Patents

Literature

65results about How to "Close to each other" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

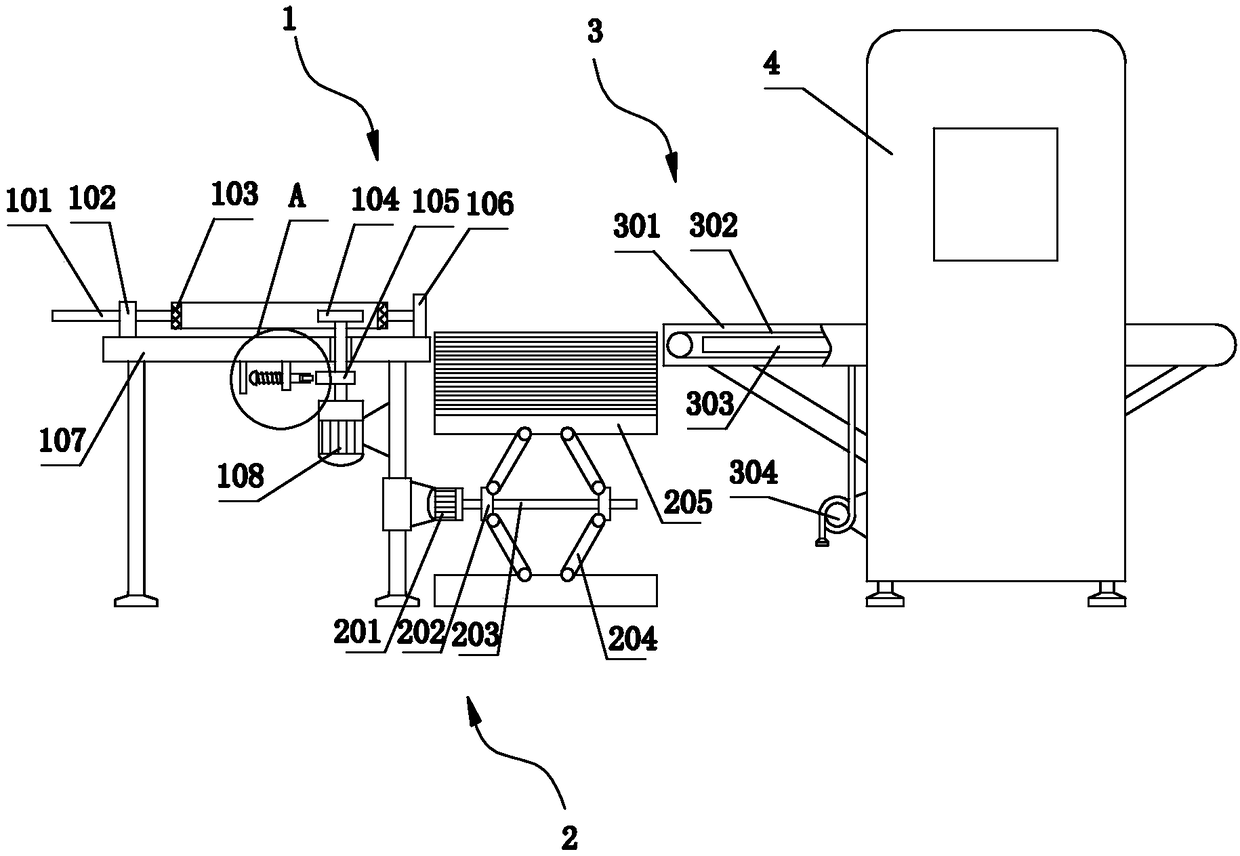

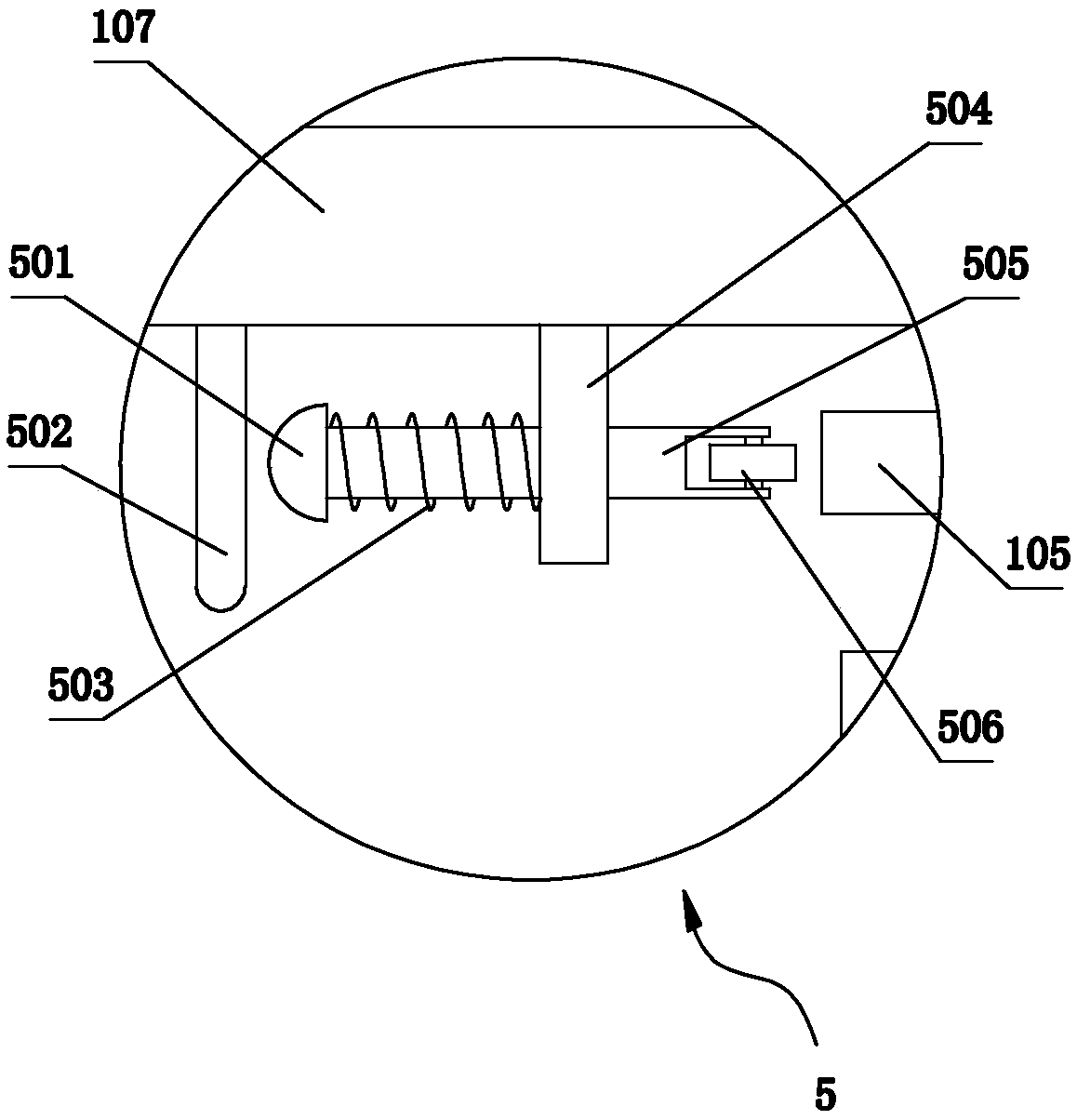

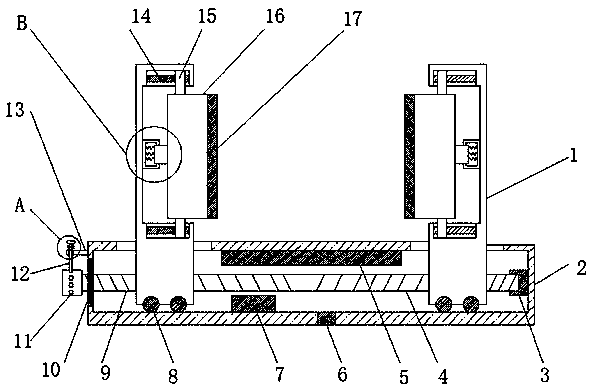

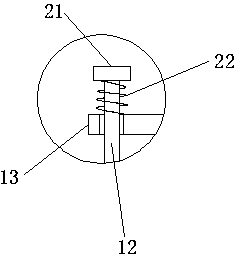

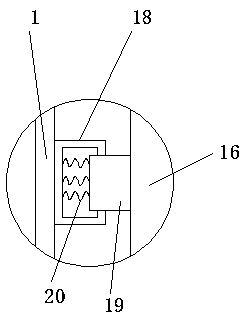

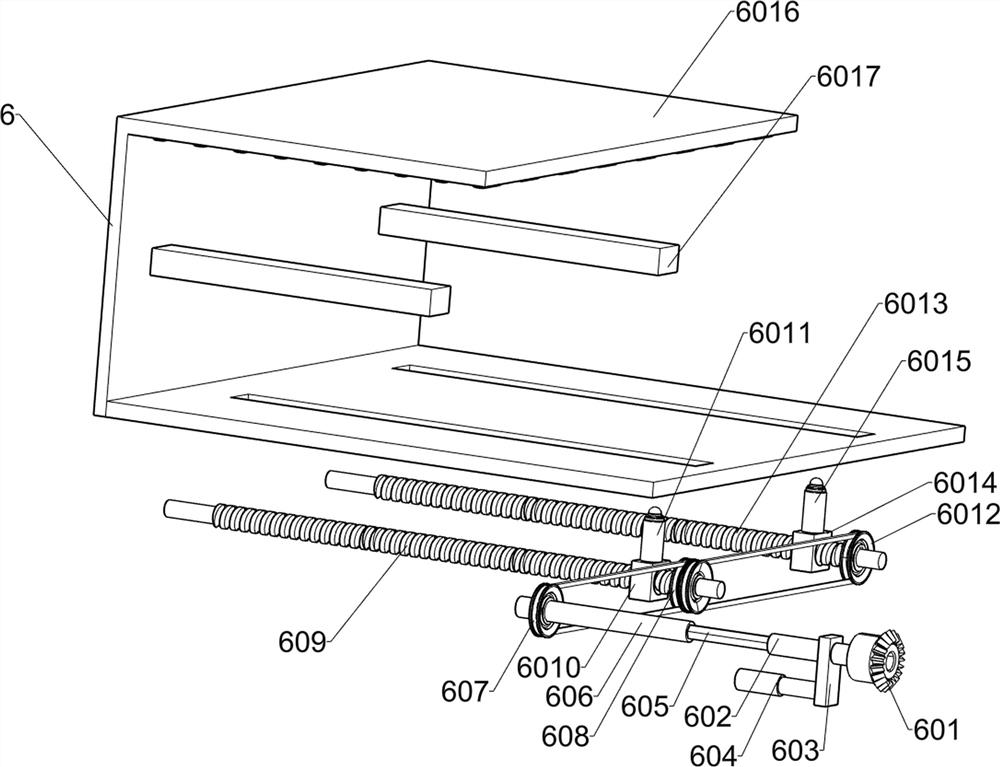

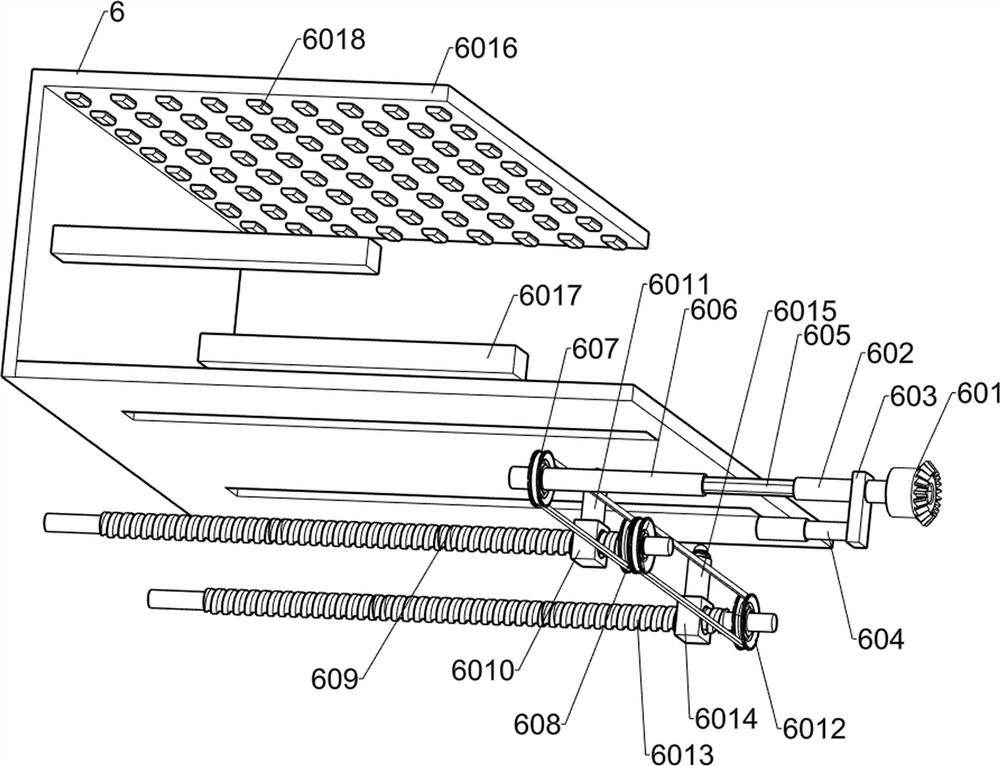

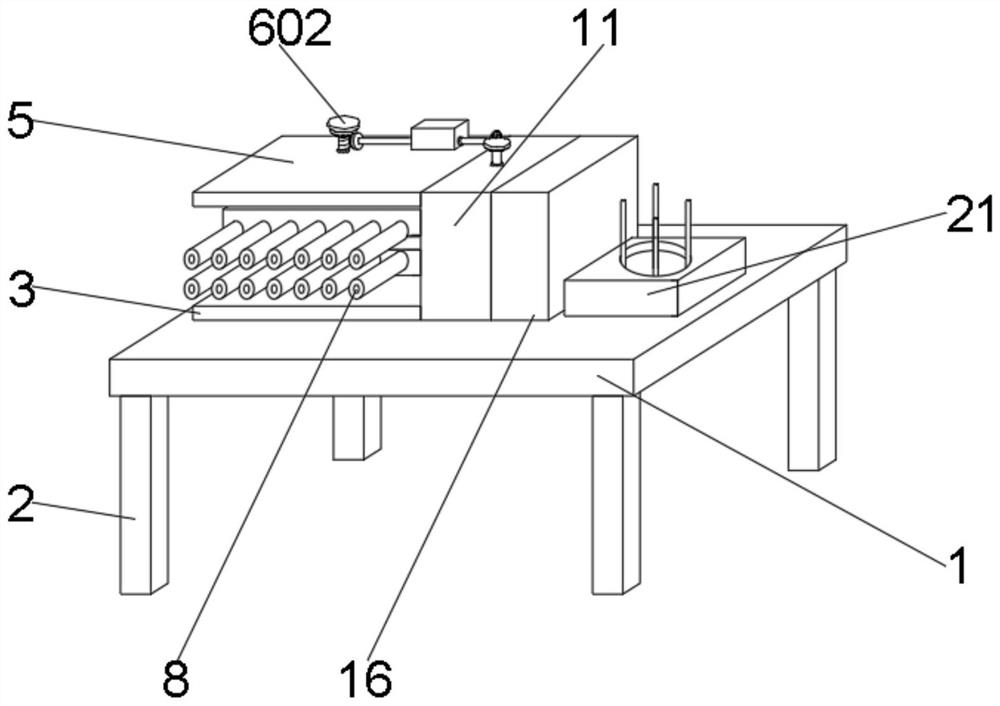

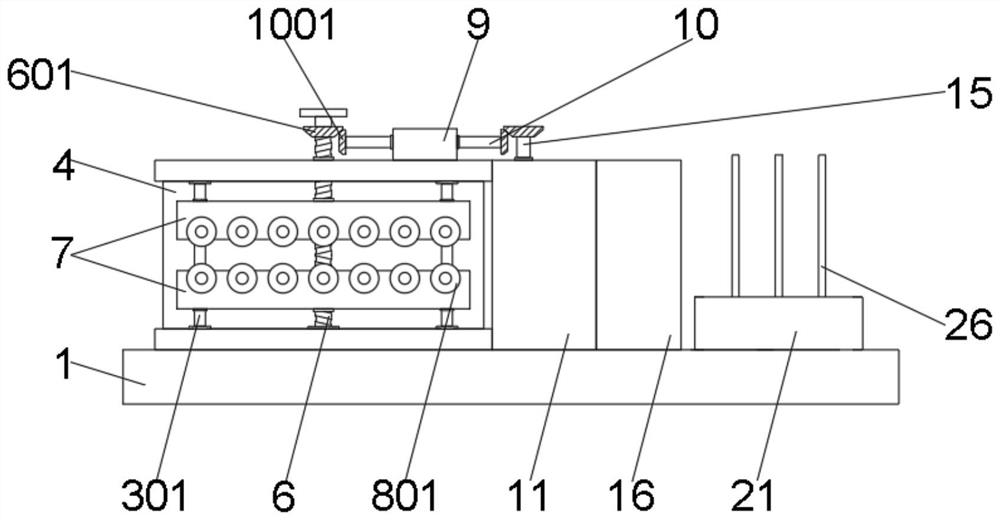

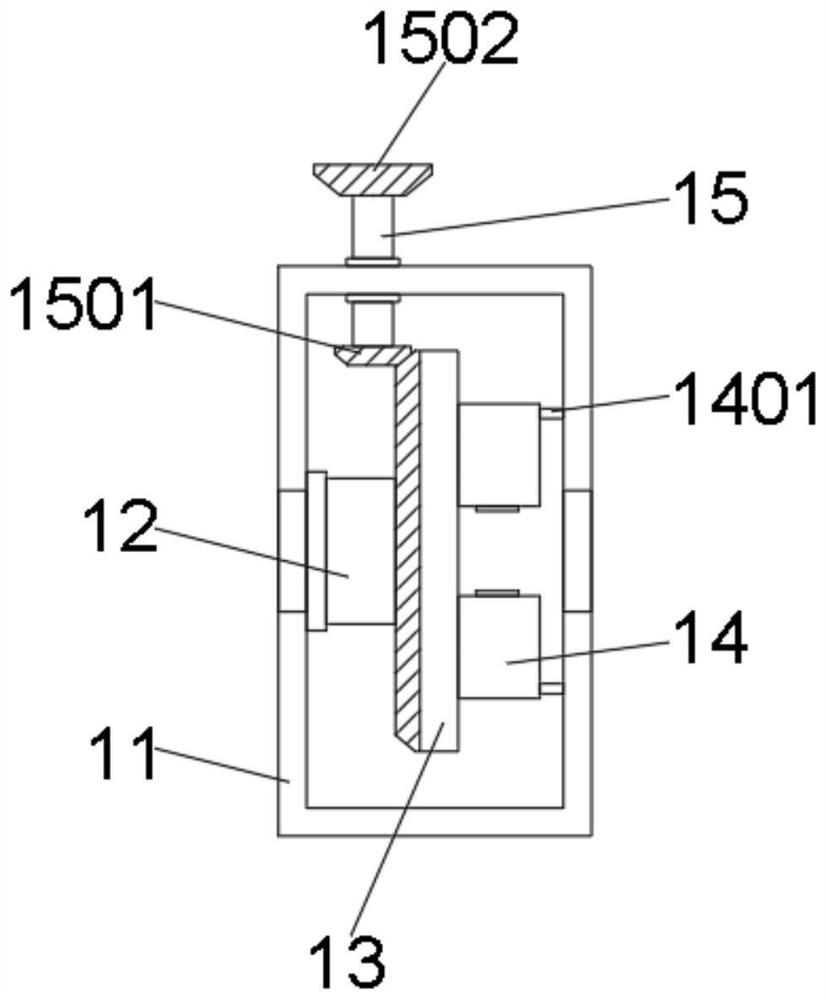

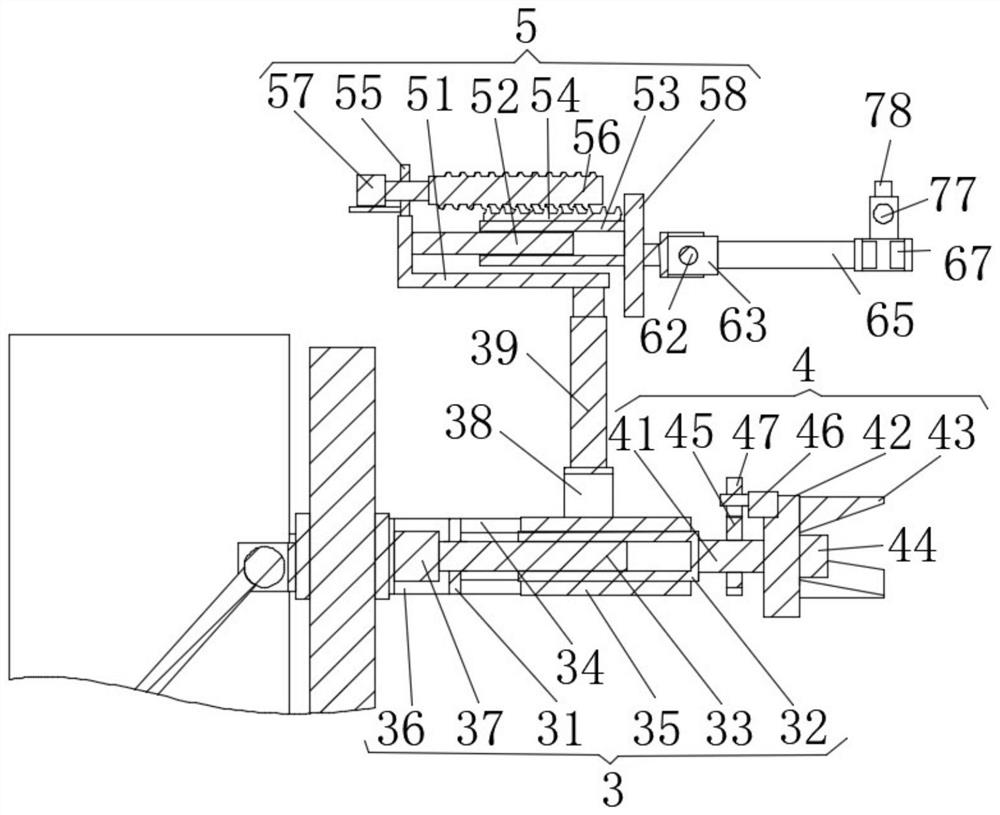

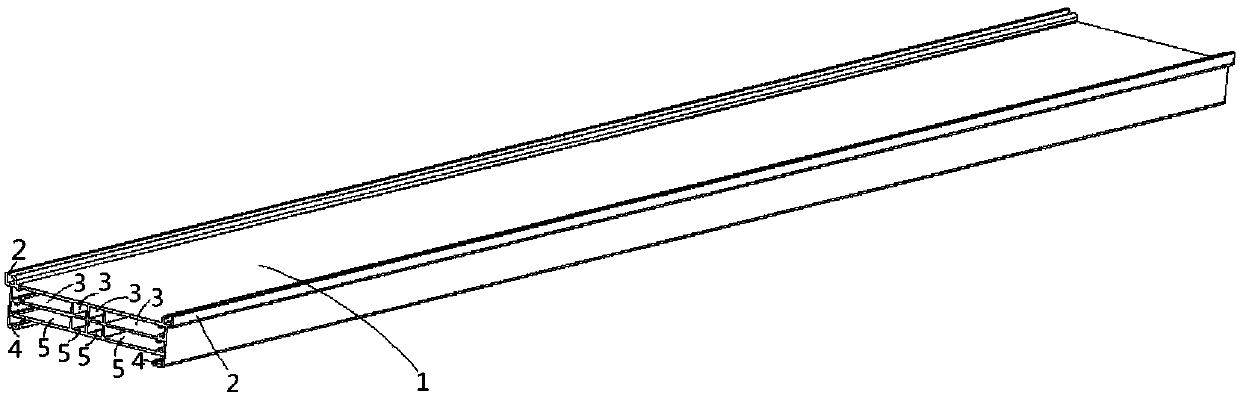

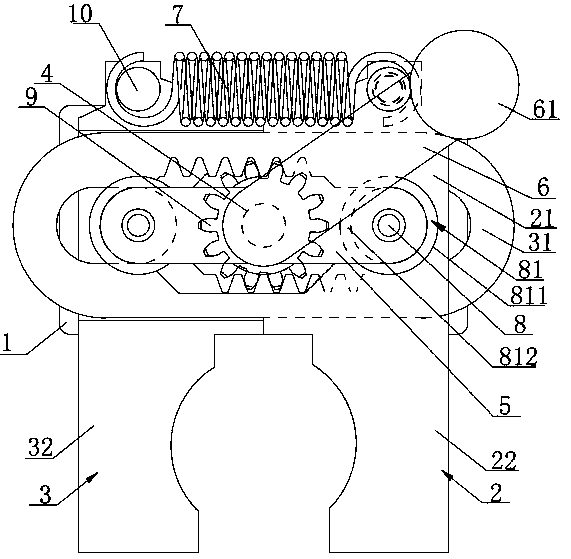

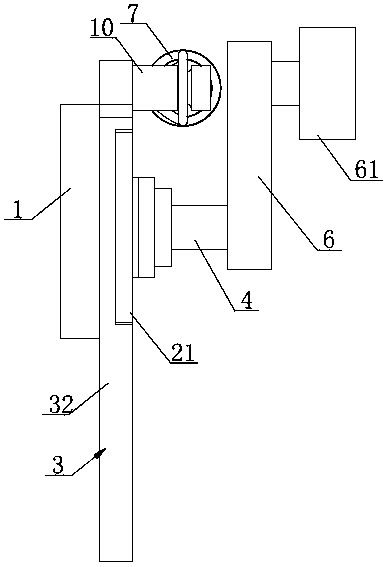

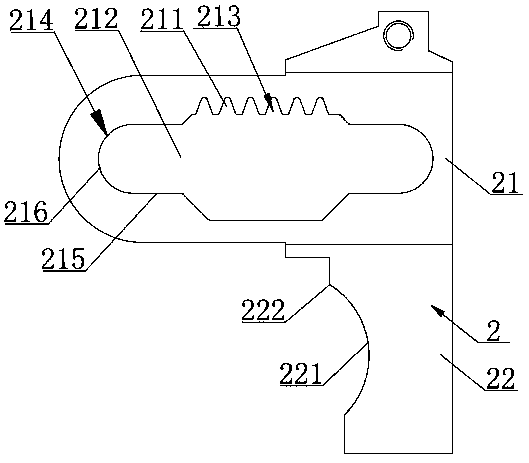

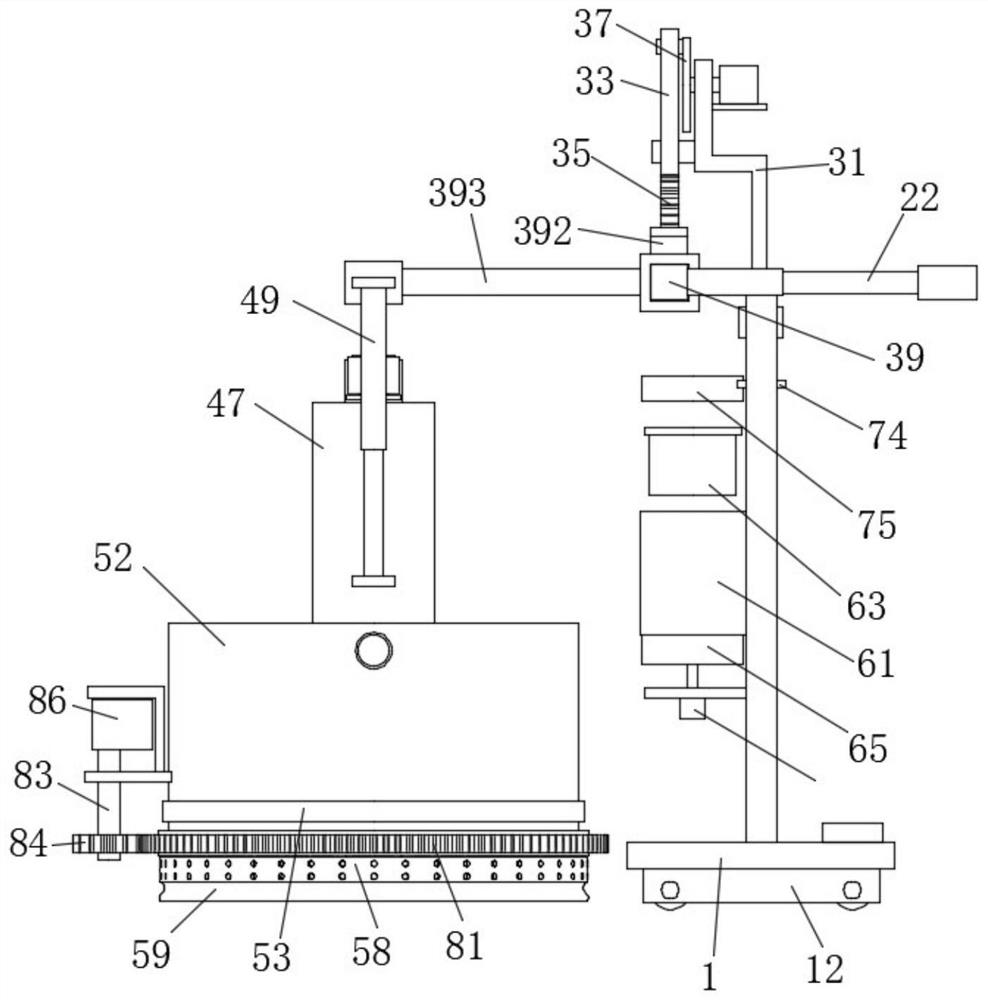

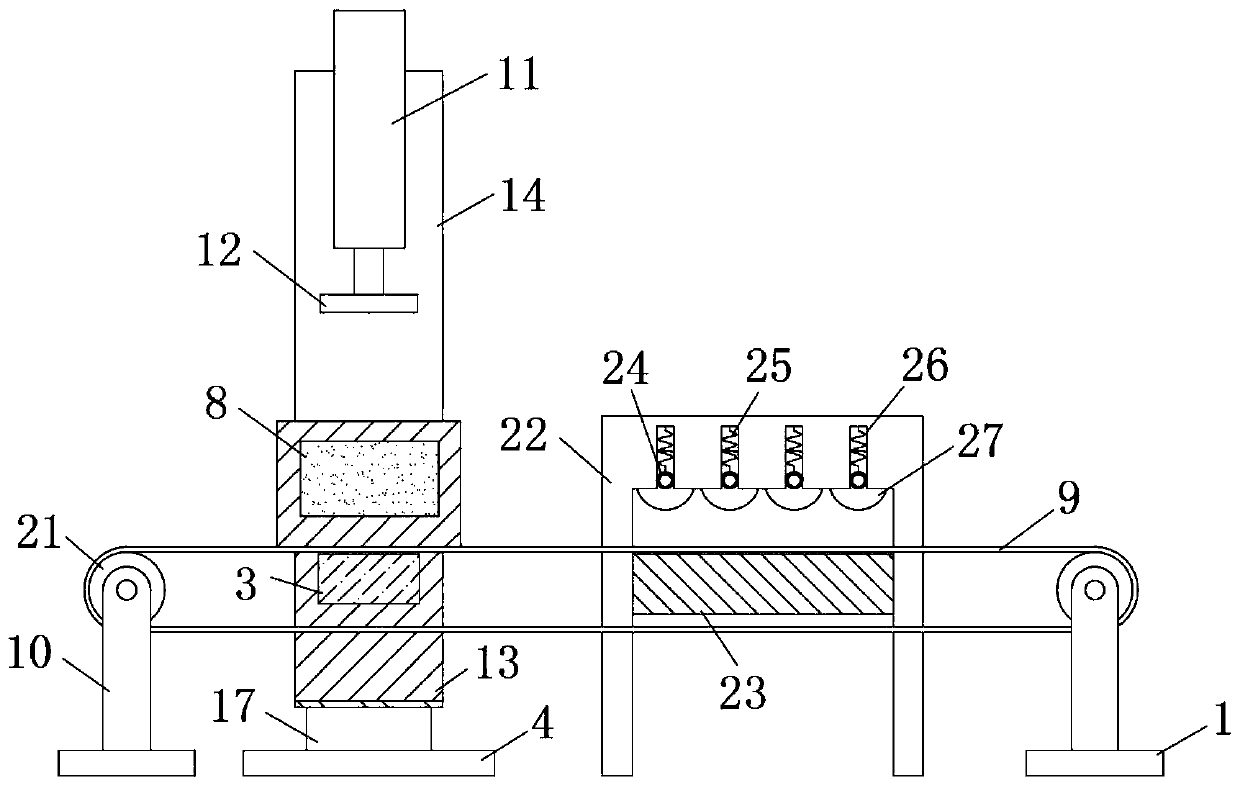

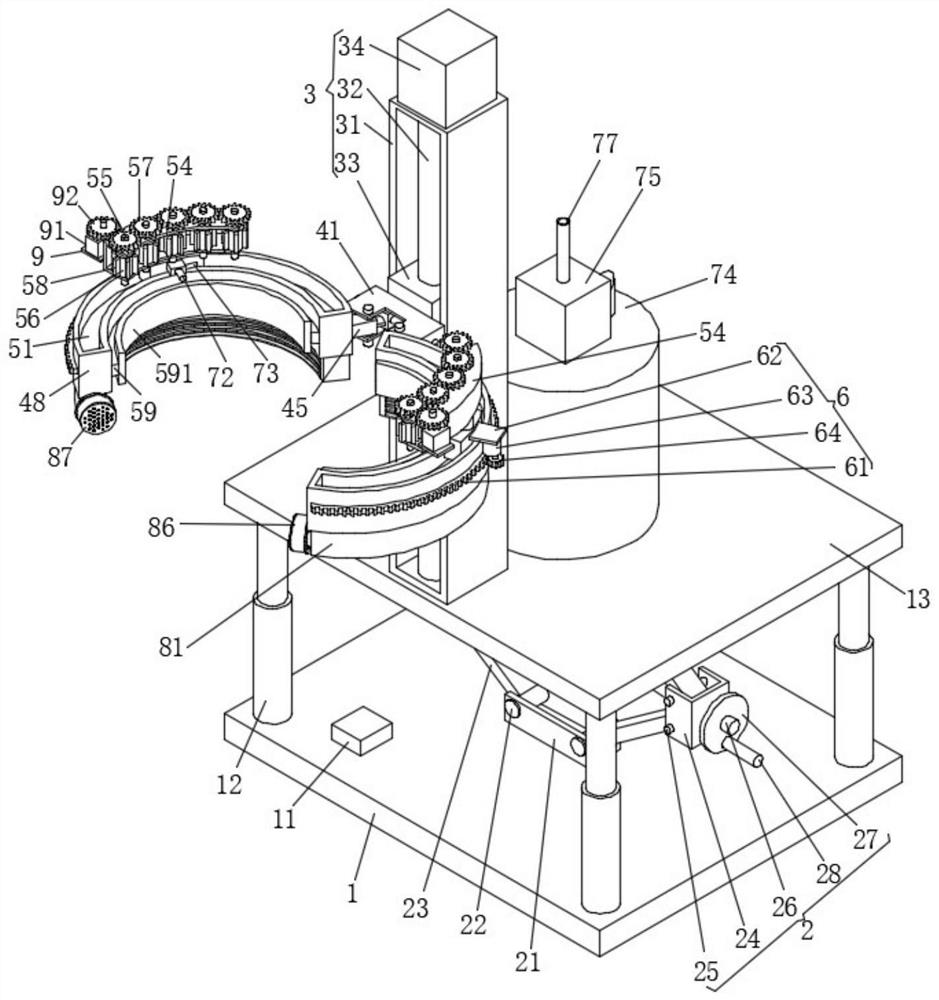

Automatic feeding equipment for corrugated paper box processing printing

InactiveCN108946233AEasy to printClose to each otherArticle feedersArticle separationCardboardMotor drive

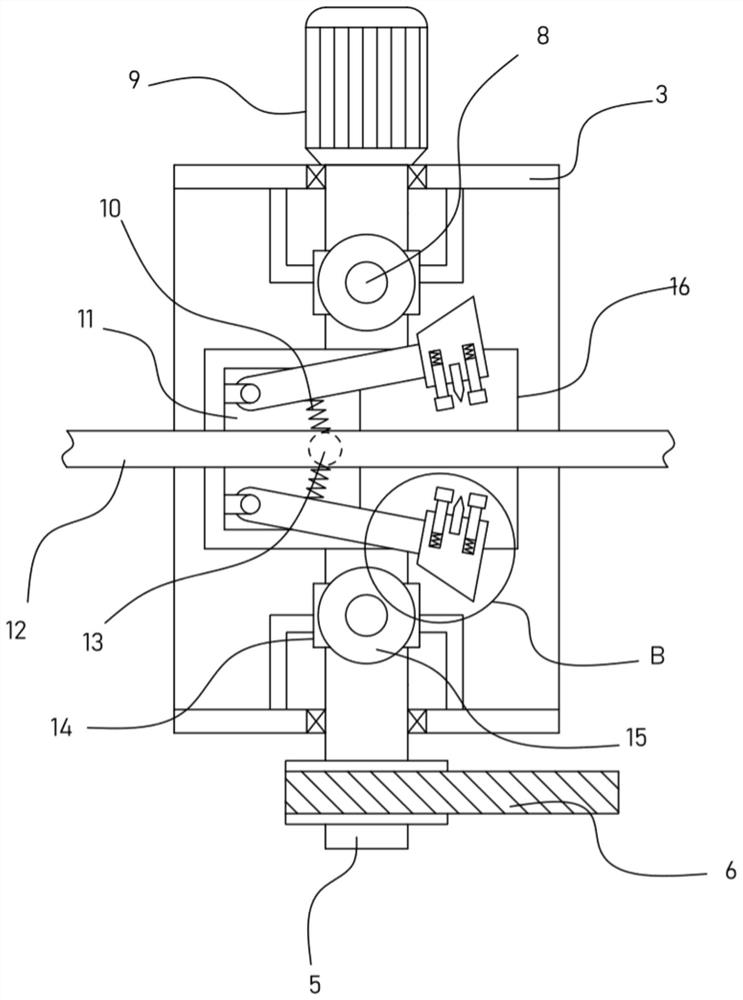

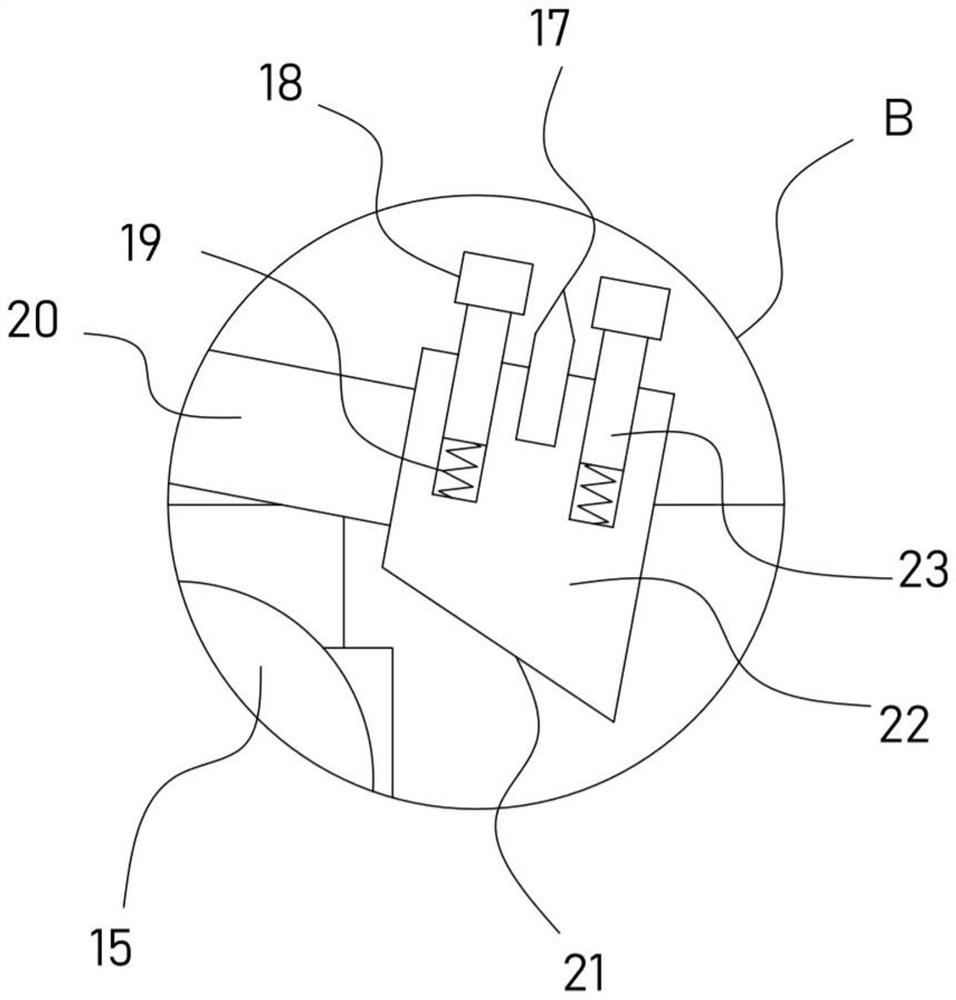

The invention discloses automatic feeding equipment for corrugated paper box processing printing. The automatic feeding equipment comprises a printing machine body. The paper board to be printed is stacked on the bearing plate, the first motor drives the default gear and the cam to rotate correspondingly, the default gear is meshed with the annular gear ring, the annular gear ring is driven to move in a reciprocating mode, the annular gear ring drives the push plate to move in a reciprocating mode, paper boards on the uppermost layer of the paper board pile are pushed into the conveying belt,and is conveyed into the printing machine body through the conveying belt for printing; in the process, the exhaust fan sucks air, the paper board is adsorbed on the conveying belt to be leveled through the hollow plate, and the paper board is more convenient to print; the cam rotates, under the action of the spring, the sliding rod drives the first conducting piece to be in intermittent contact with the second conducting piece, the circuit is connected, and each time is connected with the circuit, the second motor rotates by a certain circle number, and the two sliding blocks are close to each other. Due to the fact that two sections of opposite threads exist, the supporting plate is driven to rise to a certain height through the supporting effect of the supporting rod, so that the pushing plate can be conveniently pushed into the paper board again.

