Patents

Literature

34results about How to "Subsequent processing is smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

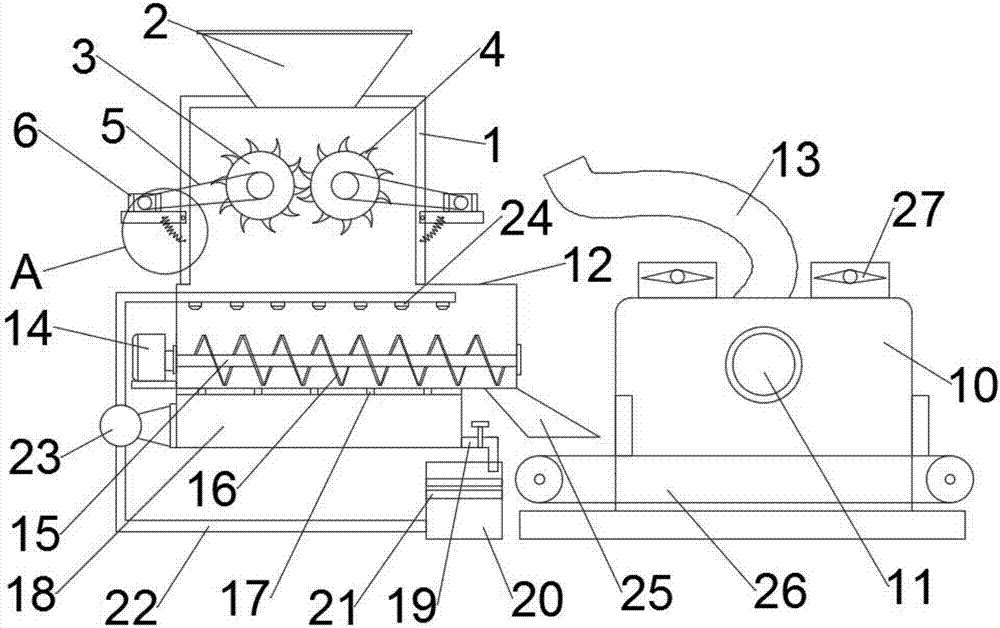

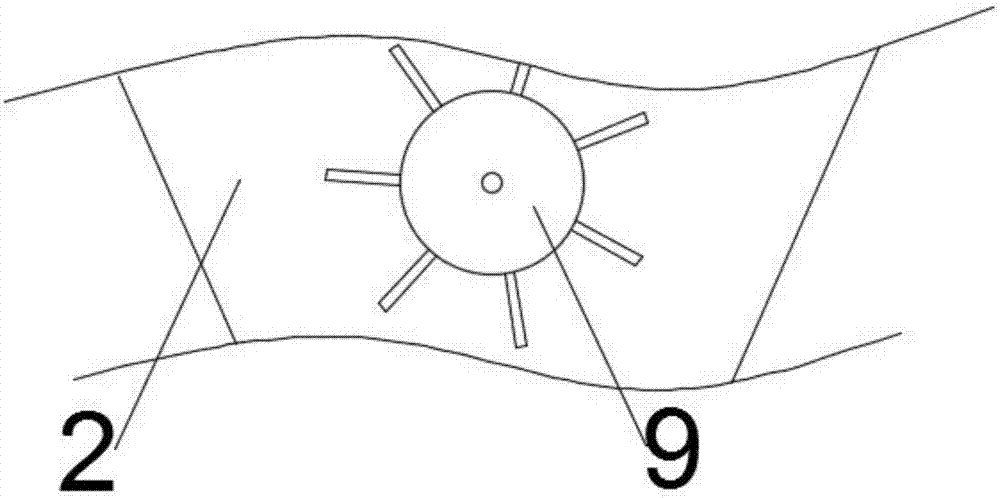

