Negative feedback type air valve device

A negative feedback, air valve technology, applied in the direction of airflow control components, etc., can solve the problems of air leakage, limited function, trouble, etc., to achieve the effect of improving accuracy and reliability, prolonging service life, and ensuring wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

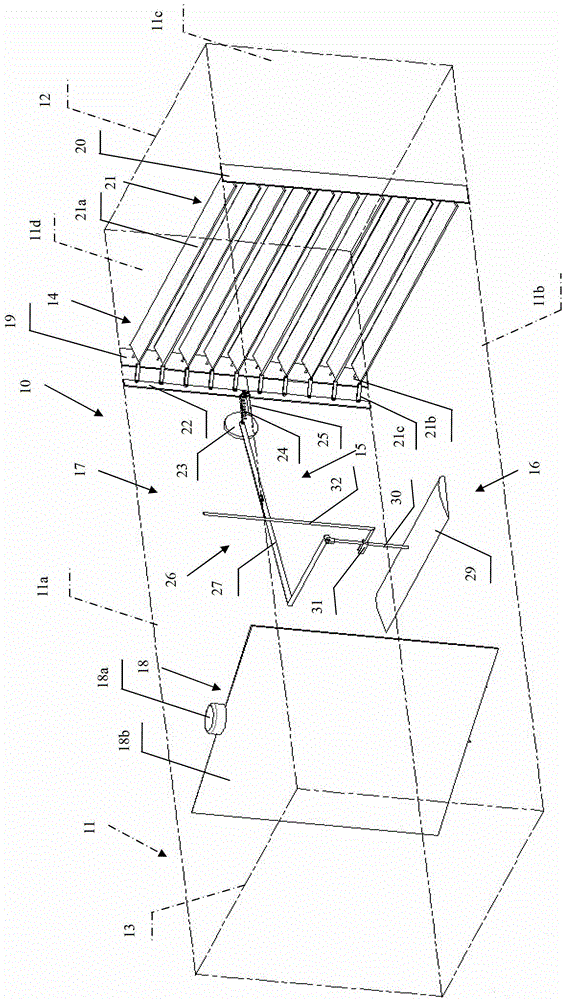

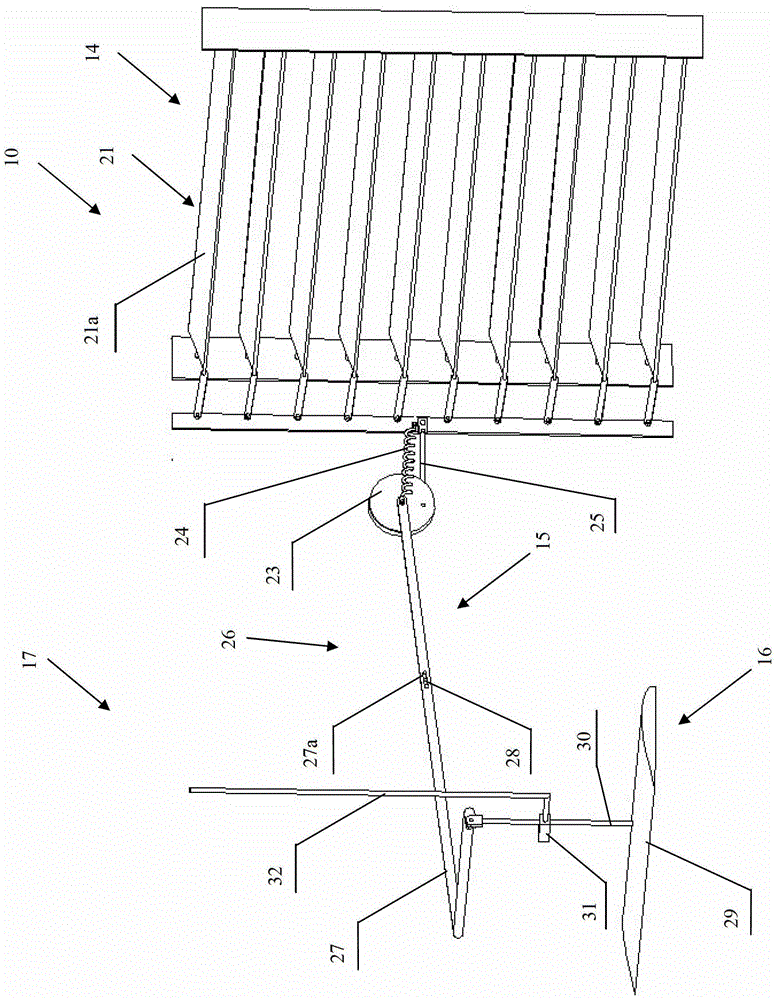

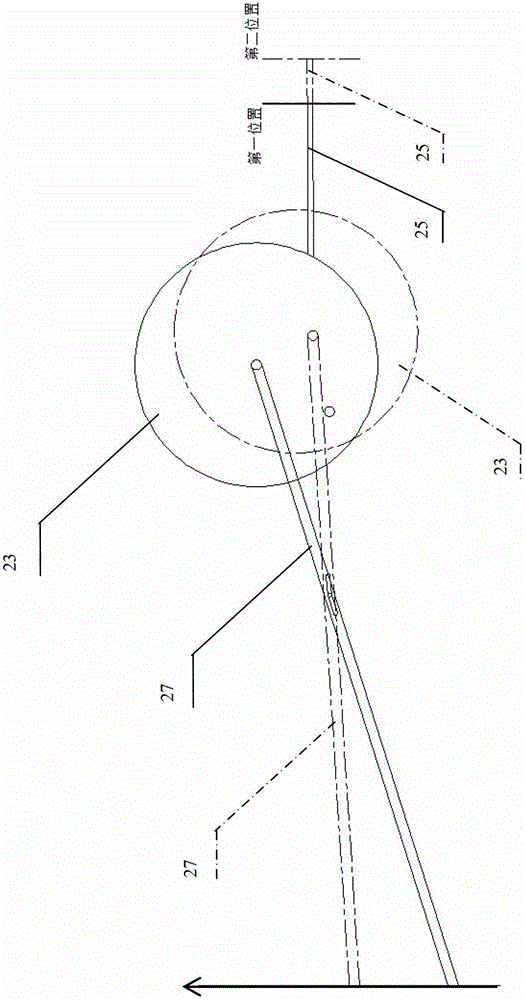

[0020] figure 1 It is a structural schematic diagram of the embodiment of the negative feedback damper device involved in the present invention.

[0021] like figure 1 As shown, the negative feedback air valve device 10 is installed inside the ventilation duct 11 shown by the dotted line in the figure, and is used to adjust the air volume of the air inlet 12 located at the front end of the ventilation duct 11, so that the The air volume of the air outlet 13 at the rear end is constant.

[0022] The negative feedback damper device 10 has: a first adjustment part 14 , a push-pull part 15 , a wind receiving part 16 , a guide part 17 and a second adjustment part 18 .

[0023] The ventilation duct 11 includes an upper duct wall 11 a , a duct lower wall 11 b , a duct left wall 11 c and a duct right wall 11 d as shown by dotted lines in the figure.

[0024] In the negative feedback air valve device 10, the first regulating part 14 is installed on the side close to the air inlet fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com