Owner:福建泉州群发包装纸品有限公司

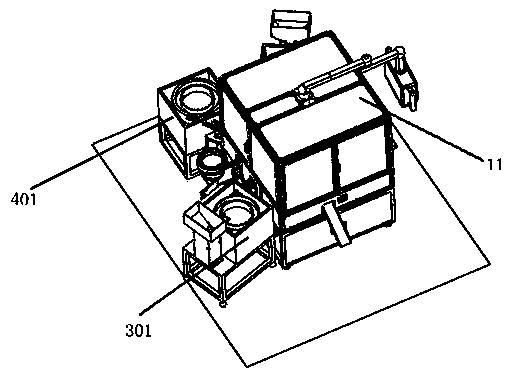

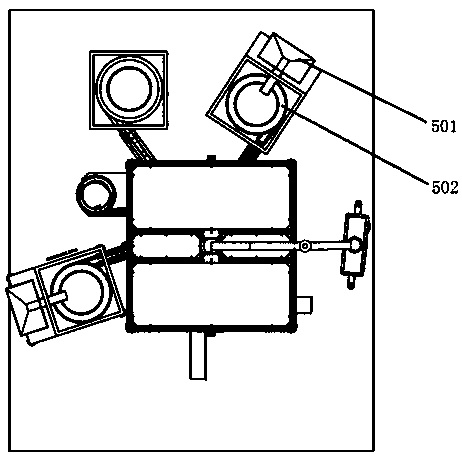

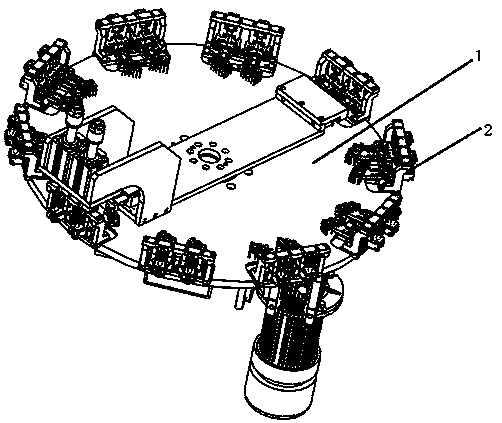

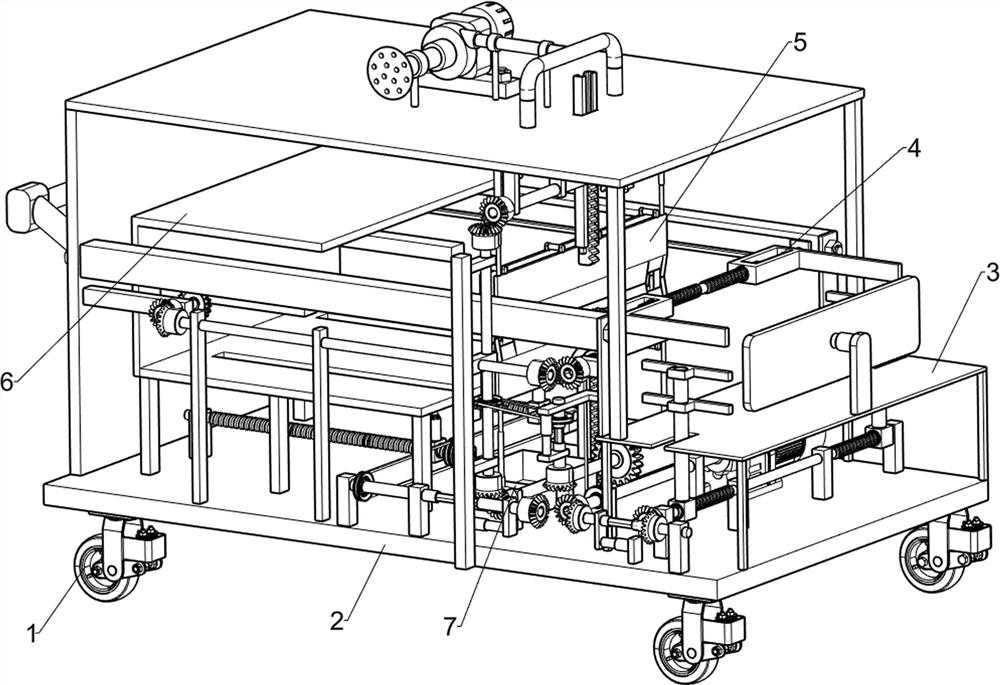

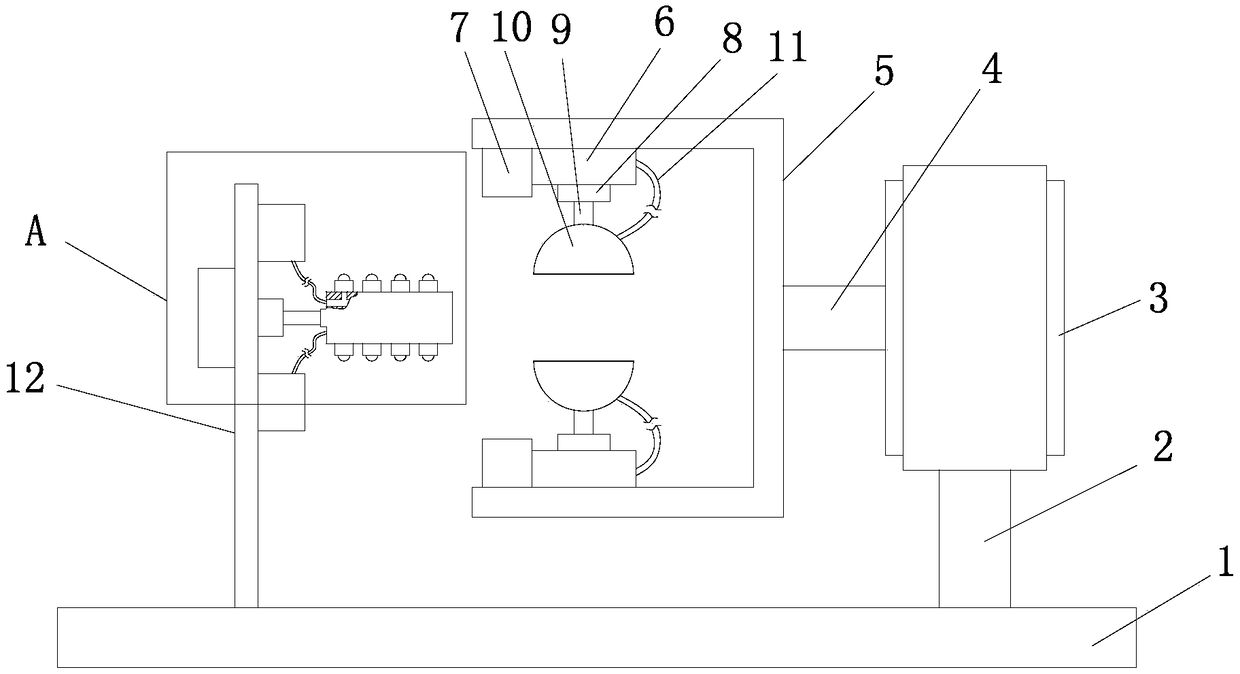

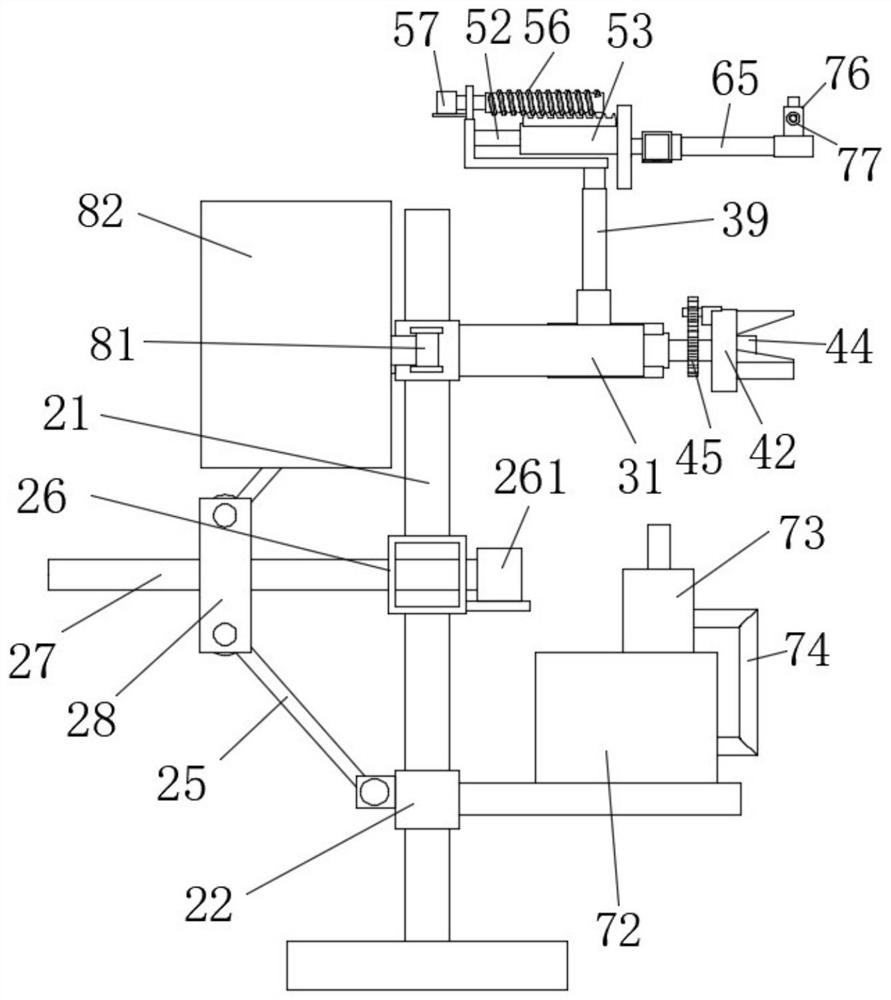

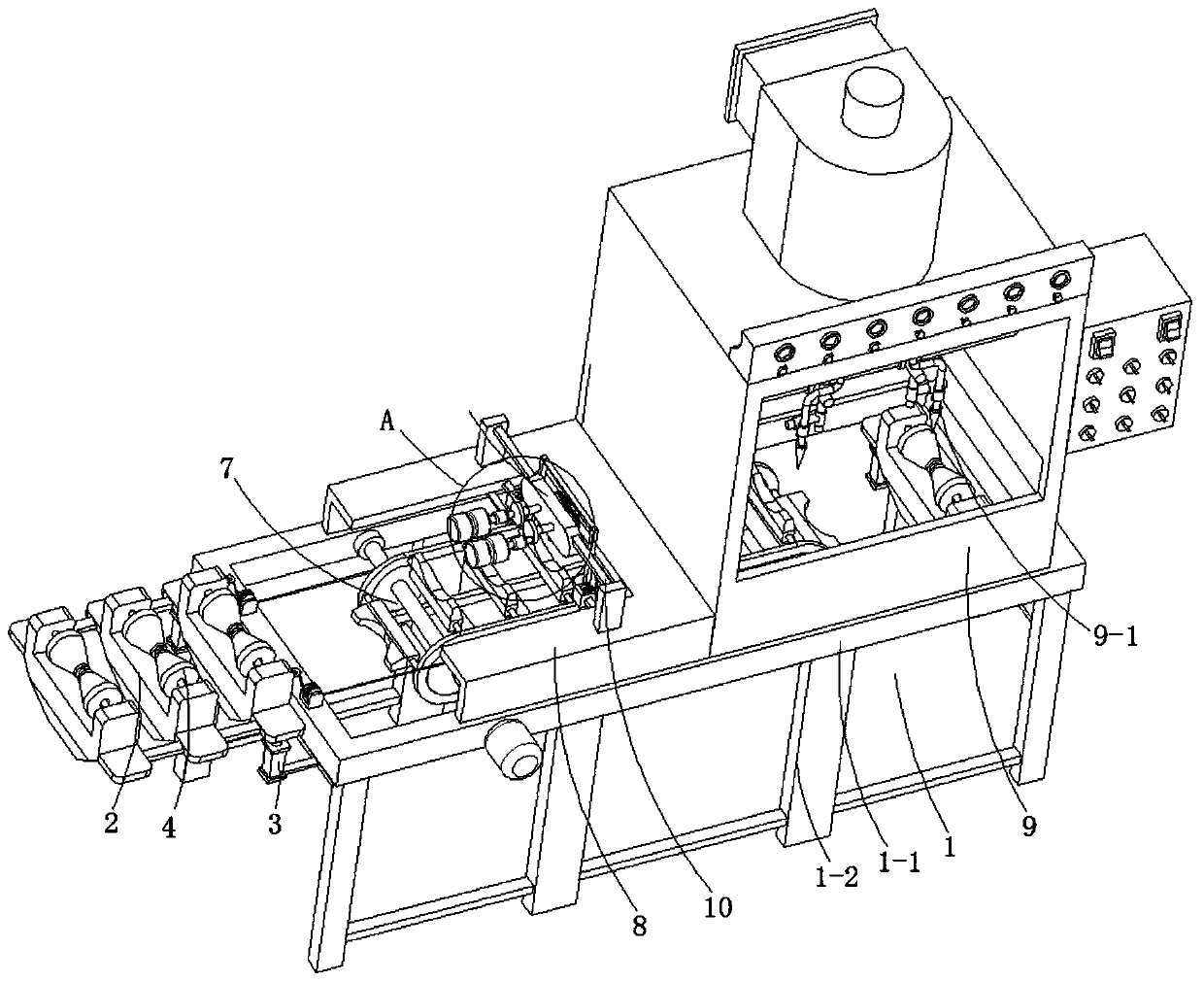

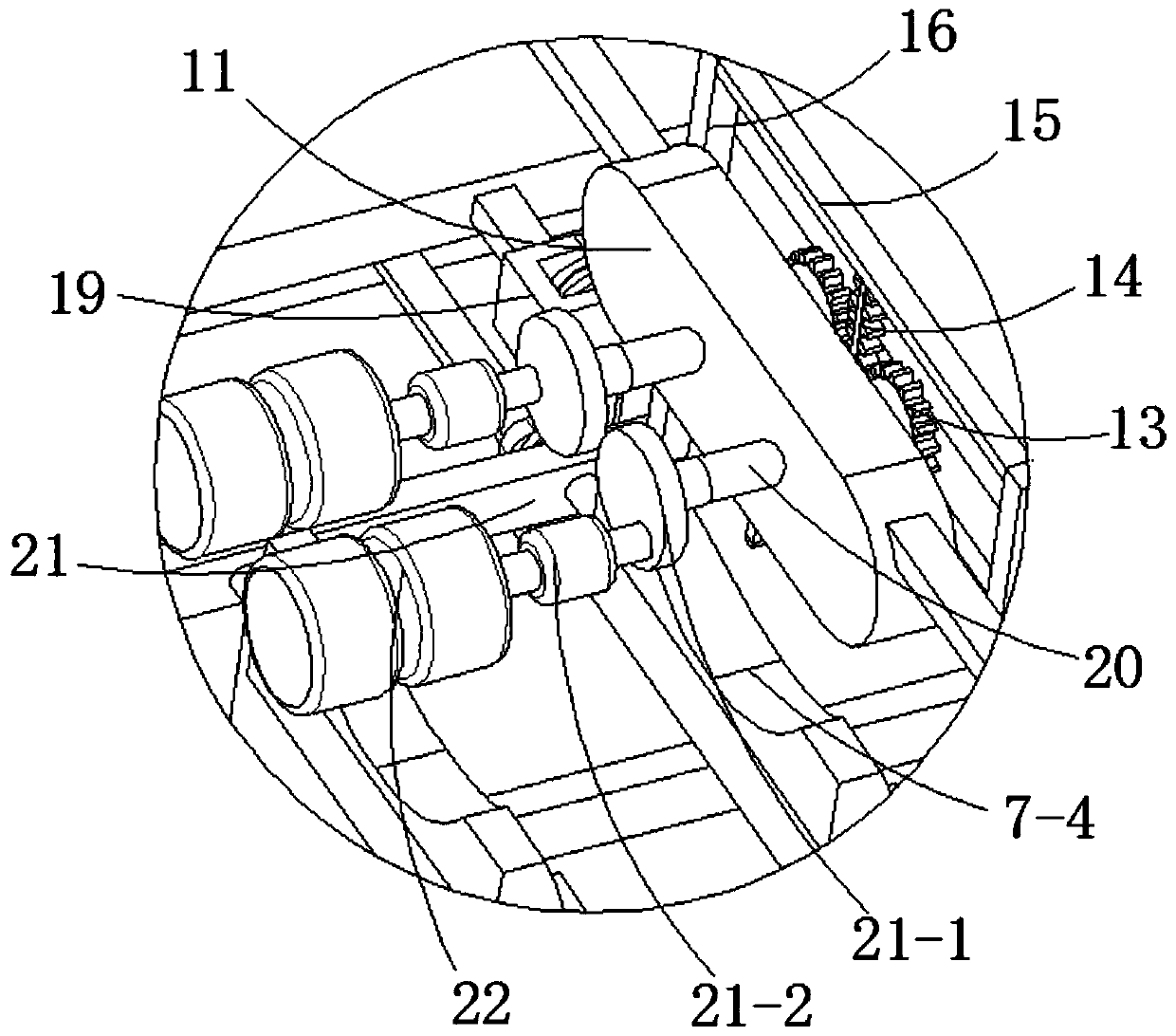

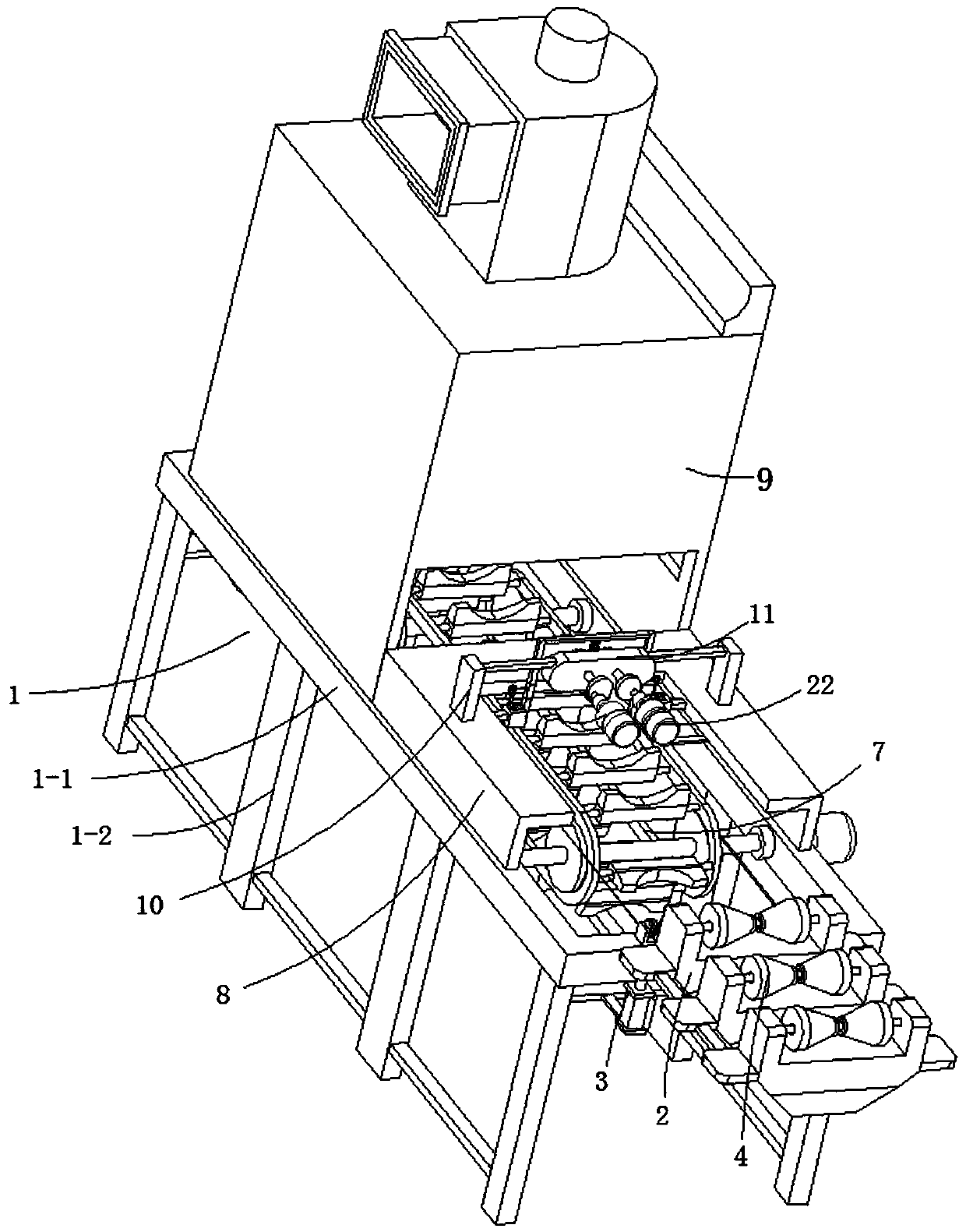

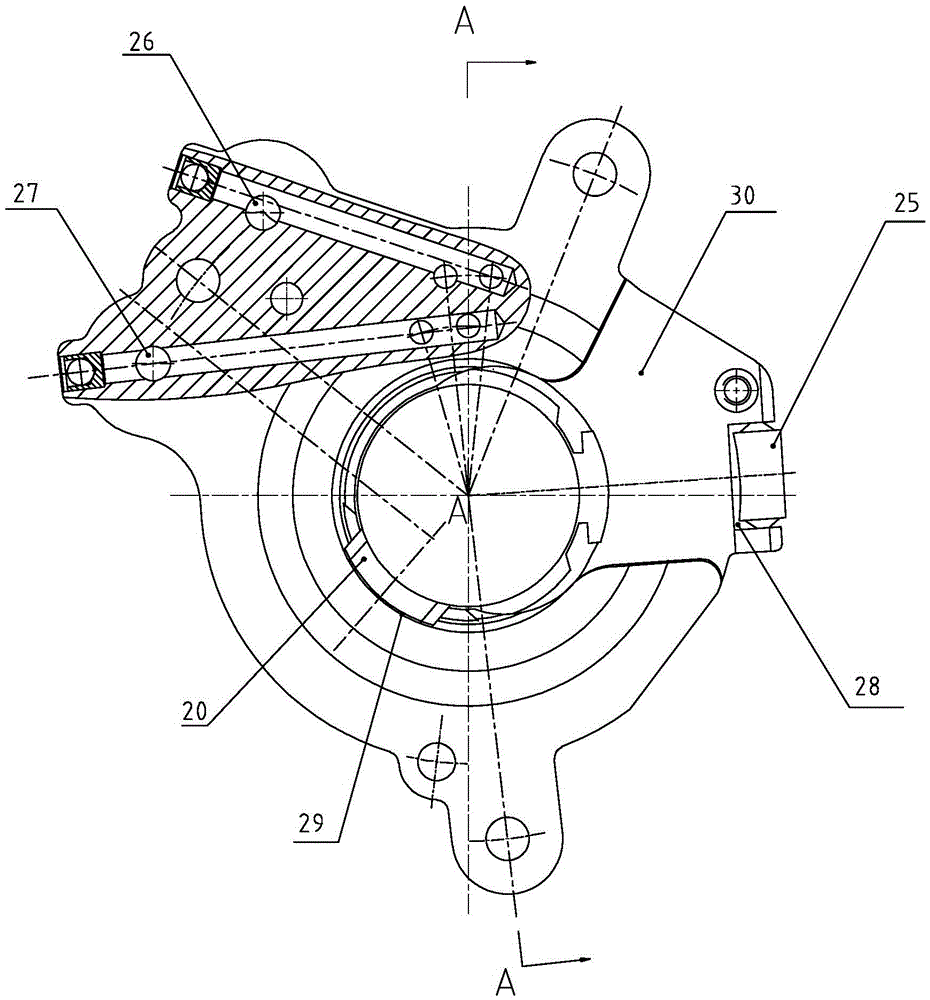

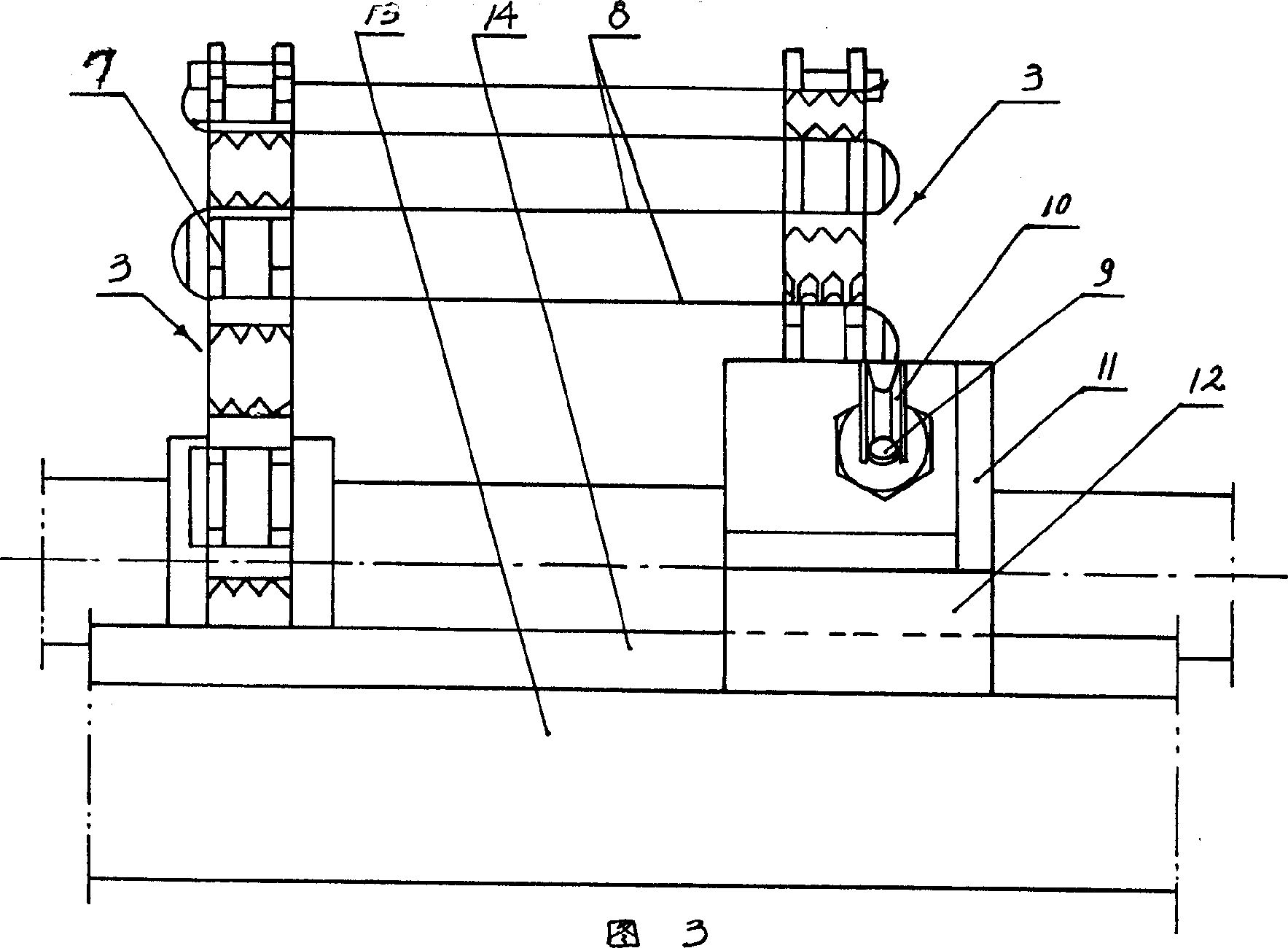

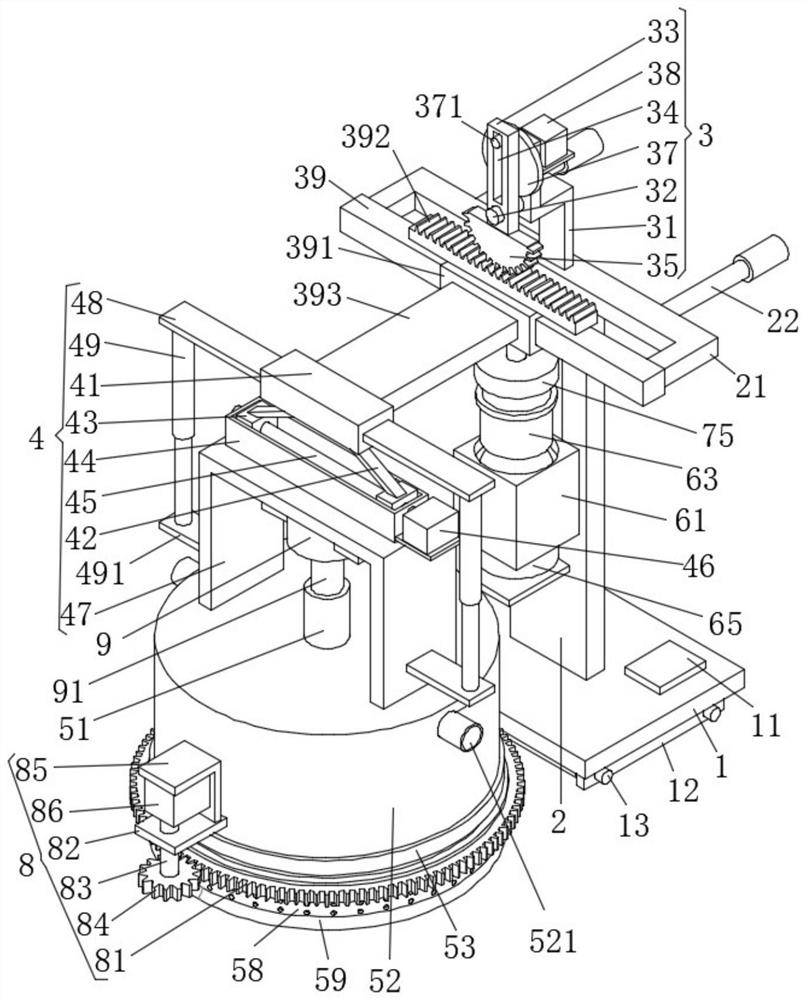

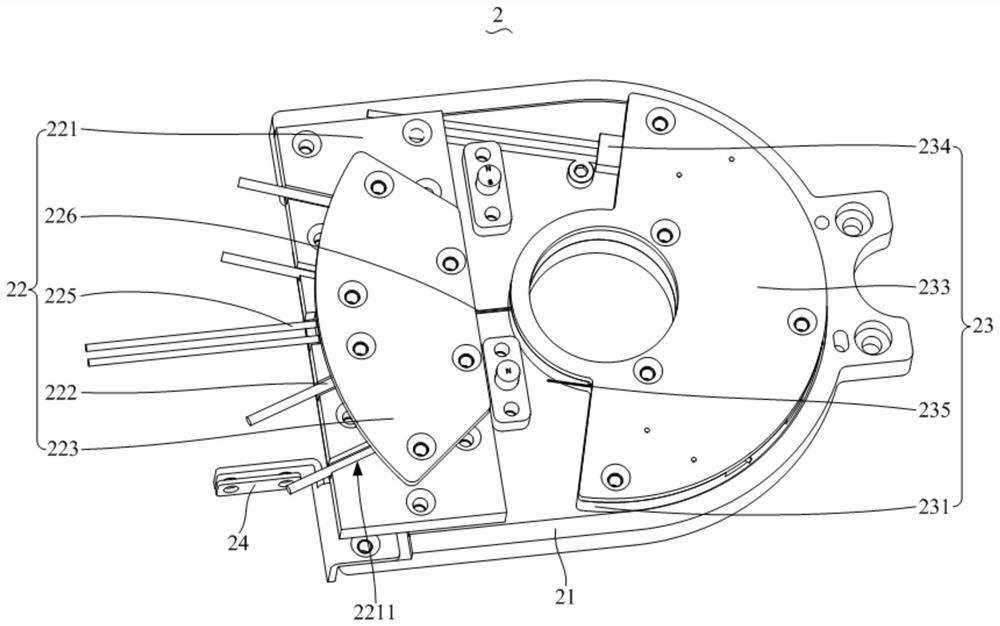

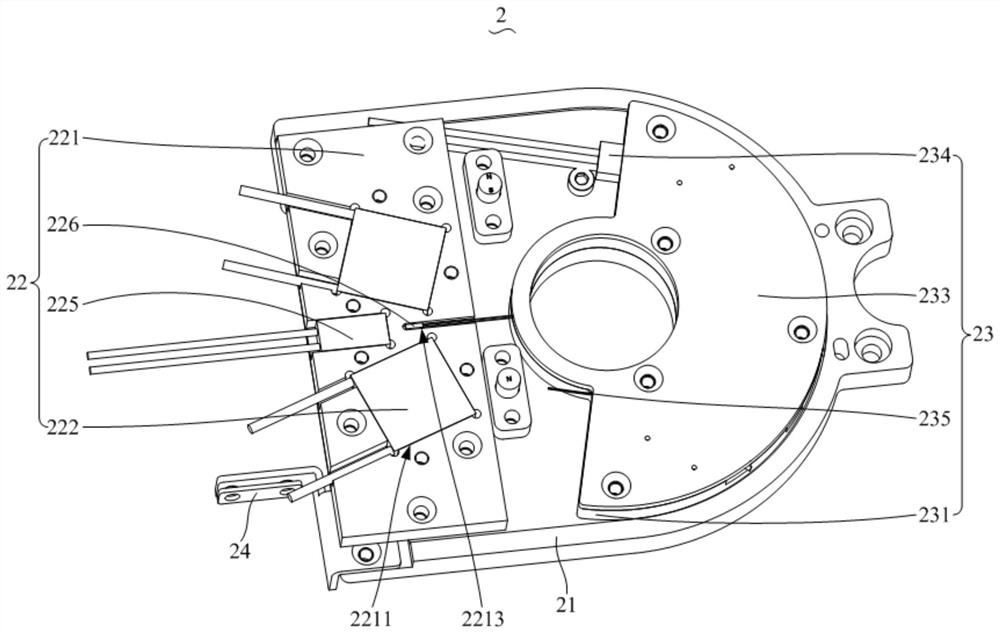

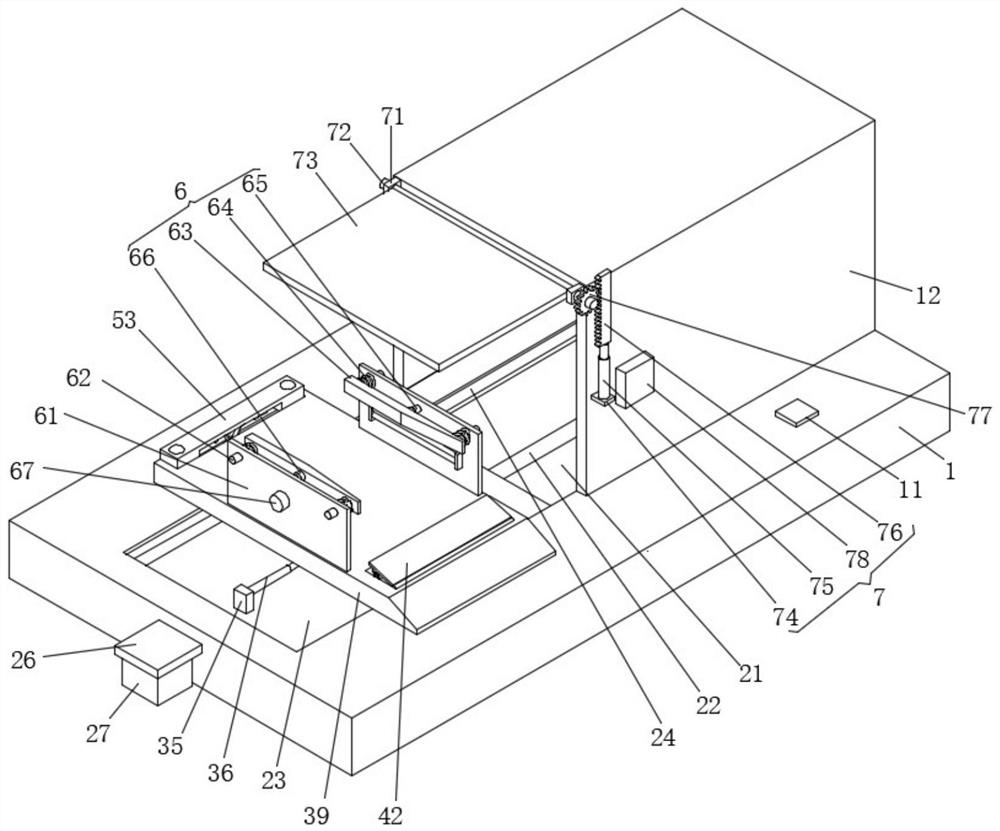

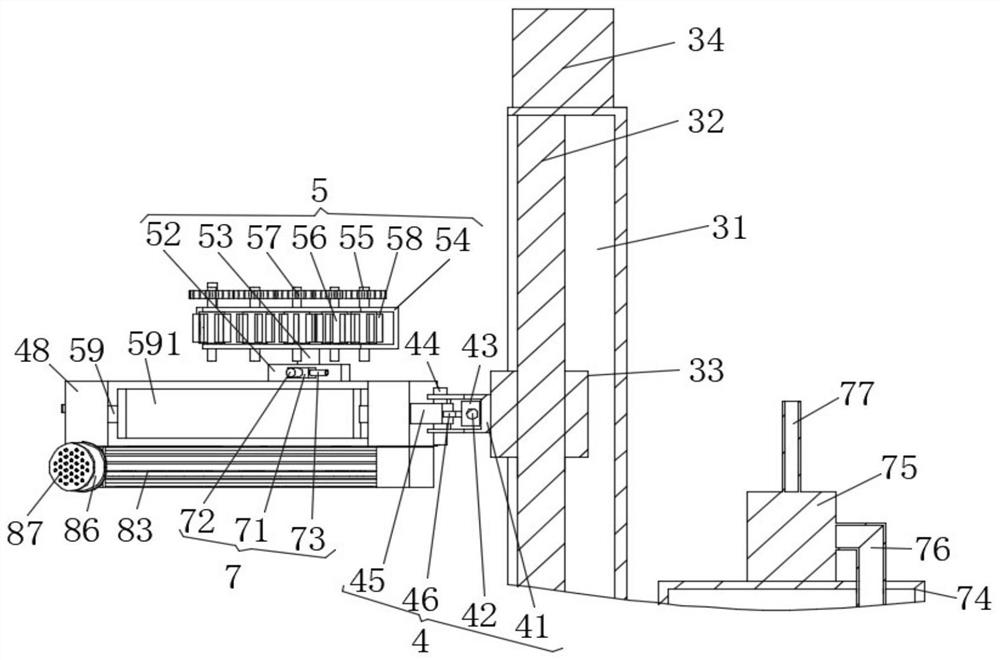

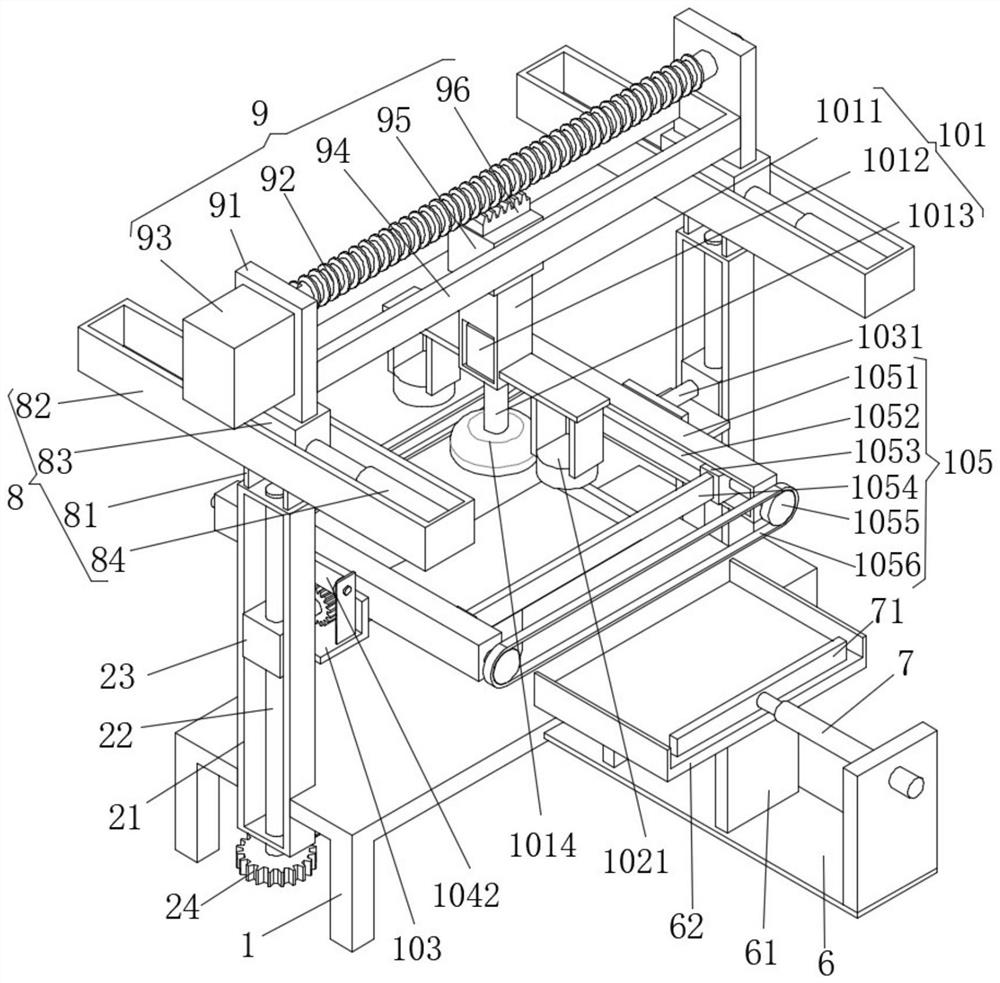

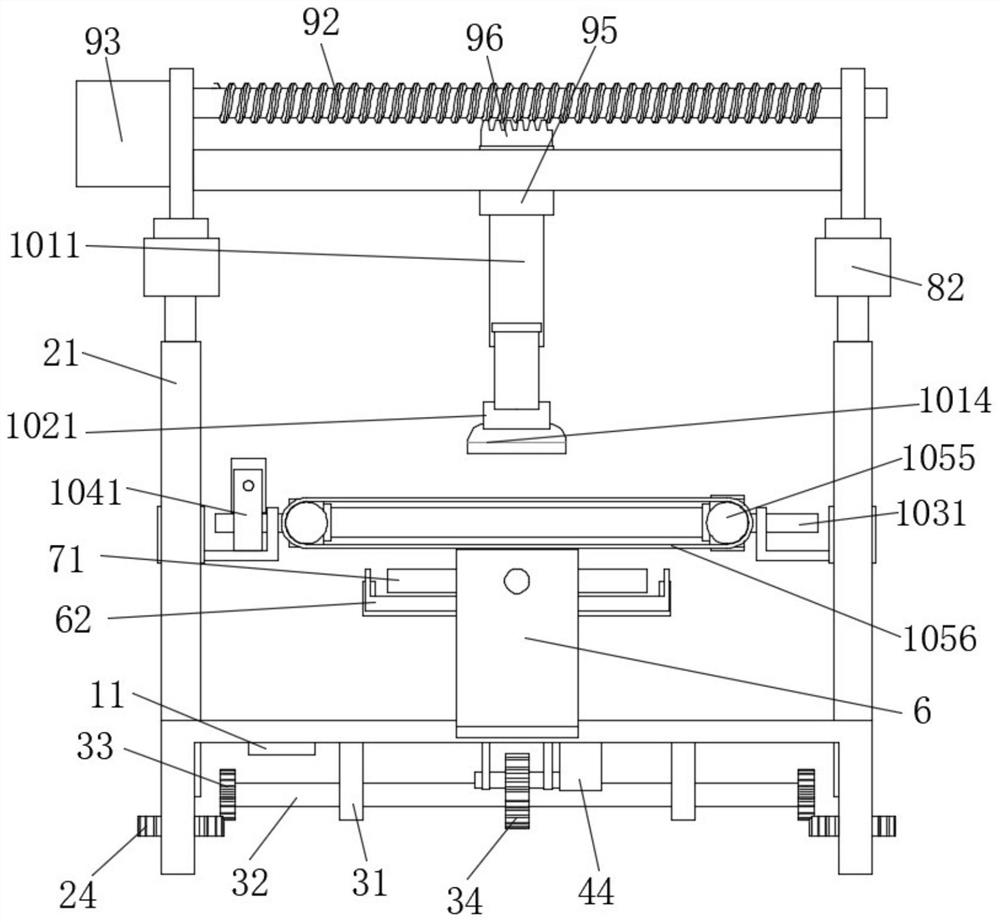

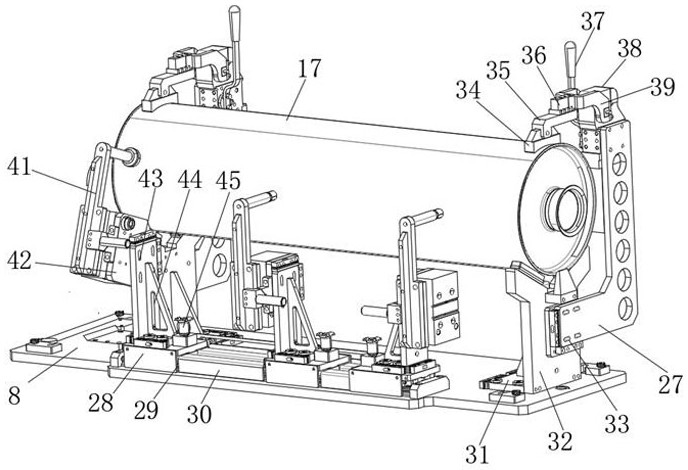

C-shaped clamp automatic assembling system

PendingCN109366118AImplement automatic assemblyReduce manual laborAssembly machinesMetal working apparatusBolt connectionC shaped

The invention relates to a C-shaped clamp automatic assembling system. The C-shaped clamp automatic assembling system comprises an assembling platform, wherein the assembling platform is disc-shaped,the assembling platform is driven by a rotary driving mechanism to rotate, a plurality of assembling seats are distributed on the assembling platform in parallel along the circumference direction of the assembling platform, a nut placement process, a gasket placement process, a C-shaped clamping frame placement process, a primary detection process, a bolt connection process, a secondary detectionprocess, a mesh pad placement process and a riveting pressure process are sequentially arranged on the outer side of the circumference of the assembling platform. The C-shaped clamp automatic assembling system has the advantages that the plurality of assembling seats, the nut placement process, the gasket placement process, the C-shaped clamp frame placement process, the primary detection process,the bolt connection process, the secondary detection process, the mesh pad placement process and the riveting and pressing process are coordinated, so that the automatic assembly of the C-shaped clamp is realized, the manual labor is reduced, and the working efficiency is improved.

Owner:江苏中伟业通讯设备有限公司

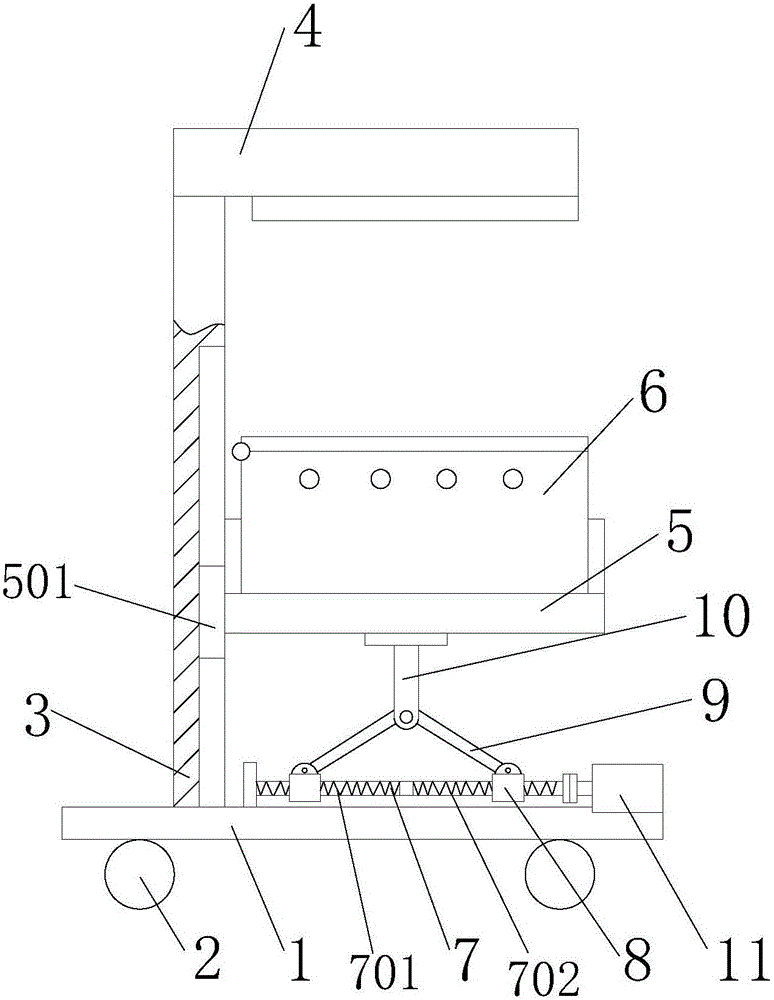

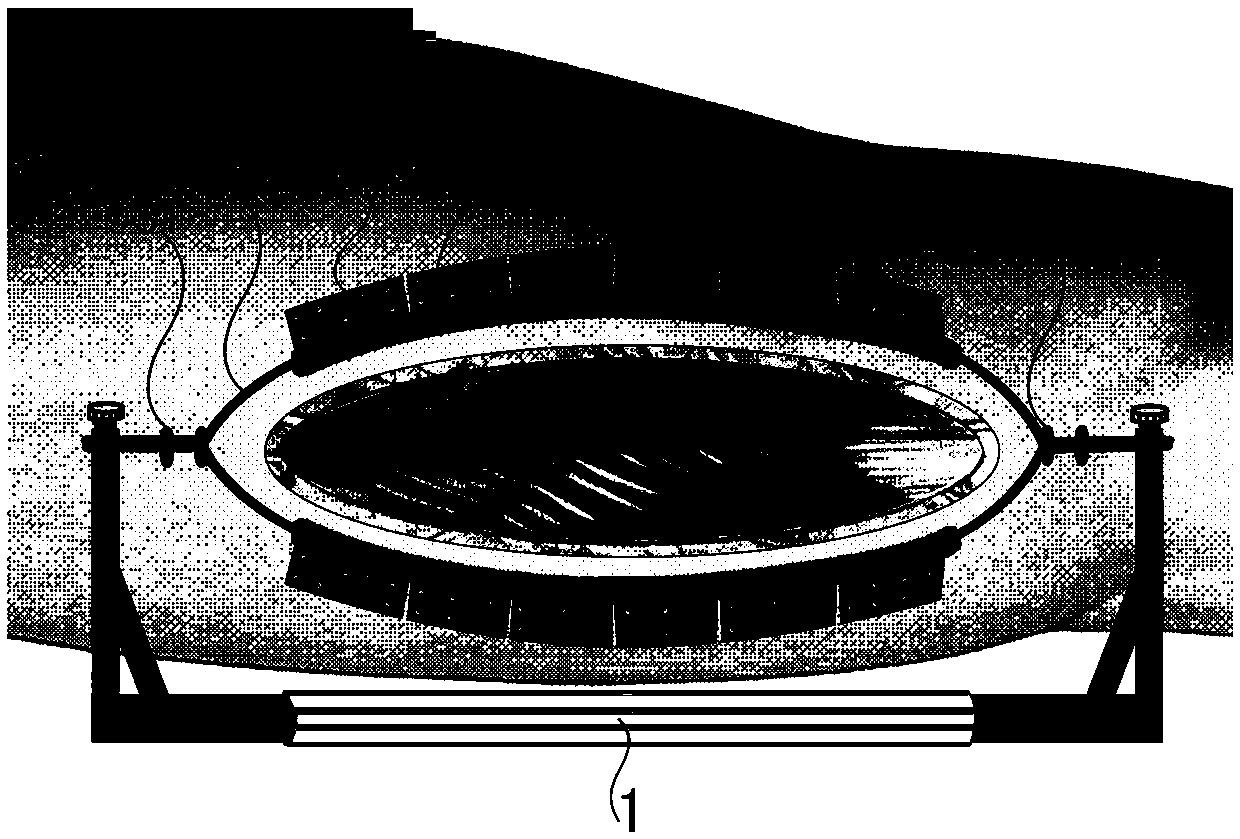

Infant warm-keeping table for department of pediatrics

InactiveCN105769486APromote recoveryReduce vibrationBaby-incubatorsLight therapyDrive motorEngineering

The invention relates to an infant warm-keeping table for the department of pediatrics.The infant warm-keeping table comprises a supporting bottom plate, walking wheels, a radiation source, a bearing plate and an infant bed.A fixed arm is arranged on one side of the upper end of the supporting bottom plate, the radiation source is arranged on the upper side of the fixed arm, the bearing plate is connected with a sliding block located on the fixed arm, a threaded rod is arranged at the upper end of the supporting bottom plate, a first thread segment and a second thread segment are arranged on the threaded rod, sliding sleeves are arranged on the first thread segment and the second thread segment respectively, the sliding sleeves are connected with an ejecting rod through first connecting rods, and one end of the threaded rod is connected with a driving motor.When it is needed to adjust the distance between the radiation source and the infant bed, the driving motor drives the threaded rod to rotate, the sliding sleeves get close to each other, the first connecting rods get close to each other at the moment, the ejecting rod moves upwards, and the sliding block on one side of the infant bed moves vertically along the fixed arm.In this way, vibration of the infant bed is reduced, and recovery of an infant is promoted.

