High-sensitivity optical fiber grating acceleration sensor based on rigid hinge

A technology of acceleration sensor and optical fiber grating, which is applied in the direction of acceleration measurement using inertial force, and can solve problems such as real-time measurement and processing errors, affecting the normal operation of the machine, and large processing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

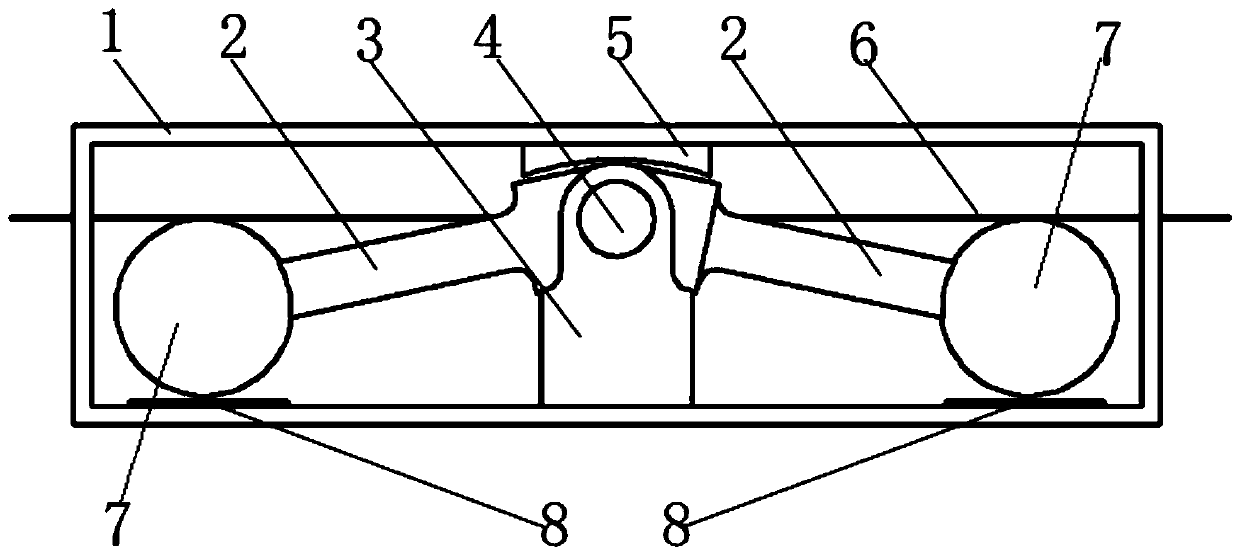

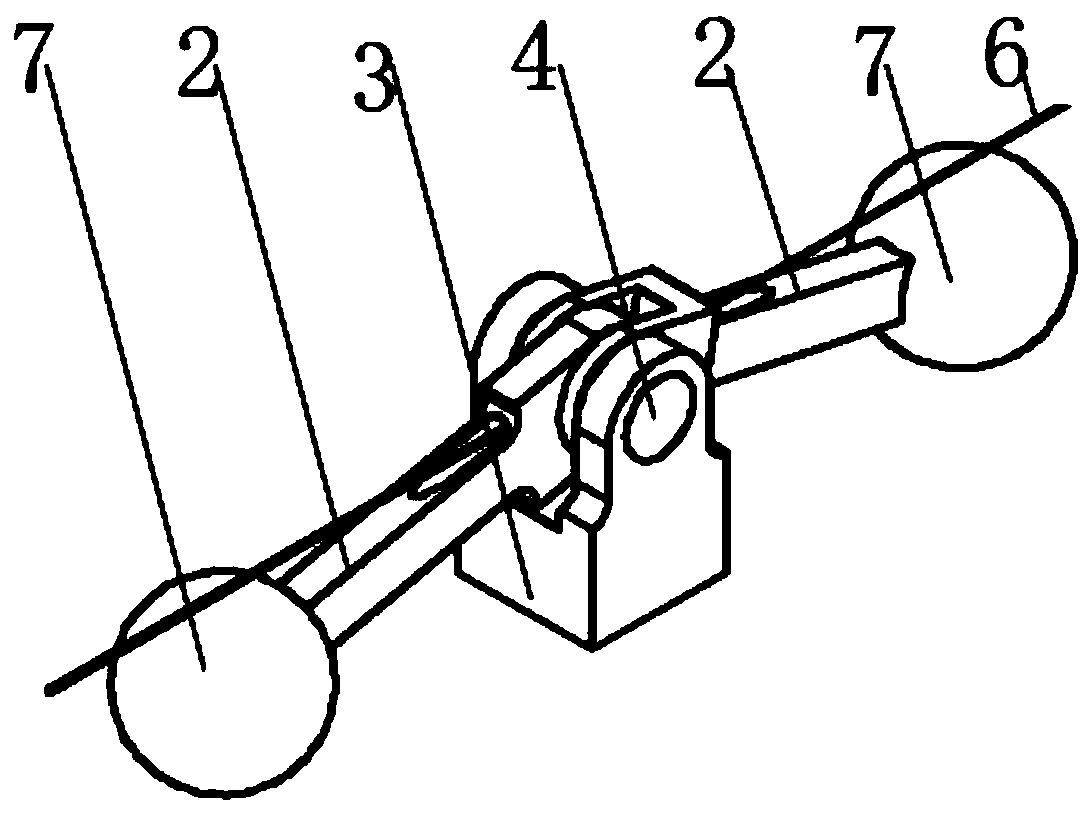

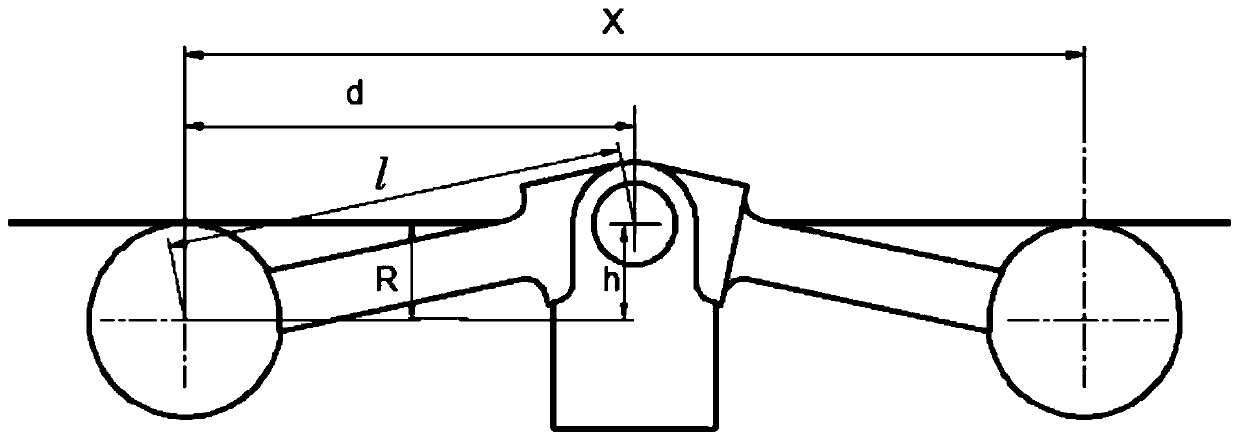

[0041] Taking Embodiment 1 as an example, the assembly and working steps are as follows:

[0042] S1. Put the base 1 on a horizontal surface, then put a swing rod 2 into the notch of the base 3 and align the hinge hole 10 of the swing rod 2 with the hinge hole 10 of the base 3 .

[0043] S2. Put another pendulum 2 into the notch of the first pendulum 2 and align the hinge holes 10 of the two.

[0044] S3, make the center line of the optical fiber of the pin shaft 4 pass through the hole 9 in the horizontal plane, draw a horizontal line on the end faces of the base 3 and the pin shaft 4 with a colored pen at the same time and extend it to the edge of the base 3, so that the optical fiber of the pin shaft 4 The central line of the passing hole 9 coincides with the central line of the optical fiber passing through the hole 9 of the two swing rods 2 .

[0045] S4. Align the horizontal line on the end face of the pin shaft 4 with the horizontal line on the base 3, slowly insert th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com