Adjustable stator coil processing tool and processing method

A technology of stator coils and processing methods, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of different sizes of stator clamping, low efficiency, poor strength of electronic coils, etc., to improve stability and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

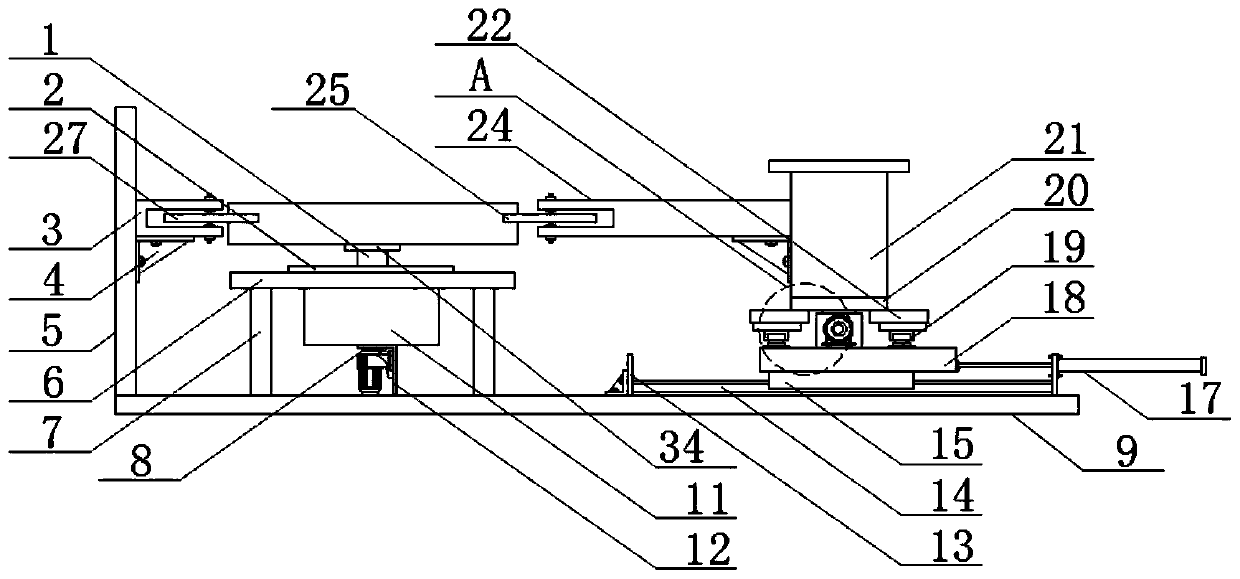

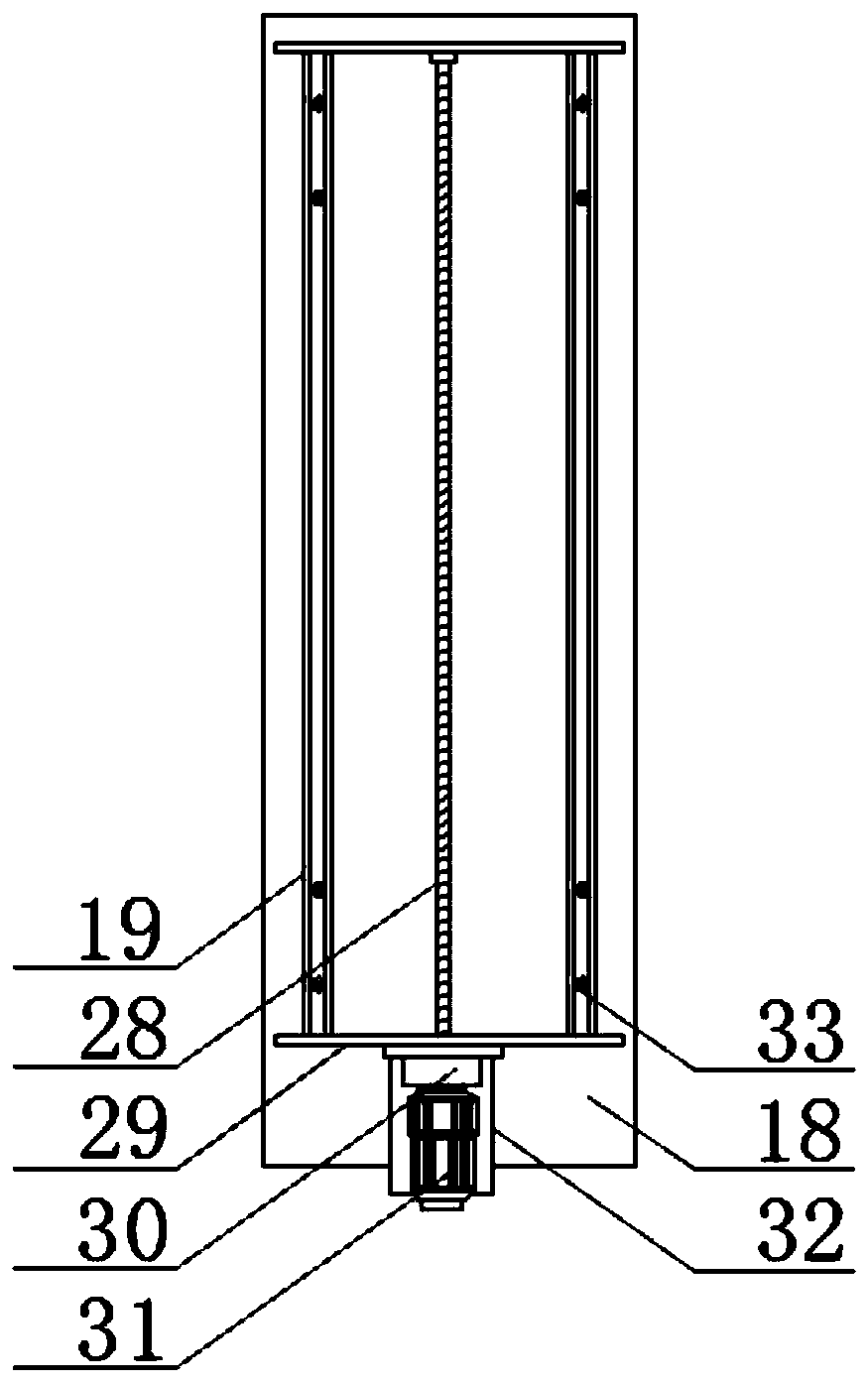

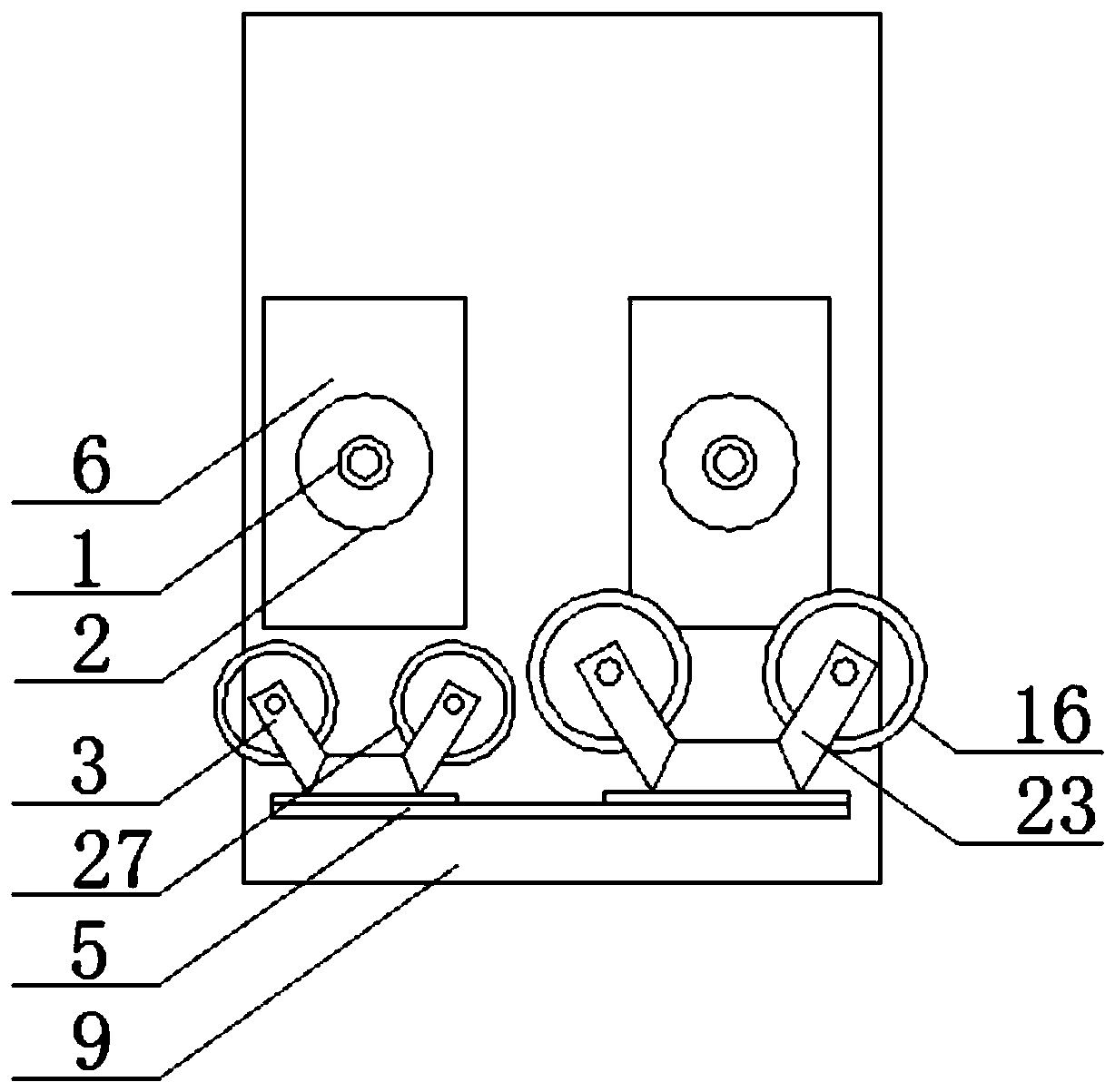

[0036] refer to figure 1 , 2 , 3, 4, an adjustable stator coil processing tooling, including a bottom plate 9, which plays a supporting role, a vertical plate 5 is fixed on one side of the upper end of the bottom plate 9, and one side of the vertical plate 5 is respectively fixed by two support members 4 There are two first mounting frames 3 and two second mounting frames 23, the first mounting frame 3 is equipped with a first fixed wheel 27, and the second mounting frame 23 is equipped with a second fixed wheel 16, which is convenient for fixing the position of the stator , the upper end of the bottom plate 9 is fixed with four bearing rods 7, and the upper ends of the four bearing rods 7 are jointly