Special clamp for drilling mechanism

A technology of drilling mechanism and special fixture, which is applied in the direction of boring/drilling, drilling/drilling equipment, clamping, etc., which can solve the problems of long manufacturing cycle, affecting work efficiency, and difficulty in ensuring accuracy, so as to reduce operation cost, improve construction efficiency, and increase benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

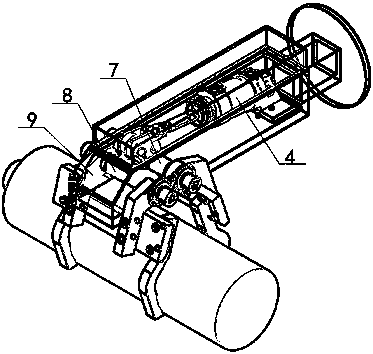

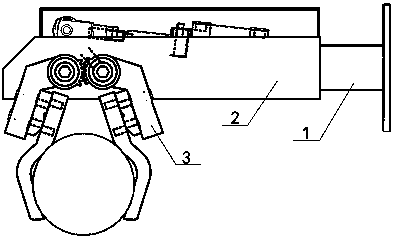

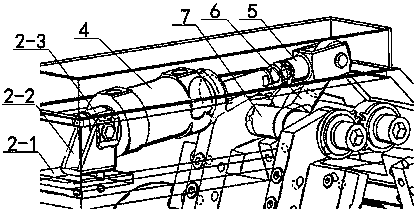

[0021] Embodiment 1: This embodiment discloses a special fixture for a drilling mechanism. The special fixture for the drilling mechanism includes a connecting body 1, which is fixedly connected to the drilling mechanism. The front end of the connecting body 1 is provided with a drive carrying box 2. The driving body 2 is provided with a driving body, which is connected to the clamping body 3. The driving body includes a hydraulic drive assembly 4, a drive link 5 connected to the hydraulic drive assembly 4, and a drive pendulum connected to the drive link 5. Rod 6, the first rotating rod 7 that links to each other with driving fork 6, the second rotating rod 8 that cooperates with the first rotating rod 7, clamping body 3 comprises driving folded rod 3-1, and drive folded rod 3-1 phase The connected transition connecting plate 3-2, the clamping claw 3-3 connected with the transition connecting plate 3-2, the connecting body 1 includes the connecting plate 1-1 and the connecting...

Embodiment 2

[0031] Embodiment 2: This embodiment discloses a drilling mechanism, which includes the special clamp disclosed in Embodiment 1. Specifically, the steps for using the drilling mechanism are as follows:

[0032] A. According to the size of the cylindrical workpiece to be clamped, the displacement of the liquid displacement device is changed to control the expansion and contraction of the piston rod of the hydraulic cylinder.

[0033] B. The reciprocating motion of the piston rod of the hydraulic cylinder drives the coordinated movement of the driving connecting rod, the movement of the driving connecting rod drives the swing of the driving swing rod, and the swing of the driving swing rod prompts the rotation of the first rotating rod, and the first ratchet of the first rotating rod and The second ratchet is engaged with the transmission, thereby driving the rotation of the second rotating rod,

[0034] C. The movement of the first rotating rod and the second rotating rod driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com