Owner:蒙泽喜

Excessive glue scraping equipment for protective film laminating rubber roller and using method of excessive glue scraping equipment

ActiveCN112756184AAchieve softeningEasy to scrape offLiquid surface applicatorsCoatingsAdhesive glueEngineering

Owner:河源昆腾电子科技有限公司

Automatic production line based on intelligent industrial robot

ActiveCN109625915ASmooth and easy movementRealize handlingConveyor partsProduction lineIndustrial engineering

The invention relates to the technical field of production lines, in particular to an automatic production line based on an intelligent industrial robot. The automatic production line comprises a production line body, wherein the production line body is equipped with a carrying mechanism; the carrying mechanism is equipped with an assembly clamping mechanism; the carrying mechanism comprises a conveying table; the right side part of the conveying table is equipped with a supporting post; the top end of the supporting post is equipped with a beam; a first movable device can be arranged on the beam in a left-right sliding mode; a carrying mechanism is arranged below the first movable device; the assembly clamping mechanism comprises a clamp body; the clamp body comprises a first clamp mounting plate, a baffle plate is arranged at one side of the top end surface of the clamp mounting plate, the middle part of the clamp mounting plate is downs sunken to form a mounting slot; a first clamping plate capable of sliding left and right is arranged in the mounting slot; and a second clamping plate capable of turning over is arranged at the inner side of the baffle plate. The automatic production line is simple in structure, is low in manufacturing cost, is good in stability in a carrying process, can automatically regulate according to different workpieces, guarantees assembly quality and improves assembly efficiency.

Owner:义乌市丹航科技有限公司

Electronic tag power supply device

PendingCN110206970AImprove securityClose to each otherBatteries circuit arrangementsStands/trestlesEngineeringInductive charging

The invention belongs to the technical field of electronic tags and particularly relates to an electronic tag power supply device. The electronic tag power supply device comprises a bottom plate. A cavity is formed in the bottom plate. Two openings are symmetrically formed in the upper end of the bottom plate. The cavity communicates with the openings. A wireless charging plate and a storage battery are arranged in the cavity. The wireless charging plate and the storage battery are fixedly connected with the upper inner side wall and the lower inner side wall of the cavity correspondingly. A charging interface is formed in the bottom end of the bottom plate, and the charging interface, the storage battery and the wireless charging plate are electrically connected. By means of the electronic tag power supply device, wireless charging can be conducted on an electronic tag, the phenomenon that a charging wire is exposed out cannot happen, and due to the fact that redundancy design of a standby storage battery is adopted, after an external power source is powered off, the electronic tag can still be normally used.

Owner:昆山市华显光电科技有限公司

Hermetia illucens egg collecting device capable of drying egg laying plates

ActiveCN112790162AAchieve fixationAchieve separationHeating arrangementAnimal husbandryAnimal scienceHermetia

