A high-pressure unfired brick making machine

A brick machine and high-pressure technology, which is applied in the field of new high-pressure unfired brick machines, can solve problems such as different strengths, different thicknesses of bricks, and increased input costs, and achieve uniform compactness, good mold forming and demoulding effects, and smoothness and good self-control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

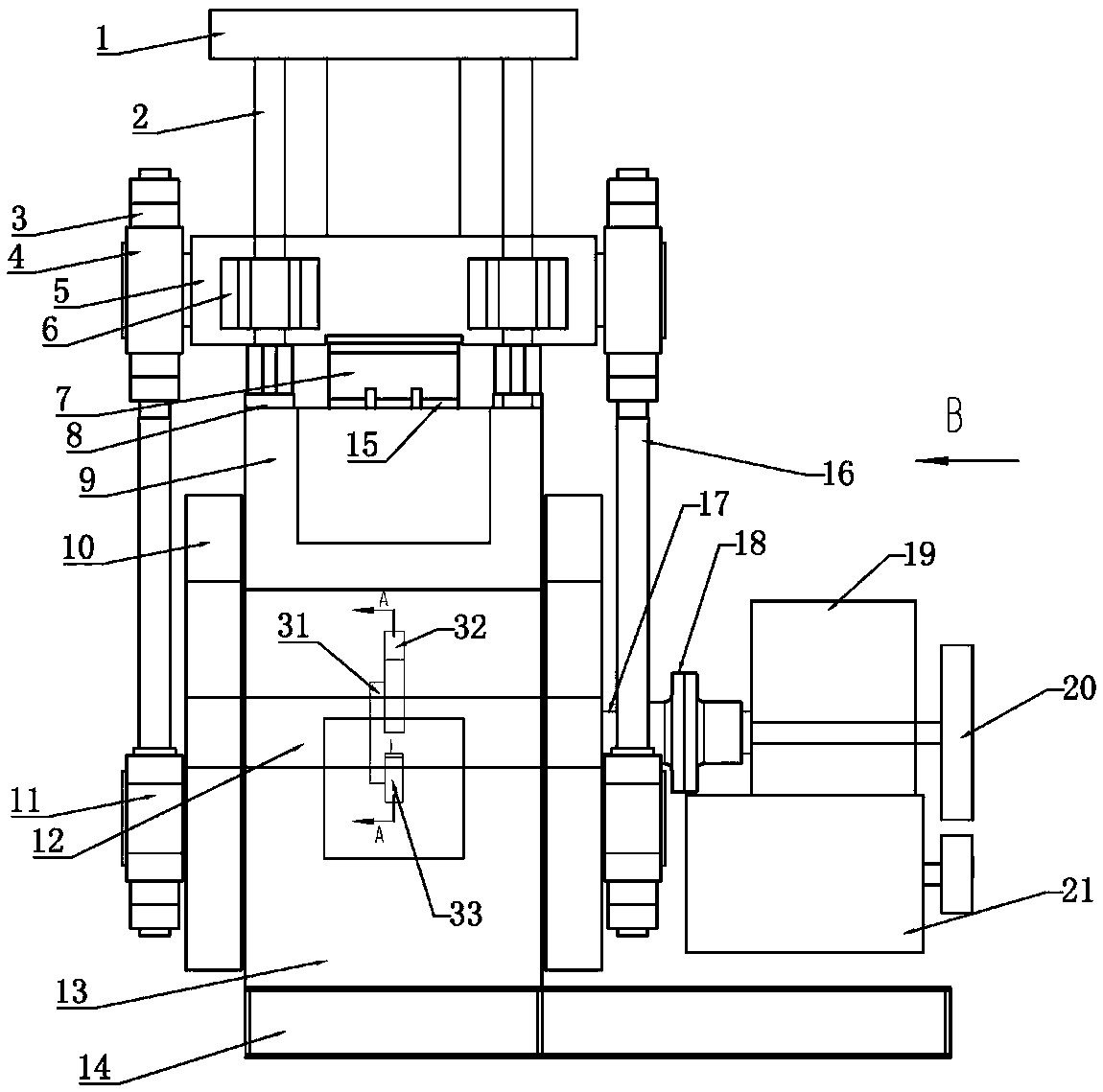

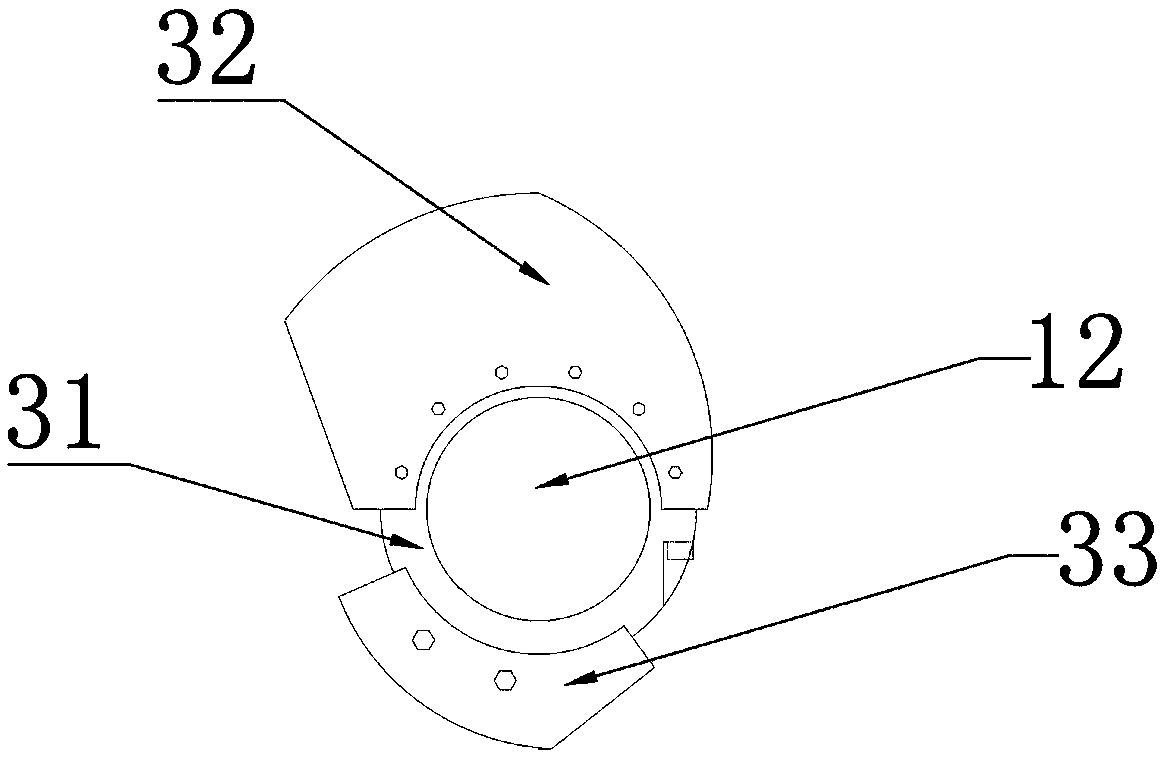

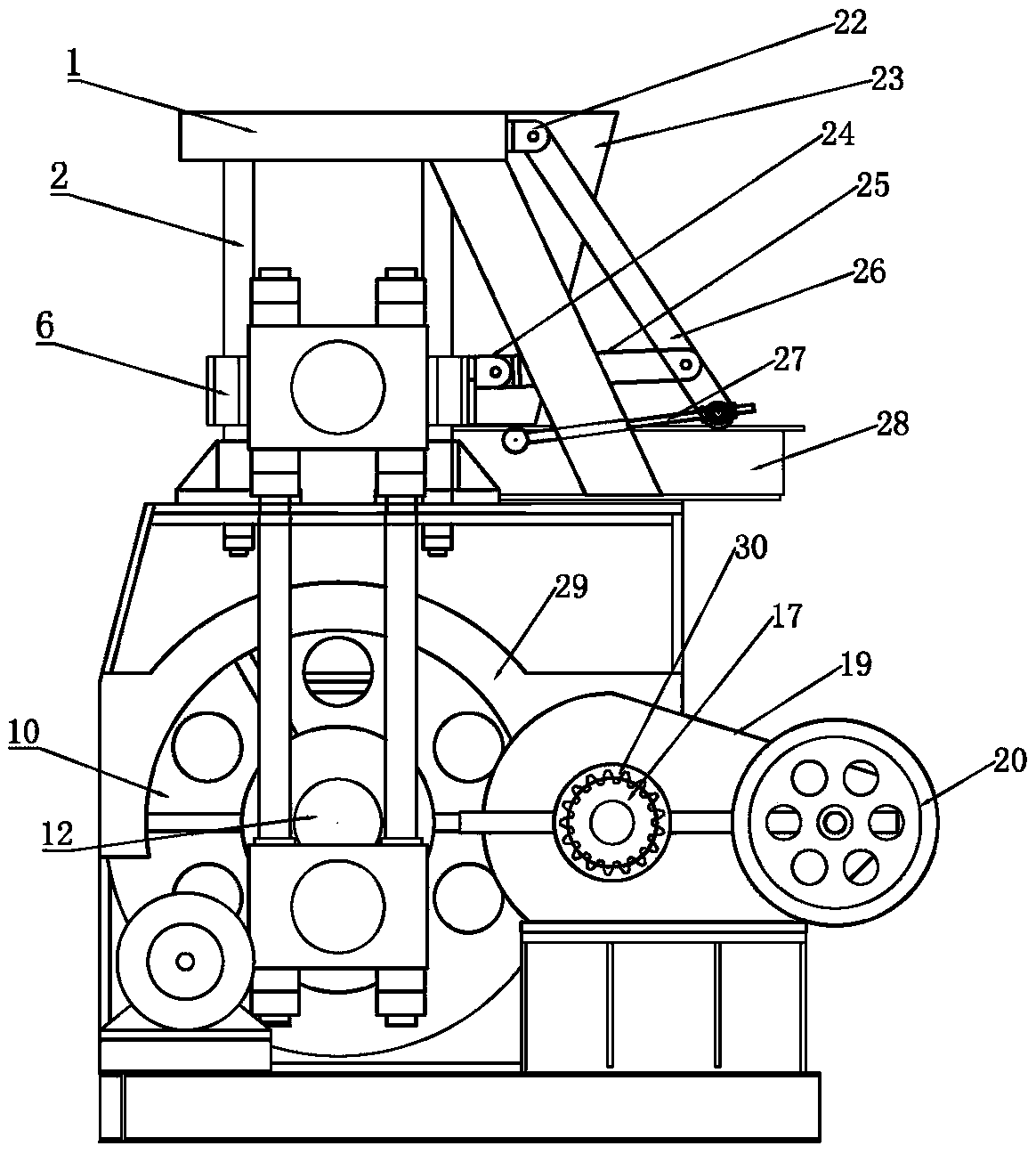

[0027] Embodiment 1: a kind of high-pressure unfired brick making machine, such as Figure 1-6 As shown, the non-burning brick machine is composed of a chassis, a feeding mechanism, a transmission mechanism, a molding mechanism, a demoulding mechanism, a seasoning mechanism and a