A spinner structure

A spinner and support structure technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of drilling tool thread damage, shaking, and the spinner cannot be automatically adjusted up and down, so as to improve clamping and prevent The effect of the buckle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

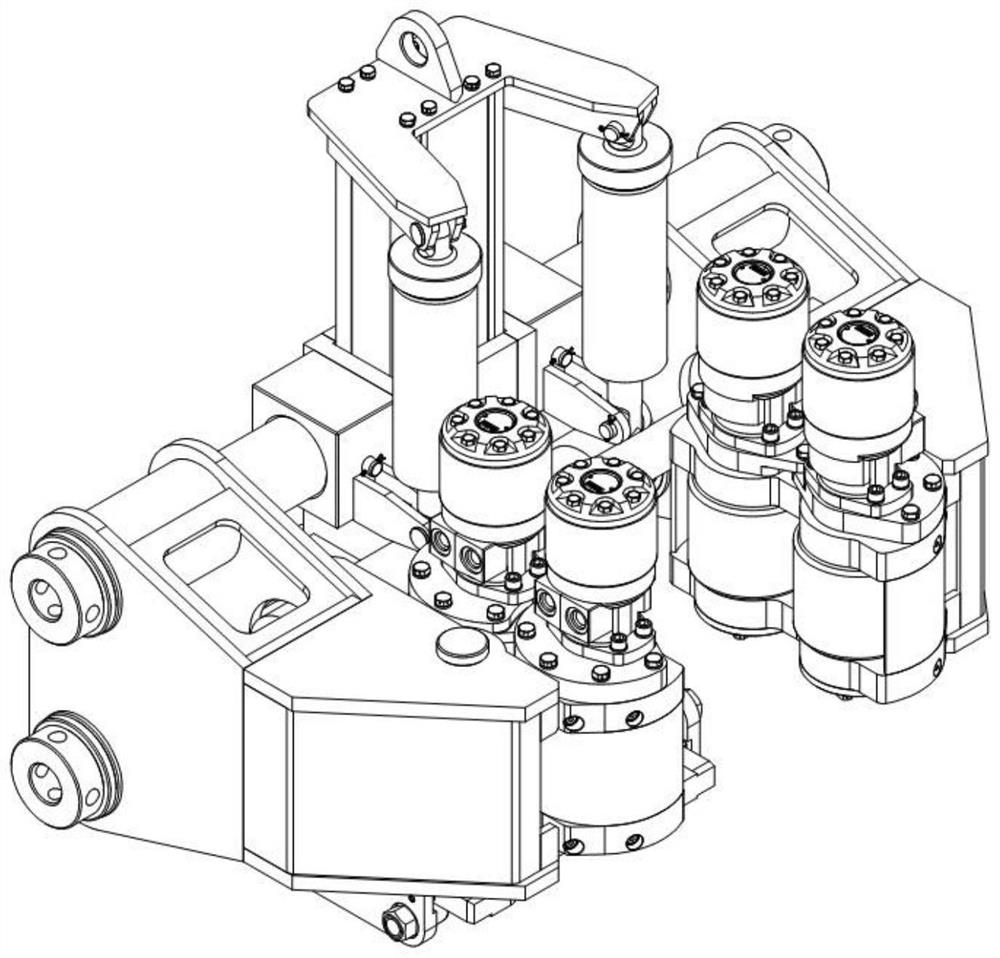

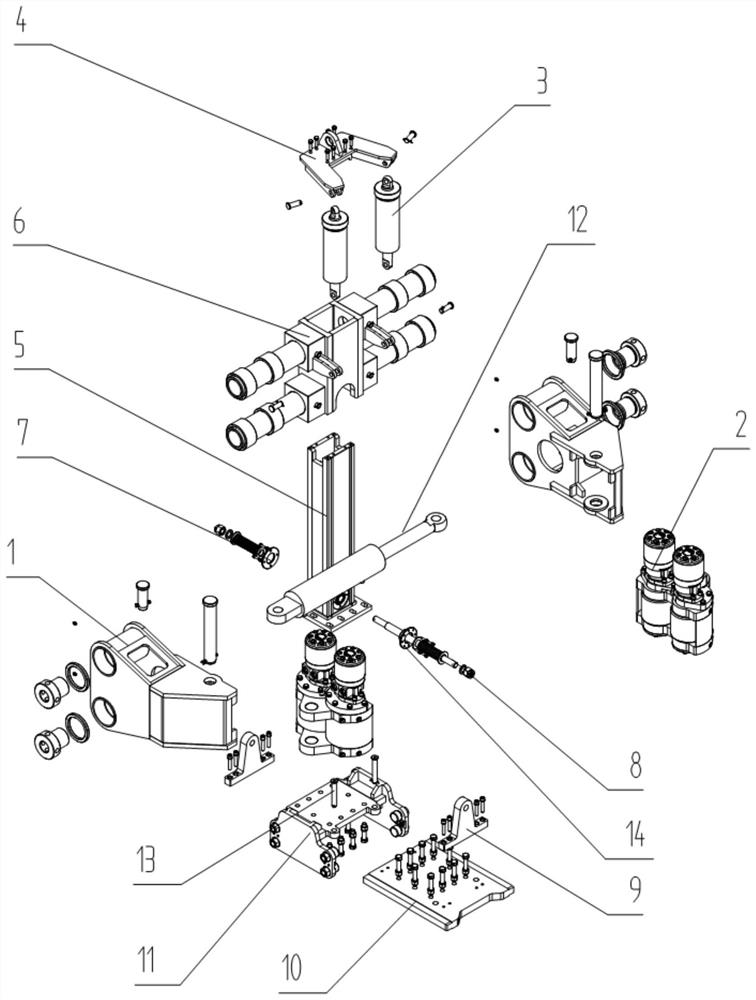

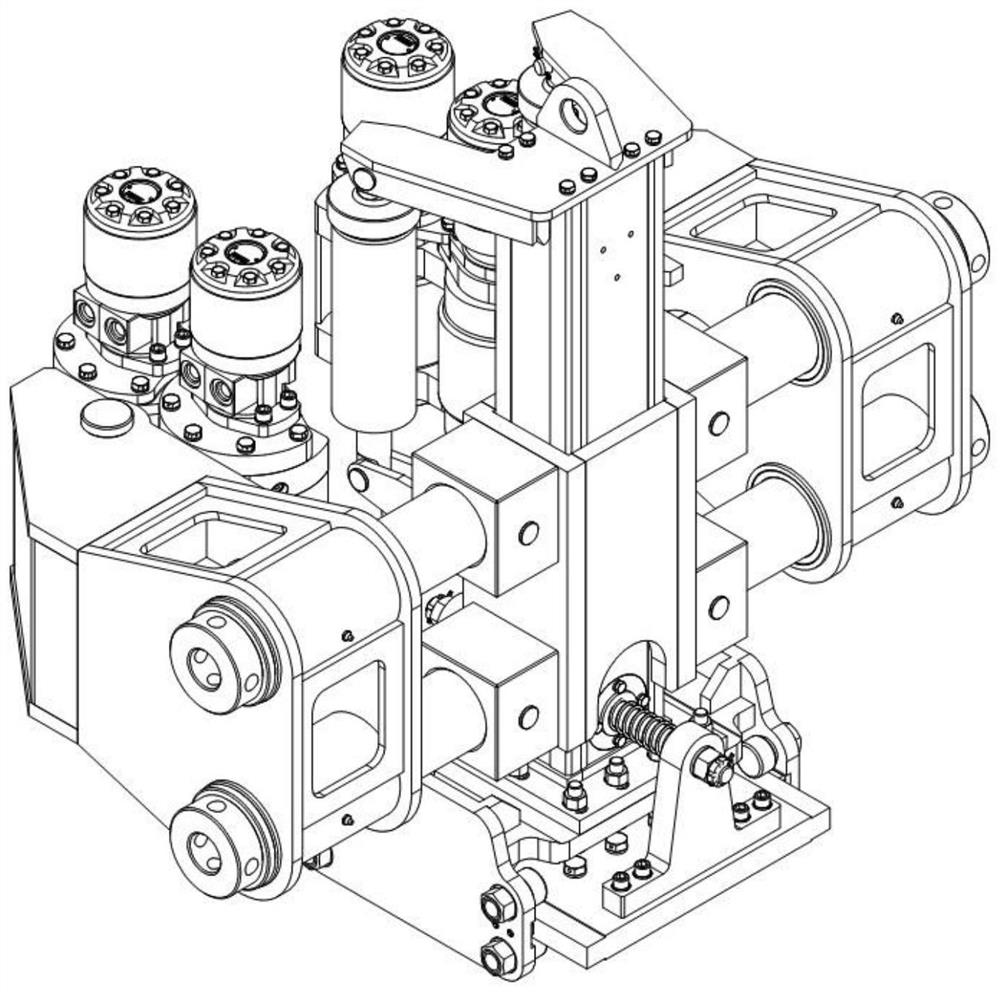

[0051] A spinner structure such asfigure 1 As shown, it includes a seat body on which a suspension assembly 3 is arranged, a support frame 6 is also arranged on the seat body, and hooks 1 are arranged on both sides of the support frame 6, and the hooks 1 A rotary wheel assembly 2 is provided on the hook, the hook 1 can move along the support frame 6, and a driving device 12 is also arranged between the hooks 1 to control the displacement of the hook 1;

[0052] The seat body is equipped with a guide frame 5 , the support frame 6 is sleeved on the guide frame 5 , the support frame 6 can slide up and down along the guide frame 5 , and one end of the suspension assembly 3 is assembled and connected with the guide frame 5 , the other end is assembled and connected with the support frame 6;

[0053] The rotary wheel assembly includes a support structure on which a power device 21 is arranged, the power device 21 is connected with a rotating shaft 23, and a rotary wheel 22 is fixed ...

Embodiment 2

[0067] On the basis of Embodiment 1, as a more specific design, two sets of bearings 111 or three sets of bearings 111 are respectively provided on both sides of the lower part of the pulley 11 , and each set of bearings 111 is two bearings 111 installed up and down. The upper and lower side walls of the mounting plate 10 are provided with guide rail grooves.

[0068] As a more specific design, the bearing sets on both sides are arranged symmetrically to ensure the uniformity of the force and the stability of the overall pulley. In a more specific design, the guide rail grooves are provided on the upper and lower side walls on both sides of the pulley mounting plate 10 . More specifically, after this design, the thickness of the position where the guide groove is located is smaller than the thickness of the chute mounting plate 10 .

Embodiment 3

[0070] Based on the designs of Embodiments 1 and 2, further design is made for the assembly relationship between the guide frame 5, the pulley 11 and the pulley mounting plate 10. The side of the pulley 11 is an inverted "concave" structure. The top side wall of the pulley 11 is provided with a plurality of through holes, and the bottom of the guide frame 5 is provided with a plurality of through holes, which are assembled and fixed by bolts. Here, the bottom of the guide frame 5 is provided with assembling wings. In addition, a bearing 111 and a friction block 112 are provided on the inner side of the side wall of the pulley 11 , and are assembled with the pulley mounting plate 10 accordingly. The pulley assembly plate 10 is provided with a plurality of through holes, which are assembled with the clamp body through bolts. The limit assembly can be realized by the limit pin 13 between the pulley assembly plate 10 and the pulley 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com