The invention relates to the field of hermetia illucens, in particular to a hermetia illucens egg collecting device capable of drying egg laying plates. A technical problem is to provide the hermetia illucens egg collecting device capable of drying egg laying plates. A technical scheme is as follows: the hermetia illucens egg collecting device capable of drying egg laying plates comprises a supporting bottom frame, a first collecting box, a second collecting box, a drying system and the like; the first collecting box and the second collecting box are arranged above the supporting bottom frame; and the supporting bottom frame is connected with a controller. Eggs need to be manually and conventionally collected on egg laying plates one by one when the eggs jump out, and collection efficiency of the eggs is improved. In combination with a characteristic that hermetia illucens like to lay eggs in a dry environment, the egg laying plates are dried and used for the second time. Besides, the detached egg laying plates are assembled again, so that a subsequent egg collection effect is improved. A current situation that existing devices cannot collect the hermetia illucens eggs and treat the egg laying plates is changed.

Owner:泉州郁之疆养殖有限公司

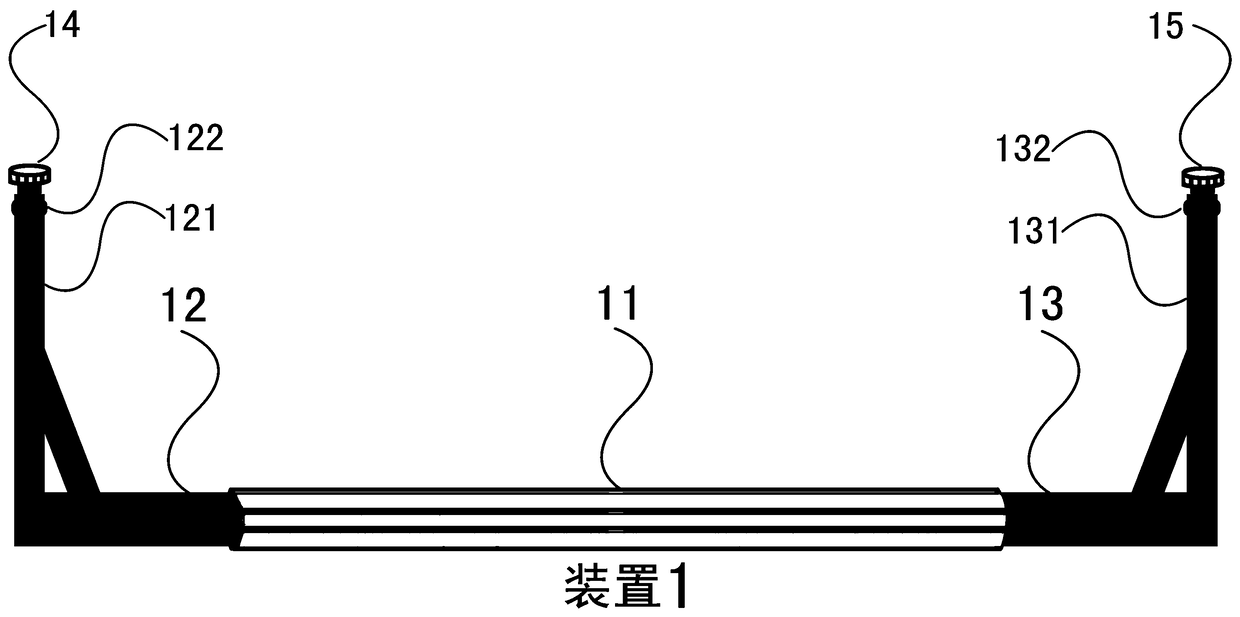

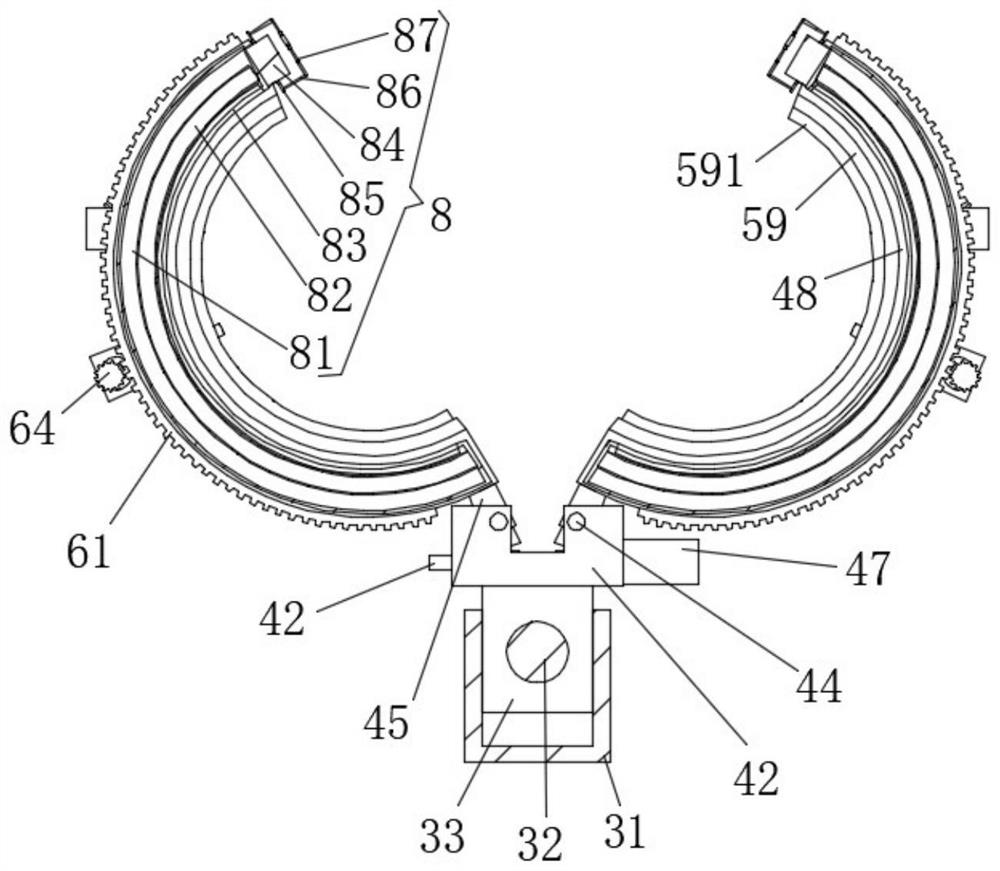

Double-reverse traction skin expander and application method thereof

The invention discloses a skin expander and an application method thereof. The skin expander structurally comprises a double-reverse traction device, suture fixation devices, steel cables and hooks, wherein the suture fixation devices arranged symmetrically are fixedly stitched to skin on both sides of a wound; the steel cables are mounted in a sleeve mode onto the suture fixation devices; both sides of the double-reverse traction device are connected with the steel cables symmetrically arranged. The double-reverse traction device enables the two arc steel cables symmetrically arranged to tendto move close each other, namely, to produce double-reverse traction force, which indirectly draw skin on both sides of the wound to gradually stretch towards the central line, and then symmetric skin flaps can slowly move close to each other and finally close the wound.

Owner:吴丹凯

Emergency power supply quick power taking connector

ActiveCN112397941AClose to each otherAchieve connectionSecuring/insulating coupling contact membersCoupling contact membersElectrical connectionStructural engineering

Owner:杭州首连电气有限公司

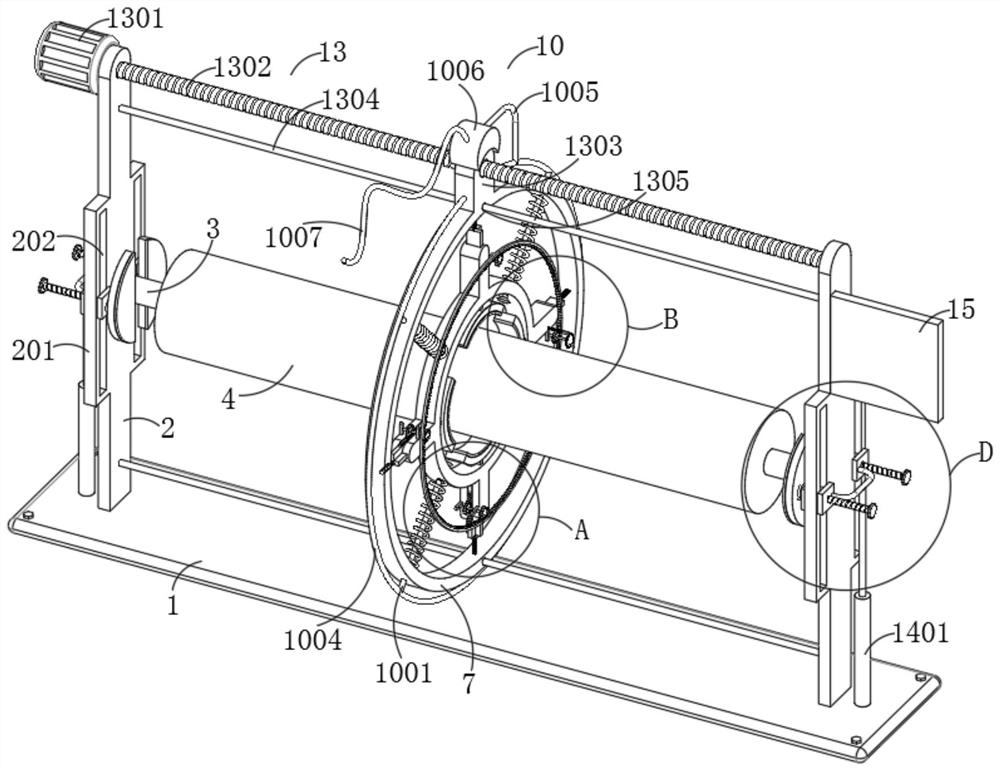

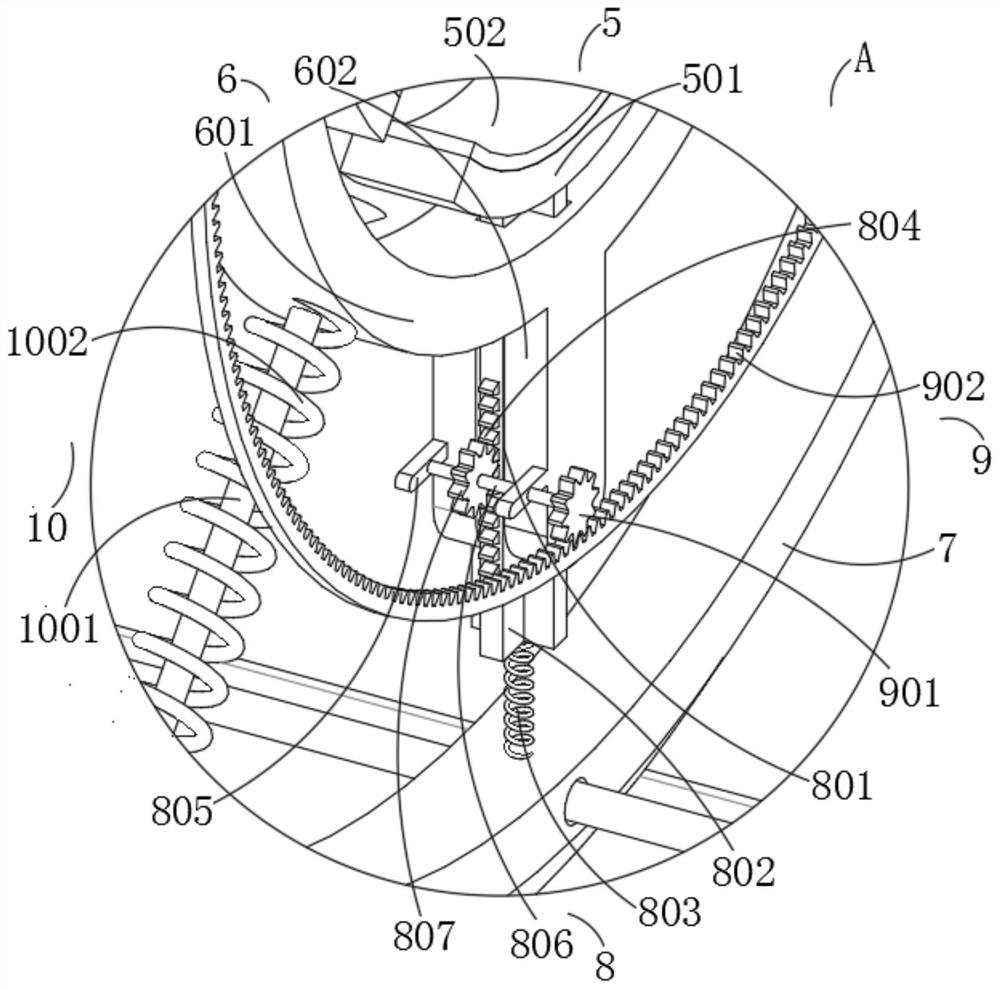

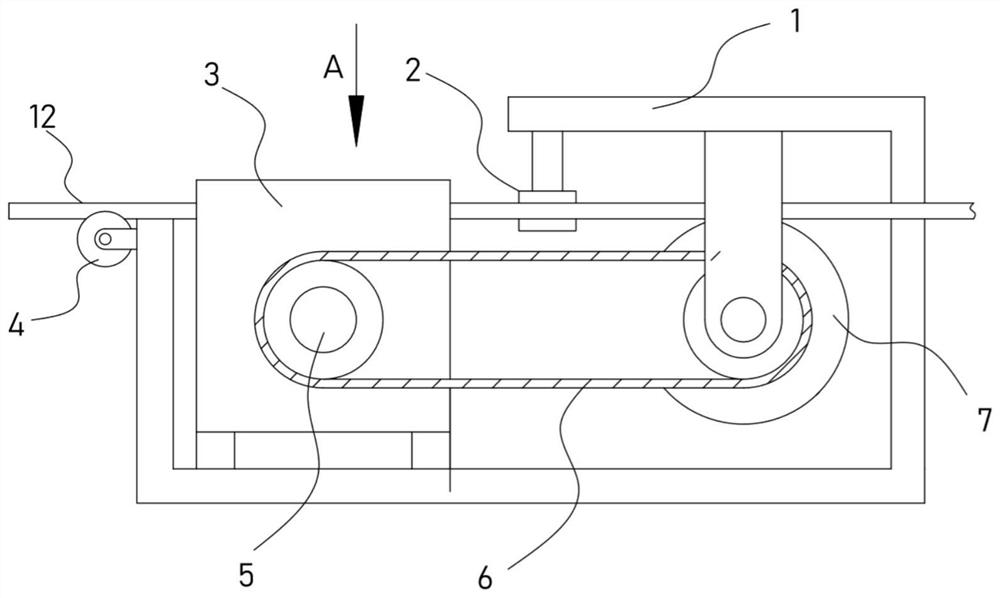

Winding device for stainless steel spring wire machining

The invention discloses a winding device for stainless steel spring wire machining. The winding device comprises a workbench, supporting legs and a bottom plate are installed at the four top corners of the bottom of the workbench, the bottom plate is installed at one end of the top of the workbench, and a fixing assembly is arranged in the center of the top of the workbench. The device has the beneficial effects that a two-way threaded rod is arranged, the two-way threaded rod is rotated to drive rotating rollers to get close to each other, a stainless steel spring wire can be limited, rotation of the fixing assembly can be achieved through meshing of multiple bevel gears while the two-way threaded rod is rotated, and the stainless steel spring wire can be limited through the rolling wheels on the clamping blocks, so stainless steel spring wires of different sizes can be machined through the two blades; burrs of the stainless steel spring wires can be reduced, and the position of a vertical rod can be adjusted through driving of a pneumatic cylinder, so spring wire finished products of different inner diameters can be wound.