pressure regulating mechanism. The chassis is top cover 1, middle box 9, and bottom from top to bottom. Case 13 and support 14, are fixedly connected by four columns 2 between top cover 1 and middle case 9, and column 2 is provided with column seat 8 with middle case 9 joints, makes column 2 fix more firmly. Column 2 is horizontally provided with crossbeam 5 that can slide up and down by sliding tile seat 6, and the four corners of crossbeam 5 pass four columns 2, and sliding tile seat 6 reduces friction when crossbeam 5 slides on column 2.

[0028] Feeding mechanism is positioned at the top of middle case 9, and feeding mechanism is made up of hopper 23, feeding hopper 28, feeding hopper placement pl...

Embodiment 2

[0036] Embodiment 2: The high-pressure unfired brick making machine involved in this embodiment will be described centering on the differences from the high-pressure unfired brick making machine involved in Example 1.

[0037] Such as Figure 7 and Figure 8 As shown, four dial shafts 47 are arranged in the feed hopper 28, and the dial shafts 47 are fixed by the shaft seat 50, one of which is driven by a motor, and the four dial shafts 47 are driven by gears 49, and the dial shafts 47 are evenly Pick pieces 48 are distributed to make the raw materials with higher viscosity and poor slump forced to be unloaded, and the unloading is uniform. Feeder hopper placement platform 42 is provided with guide rail 43, and feed hopper 28 is fixed on guide rail 28 upper ends, and feed hopper 28 can laterally slide on guide rail 43, reduces the friction of feed hopper 28 bottoms, increases the service life of feed hopper 28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com