Drilling equipment for building construction

A technology for drilling equipment and building construction. It is applied in the direction of stone processing equipment, working accessories, manufacturing tools, etc. It can solve the problems of reducing drilling operation efficiency, large vibration, and inconvenient adjustment of drilling equipment, and achieves flexible operation and lifting. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

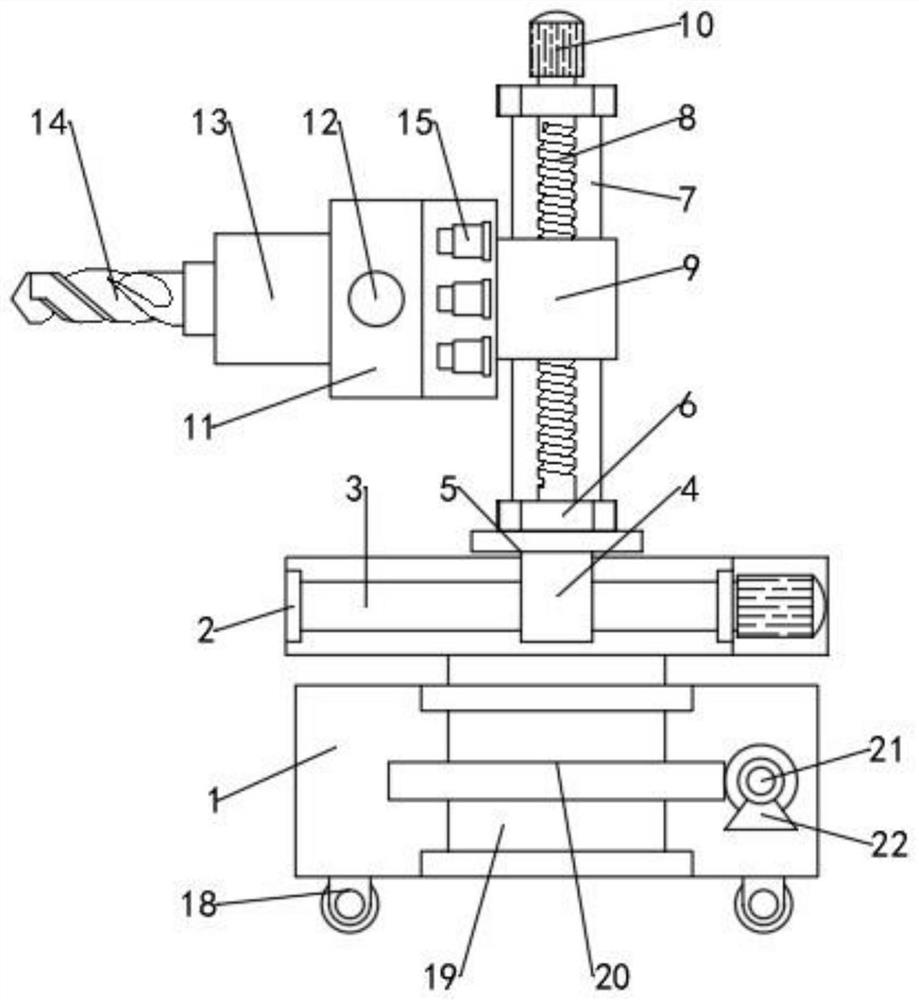

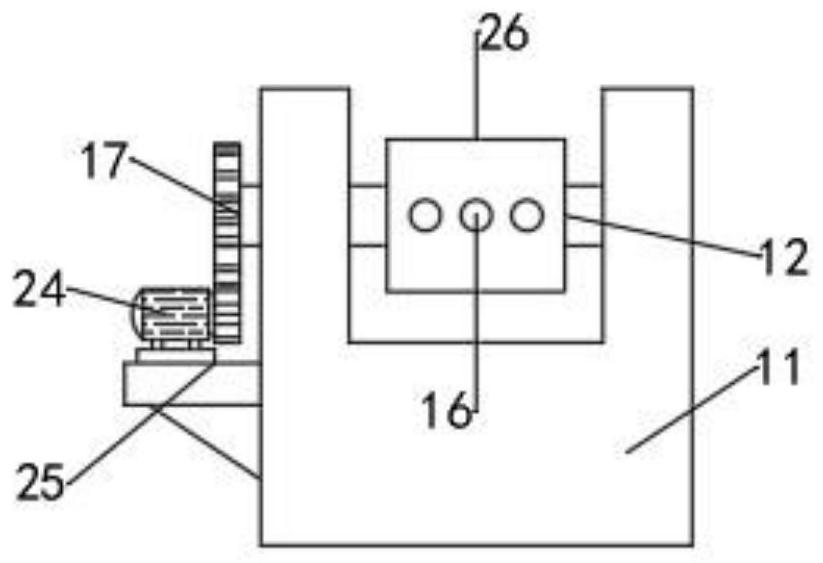

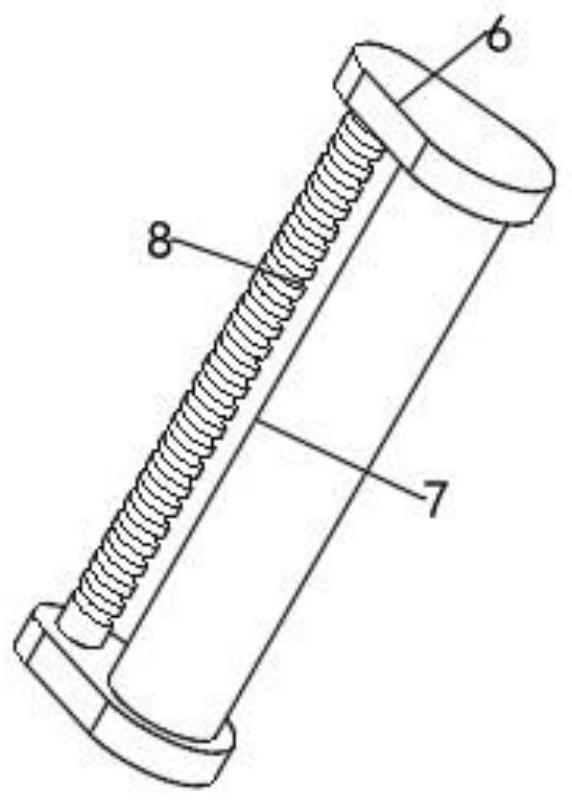

[0021] see Figure 1-5 , a kind of drilling equipment for building construction, comprising a base 1, a worktable 2 is movably assembled above the base 1, a fixed seat 5 is movably connected to the workbench 2, and a base 6 is fixedly connected to the upper end of the fixed seat 5 , the top of the base 6 is provided with another base 6, and a vertical coupling column 7 and a lifting screw 8 are fixedly connected between the two bases 6, and the coupling column 7 and the lifting screw 8 are arranged at intervals, and the lifting One end of the screw mandrel 8 extends above the base 6 of the upper end and is connected with a lifting motor 10 in transmission; a mounting seat 9 is equipped between the coupling column 7 and the lifting screw mandrel 8, and the mounting base 9 is slidably connected with the coupling column 7 and is connected with the lifting motor 10. The screw rod 8 is driven and matched; one side of the mounting seat 9 is fixedly connected with an assembly seat 11...

Embodiment 2

[0030] In Embodiment 1, the drilling machine 13 can carry out vertical and horizontal drilling operations under the adjustment of the turning motor 24. In actual use, multi-faceted drilling is often required in the horizontal direction. The installation angle of the hole equipment increases the labor intensity of the operator, and the manual adjustment of the installation position of the base 1 is likely to have an offset, which is not convenient for subsequent tool setting; therefore, this embodiment is improved on the basis of Embodiment 1. The improvement is: the base 1 is equipped with a vertical adjustment shaft 19, one end of the adjustment shaft 19 extends above the base 1 and is fixedly connected with the bottom surface of the workbench 2, and the adjustment shaft 19 is fixedly connected with a worm wheel 20 , the interior of the base 1 is provided with two assembly frames 22 at intervals, a worm 21 is installed between the two assembly frames 22, the worm 21 is in tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com