Micro-sensing clamping device

A clamping device and clamping technology, applied in the direction of chuck, micro manipulator, manipulator, etc., to achieve the effect of high practicability and improving the degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

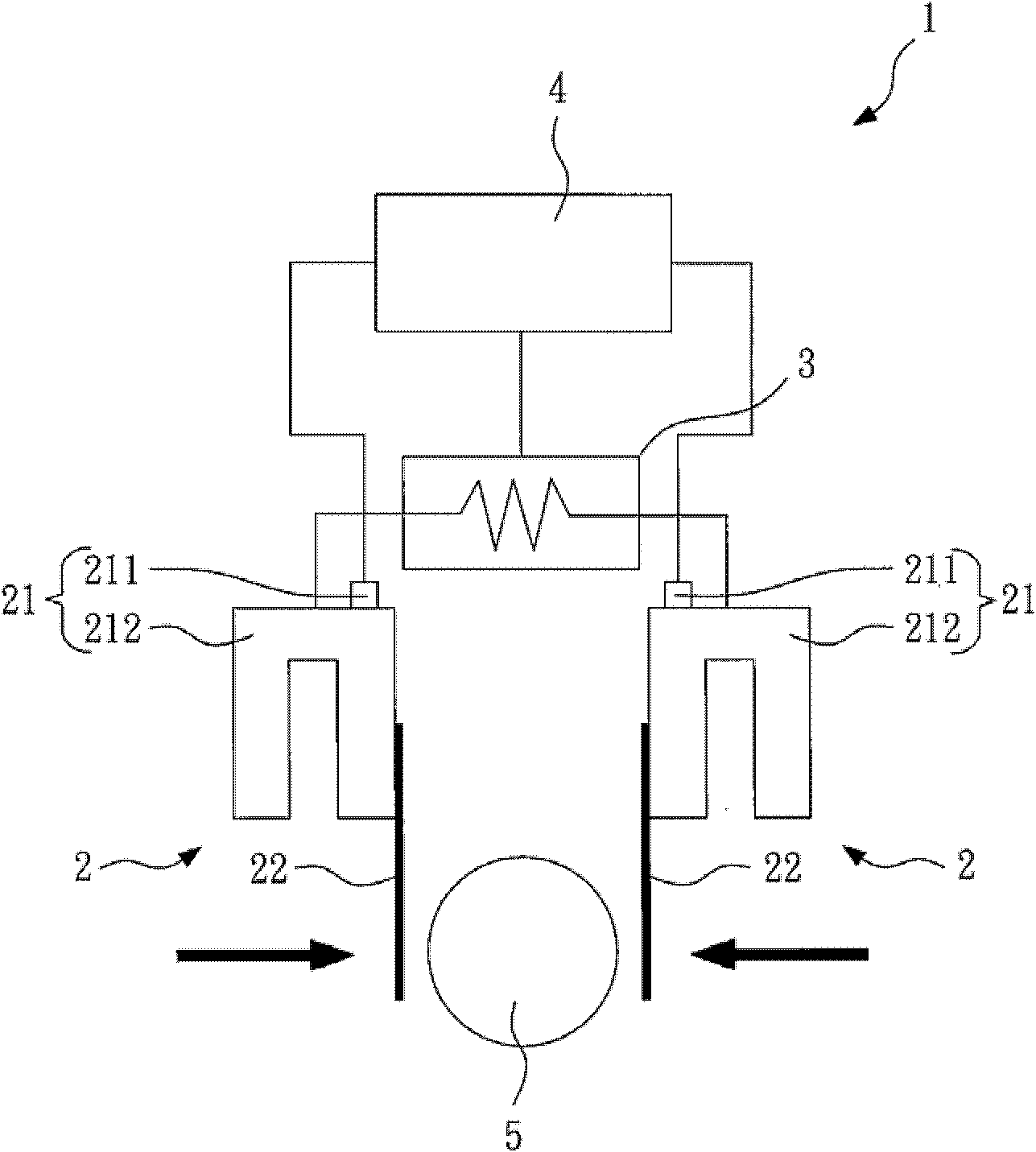

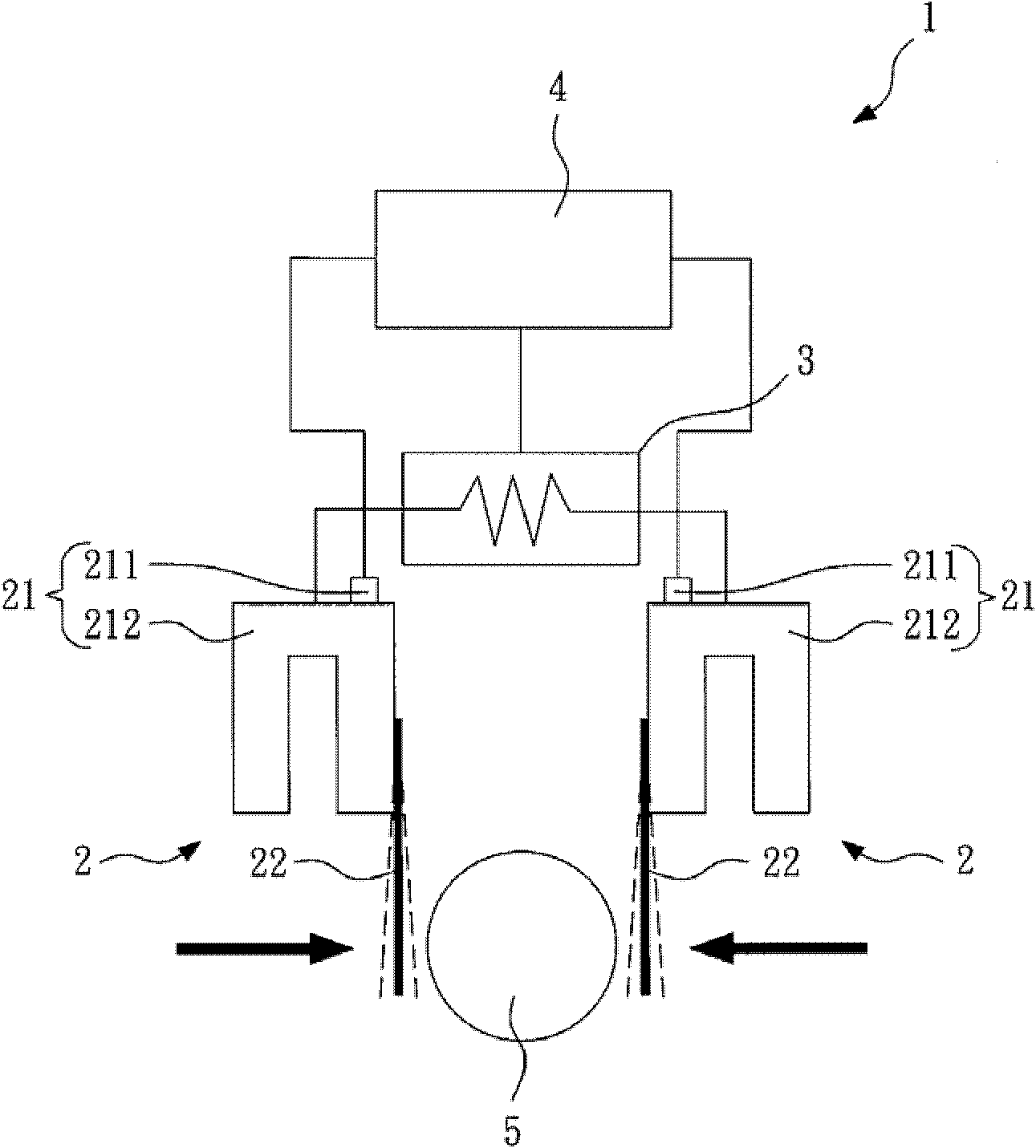

[0040] figure 1 A schematic diagram showing the micro-sensing clamping device of the present invention. The micro-sensing clamping device 1 of the present invention includes two clamping units 2 , a moving unit 3 and a control unit 4 . At least one of the two clamping units 2 includes an oscillating device 21 for generating oscillation.