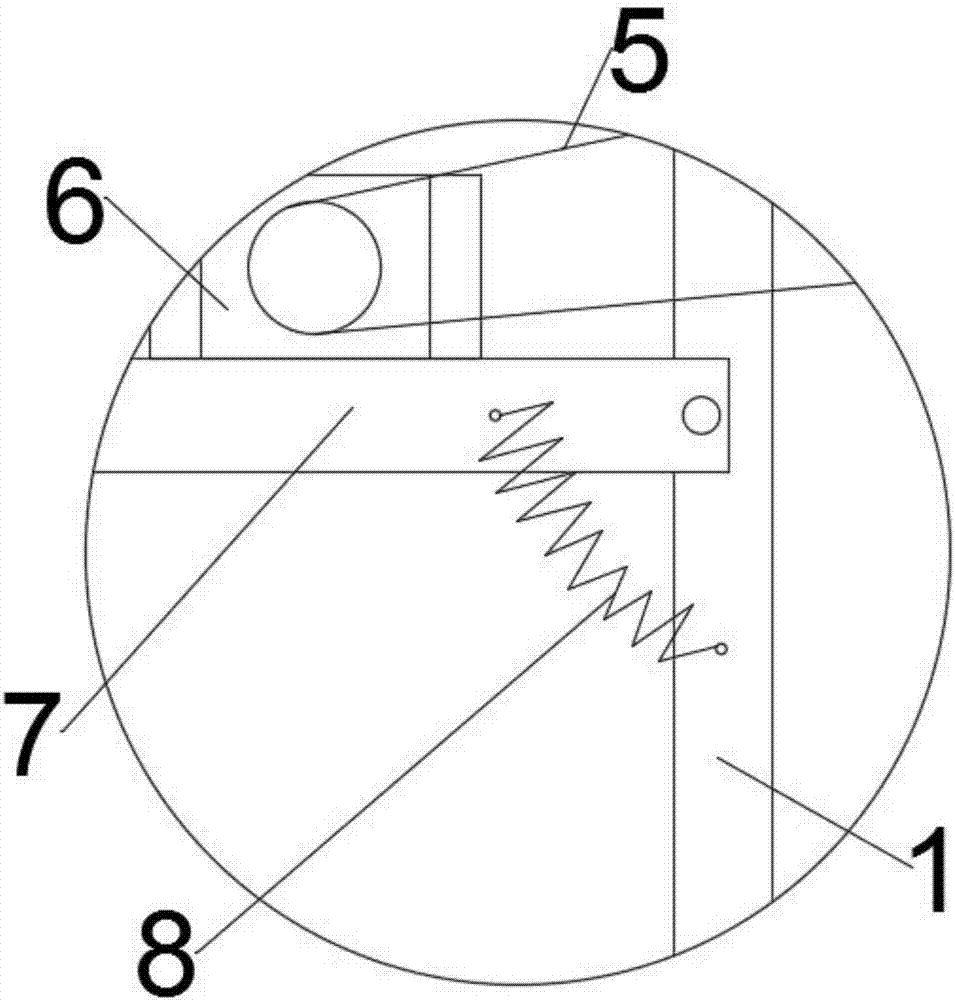

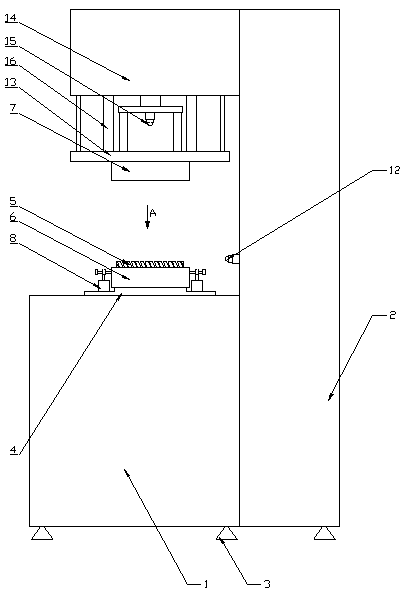

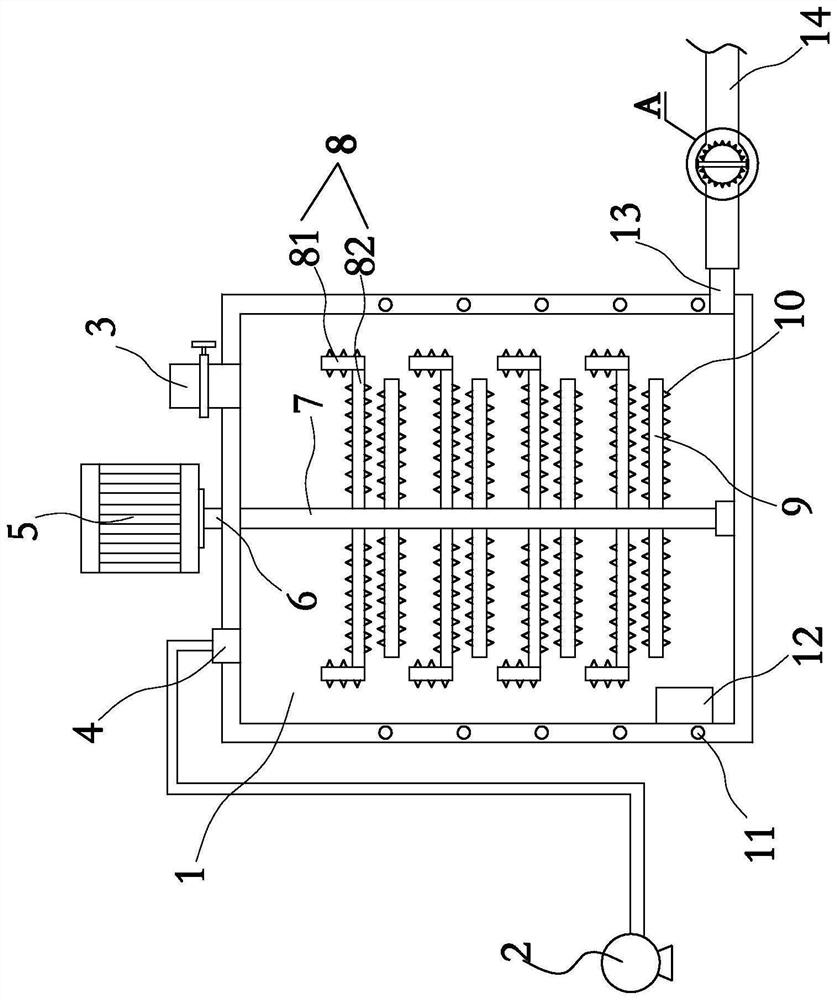

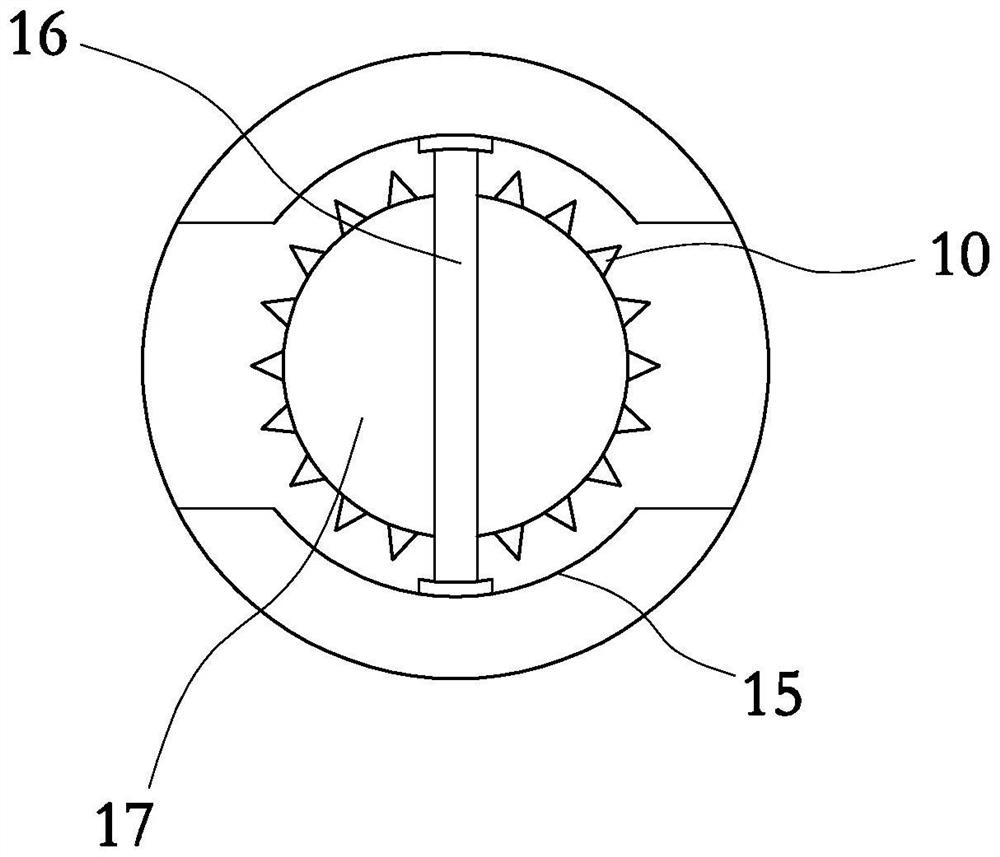

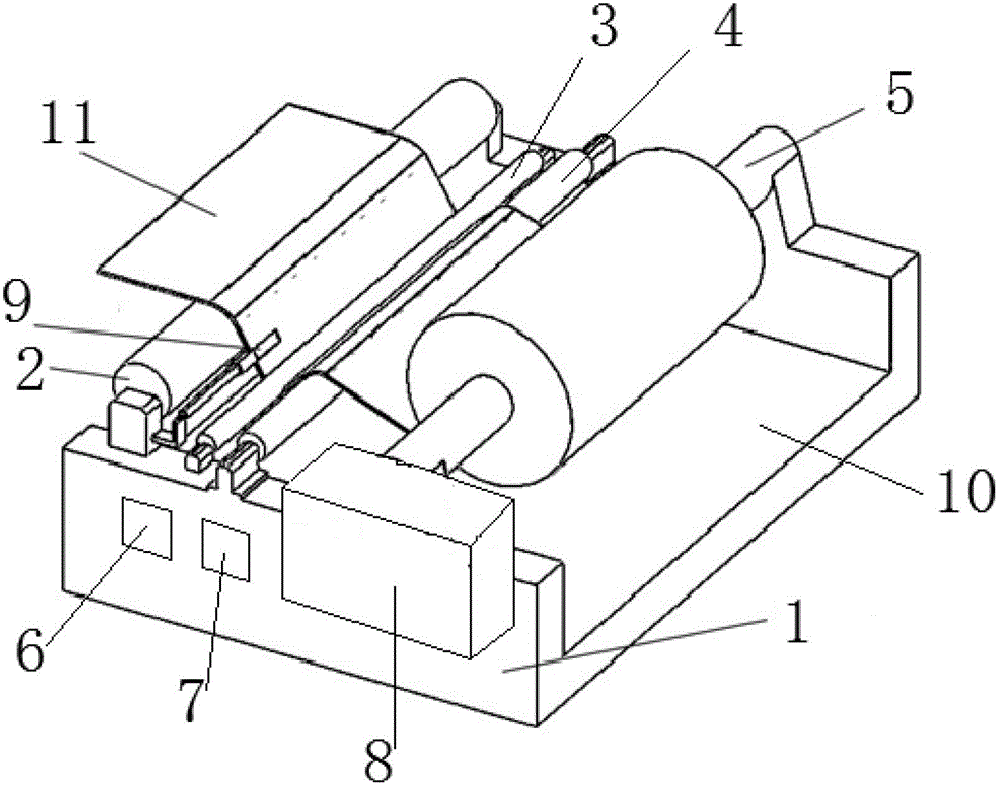

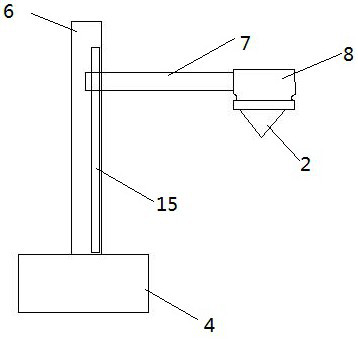

Continuous integrated waste plastic garbage crushing and cleaning treatment device

InactiveCN107116725ASmooth entryImprove cleanlinessPlastic recyclingMechanical material recoveryPull forceWater vapor

