Uncapping mechanism of test tubes

A test tube cap and test tube technology, applied in the field of medical devices, can solve problems such as difficult functional requirements and no solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

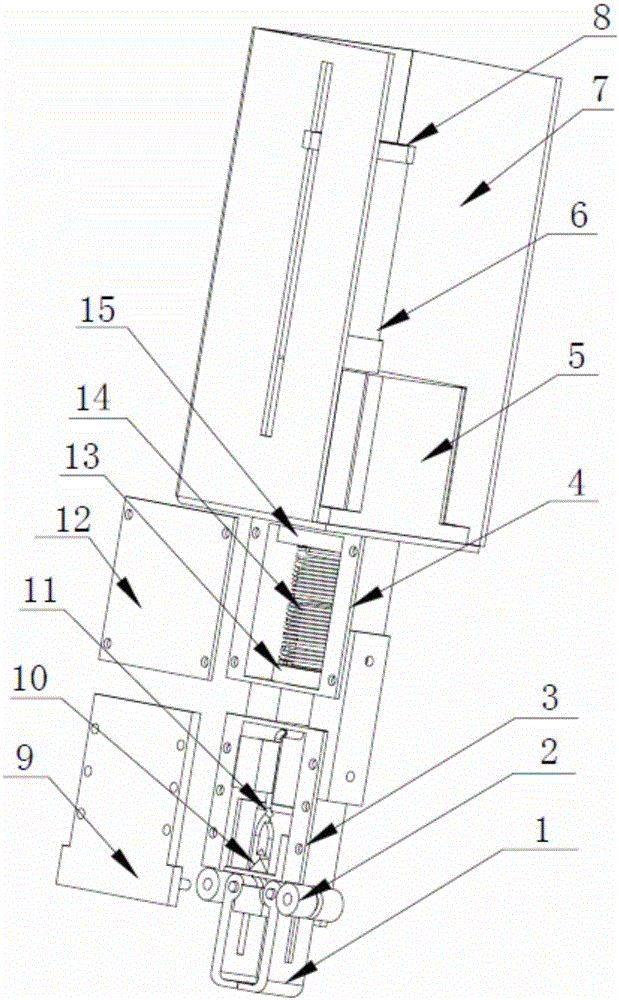

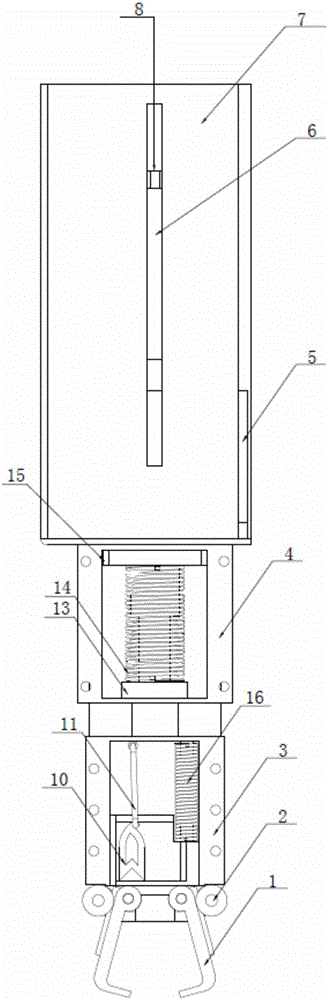

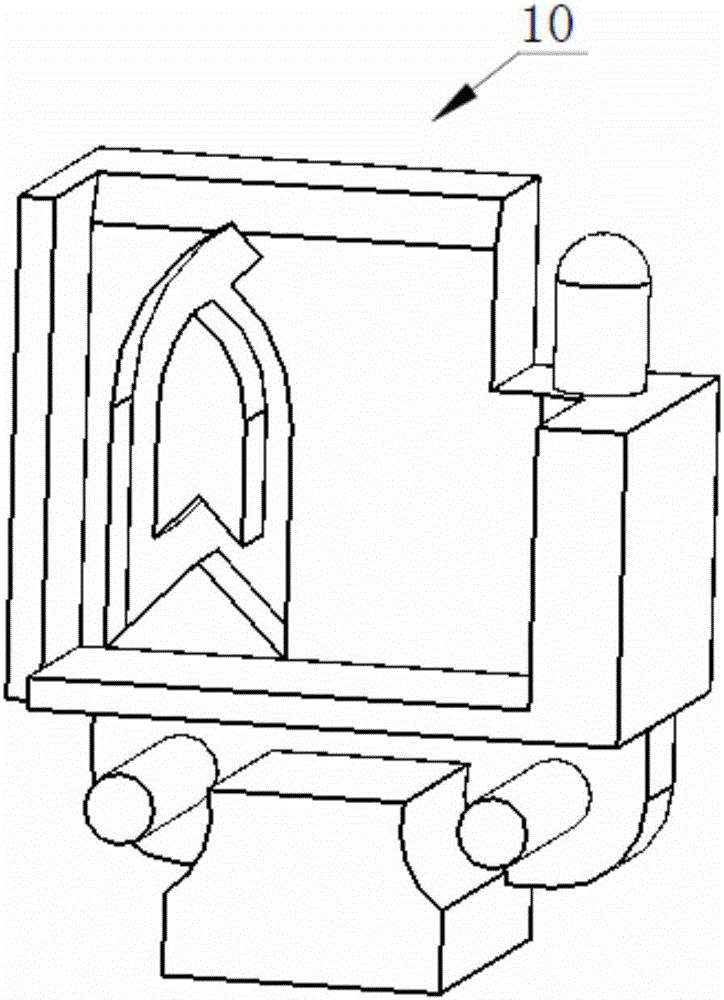

[0021] Such as figure 1 As shown, the test tube cap removal mechanism according to the present invention includes: claw 1, button 2, cover cavity 3, transition cavity 4, linear motor 5, motor screw 6, support sheet metal 7, upper gasket 8, claw Sealing plate 9, claw fixing plate 10, hook 11, transition plate 12, lower gasket 13, first compression spring 14, lead screw nut 15, second compression spring 16.

[0022] Wherein, the test tube capping mechanism has a supporting sheet metal 7, and the interior forms a rectangular accommodation space as a whole. A linear motor 5 is arranged at the bottom of the accommodating space, and the bottom end of the linear motor 5 is fixed on the lower bottom surface of the supporting sheet metal 7 with four fasteners for driving the motor lead screw 6 .

[0023] The upper end of the motor lead screw 6 has an upper gasket 8, and the lower gasket 13 is arranged at the bottom. Wherein the upper gasket 8 is a strip-shaped structure, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com