Owner:广东省粤钢新材料科技有限公司

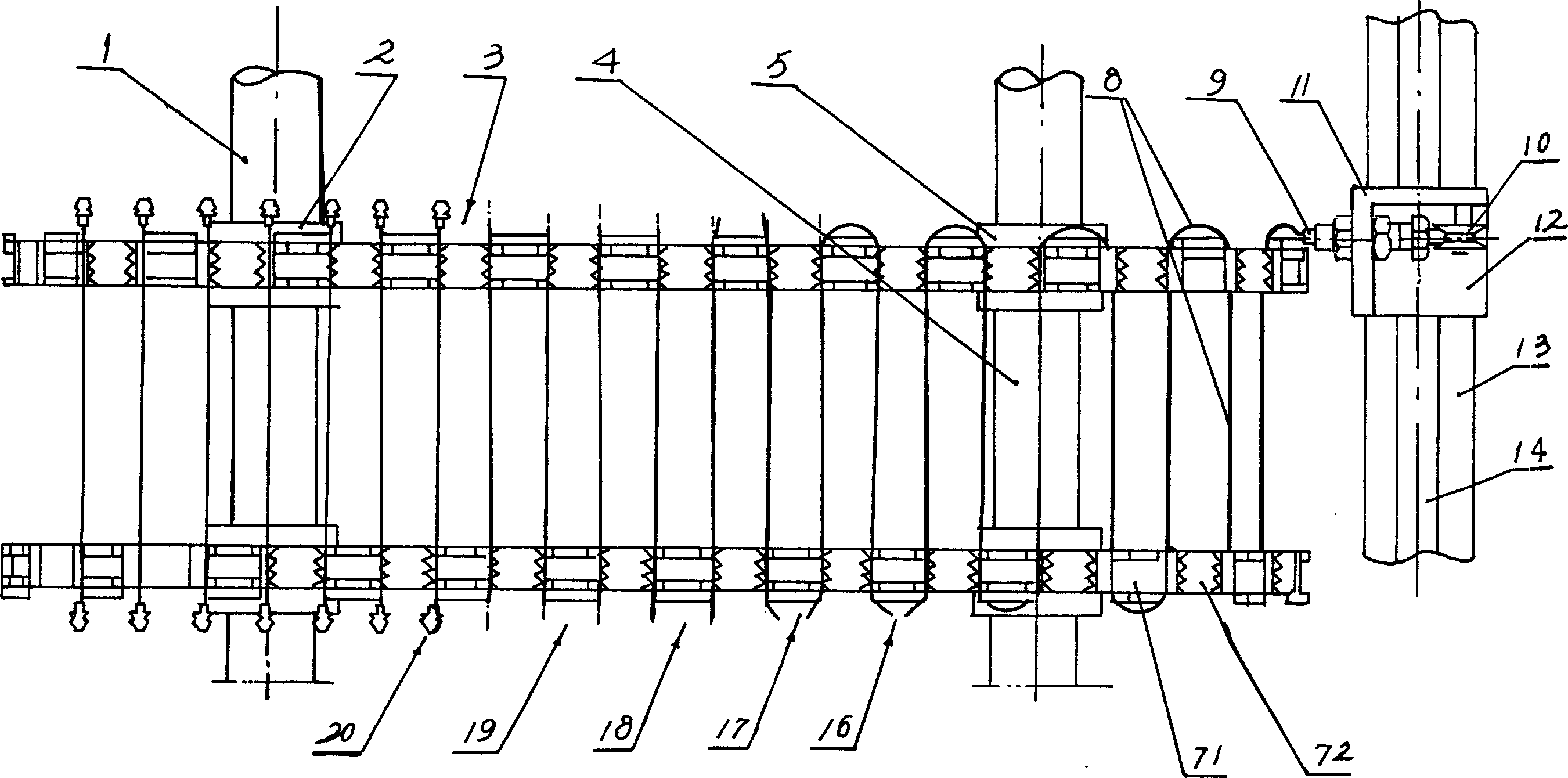

Constructional engineering continuous steel bar cutting-off device

InactiveCN111872281AClose to each otherTo achieve the truncation effectDrive shaftElectric machinery

The invention discloses a constructional engineering continuous steel bar cutting-off device, and relates to the technical field of building construction. The constructional engineering continuous steel bar cutting-off device comprises a supporting frame, a driving shaft extending into a fixing frame is coaxially fixed to an output shaft of a driving motor, a rotating roller with the surface abutting against steel bars is fixed to the driving shaft in a sleeving mode, and a tool apron is fixedly connected to each swing mechanism. A cutting-off mechanism used for cutting off the steel bars is arranged on each tool apron. According to the constructional engineering continuous steel bar cutting-off device, the arranged rotating roller is driven by the driving motor to rotate, thus the two swing mechanisms drive the cutting-off mechanisms to rotate, in the rotating process, the wedge faces of the tool aprons are in transmission with abutting transmission roller in an abutting mode intermittently, then two swing rods periodically get close to each other, and the effect of driving tool blocks in the cutting-off mechanisms to cut off the steel bars is achieved; and when the rotating roller rotates by a circle, the steel bars are conveyed leftwards by a certain length, the cutting-off mechanisms cut off the steel bars once, the equal-interval and continuous cutting-off effect of the steel bars is achieved, and the efficient cutting-off effect of the steel bars during building construction is greatly improved.

Owner:韦楚旺

Automatic book storage device for library

PendingCN113120805AClose to each otherChieve away fromLifting devicesElectric machineryStructural engineering

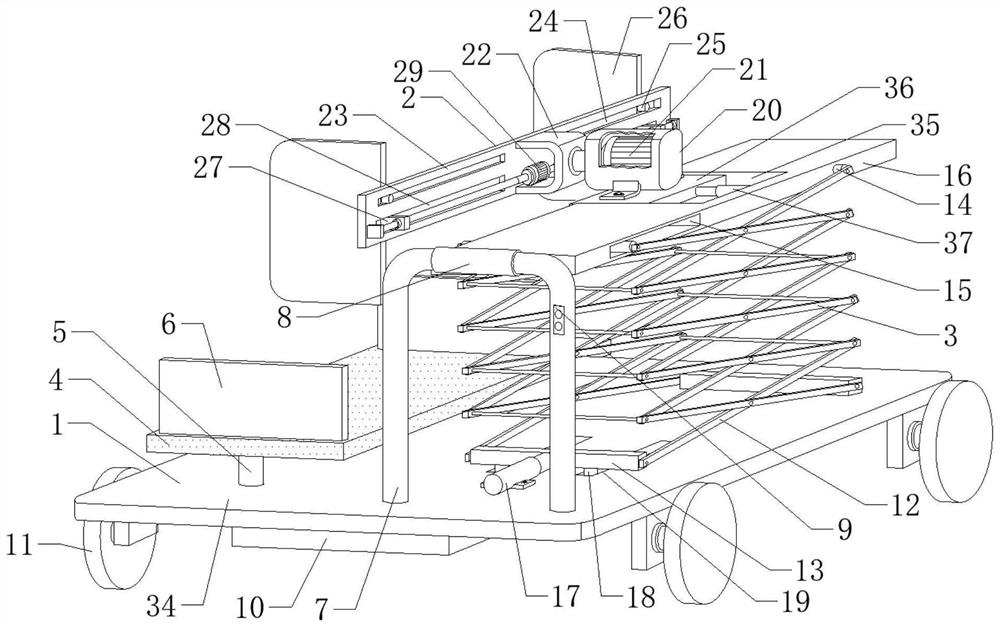

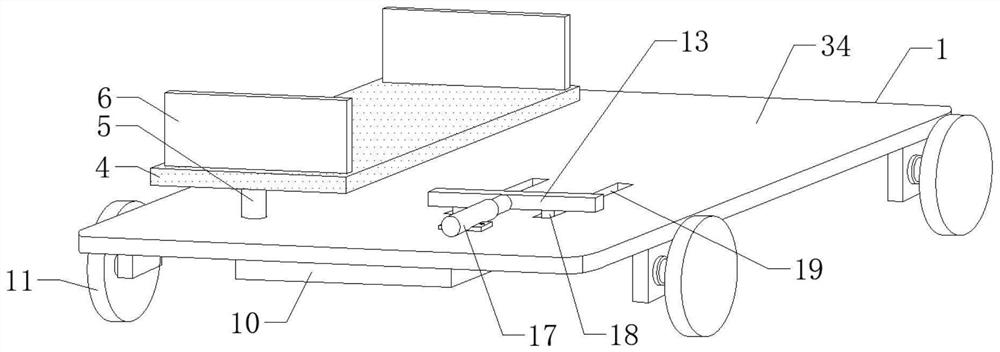

The invention discloses an automatic book storage device for a library, and relates to the field of automatic book storage devices. The automatic book storage device comprises a movable vehicle, a storage device and a lifting device, wherein the movable vehicle comprises a bottom plate; front and rear ends at left and right ends of the bottom plate are equipped with movable wheels; and the lifting device comprises two telescopic connecting rods. A connecting plate, a rotating plate, a slide slot, a circular slide block, clamping plates, a butt-joint plate, a butt-joint slot, a dual-axis motor, a threaded rod, a threaded barrel and a positioning plate are matched, so that the two clamping plates get close to each other or away from each other, and thus, the distance between the two clamping plates can be adjusted according to the number of the stored books; and the to-be-stored books are clamped by the two clamping plates, so that the number of the books stored once can be greatly increased in a mode of clamping the books through the two clamping plates compared with manual book storage, and thus, book storage efficiency can be effectively improved, and large-scale book storage needs of the library can be met.

Owner:RIZHAO POLYTECHNIC

Inner hole spraying device of hardware product

InactiveCN109127224ARealize initial limit fixationRealize limit fixationSpraying apparatusHydraulic pumpPiston

The invention provides an inner hole spraying device of a hardware product. The inner hole spraying device comprises a base, a motor support is installed at the upper end of the base, a motor is installed at the upper end of the motor support, a rotating shaft is installed on one side of the motor, and a rotating frame is arranged on the side, away from the motor, of the rotating shaft. First pistons are installed on the inner walls, opposite to each other, of the rotating frame in the vertical direction. First piston shafts are arranged on the sides, away from the rotating frame, of the firstpistons. Suction cups are installed on the sides, away from the first pistons, of the first piston shafts. A first hydraulic pump is further arranged on one side of each compressor, and a mounting shaft is further arranged at the upper end of the base and located on one side of the rotating frame. Sprayer installing bases are installed on the side, close to the rotating frame, of the mounting shaft, sprayers are arranged on the sprayer installing bases, and a spray box communicating with the sprayers is installed on one side of the mounting shaft. According to the device, the efficiency and quality of spraying paint to hardware inner holes can be effectively improved.

Owner:平湖市万顺达机械有限公司

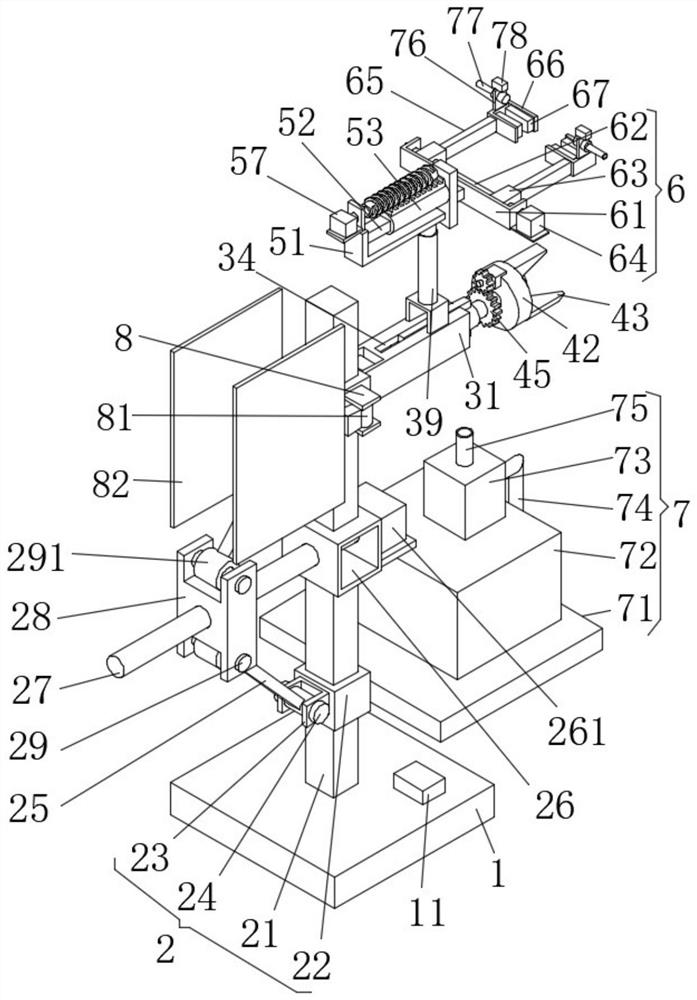

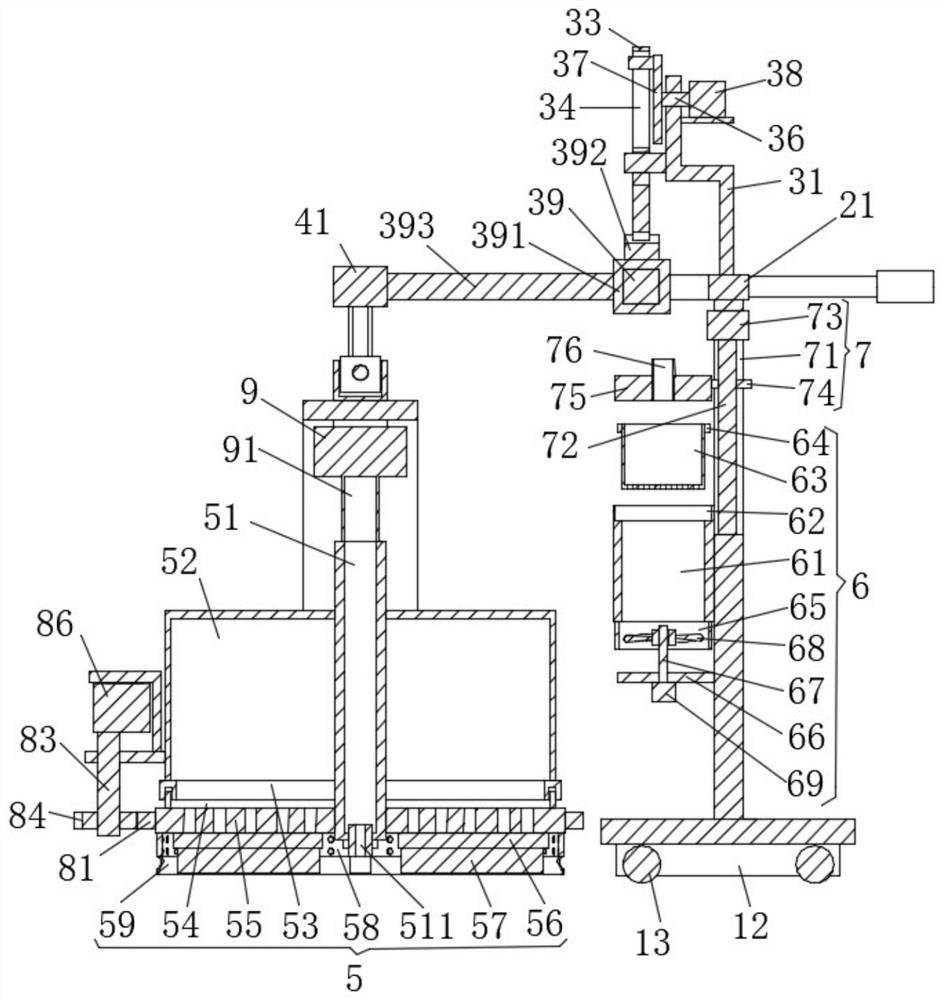

Intelligent mechanical equipment for cleaning blades of wind driven generator

InactiveCN112756291ARealize intelligent positioningRealize linear slidingMachines/enginesCleaning using toolsWind drivenElectric machinery

The invention discloses intelligent mechanical equipment for cleaning blades of a wind driven generator. The intelligent mechanical equipment comprises a bottom plate, a lifting assembly and an extending assembly, wherein a lifting assembly is arranged on the surface of the bottom plate; the extending assembly is arranged on the lifting assembly; a rotating assembly and an adjusting assembly are arranged on the extending assembly; a cleaning assembly is arranged on the adjusting assembly; the lifting assembly comprises a square rod, two square frames, supporting seats, pin shafts, connecting rods, mounting frames, first motors, lead screws, connecting seats, limiting pins and lantern rings; the square rod is arranged in the middle of the surface of the bottom plate; the two square frames are symmetrically arranged up and down; the upper side and the lower side of the square rod are movably sleeved with the two square frames correspondingly; and the supporting seats are symmetrically arranged on the side faces of the square frames located on the upper side and the lower side; and the pin shafts penetrate through the two sides of the supporting seats. According to the intelligent mechanical equipment for cleaning the blades of the wind driven generator, automatic cleaning of the blades of the wind driven generator can be achieved, manpower is saved, the working efficiency is improved, the cleaning effect is relatively good, and practicability is relatively high.

Owner:温州闪友建筑有限公司

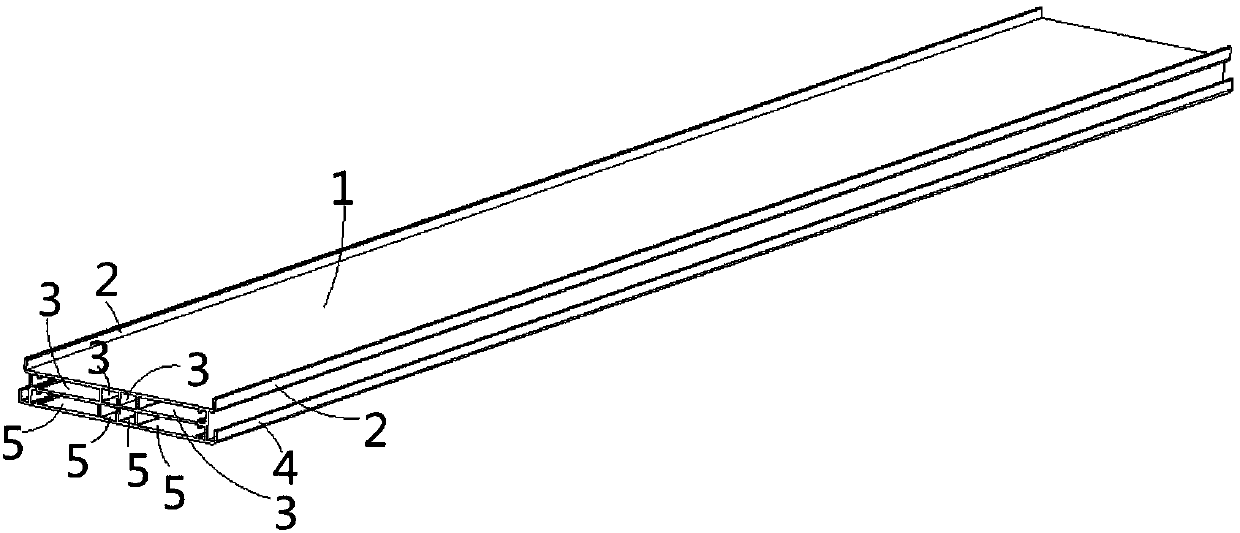

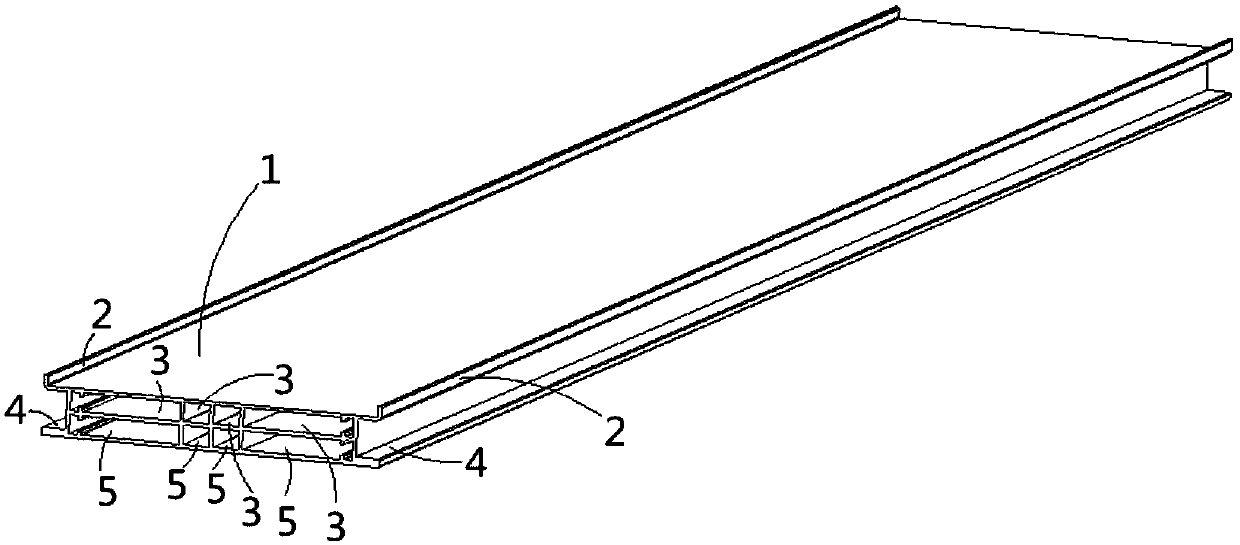

Reflection plate

The invention relates to the field of mobile communication, and more specifically relates to a reflection plate. The reflection plate comprises a reflection plate surface, as well as left and right side plates fixed on the two sides of the reflection plate surface, a cavity structure and a metal plate extension structure, wherein the cavity structure is fixed below the reflection plate surface, and the metal plate extension structure is fixed on the outer side of the bottom of the cavity structure. According to the reflection plate disclosed by the invention, due to the arrangement of the leftand right side plates, the cavity structure and the metal plate extension structure, the reflection plate has an excellent front and back ratio, the antenna design is more concise, the assembly is reduced, the production is convenient, and the cost is reduced.

Owner:佛山市恒爱网络科技有限公司

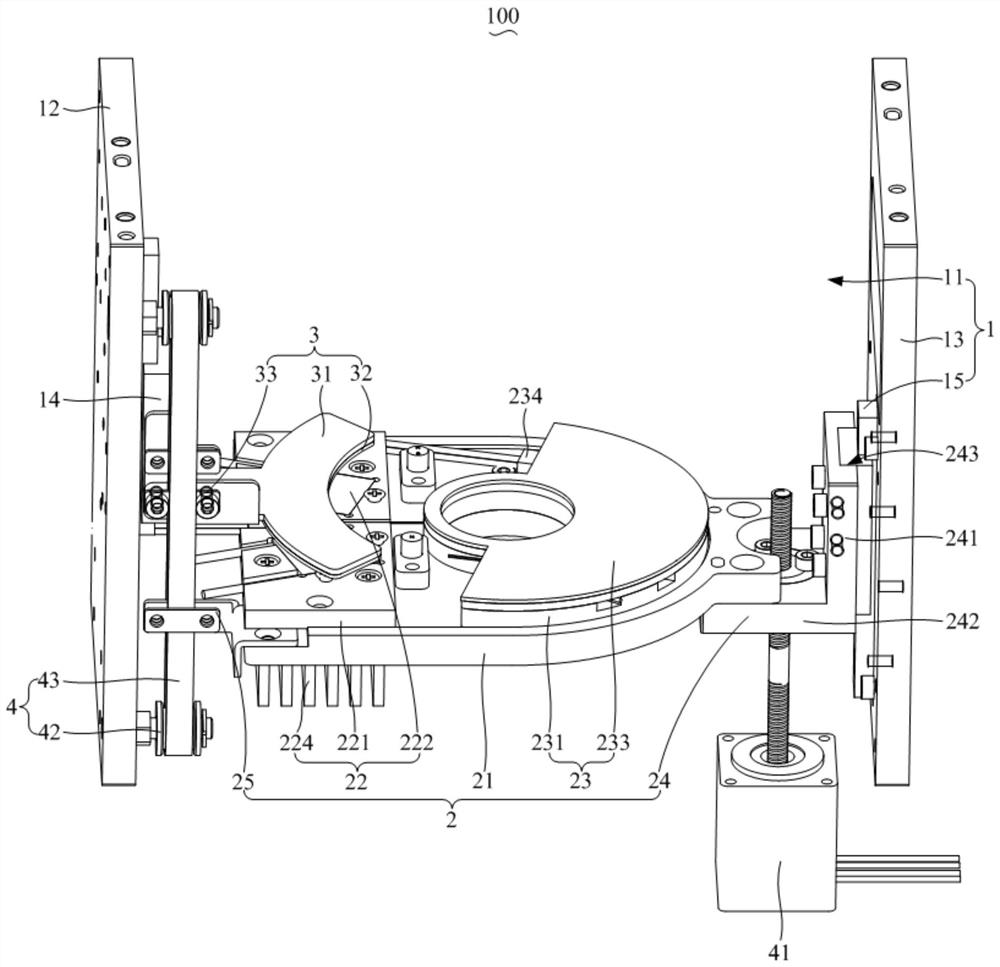

Bottle clamping mechanism used for clamping bottle opening

The invention discloses a bottle clamping mechanism used for clamping a bottle opening. The bottle clamping mechanism comprises a pair of clamping pieces arranged on an installing base. Each clampingpiece comprises a clamping piece connecting part and a clamping piece clamping part. Each clamping piece connecting part is provided with a rack. The racks of a pair of clamping piece connecting partsare meshed with the two sides of a gear correspondingly. The gear is fixed to a main shaft. The main shaft is movably installed on a connecting plate. The connecting plate is fixed to the installingbase. The upper end of the main shaft extends out of the connecting plate and is fixedly connected with a swing rod. The swing rod is driven by a swing drive mechanism. A resetting tension spring is connected between a pair of clamping piece connecting parts. Under driving of the swing drive mechanism, the swing rod drives the gear on the main shaft to rotate, and thus the clamping piece connecting parts are driven to get away from each other until the bottle opening can be clamped in or drop out. After the swing rod and the swing drive mechanism are separated, under the effect of the resetting tension spring, the clamping piece clamping parts get close to each other until the bottle opening is clamped. The bottle clamping mechanism has the beneficial effects of being simple and ingeniousin structure and feeding and discharging bottles reliably.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Building frame erecting steel pipe surface cleaning equipment

ActiveCN111318968AEasy for sandblastingClose to each otherAbrasive blasting machinesSurface cleaningSand blasting

The invention provides building frame erecting steel pipe surface cleaning equipment. The equipment comprises a support, a supplied material bearing block and a transmission mechanism, wherein the supplied material bearing block is located at the front end of the support, the supplied material bearing block is specifically and telescopically arranged on the side wall of the support through a telescopic air cylinder, symmetrical bearing wheels are rotationally connected to the top end of the supplied material bearing block, a first traction hook is further fixedly arranged on the side wall of the supplied material bearing block, a first traction wheel is fixedly arranged at the top of the front end of the support, the transmission mechanism is fixedly arranged on the inner side wall of thesupport, a mounting box fixedly arranged at the top of the support and a sand blasting box fixedly connected with the mounting box are further included, a mounting block is fixedly arranged on the mounting box through a connecting rod, a driving mechanism is arranged on the side wall of one side of the mounting block, the driving mechanism comprises two gears fixedly arranged on the side wall of the mounting block, and a rack used for driving the gears to rotate is arranged between the two gears. According to the technical scheme of the equipment, the problem that in the prior art, equipment which facilitates overturning of a steel pipe and cannot thoroughly clean the surface of the steel pipe is lacked is effectively solved.

