Synchronous profiling sharpening machine of anti-arc steel gate

A grinding machine and water stop technology, which is applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of affecting the repair accuracy, uneven force, and poor repair quality, so as to improve the repair accuracy and reduce the Labor intensity, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

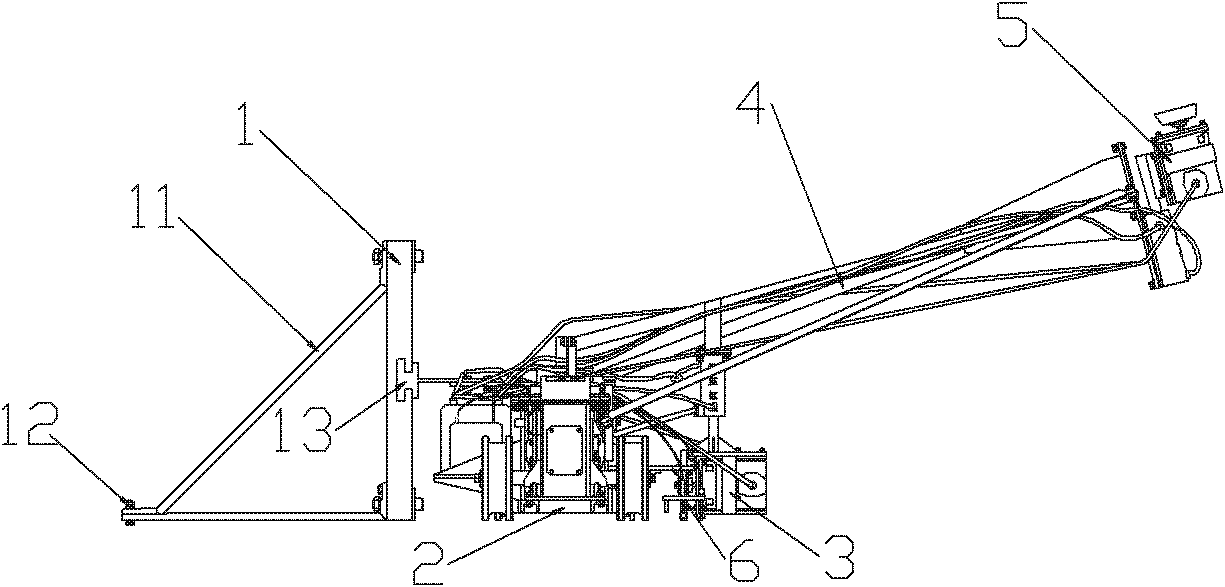

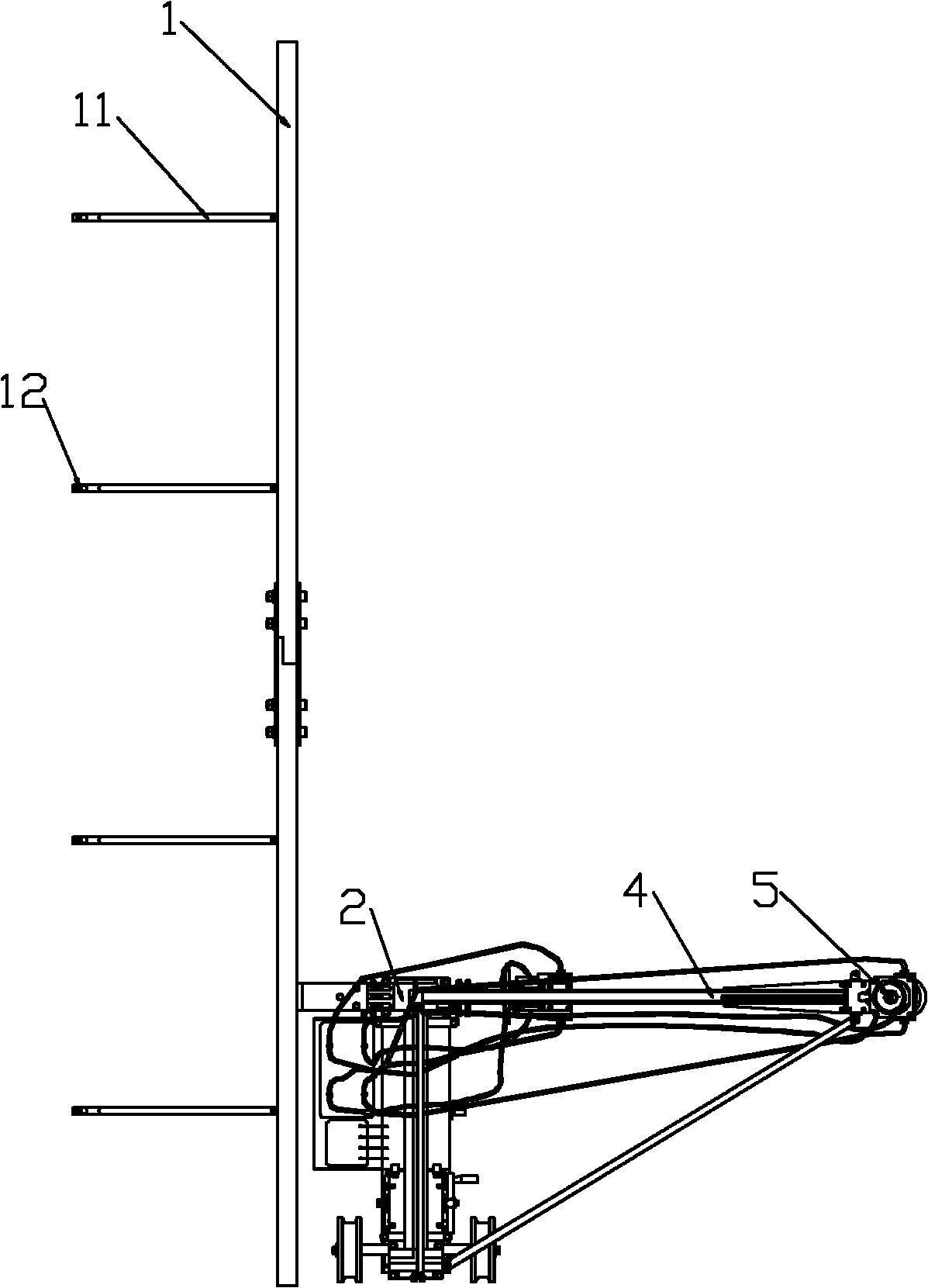

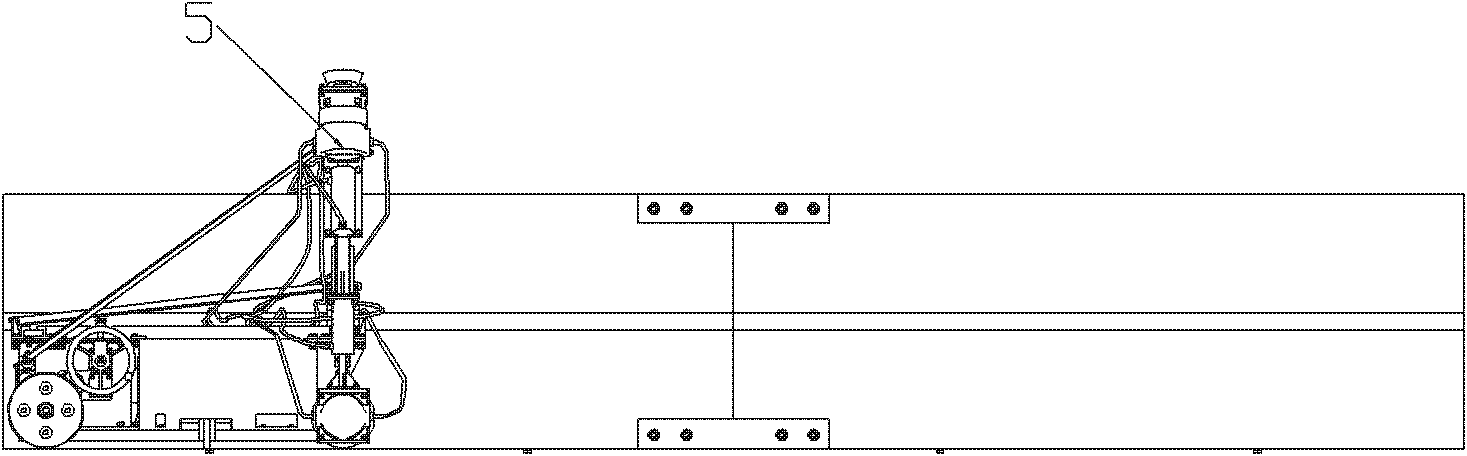

[0037] Such as figure 1 , figure 2 and image 3 Among them, an anti-arc door steel water-stop synchronous profiling grinding machine, the anchor bolts 12 are driven into the concrete outside the steel plate of the sill embedded part, and the track plate is erected on the sill embedded part with the tie rod 11 and the rod On the steel plate, a guide rail 13 is horizontally arranged in the middle of the track plate, thereby forming the walking track 1 of the device. One side of the running mechanism 2 is slidingly connected with the guide rail 13, thereby realizing the constraint on the movement track of the running mechanism 2. The track plate can be used according to the gate. The chamber size is set to multi-segment. The top of the walking mechanism 2 is equipped with a door frame 4 through the door frame mounting seat 29, and the reinforcing rib is connected with the running mechanism 2 through the upper profiling head reinforcing rib fixing plate 24, and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com