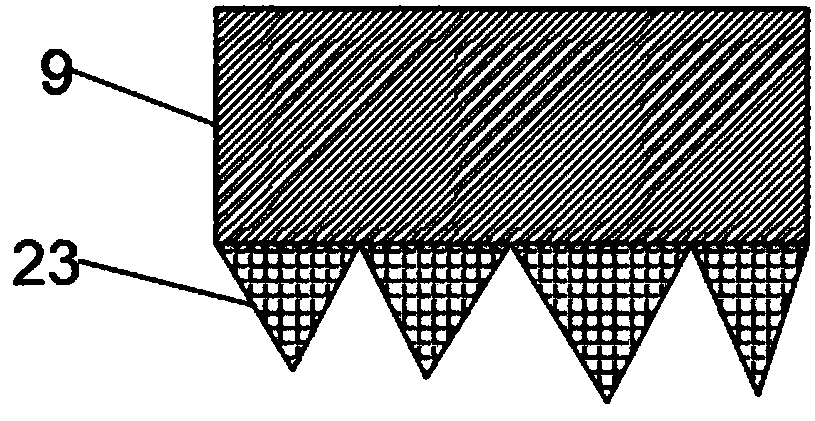

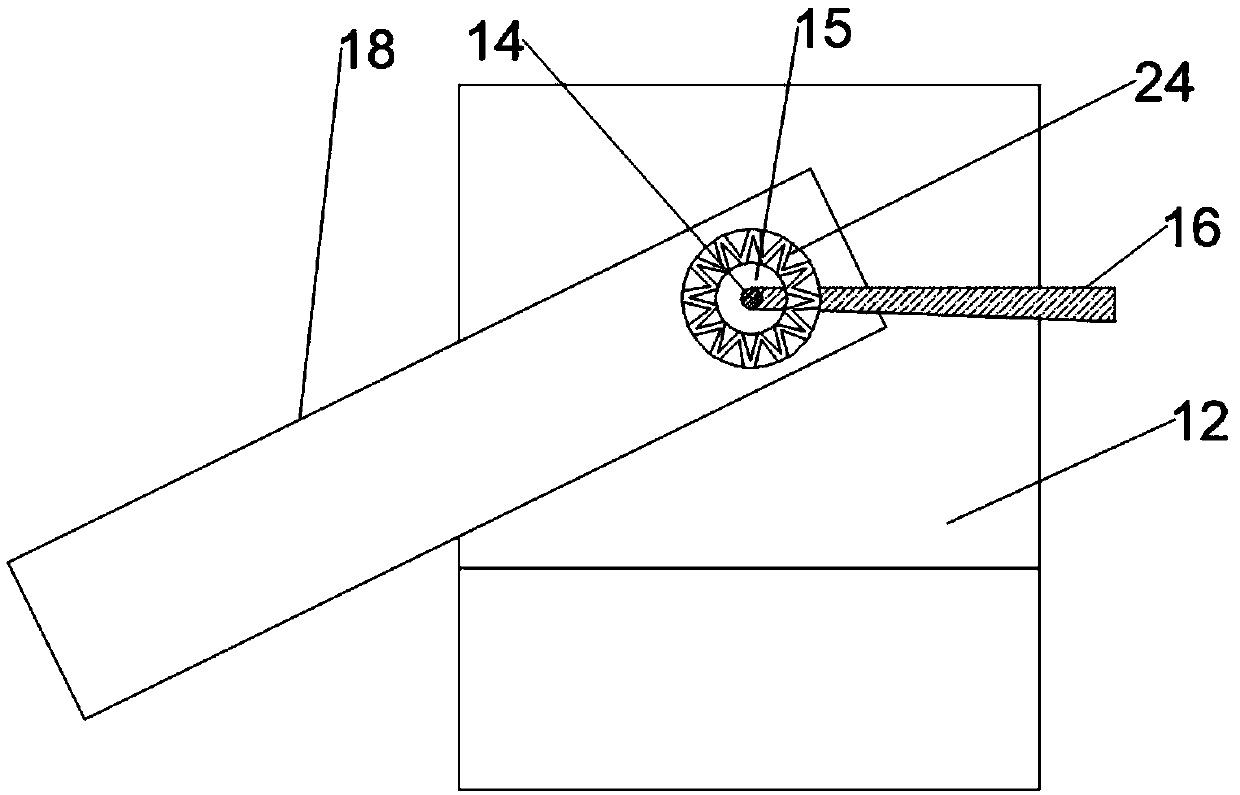

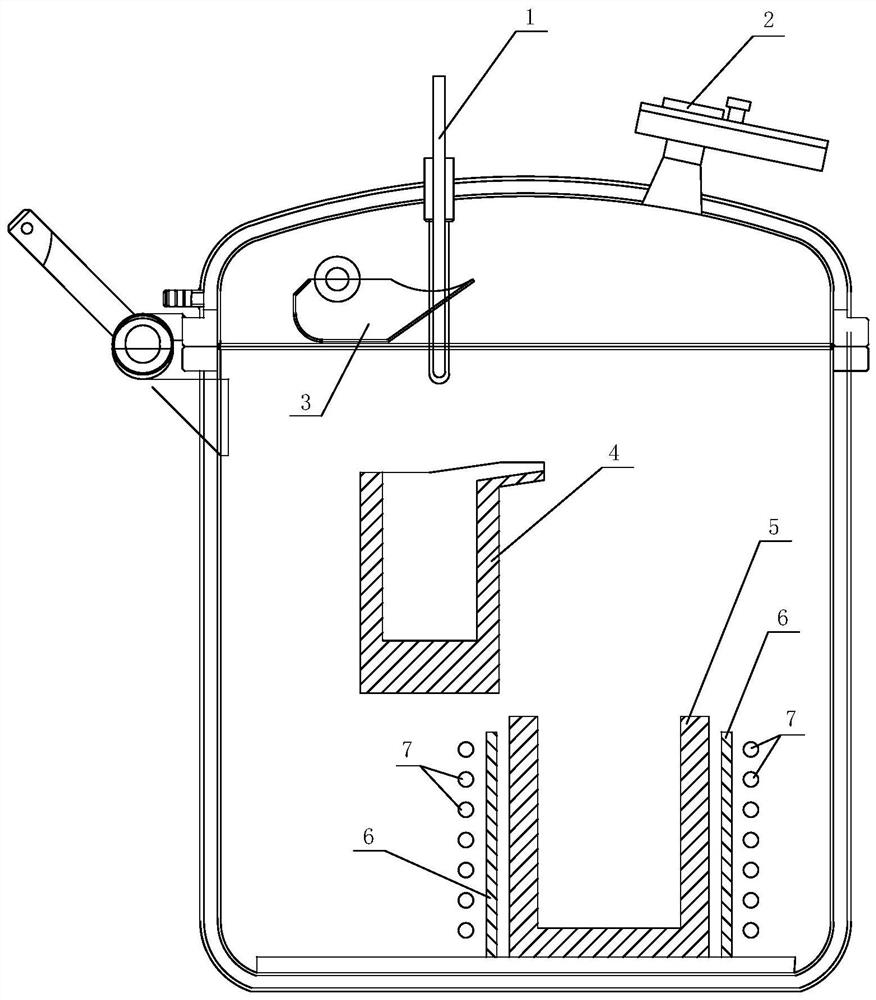

The invention discloses a continuous integrated waste plastic garbage crushing and cleaning treatment device. The device comprises a crushing machine body; a feed hopper is arranged at the top of the crushing machine body; a poking turntable is arranged in the feed hopper; a pair of rotating circular rollers is arranged in the middle position of an inner cavity of the crushing machine body in parallel; a movable support plate is hinged to the outer side wall, opposite to the rotating circular rollers, of the crushing machine body; a transmission motor is mounted above the movable support plate; an output shaft of the transmission motor is connected to center rotating shafts of the rotating circular rollers through transmission conveying belts; and the top position of a box body of a quick drying box communicates with a water vapor discharge pipe. The transmission motor enables the transmission conveying belts to always keep in a tensioned state through self weight and tension of a powerful tension spring; and dissipated water vapor is discharged through the water vapor discharge pipe, so that subsequent finished products are directly used in a dried state.

Owner:苏天平

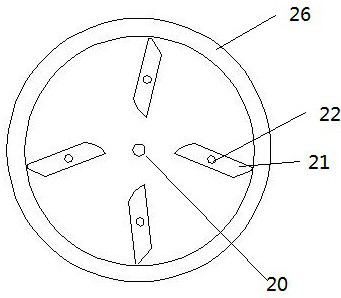

Lorry hydrodynamic retarder impeller machining method

ActiveCN106862489ARealize mass productionReduce manufacturing costFoundry mouldsFoundry coresImpellerWax

The invention relates to a lorry hydrodynamic retarder impeller machining method. The machining method comprises the steps of wax mold manufacturing, wax mold finishing, wax mold tree assembly, module cleaning, wax mold shell manufacturing, dewaxing, wax dewatering, wax recovery and molded shell roasting. The machining method has the following advantages: the machining method is realized through the steps of wax mold manufacturing, wax mold finishing, wax mold tree assembly, module cleaning, wax mold shell manufacturing, dewaxing, wax dewatering, wax recovery and molded shell roasting, can synchronously machine multiple wax molds through wax mold tree assembly to realize batch production, and can recycle wax through wax dewatering and wax recovery to reduce the production cost.