Owner:江苏中装建设有限公司

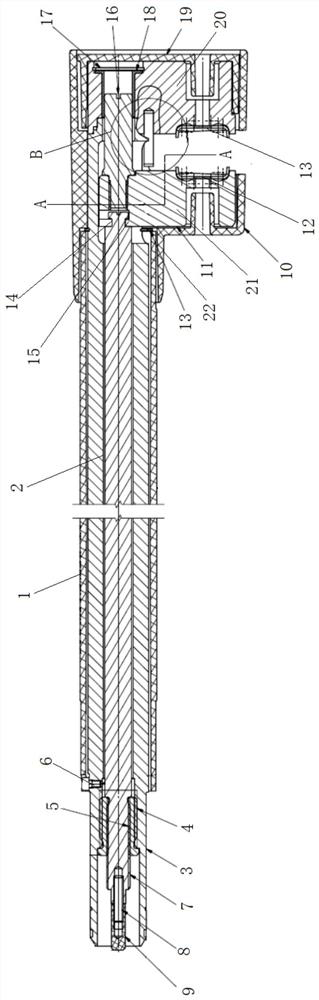

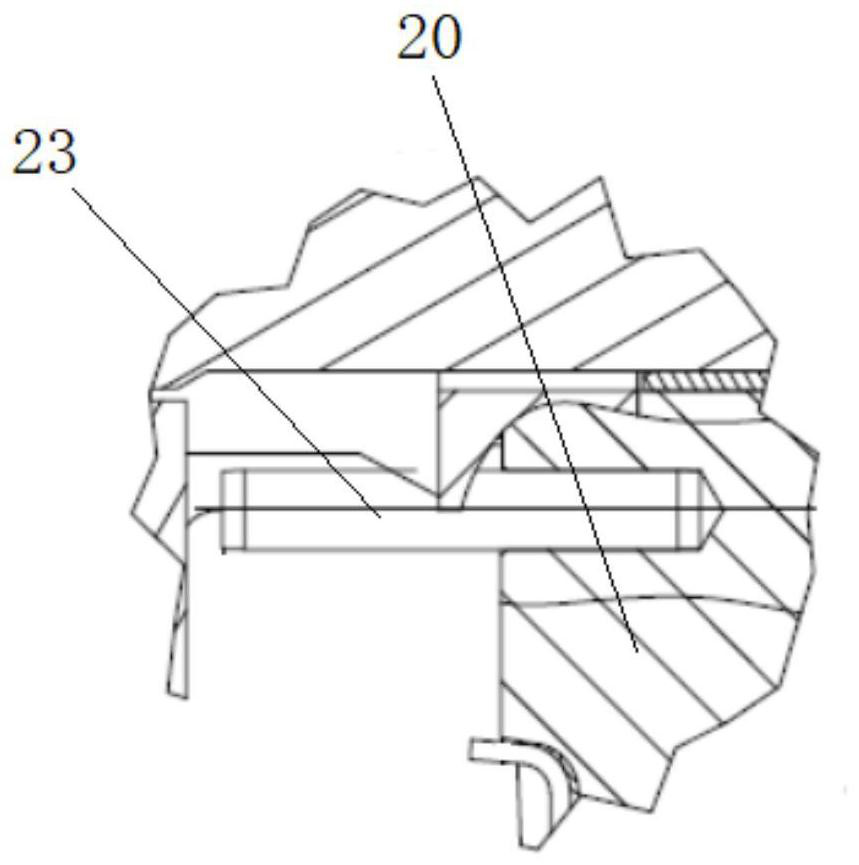

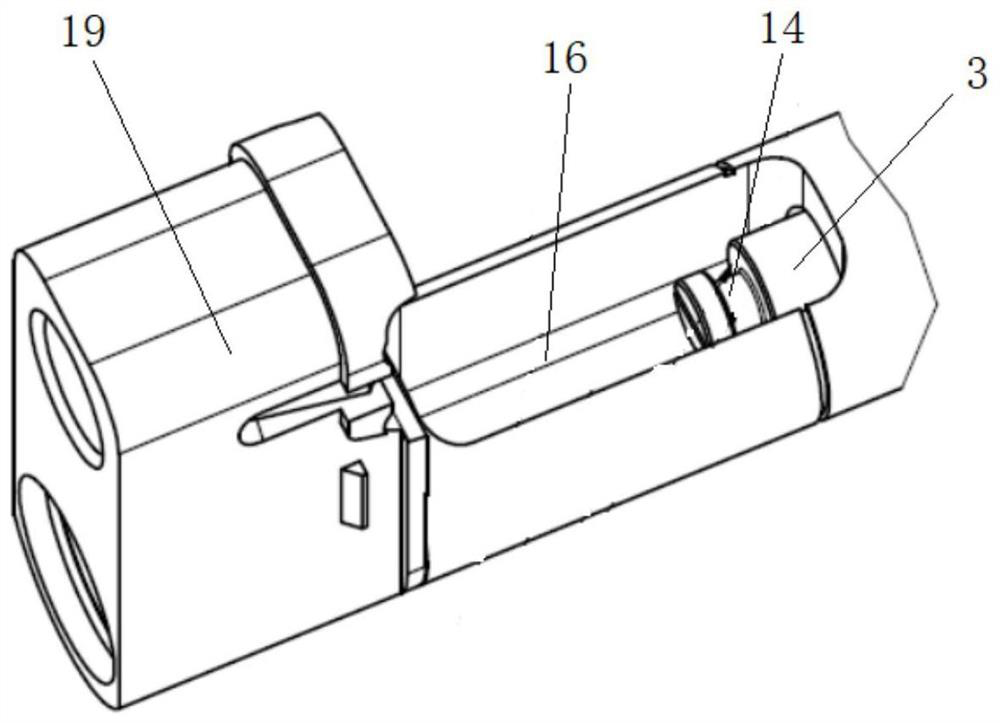

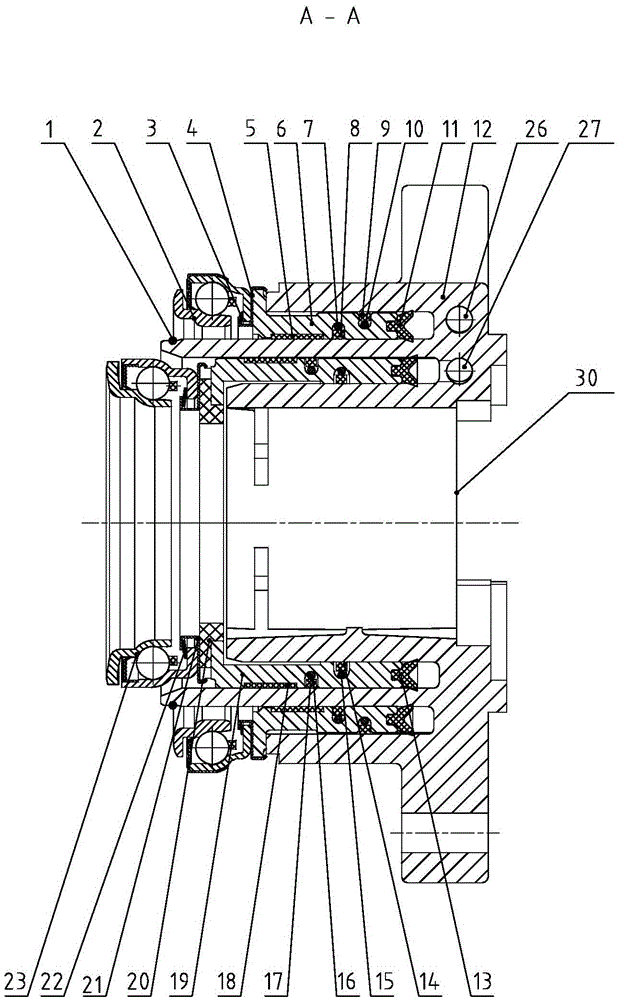

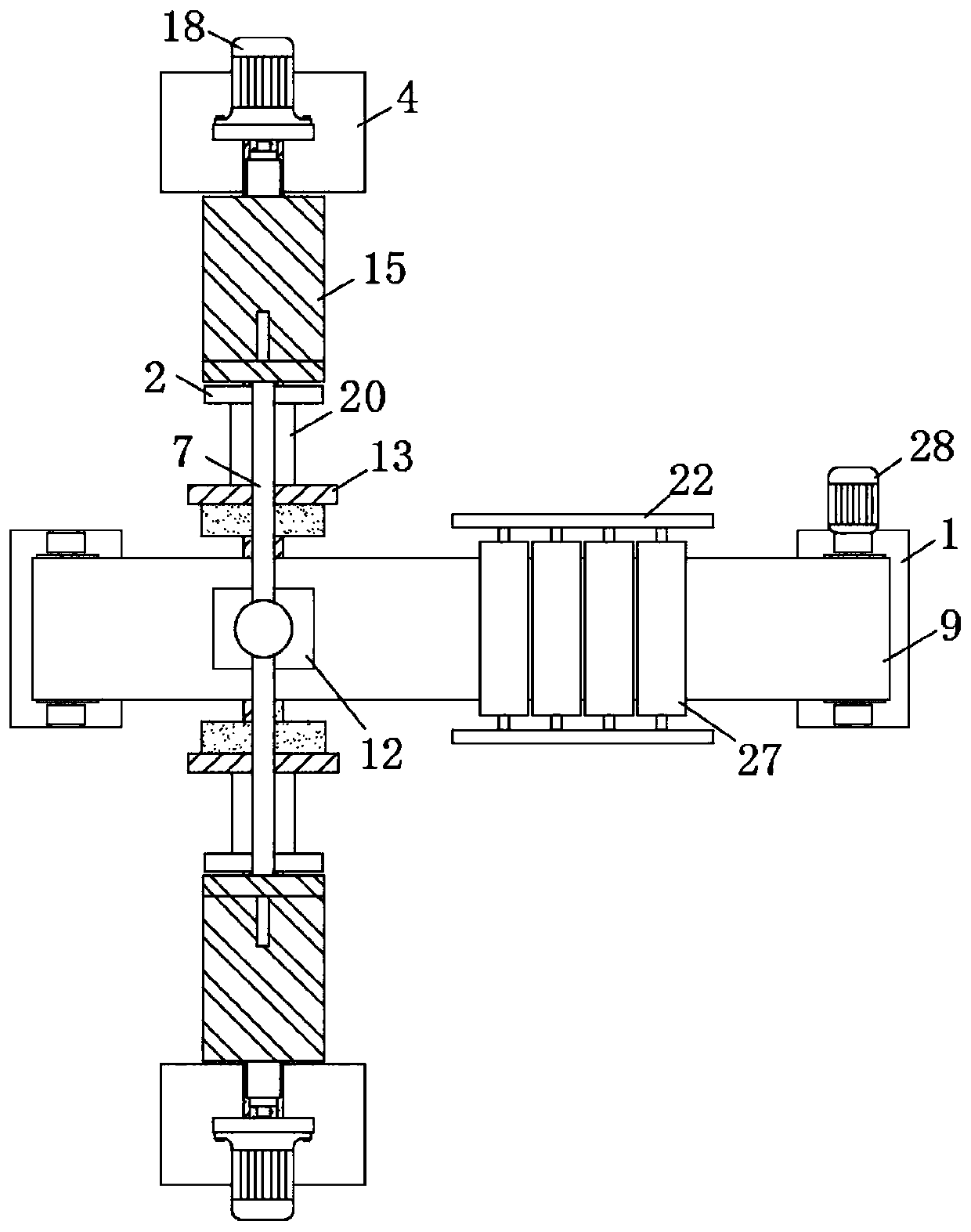

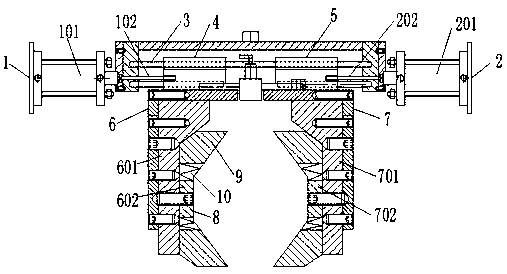

Dry-type dual-clutch hydraulic combination and separation bearing assembly

ActiveCN105465223ASimplified Separation MechanismClose to each otherFluid actuated clutchesClutchMutual position

The invention belongs to the technical field of car clutch separation, and relates to a dry-type dual-clutch hydraulic combination and separation bearing assembly, in particular to a dry-type dual-clutch hydraulic combination and separation bearing assembly adopted on a pony car. The dry-type dual-clutch hydraulic combination and separation bearing assembly comprises a first separation bearing, a first piston, a second piston, a cylinder and a second separation bearing. Two coaxially-arranged hydraulic cavities are arranged at one end of the cylinder. The two coaxially-arranged hydraulic cavities of the cylinder are connected with the first piston and the second piston respectively in a sliding mode. The two independent separation bearings and a separation mechanism are combined into a whole, hydraulic force is adopted for alternately pushing the first piston and the second piston to axially slide in a reciprocating mode inside the two axially-arranged hydraulic cavities, the first separation bearing and the second separation bearing are driven to alternately extrude two diaphragm springs to be separated so as to achieve combination and separation of a dry-type clutch, variable speed gear shifting is achieved, the separation mechanism is simplified, the mutual positions are compact, the boundary dimension is small, the weight is low, separation is stable, and no impact noise is generated.

Owner:WUXI MINLIAN AUTOMOBILE PARTS CO LTD

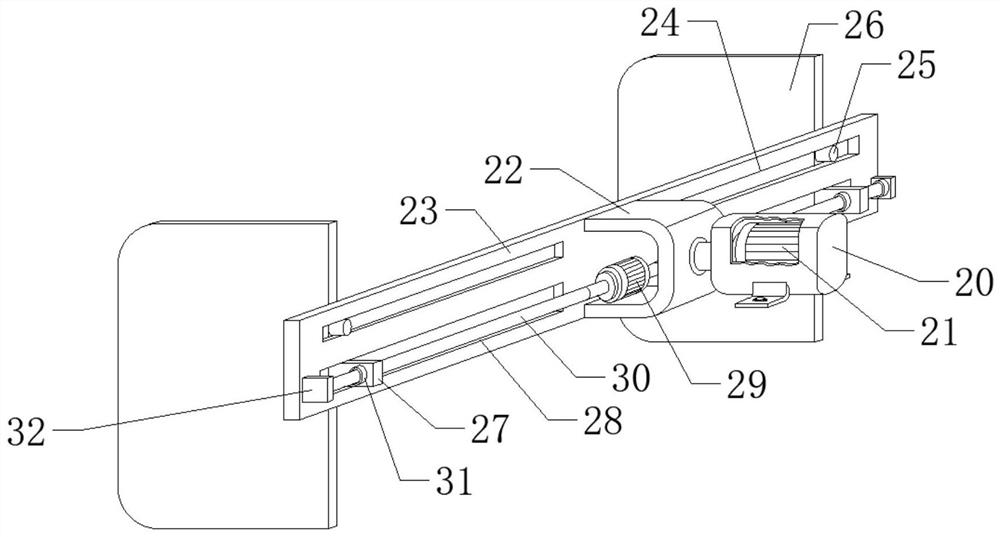

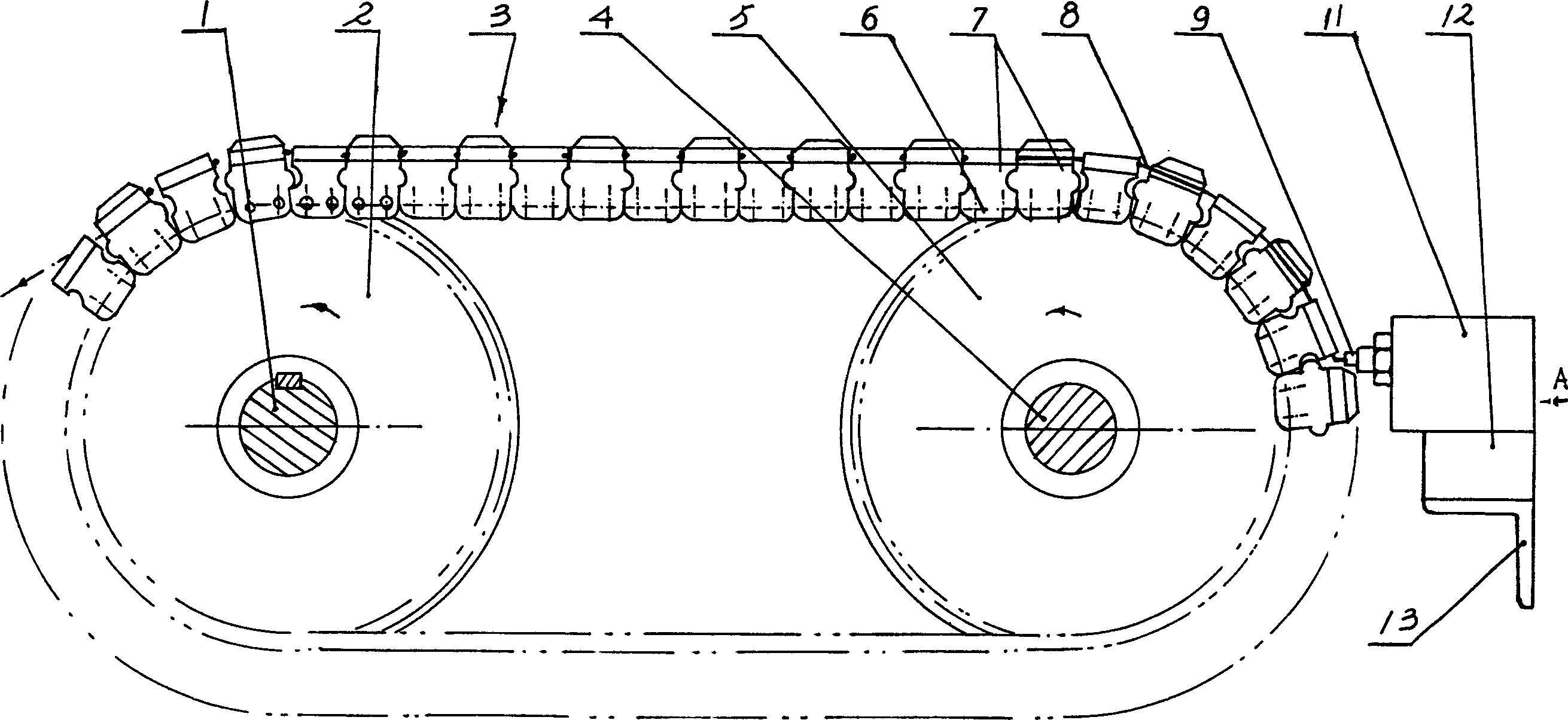

Wire delivery mechanism of full automatic wire stripping machine

InactiveCN1414667AGuaranteed uptimeGuaranteed synchronizationLine/current collector detailsDrive wheelDrive shaft

A wire conveying mechanism for automatic wire peeling and punching machine is mainly used for wire peeling to conductive wire end and for aluminium or copper sheet fitting to be wrapped on the wire end having been peeled. The said wire conveying mechanism has driving wheel on driving shaft and driven wheel on driven shaft, conveying belt connecting driving and driven wheels to form a ratory device. There is a wire fixing block on the conveying belt and a wire winding mechanism at one end of rotary device. The winding mechanism draws the conductive wire and winds it on the wire fixing block aswell as the conductive wire to be clamped by the wire fixing block. The wire fixing block not only can wind the wire but also can champ the wire to feed the conductive wire laterally.

Owner:翁新华 +1

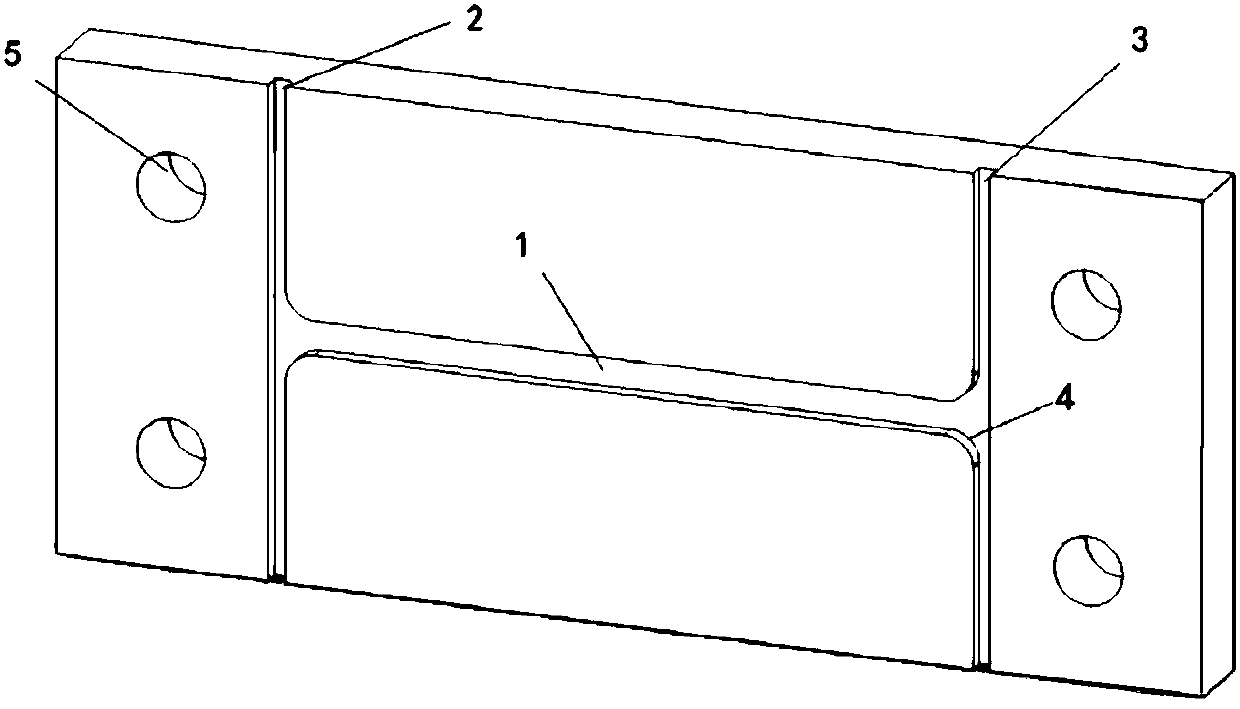

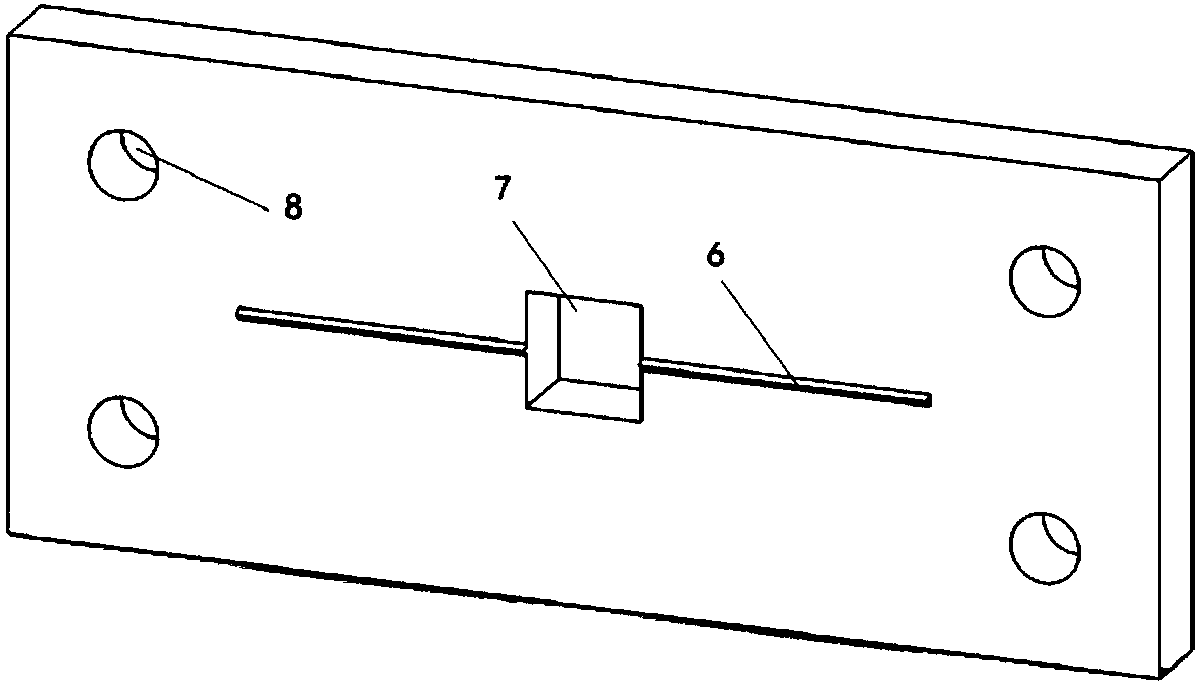

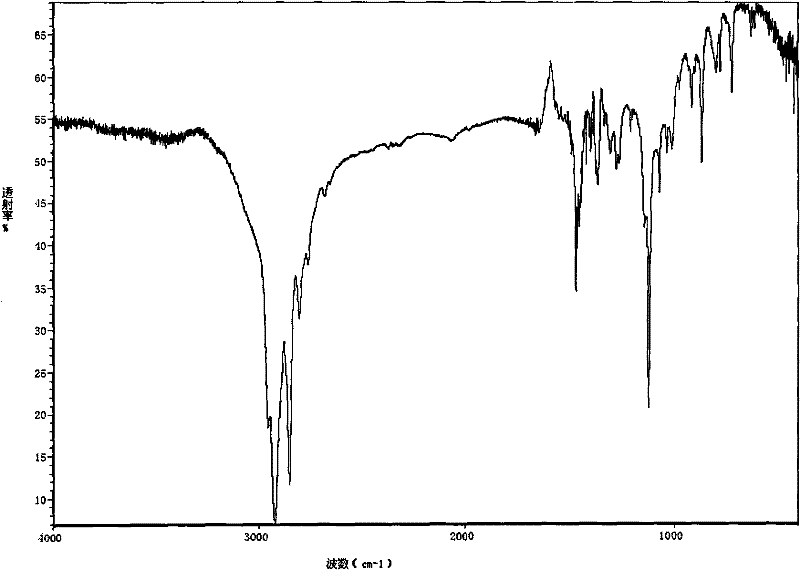

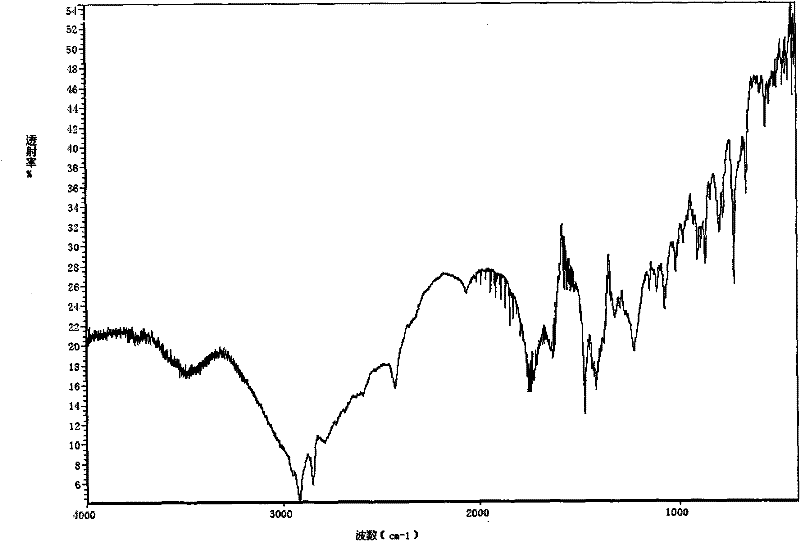

Dry-type air-core reactor preparation mould provided with air gaps of fixed size and sample preparation method

