Boiler water cold wall pipe detection probe clamping device

A technology for water-cooled wall tubes and detection probes, which is applied to measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as difficulty in ensuring detection accuracy, difficult detection work, small probe size, etc., to achieve Improve the detection accuracy and efficiency, and solve the effect of probe clamping problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A boiler water wall tube detection probe clamping device of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

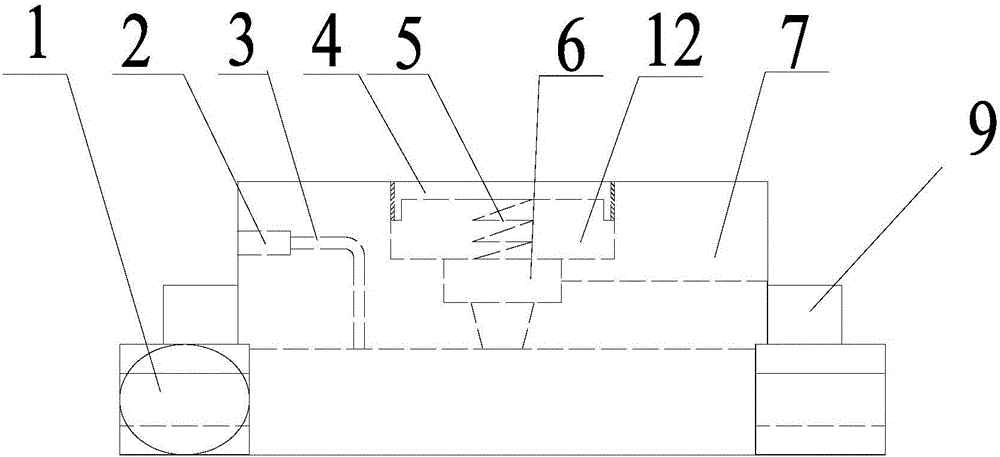

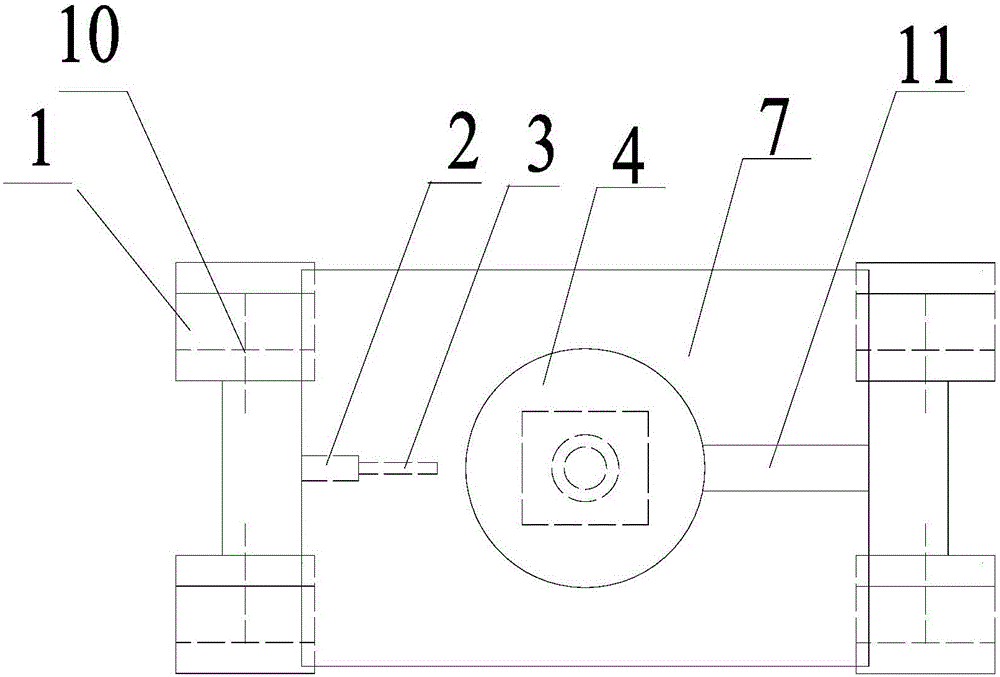

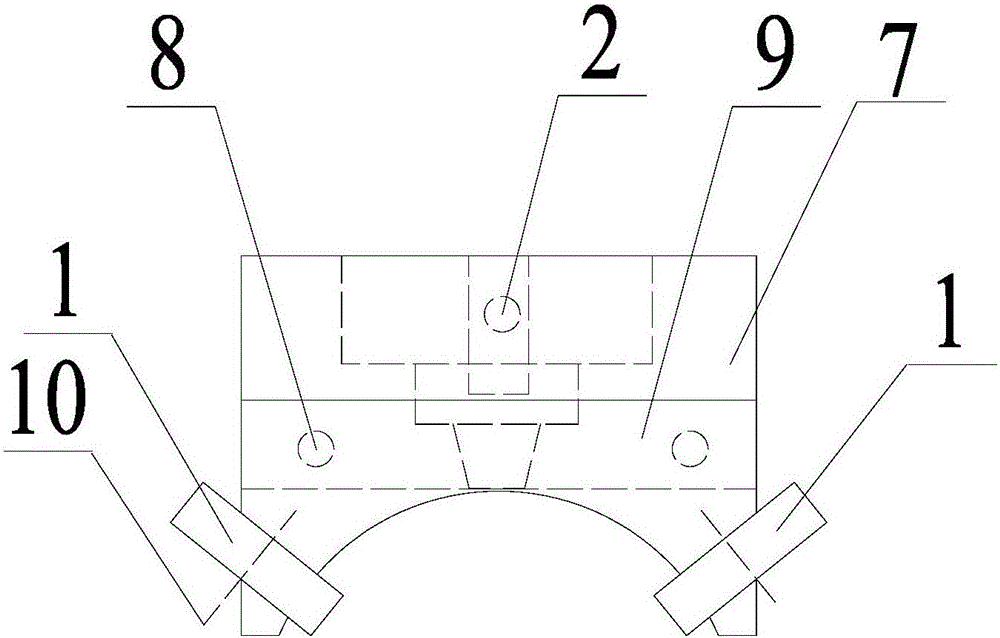

[0022] Such as figure 1 , figure 2 As shown, a boiler water-cooled wall tube detection probe clamping device of the present invention includes a housing 7, and the center of the housing 7 is formed with a stepped through-hole structure for placing the probe through the upper and lower sides. One side of the stepped through-hole structure in the casing 7 is provided with a couplant application hole 2 whose end is located on one side of the casing 7 and connected to an external couplant application device, and the other end of the couplant application hole 2 is connected to the One end of the couplant conduit 3 in the casing 7, the other end of the couplant conduit 3 is located on the bottom surface of the casing 7 and corresponds to the measured tube at the bottom of the casing 7, on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com