Owner:JIANGSU TANGCHEN AUTOMOBILE PARTS

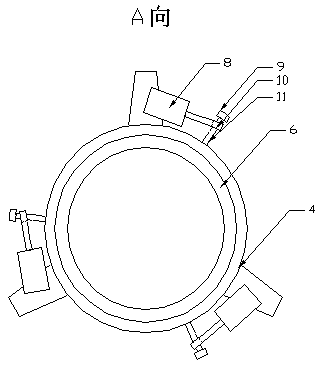

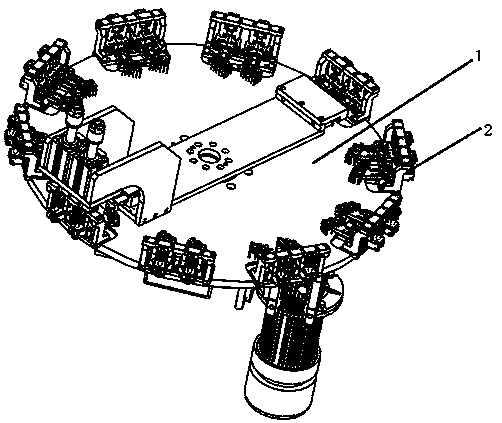

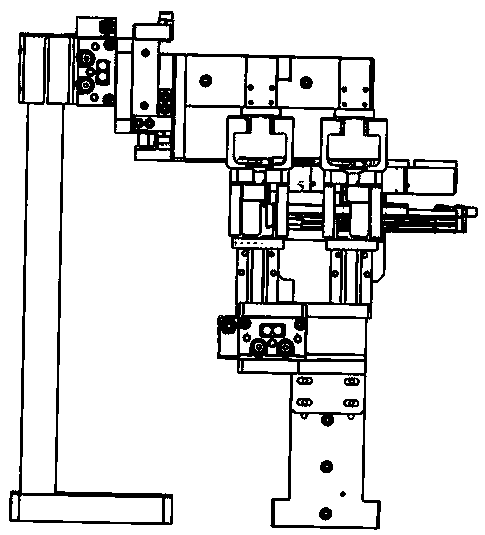

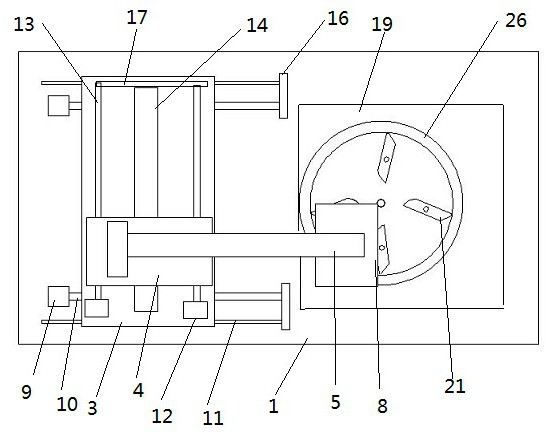

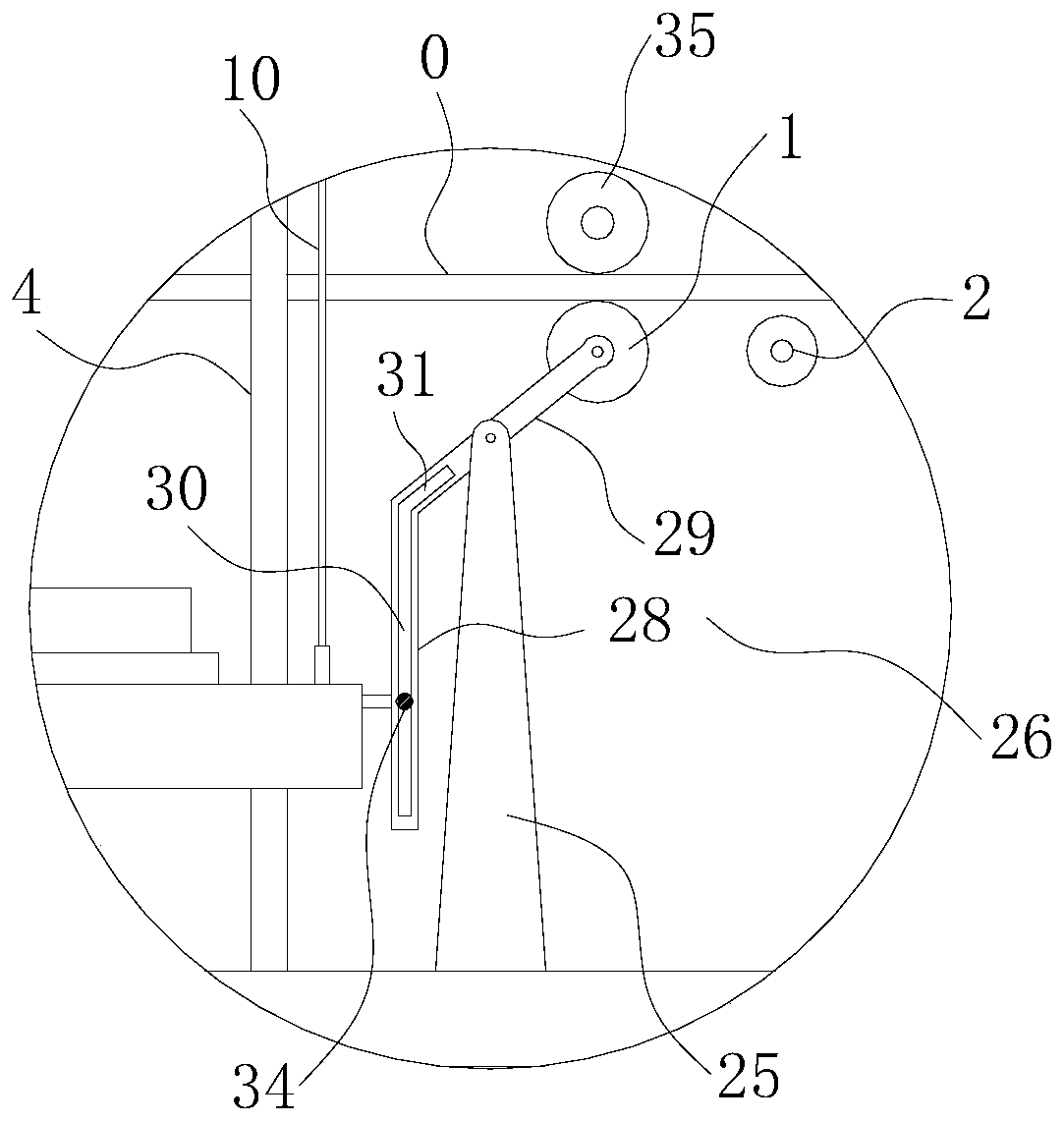

C-shaped clamp automatic assembling system

PendingCN109366118AImplement automatic assemblyReduce manual laborAssembly machinesMetal working apparatusBolt connectionC shaped

The invention relates to a C-shaped clamp automatic assembling system. The C-shaped clamp automatic assembling system comprises an assembling platform, wherein the assembling platform is disc-shaped,the assembling platform is driven by a rotary driving mechanism to rotate, a plurality of assembling seats are distributed on the assembling platform in parallel along the circumference direction of the assembling platform, a nut placement process, a gasket placement process, a C-shaped clamping frame placement process, a primary detection process, a bolt connection process, a secondary detectionprocess, a mesh pad placement process and a riveting pressure process are sequentially arranged on the outer side of the circumference of the assembling platform. The C-shaped clamp automatic assembling system has the advantages that the plurality of assembling seats, the nut placement process, the gasket placement process, the C-shaped clamp frame placement process, the primary detection process,the bolt connection process, the secondary detection process, the mesh pad placement process and the riveting and pressing process are coordinated, so that the automatic assembly of the C-shaped clamp is realized, the manual labor is reduced, and the working efficiency is improved.

