Automatic automobile crankshaft grinding device

A crankshaft and automatic technology, which is applied in the direction of grinding automatic control device, grinding machine, grinding workpiece support, etc., can solve the problems of high labor intensity, low grinding quality, uneven grinding, etc. The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

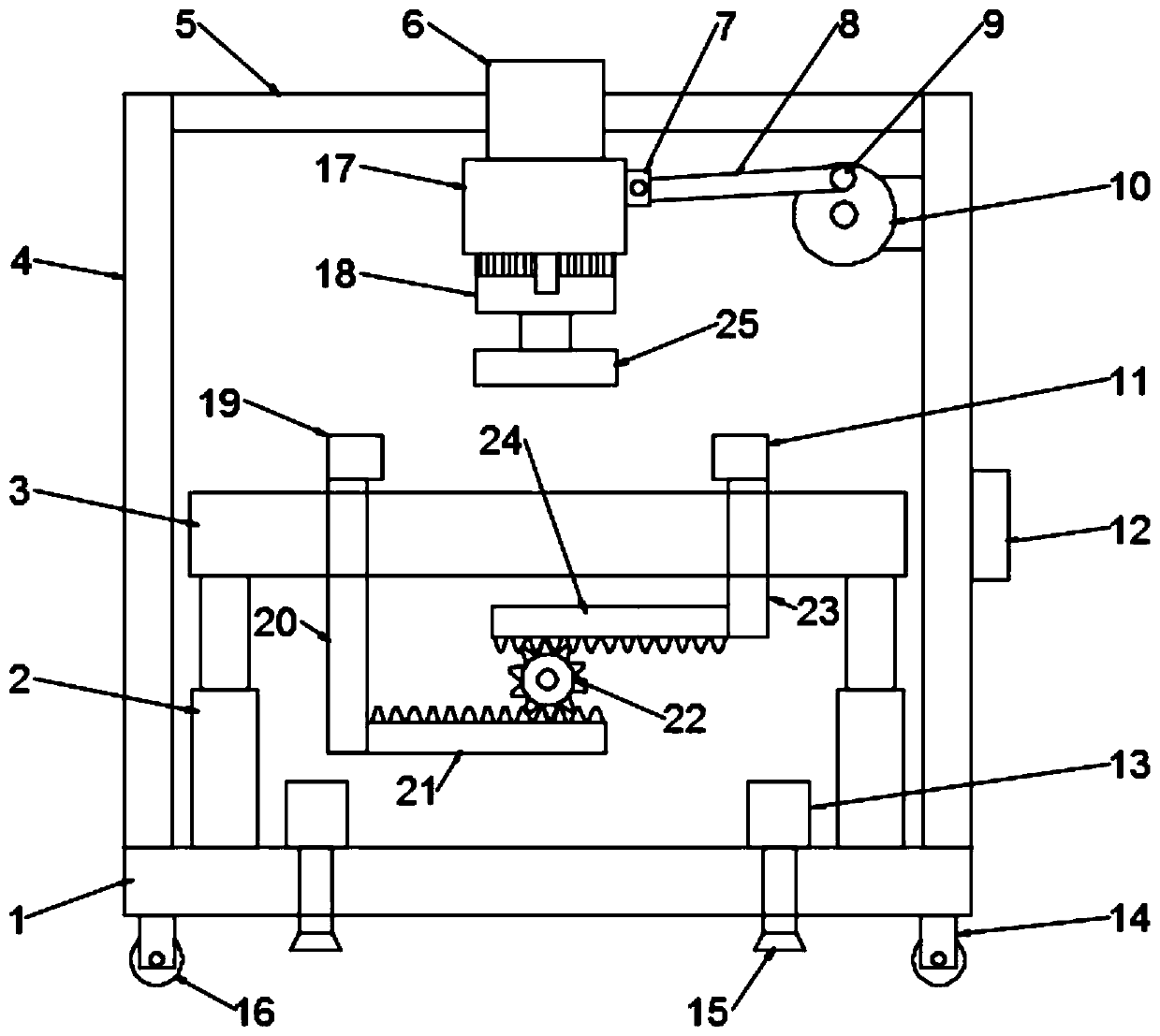

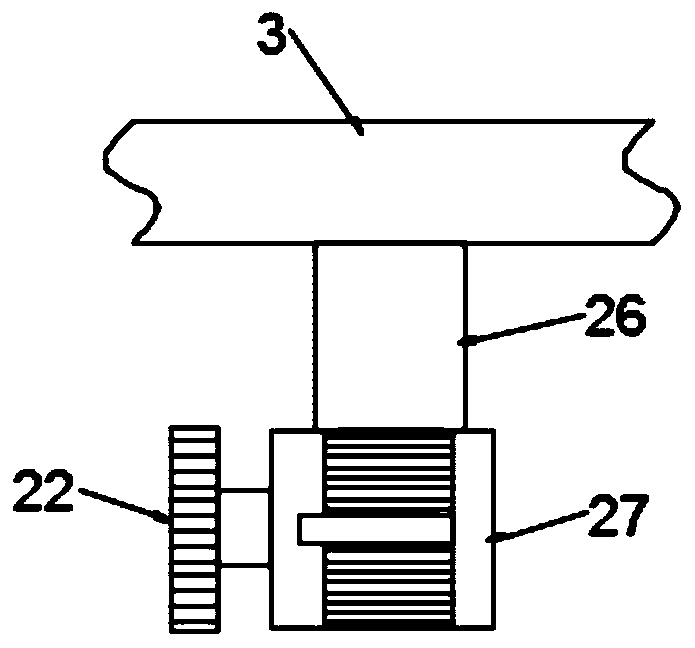

[0020] see Figure 1-2 , in the embodiment of the present invention, a kind of automobile crankshaft automatic polishing device comprises base plate 1, and the left and right sides of the upper end surface of base plate 1 are all connected with side support plate 4, and side support plate 4 is two left and right symmetrically arranged, and base plate 1 A workbench 3 is provided above; a hydraulic telescopic rod 2 is connected between the base plate 1 and the workbench 3, and the hydraulic telescopic rods 2 are two left and right symmetrically arranged, and a controller 12 is installed on the side of the side support plate 4, and the hydraulic pressure The telescopic rod 2 is electrically connected with the controller 12. The controller 12 can control the expansion and contraction of the hydraulic telescopic rod 2. The expansion and contraction of the hydraulic telescopic rod 2 drives the workbench 3 to lift. The top of the workbench 3 is provided with a grinding motor 18. The ...

Embodiment 2

[0028] see figure 1 , in the embodiment of the present invention, an automobile crankshaft automatic grinding device is different from embodiment 1 in that a second support 14 is installed on the bottom of the base plate 1, and a roller 16 is installed on the second support 14, and the roller 16 is 16 can move this automobile crankshaft automatic grinding device conveniently, also be equipped with hydraulic cylinder 13 on the base plate 1, the output end of hydraulic cylinder 13 is connected with support foot 15, and hydraulic cylinder 13 is electrically connected with controller 12, can control by controller 12 The hydraulic cylinder 13 drives the supporting foot 15 to move up and down. After the movement of the automatic crankshaft grinding device of the automobile is completed, the hydraulic cylinder 13 is used to drive the supporting foot 15 to descend, so that the roller 16 is separated from the ground, and the supporting foot 15 touches the ground and supports the automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com