the rack and pinion is composed of a main body shell 1, a fixed bearing of the gear shaft 2, a gear shaft 3, a rack 4, a rack support seat cushion 5, a rack support seat 6, and an adjustment screw plug 7 , gap pre-tightening spring 8, gap adjustment worm 9, and worm stop pin 10. A gear shaft 3 is fixed in the main body shell 1 through a gear shaft fixed bearing 2, and a rack 4 is meshed on the gear shaft 3. In order to eliminate the gear shaft 3 The meshing gap when it is transmitted with the rack 4, the rack support seat cushion 5 and the rack support seat 6 are installed on the back side of the rack 4, the pre-tightening force of the rack support seat 6 is provided by the gap pre-tightening spring 8, and the gap The other end of the preload spring 8 adjusts the preload of the spring by adjusting the screw plug 7 . There is a worm installation hole 12 on the hole wall of the installation adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com