ActiveCN107599278AInsulation deformation damage avoidanceInsulation deformation damage will not occurPreparing sample for investigationCoils manufactureGroove widthEpoxy

The invention relates to a dry-type air-core reactor preparation mould provided with air gaps of a fixed size and a sample preparation method. A mould composed of a cover plate and a bottom plate is utilized to conduct sample preparation, two same enamel insulated aluminum wires are embedded into a doubling groove of a mould groove, a gap sheet is utilized to be inserted into the position betweenthe two aluminum wires to construct the air gaps of the fixed size, the groove depth and the groove width of a through groove in the bottom plate are equal, the groove depth of the doubling groove isequal to the groove depth of the through groove, the groove width of the doubling groove is equal to the sum of double of the groove width of the through groove and the thickness of the gap sheet, andbubbles in epoxy resin glue are effectively removed through three times vacuumizing operation. Compared with the prior art, the dry-type air-core reactor preparation mould provided with the air gapsof the fixed size and the sample preparation method have the advantages that the insulation deformation damage of line outgoing in the sample demoulding process is avoided, unevenness of interturn gaps is avoided, increasing of the interturn gaps which are brought in an original sample heating and shaping process is avoided, and discharging of the bubbles inside the epoxy resin is more facilitated.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Household carpet dust removal equipment in flexible contact mode

InactiveCN112971593APrevent dispersalAchieve sealingSuction filtersSuction nozzlesDust controlElectric machinery

The invention discloses household carpet dust removal equipment in a flexible contact mode. The household carpet dust removal equipment comprises a base, a reciprocating assembly and a dust raising assembly, wherein side plates are symmetrically arranged on the two sides of the bottom face of the base, rollers are rotationally connected to the side plates, a vertical plate is arranged in the middle of the surface of the base, a mounting frame is arranged at the top of the vertical plate, push rods are symmetrically arranged on the two sides of the side face of the mounting frame, the reciprocating assembly is arranged on the mounting frame, and is provided with an adjusting assembly, the adjusting assembly is provided with the dust raising assembly, and the dust raising assembly is provided with a rotating assembly; the reciprocating assembly comprises a support, a limiting pin, a movable plate, a guide groove, an arc-shaped toothed plate, a rotating shaft, a rotating disc, a pin rod, a first motor, a guide rod, a sliding block, a rack and a frame plate. According to the household carpet dust removal equipment, the dust removal effect is effectively improved, dust deep in the surface of a carpet can be effectively removed, and adjustment can be conveniently conducted according to needs; meanwhile, through flexible contact with the carpet, the carpet can be prevented from being damaged, and the practicability is high.

Owner:温州黎肯电子商务股份有限公司

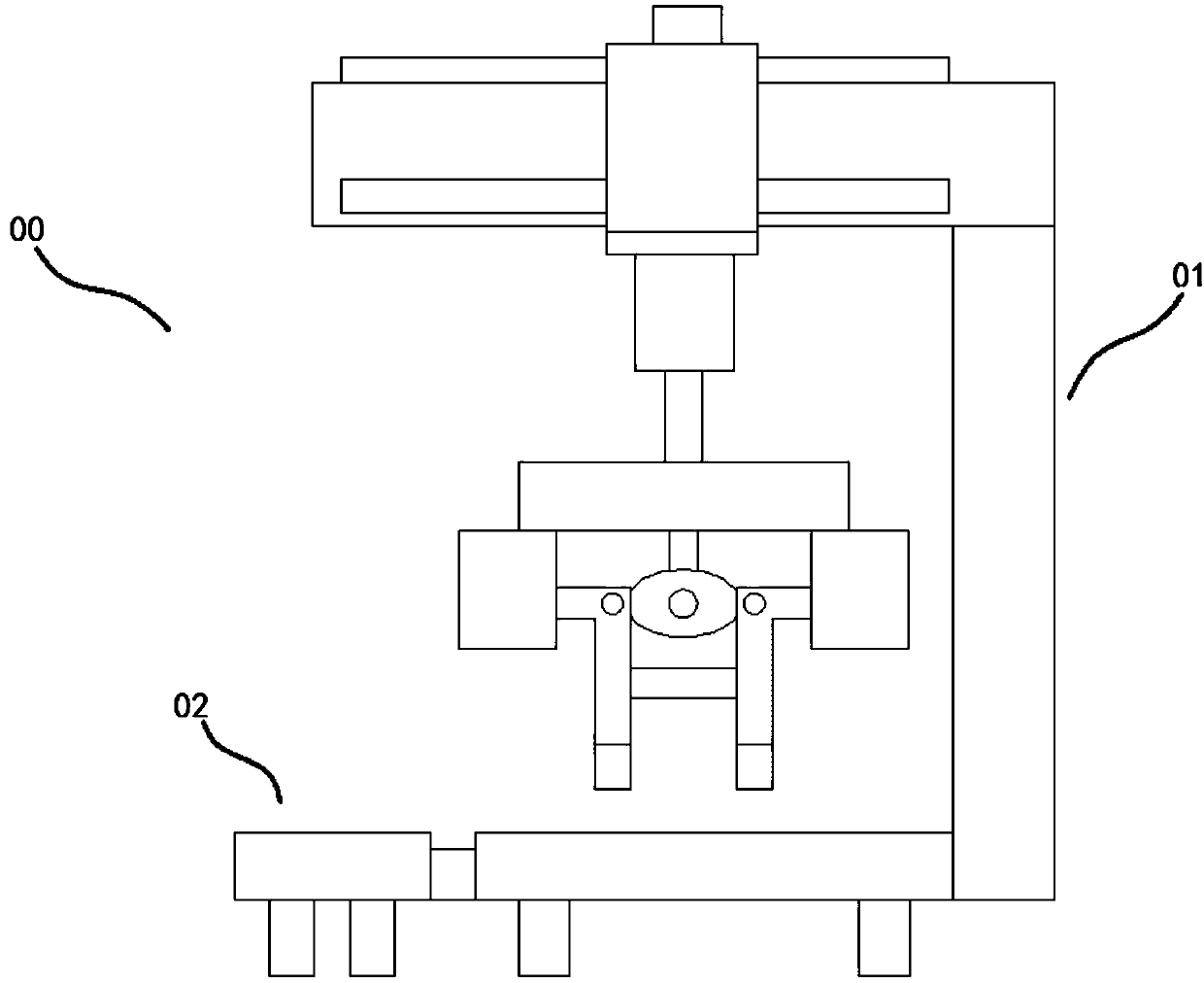

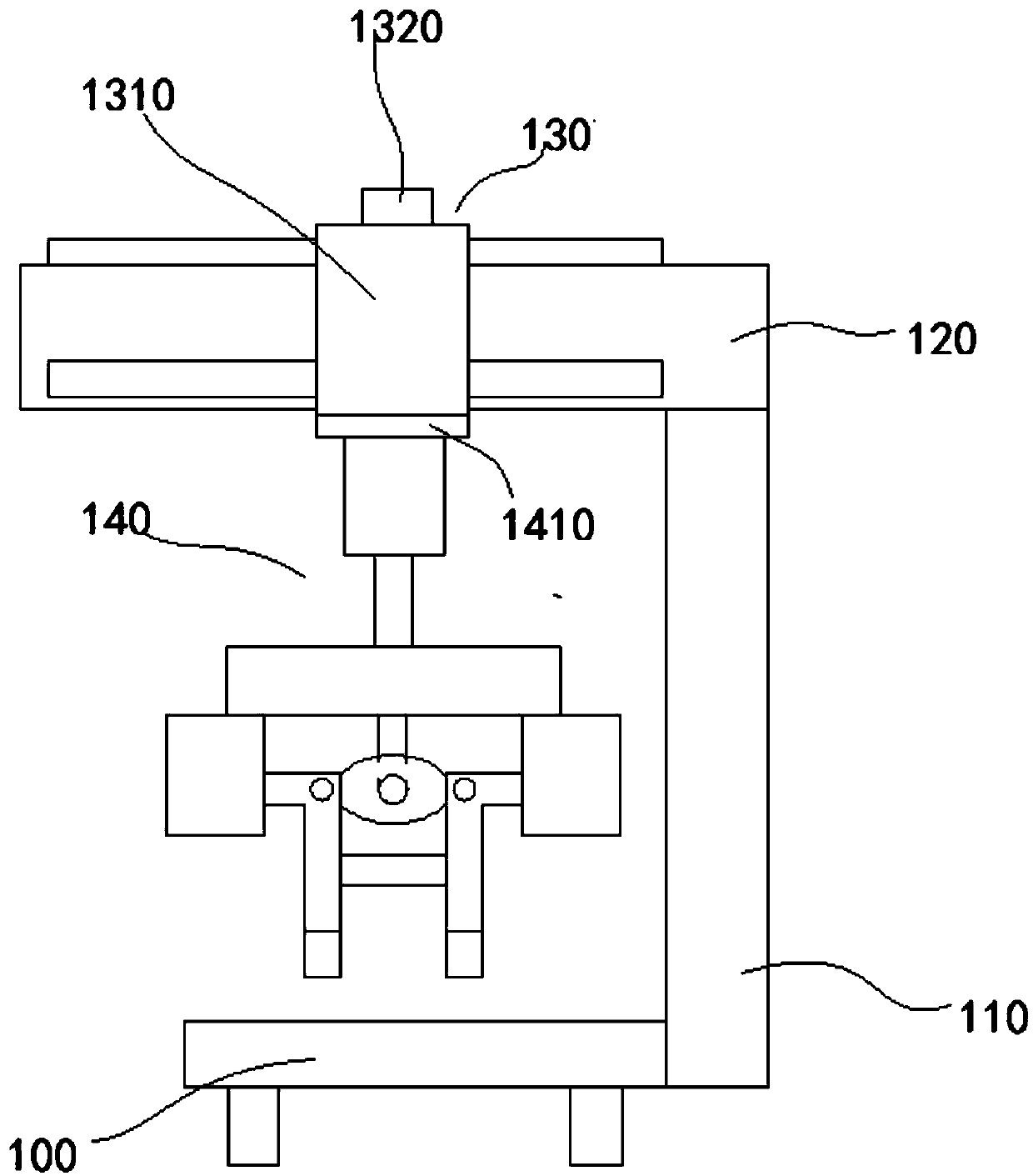

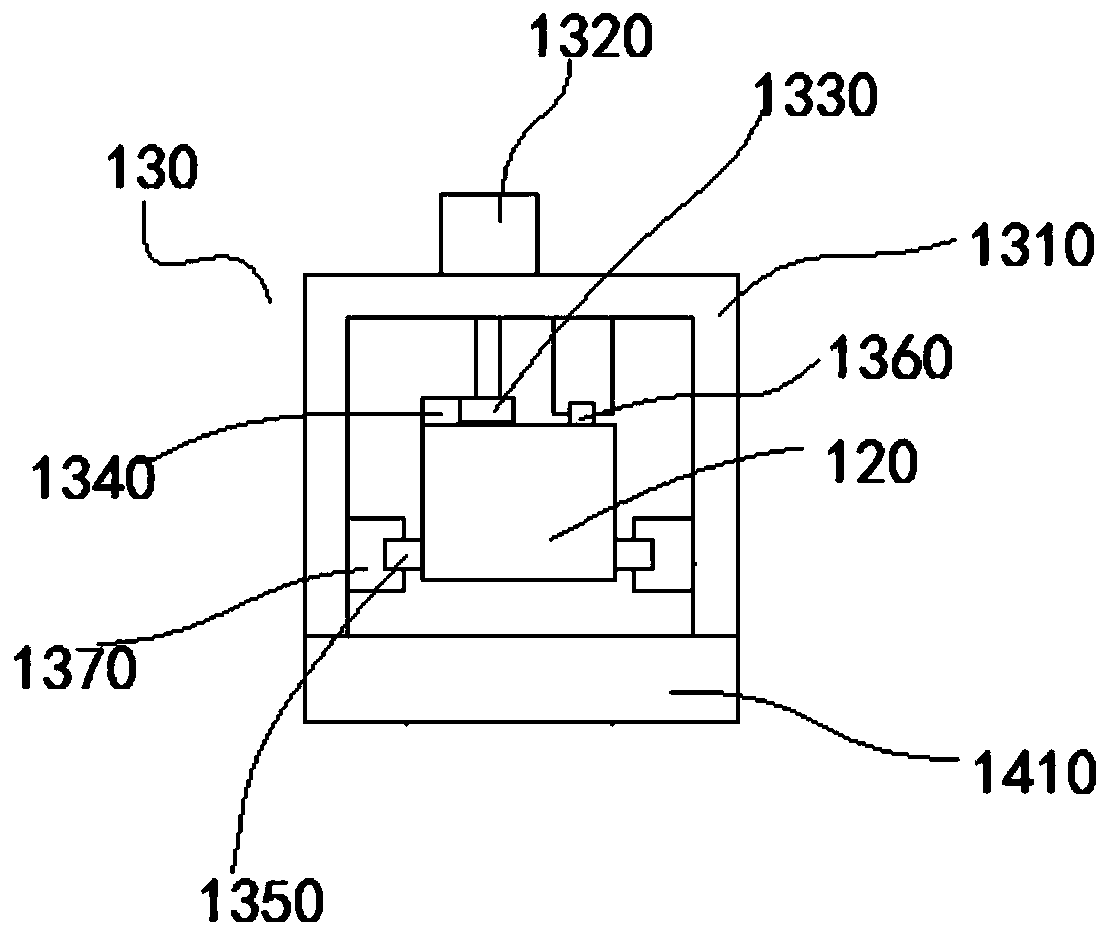

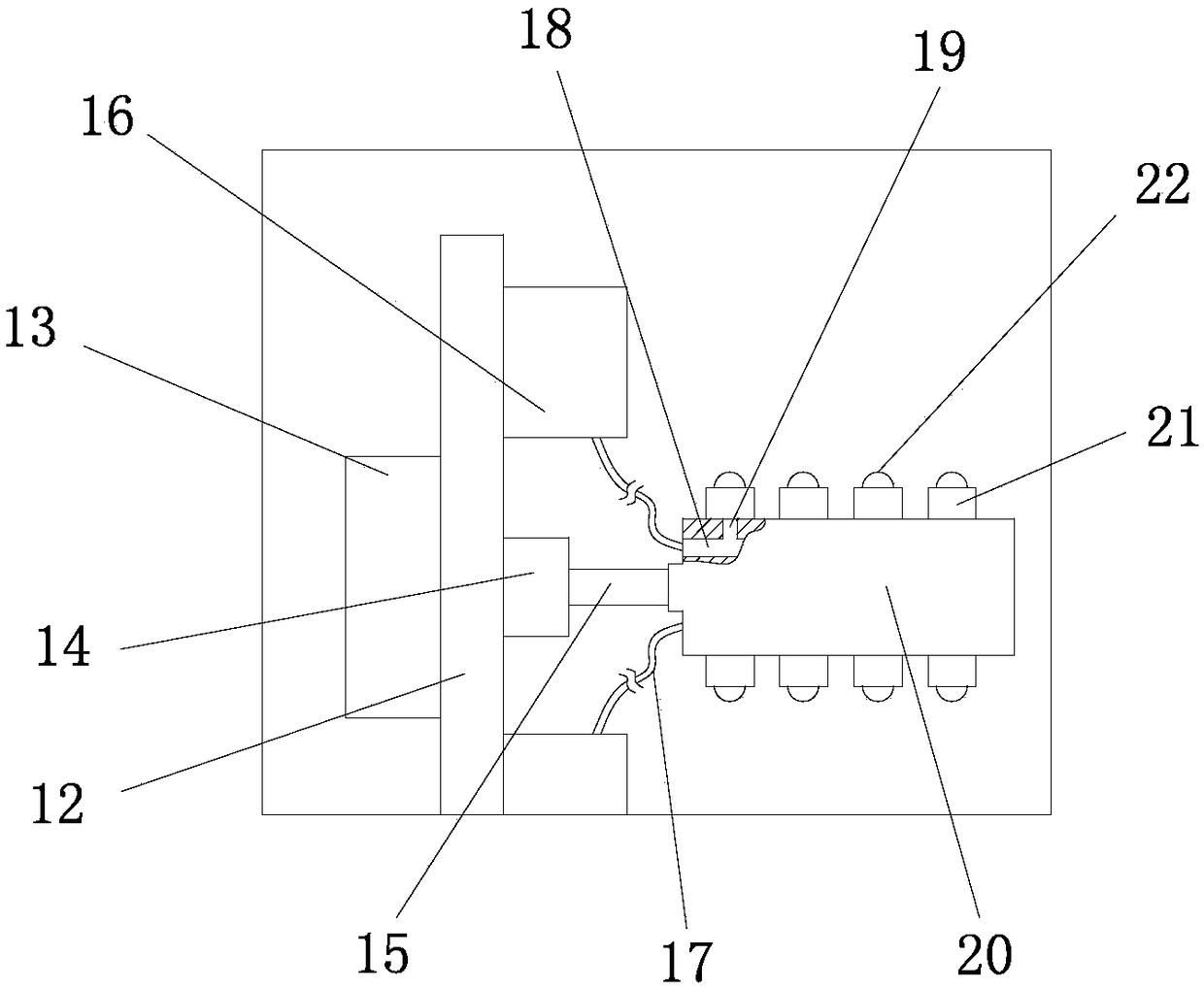

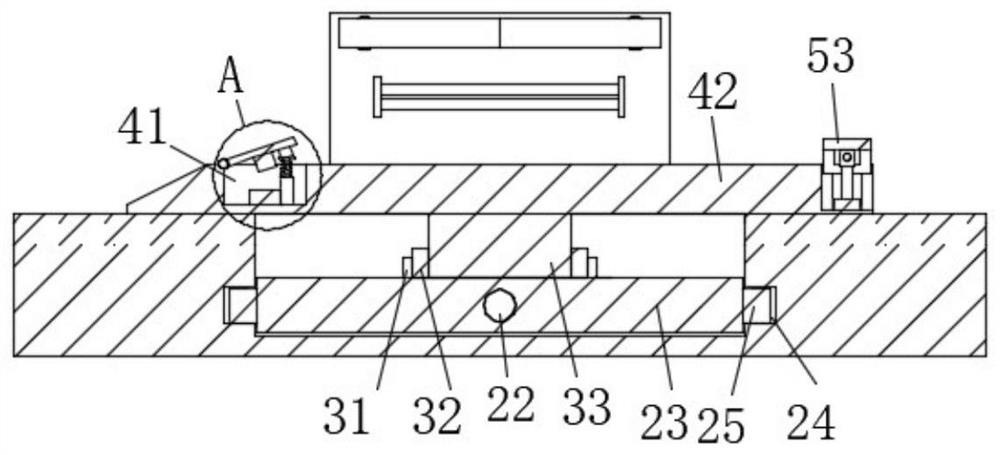

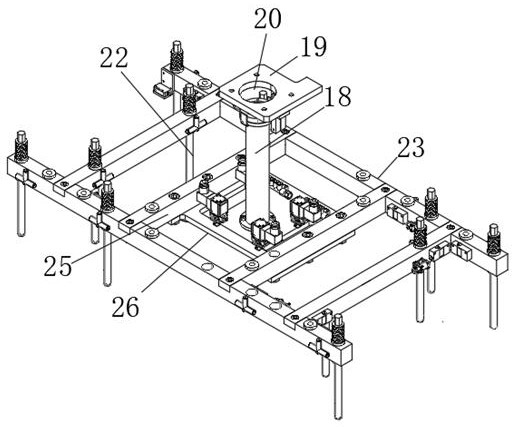

PCR microfluidic temperature control device

PendingCN113832023AAchieving tightnessFast heating and cooling rateBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlMicrofluidics

The invention discloses a PCR microfluidic temperature control device. The PCR microfluidic temperature control device comprises a machine body, a heating assembly and a lifting assembly, wherein the machine body is provided with a mounting space, the heating assembly comprises a heating table and a pressing plate, the pressing plate and the heating table are movably arranged in the mounting space and are oppositely arranged, the heating table is used for containing and heating reagent cards, and the lifting assembly is connected with the heating table and / or the pressing plate to drive the heating table and / or the pressing plate, so that the heating table and the pressing plate get close to each other or get away from each other to press or release the reagent cards. The invention aims to provide the PCR microfluidic temperature control device which is low in heat loss, high in heating and cooling speed and simple in structure, and the PCR microfluidic temperature control device effectively reduces the heat loss, realizes the attaching degree of the amplification area of a reagent disc and a heat conducting plate, and improves the heating and cooling speed of the reagent disc.

Owner:ZYBIO INC

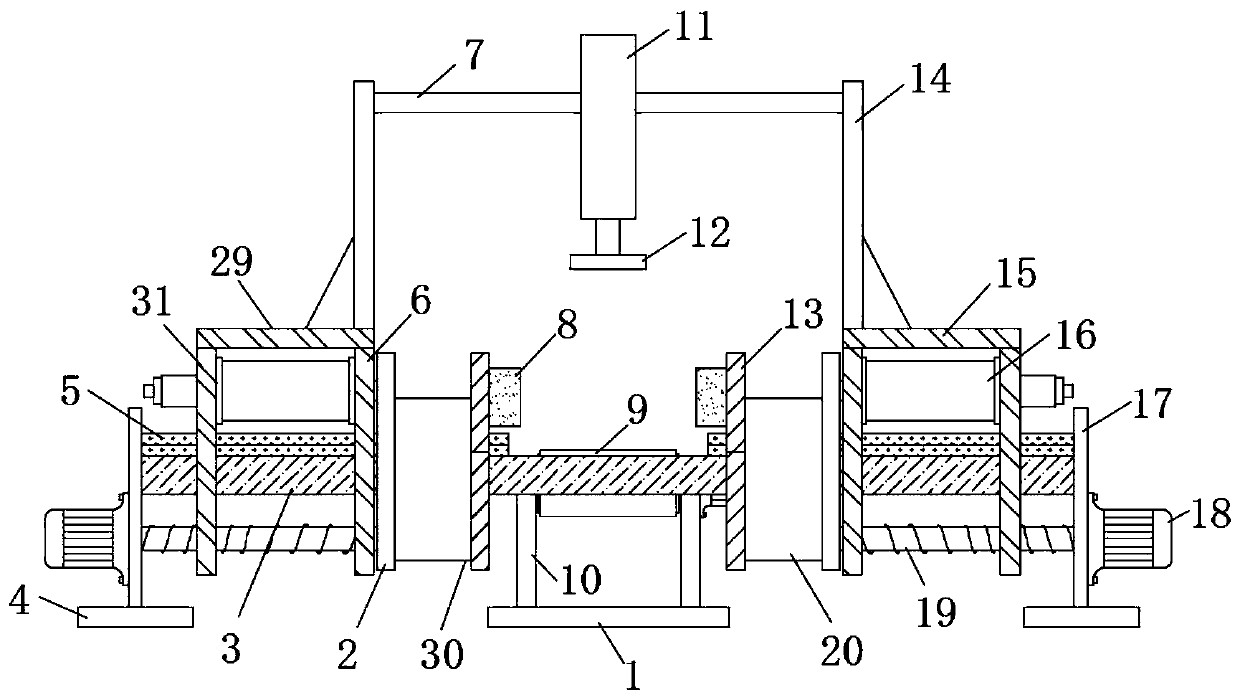

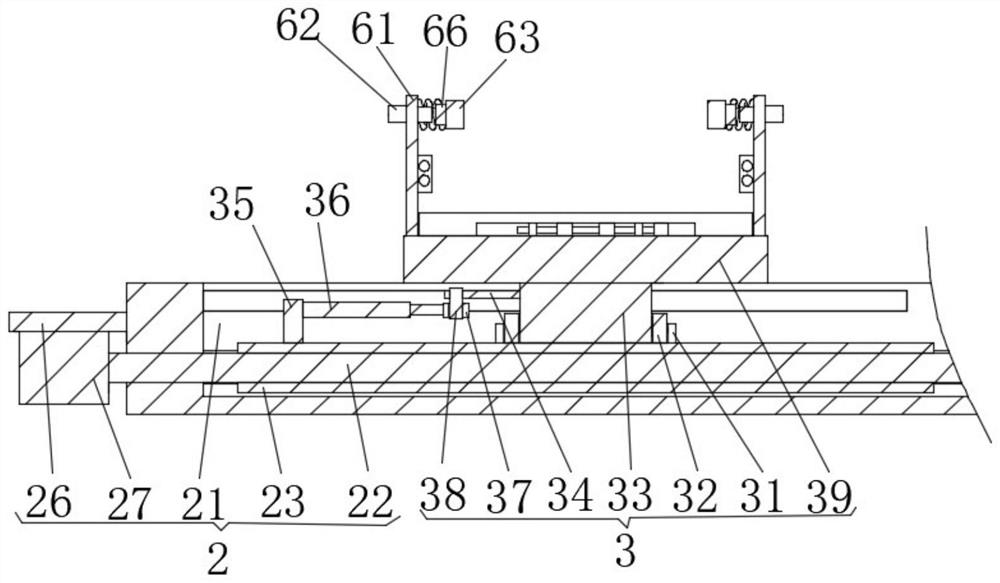

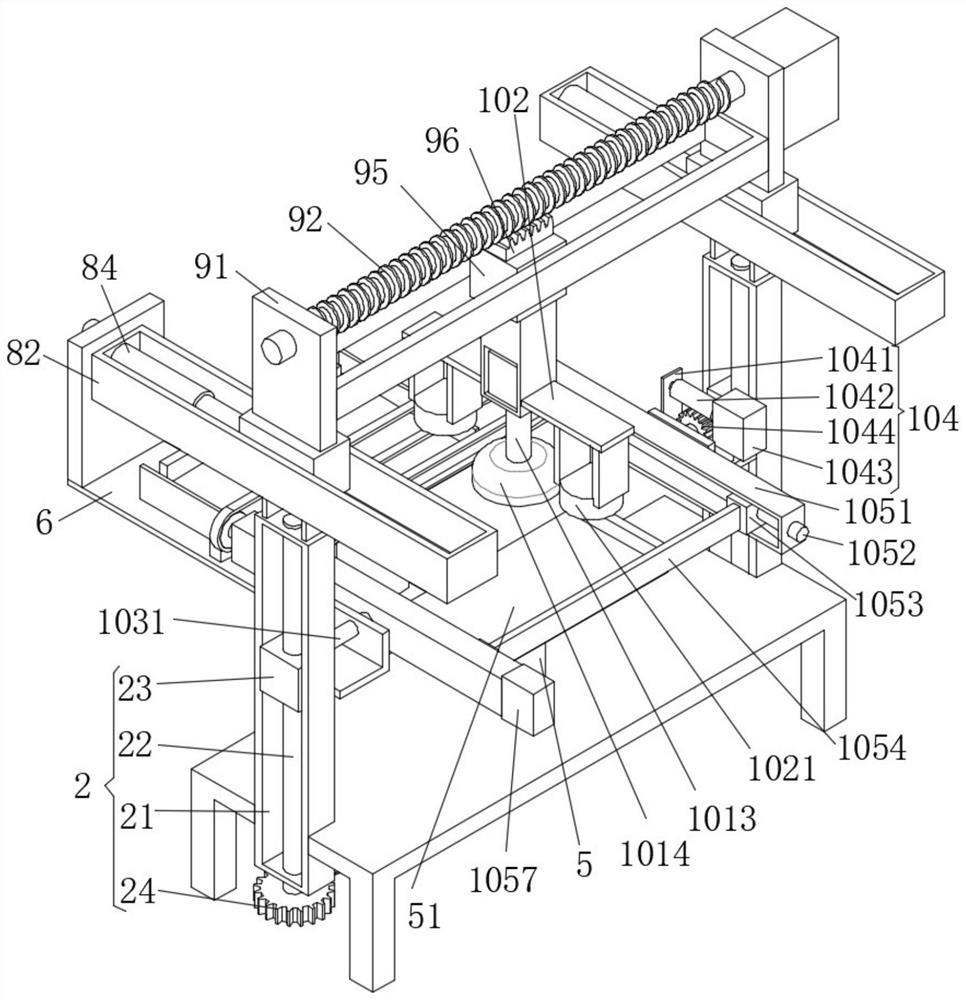

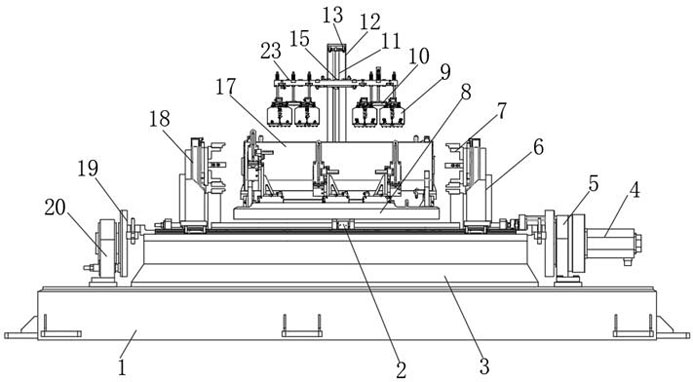

An automatic control processing device for large-scale new energy auto parts with high thermal conductivity radiator