Owner:江苏中伟业通讯设备有限公司

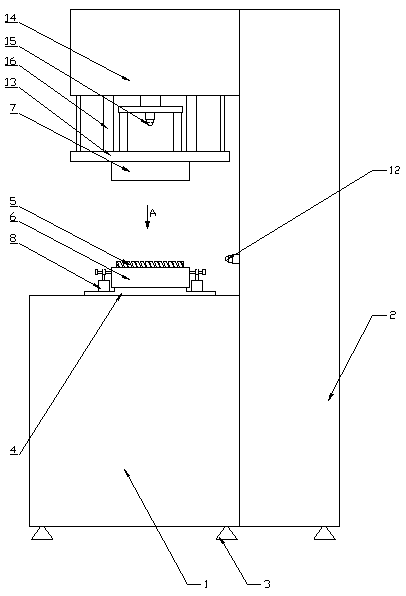

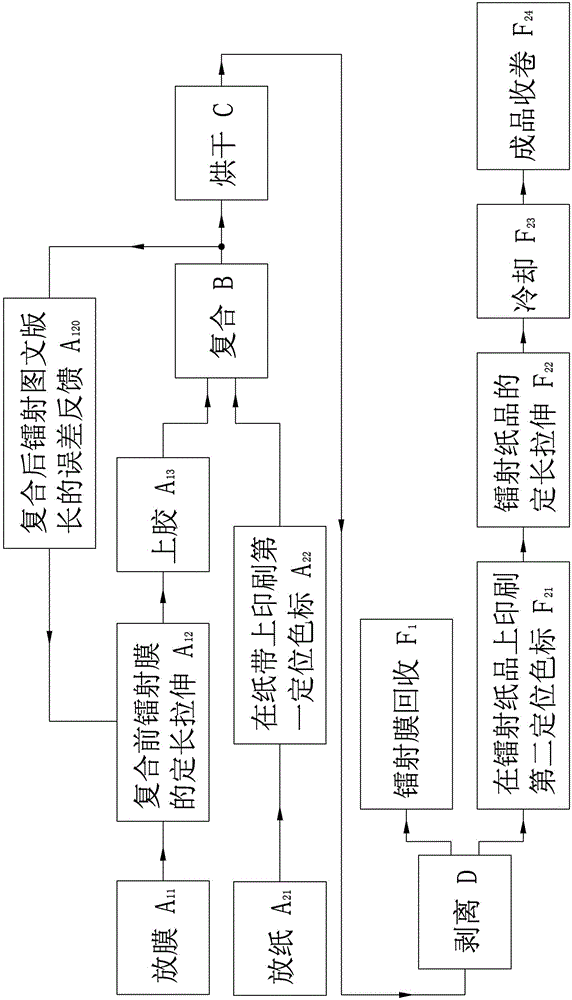

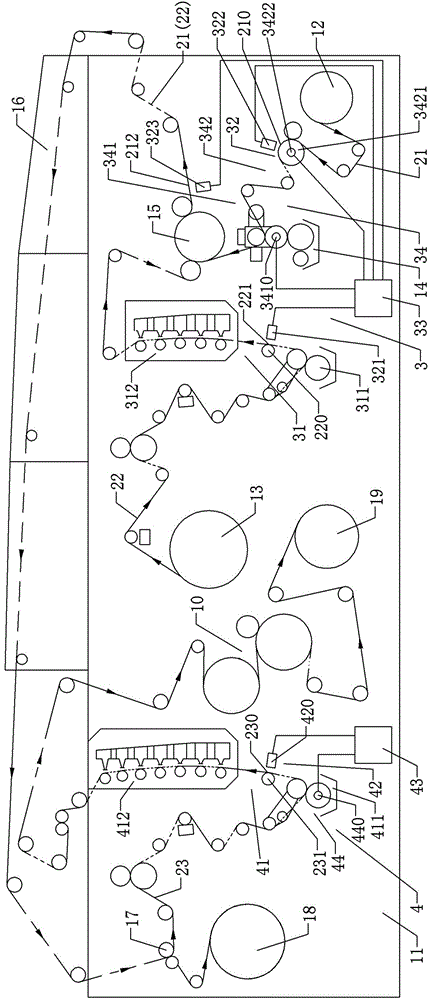