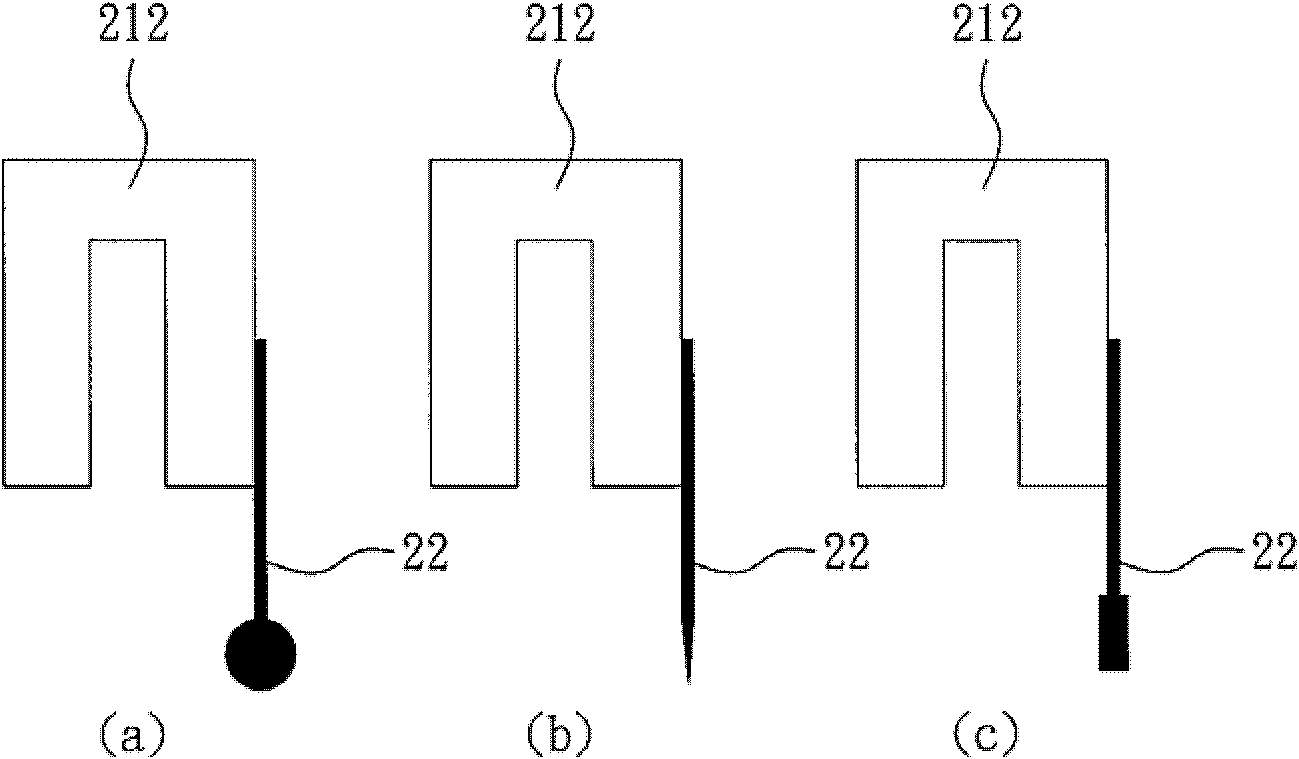

[0041] In this embodiment, each clamping unit 2 includes one oscillating device 21 , and each clamping unit 2 further includes a clamping arm 22 . The ends of these clamping arms 22 can be an enlarged portion, such as spherical or rectangular (such as figure 2 a, 2c shown), alternatively, the ends of these clamping arms 22 can be a narrowing portion, such as a pointed cone (such as figure 2 shown in b).

[0042] In this embodiment, each oscillating device 21 includes an oscillating source 211 and a tuning fork element 212 . The oscillation source 211 can generate an oscillation with a fixed frequency, and the tuning fork element 212 ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com