ActiveCN109986337BFully automatedIncrease productivityVehicle componentsMetal working apparatusAutomatic controlNew energy

The invention discloses an automatic control processing device for a large profile new energy automobile part high heat conduction radiator. The automatic control processing device comprises two firstsupporting seats which are symmetrically arranged, two second supporting seats which are symmetrically arranged and two mounting frames which are symmetrically arranged, wherein a connecting line between the two first supporting seats is perpendicular to a connecting line between the two second supporting seats, two first supporting frames are symmetrically and fixedly connected to each first supporting seat, a first motor is arranged on the side wall of one of the first supporting frames, a transmission roller is rotatably connected between the two first supporting frames at corresponding positions, and a conveyor belt is jointly arranged on the two transmission rollers in a sleeving mode. The automatic control processing device has the advantages that the structure is ingenious, the automation of press fitting of a main board of the new energy automobile part high heat conduction radiator is realized, and the working efficiency is improved, so that the press fitting quality of the main board is ensured; and meanwhile, the production cost of the new energy automobile part high heat conduction radiator is reduced by controlling the labor cost, and the profit space is expanded.

Owner:诸暨市旺润针织厂

Intelligent building garage management auxiliary assembly

ActiveCN112459578AAchieve teleportationRealize linear slidingAnti-collision systemsParkingsConstruction engineeringElectric machinery

The invention discloses an intelligent building garage management auxiliary assembly which comprises a base, a conveying assembly and a steering assembly. A garage is arranged on one side of the surface of the base, and an anti-theft assembly is arranged on the garage. The conveying assembly comprises conveying grooves, screw rods, conveying bases, guide grooves, guide plates, a fixing plate and afirst motor, the conveying grooves are formed in the surface of the base and correspond to the garage, the screw rods are rotatably connected to the middles of the conveying grooves, the conveying bases are in threaded connection to the screw rods through threaded holes in the middles, and the two guide grooves are symmetrically formed. The two guide grooves are formed in the two opposite side faces of the conveying groove respectively, the guide plates are connected into the guide grooves in a sliding mode, the two sides of the conveying base are fixedly connected with the guide plates on the two sides respectively, and the fixing plate is fixedly connected to the side face of the base. The time required for parking is effectively saved, and the practicability is high.

Owner:上海基通建设工程有限公司

Paper holding device

Owner:王翔

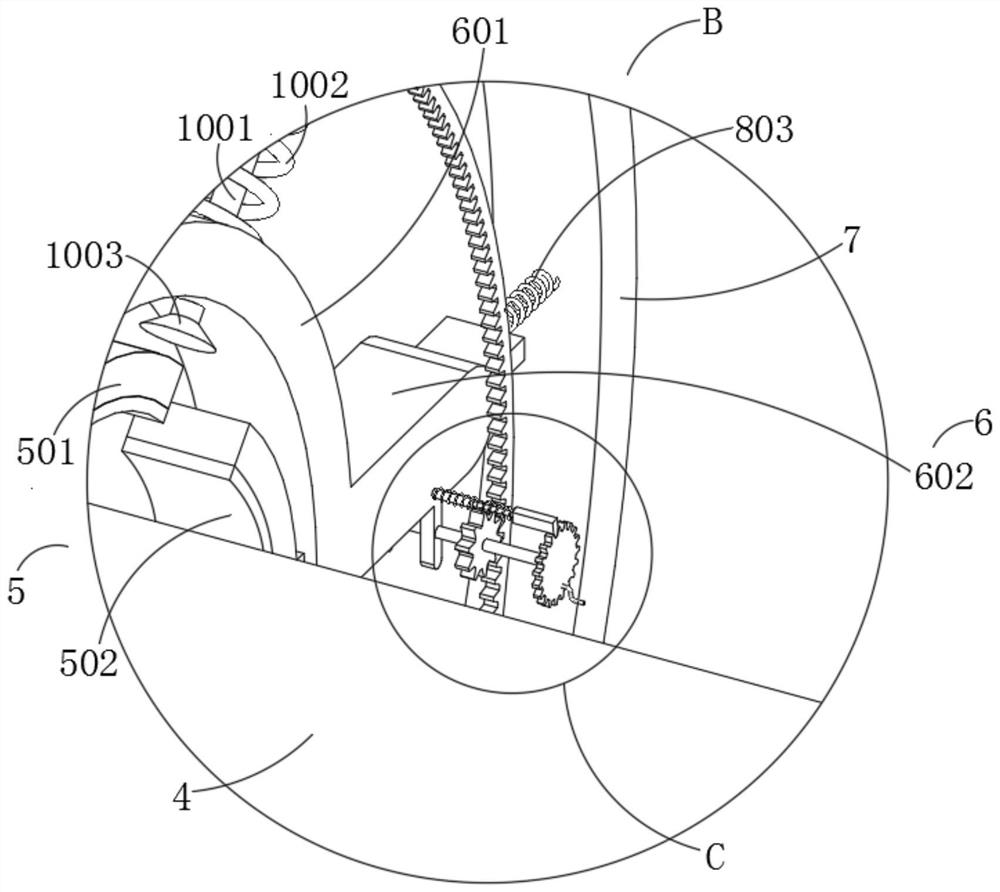

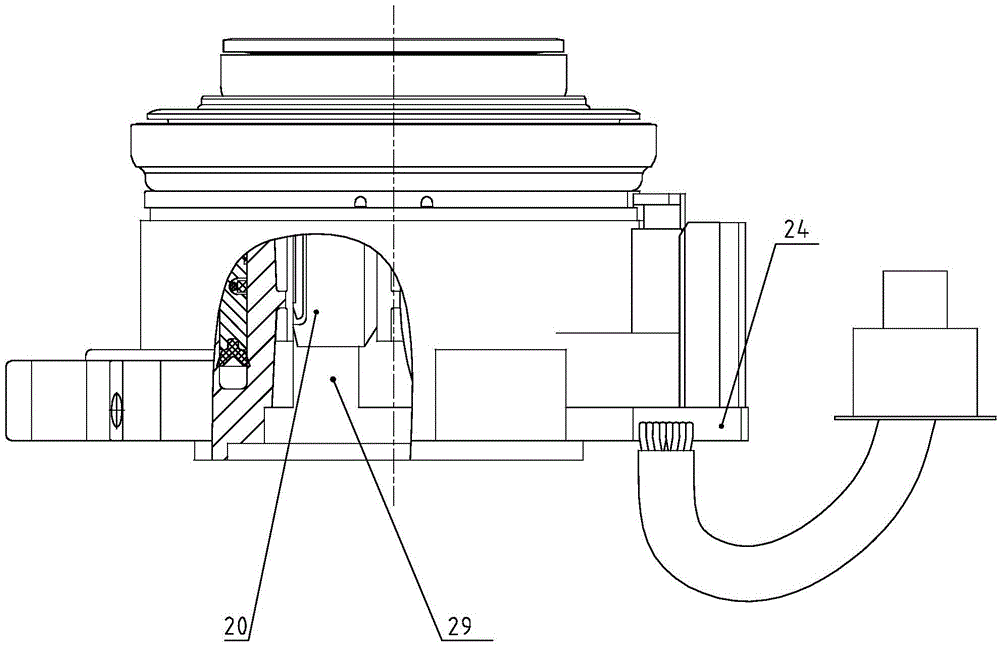

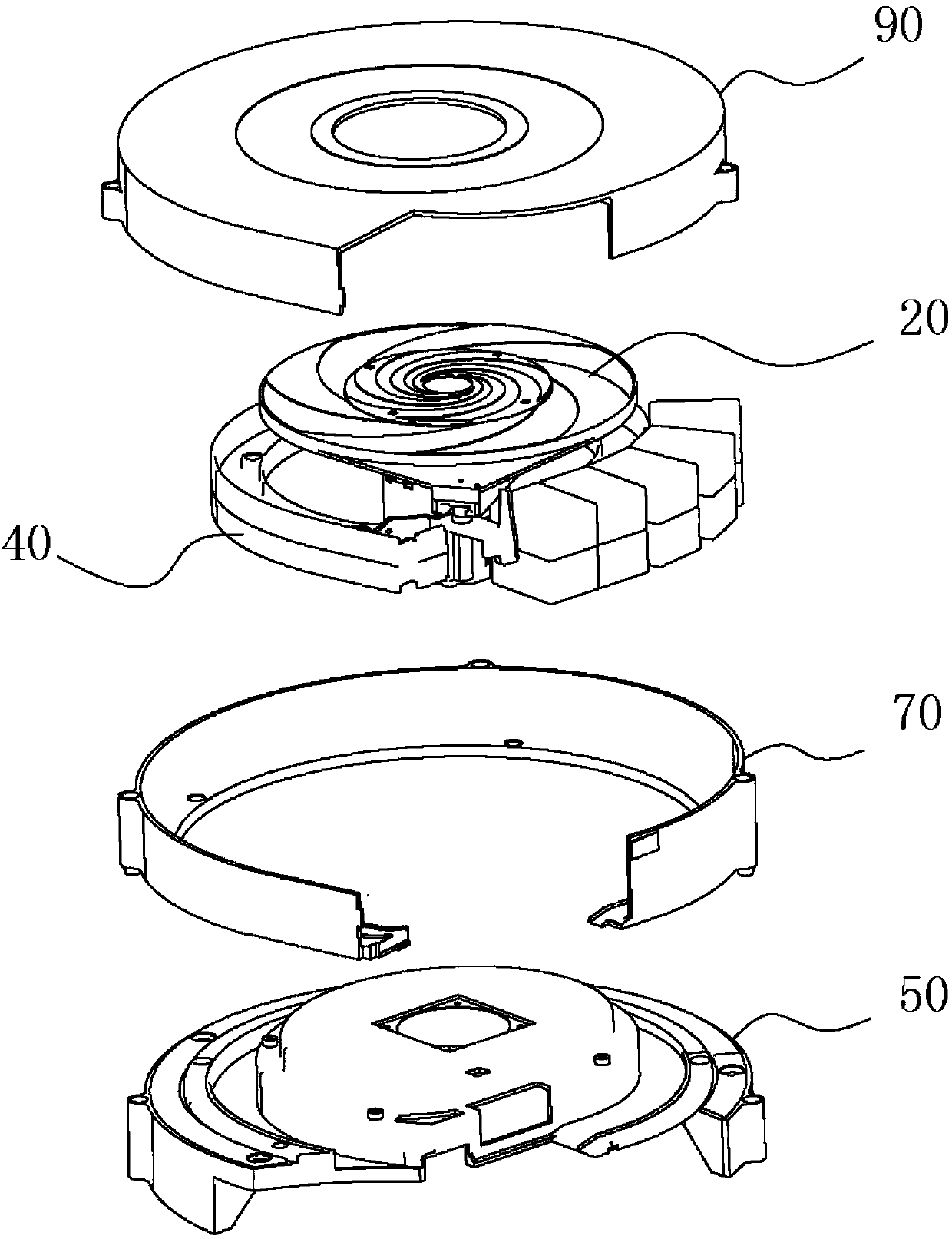

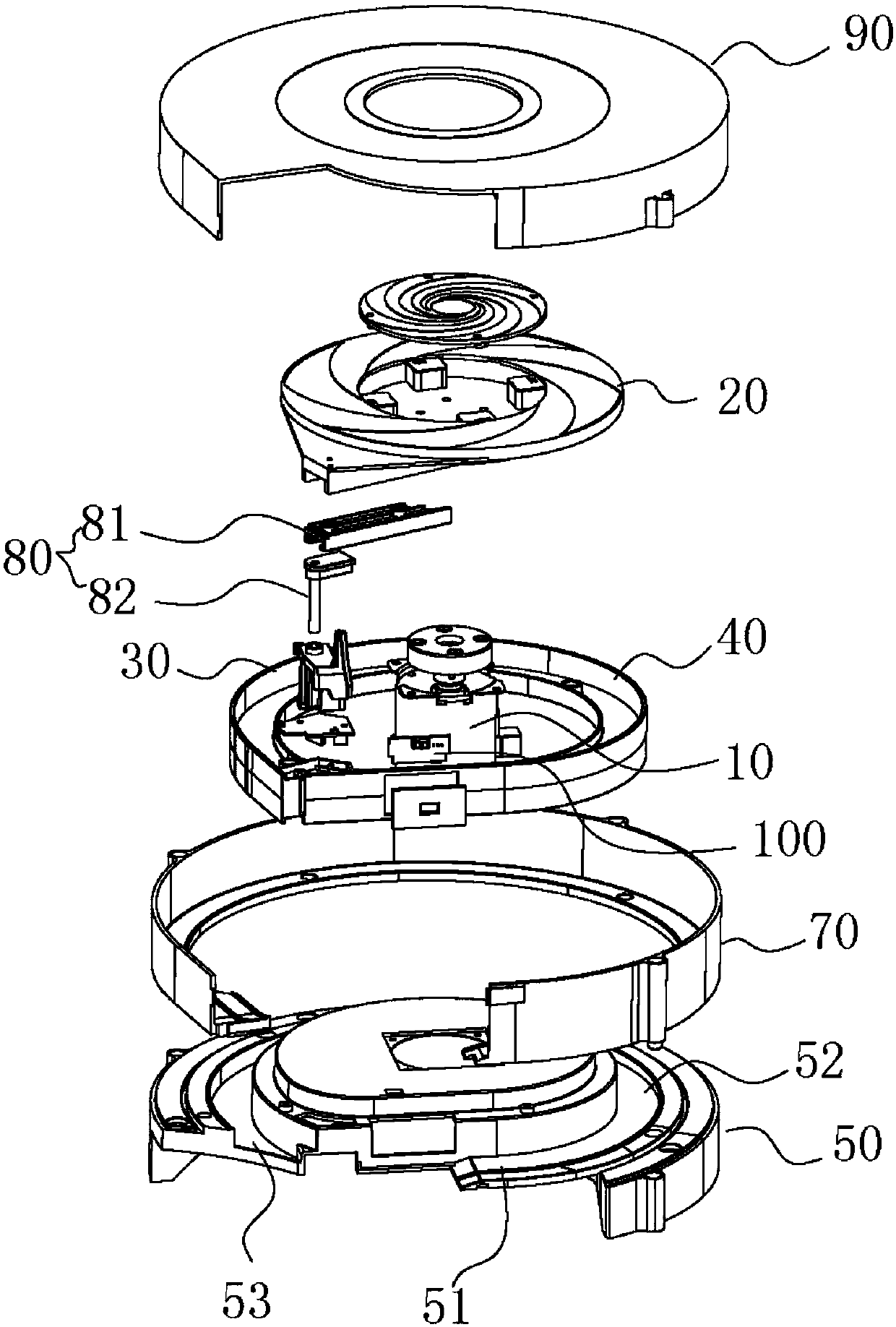

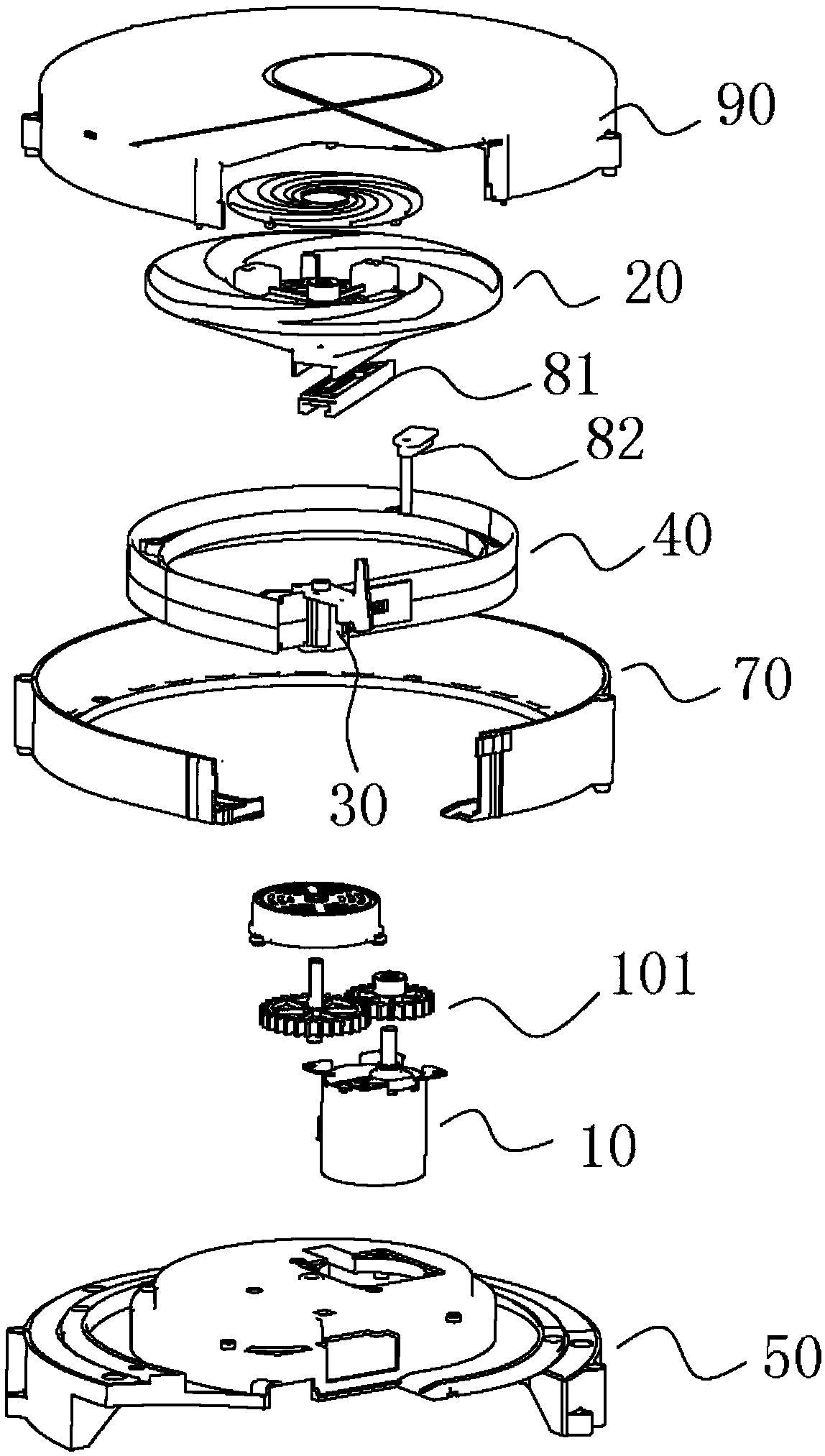

Tile pushing groove and annular tile pushing device of mahjong machine and automatic mahjong machine

The invention discloses a tile pushing groove and an annular tile pushing device of a mahjong machine and an automatic mahjong machine, and belongs to the technical field of mahjong machines. The problems that an existing mahjong machine is large in size, complex in structure and the like are solved. The tile pushing groove of the mahjong machine comprises a base, an annular upright baffle and anannular tile stopping side plate, the annular upright baffle and the annular tile stopping side plate are arranged on the base, the annular tile stopping side plate is located at the periphery of theannular upright baffle. The bending angle of the annular upright baffle is larger than 180 degrees. Due to the designed tile pushing groove, the tile storage amount is increased, more mahjong tiles can be contained inside the tile pushing groove, the mahjong tiles in the tile pushing groove are arranged in an arc shape, and more space is saved compared with the prior art that mahjong tiles are arranged in straight rows.

Owner:MATSUOTA MECHANICAL & ELECTRICAL CHINA CO LTD

Cleaning machine capable of quickly and thoroughly cleaning glass fiber reinforced plastics in all directions

InactiveCN112657955AAchieve cleaningAchieve rotationHollow article cleaningDrying gas arrangementsGlass fiberStructural engineering

The invention discloses a cleaning machine capable of quickly and thoroughly cleaning glass fiber reinforced plastics in all directions. The cleaning machine comprises a bottom plate, a lifting assembly and a brushing assembly, wherein telescopic rods are fixedly connected to the four right angles of the surface of the bottom plate; a stand is fixedly connected to the top ends of the telescopic rods; an adjusting assembly and a liquid supply assembly are arranged on the stand; an opening and closing assembly is arranged on the adjusting assembly; a sliding assembly and a drying assembly are arranged on the opening and closing assembly; the lifting assembly comprises connecting bases, pin shafts, connecting rods, mounting bases, limiting pins, a first bidirectional screw, a rotary disc and a handle; the two connecting bases are correspondingly arranged and are respectively and fixedly connected to the middles of the opposite surfaces of the stand and the bottom plate; and the two pin shafts are symmetrically arranged and penetrate through the two sides of the connecting bases respectively. The cleaning machine capable of quickly and thoroughly cleaning glass fiber reinforced plastics in all directions can clean glass fiber reinforced plastic pipes comprehensively; cleaning is more thorough and comprehensive; cleaning efficiency is improved; quick drying can be achieved; and practicability is relatively high.

Owner:杭州轩旷科技有限公司

A method of using an aluminum-plastic plate grinding equipment with a positioning mechanism

ActiveCN112338668BAchieve clamping positioningClose to each otherGrinding carriagesGrinding drivesElectric machineryScrew thread

Owner:浙江吉尔泰机械股份有限公司

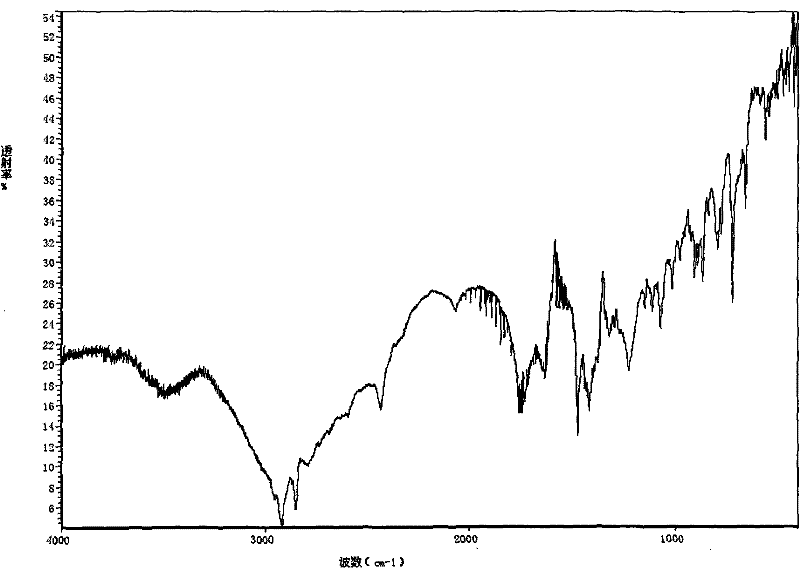

Gemini ampholytic surfactant with flexible linking group and preparation method thereof

InactiveCN101564661BReduce electrostatic repulsionClose to each otherTransportation and packagingMixingAliphatic amineCarboxylic acid

The invention discloses a novel gemini ampholytic surfactant with flexible linking group, which is a novel emini ampholytic surfactant using aether dihalide as a linking group and has a chemical name of N,N'-dialkyl-N,N'-dicarboxy-3-oxa-1,5-pentamethylene diamine. The surfactant obtains an intermediate product N,N'-dialkyl-3-oxa-1,5-pentamethylene diamine through reaction of the aether dihalide and primary aliphatic amine; and the intermediate product performs a condensation reaction with halogenated carboxylic acid to obtain the final product. The surfactant aqueous solution has low surface tension, has excellent performance in foam forming and foam stabilization, has good compound performance with a non-ionic surfactant and simple synthesis process, and is expected to be popularized andused.

Owner:NANJING TECH UNIV

Construction vehicle axle tube processing integrated equipment

ActiveCN112247468ATwist to achieveSimple structureWelding/cutting auxillary devicesAuxillary welding devicesElectric machinerySteel tube

The invention discloses construction vehicle axle tube processing integrated equipment. The construction vehicle axle tube processing integrated equipment comprises a platform, wherein a bearing mounting base is welded on the upper surface of the platform; left and right sides of the upper surface of the platform are equipped with a bearing base I and a bearing mounting fixing base separately; thedrive end of the bearing base I is equipped with a motor I; a motor II is mounted on the outer wall of the bearing base I; one end of the bearing base I is equipped with a rotary rod; and a supporting platform is mounted on the outer wall of the rotary rod. According to the construction vehicle axle tube processing integrated equipment, a preset tube I is positioned on the outer wall of a steel tube, a welding hand is controlled to perform welding point fixation on a contact part of the steel tube and the preset tube I, and a cavity slide base is controlled to slide on a rail of a slide strip, so that left-right displacement of a nut butt-joint plate can be realized, and welding on different positions of the outer wall of the steel tube is convenient; and a limiting block mounted betweentwo groups of cavity slide bases is used for controlling a distance therebetween, so that the two groups of the cavity slide bases are prevented from getting close to cause uneven welding.

Owner:YANGLING VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com