AGM acid absorption saturability testing method

A test method and saturation technology, applied in the field of AGM acid absorption saturation test, can solve the problems of inconvenient operation and low test accuracy, and achieve the effect of flexible and convenient use, convenient drilling operation, and convenient test operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

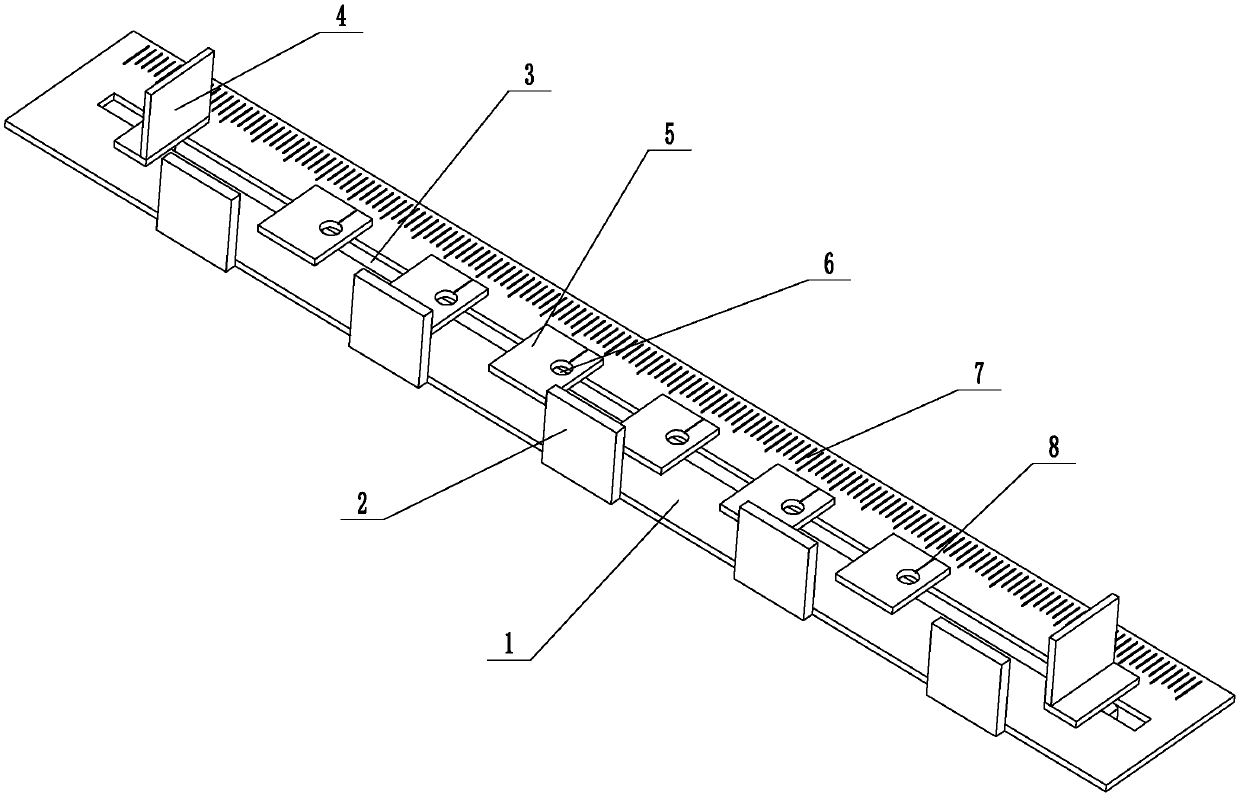

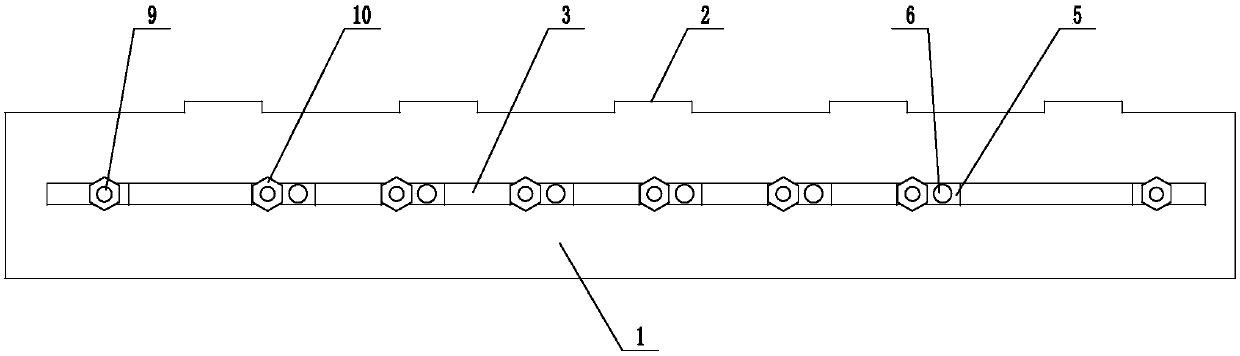

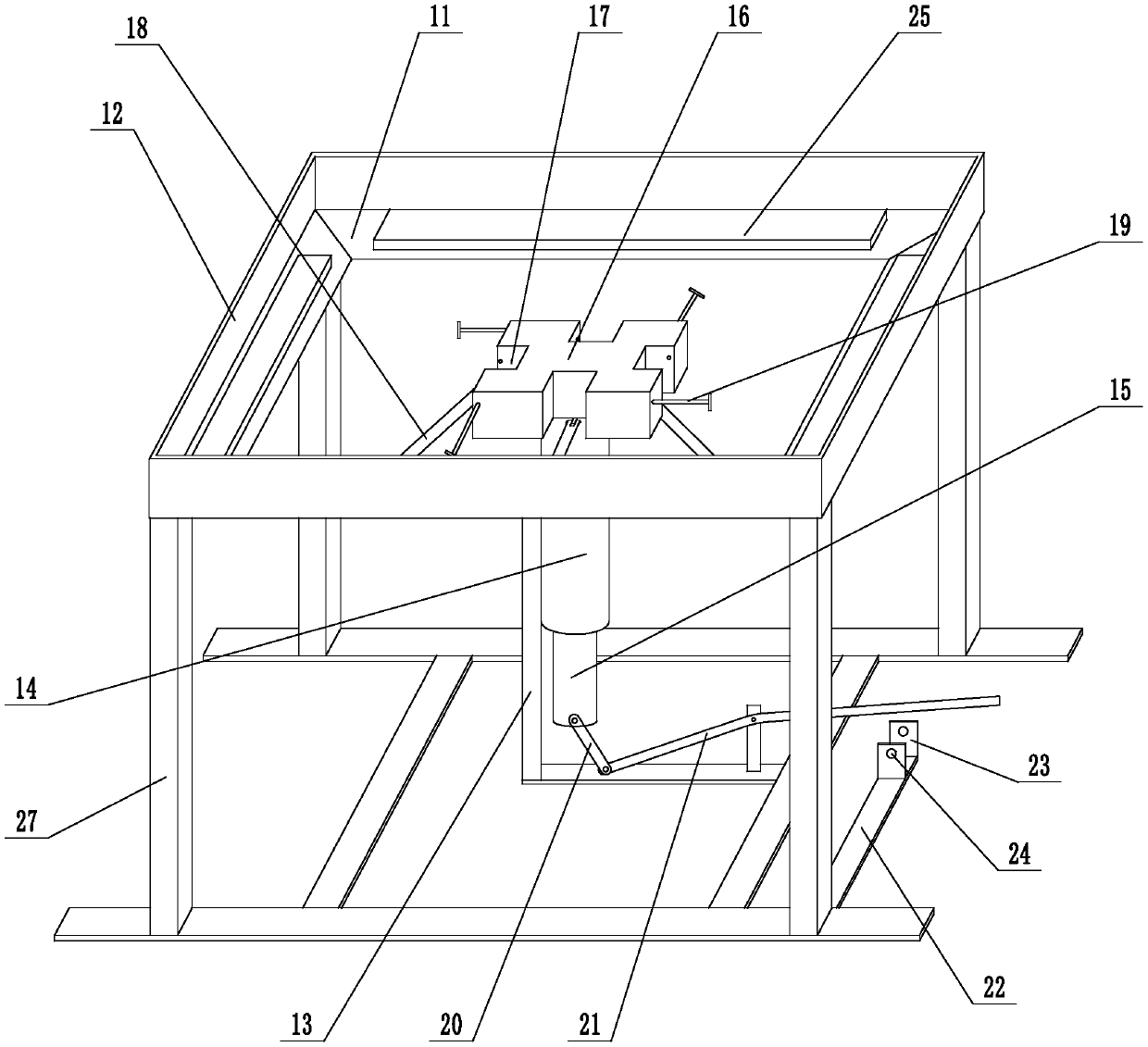

[0020] Embodiment: a kind of AGM acid absorption saturation test method (see attached figure 1 to attach Figure 4 ), including the following steps: a. Fully charge the battery and place it in an environment with a temperature of 25±3°C for more than 24 hours. During the process, test and record the open circuit voltage and internal resistance of the battery; b. Cut off the upper cover of the battery, Test and record the open circuit voltage and internal resistance of each single power supply; c. Drill a hole at the corresponding position of each single power supply at the bottom of the battery to form a collection hole at the bottom; d. Place the battery on the bracket 27 and weigh the acid collection The weight of the bottle is S2, and the acid collection bottle is placed under the bottom collection hole; e. Weigh the weight of the acid-containing dropping bottle and record M2; f. Add 5-10ml of acid to the AGM corresponding to each single power supply, and wait for 1-2 Minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com