Method for determining remaining time of cleaning filter screen, air feeding equipment and control method for air feeding equipment

A technology of air supply equipment and remaining time, which is applied in space heating and ventilation control input, heating and ventilation control system, and control input related to air characteristics, etc. To achieve the effects of enhanced flexibility and practicability, guaranteed air volume output, and improved intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

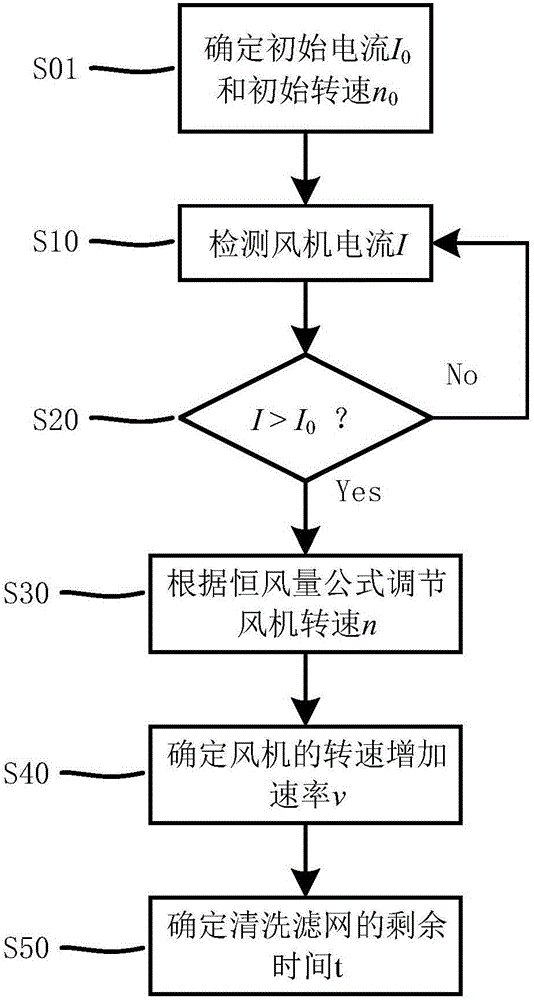

[0052] Aiming at the deficiencies of the air supply equipment in the prior art (such as air-conditioning indoor units, fresh air fans, air purifiers, etc.) in the reminder function of indicating to clean the filter screen, the present invention proposes a new method for determining the remaining time for cleaning the filter screen The method can intelligently and flexibly calculate the remaining time according to the degree of dirt and blockage of the filter screen, so as to prompt the user to clean the filter screen.

[0053]The present invention recognizes that during the operation of the blower fan, if the filter screen is dirty and clogged, it will inevitably increase the load of the fan, and the more serious the degree of dirty clogging, the more obvious the increase of the fan load will be, thus causing the fan current correspondingly increases. Therefore, detecting the change of the fan current can also reflect the degree of dirt and blockage of the filter screen. On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com