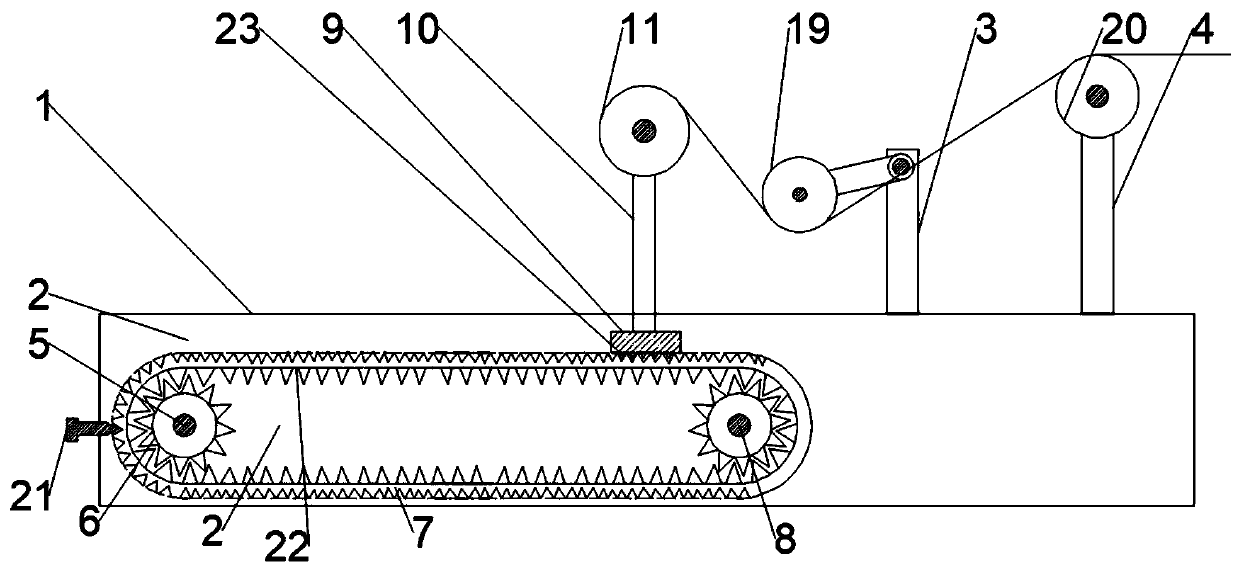

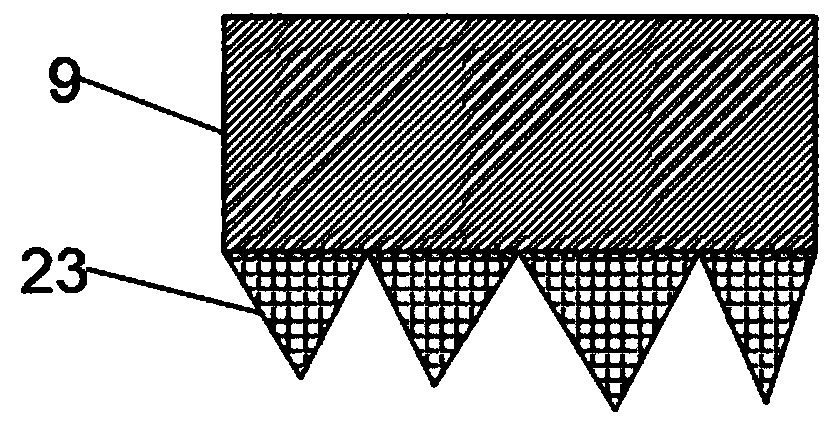

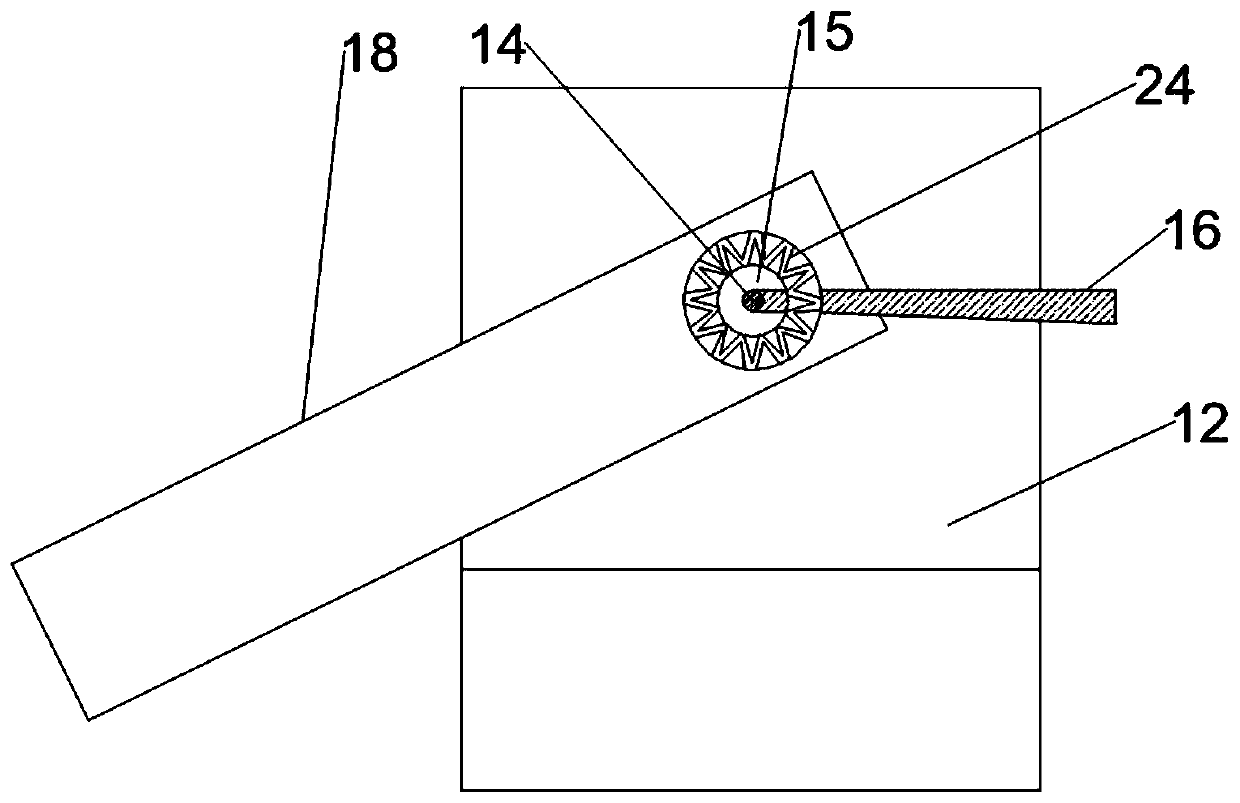

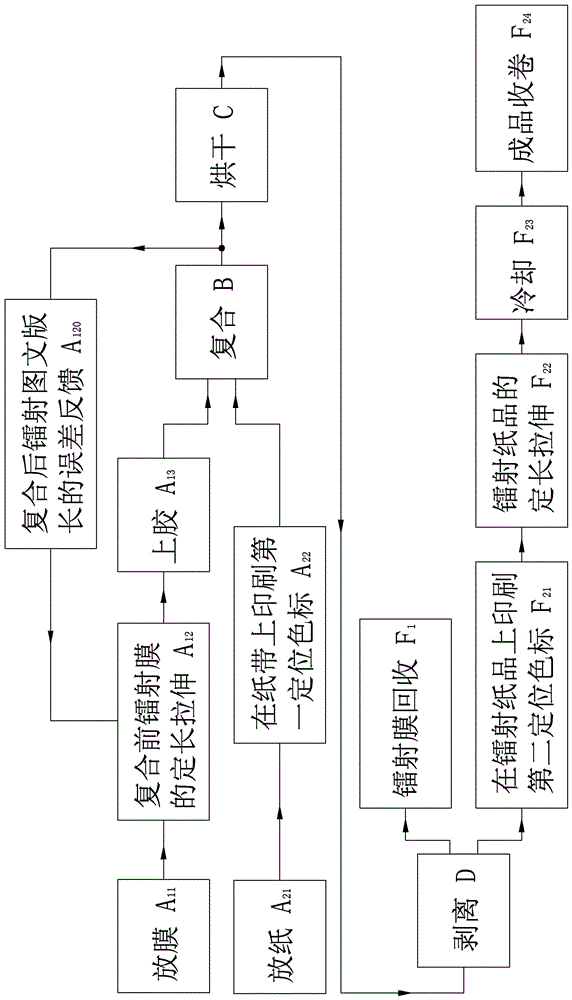