fixed with a support plate 6, which is convenient for supporting. The support plate 6 is provided with a rotating device, and the upper end of the rotating device is fixed with a positioning block 34. The stator is sleeved on the positioning block 34, and under the action of the...

Embodiment 2

[0053] refer to figure 1 , 2 , 3, 4, an adjustable stator coil processing tooling, including a bottom plate 9, which plays a supporting role, a vertical plate 5 is fixed on one side of the upper end of the bottom plate 9, and one side of the vertical plate 5 is respectively fixed by two support members 4 There are two first mounting frames 3 and two second mounting frames 23, the first mounting frame 3 is equipped with a first fixed wheel 27, and the second mounting frame 23 is equipped with a second fixed wheel 16, which is convenient for fixing the position of the stator , the upper end of the bottom plate 9 is fixed with four bearing rods 7, and the upper ends of the four bearing rods 7 are jointly fixed with a support plate 6, which is convenient for supporting. The support plate 6 is provided with a rotating device, and the upper end of the rotating device is fixed with a positioning block 34. The stator is sleeved on the positioning block 34, and under the action of the...

Embodiment 3

[0071] refer to figure 1 , 2 , 3, 4, an adjustable stator coil processing tooling, including a bottom plate 9, which plays a supporting role, a vertical plate 5 is fixed on one side of the upper end of the bottom plate 9, and one side of the vertical plate 5 is respectively fixed by two support members 4 There are two first mounting frames 3 and two second mounting frames 23, the first mounting frame 3 is equipped with a first fixed wheel 27, and the second mounting frame 23 is equipped with a second fixed wheel 16, which is convenient for fixing the position of the stator , the upper end of the bottom plate 9 is fixed with four bearing rods 7, and the upper ends of the four bearing rods 7 are jointly fixed with a support plate 6, which is convenient for supporting. The support plate 6 is provided with a rotating device, and the upper end of the rotating device is fixed with a positioning block 34. The stator is sleeved on the positioning block 34, and under the action of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com