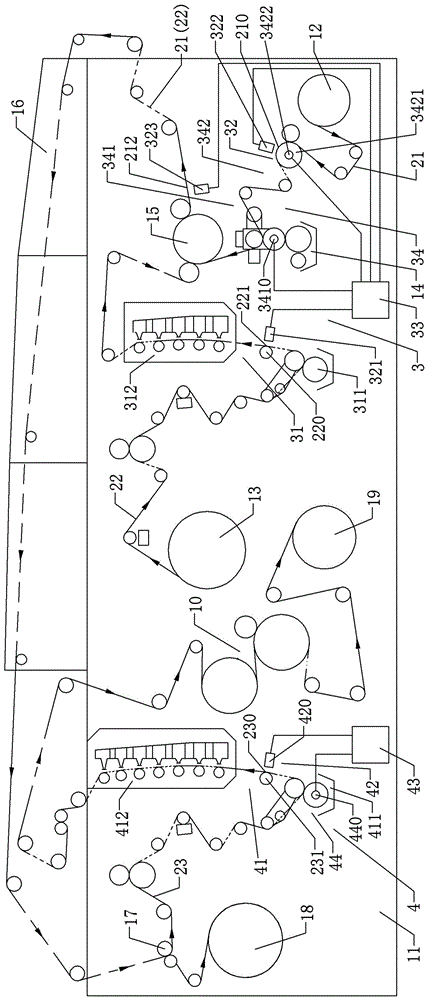

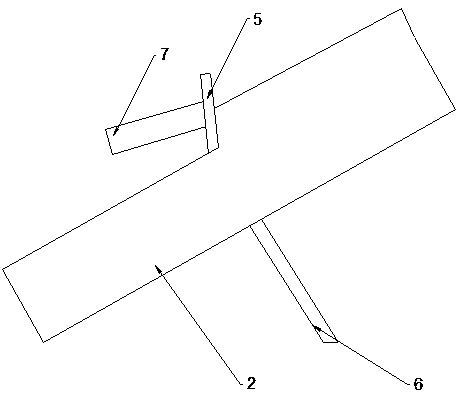

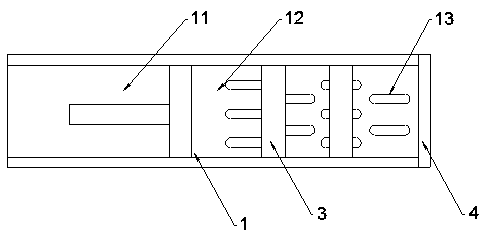

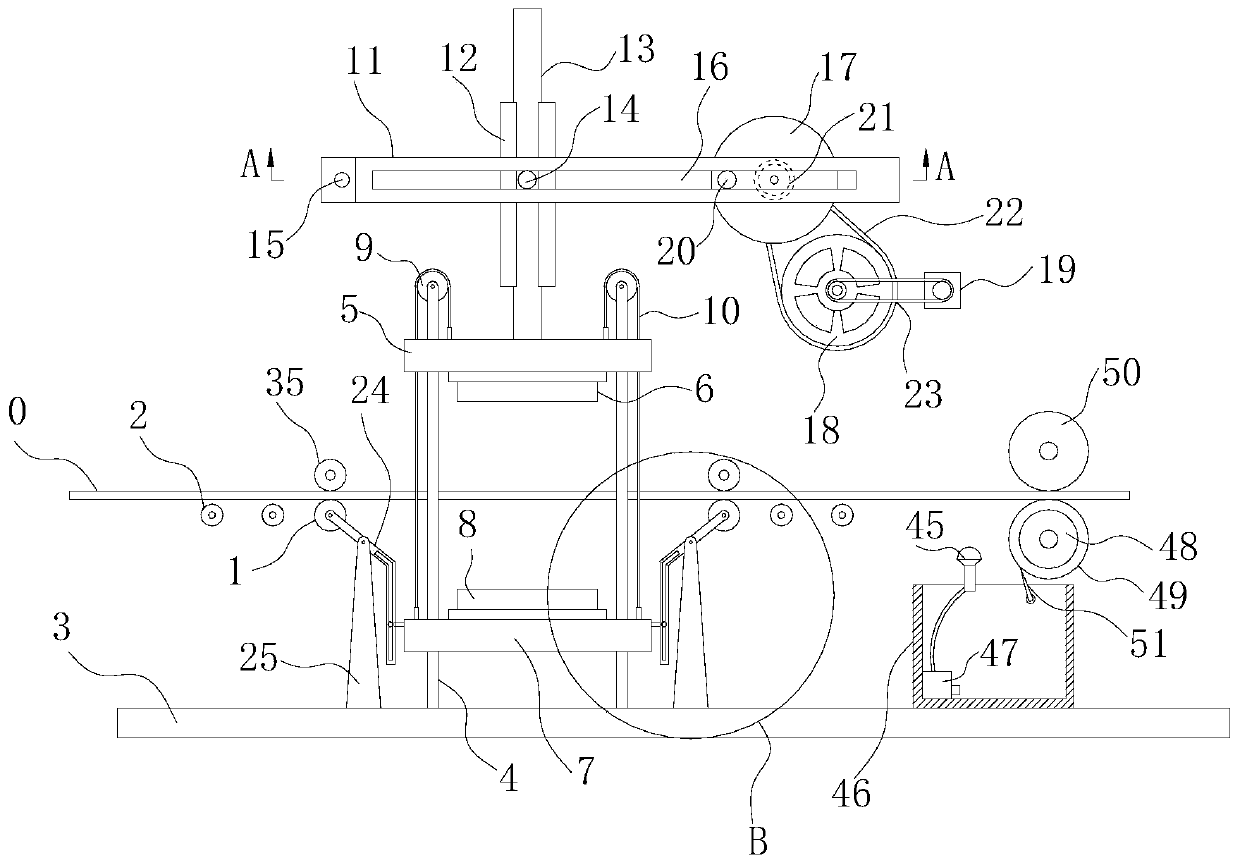

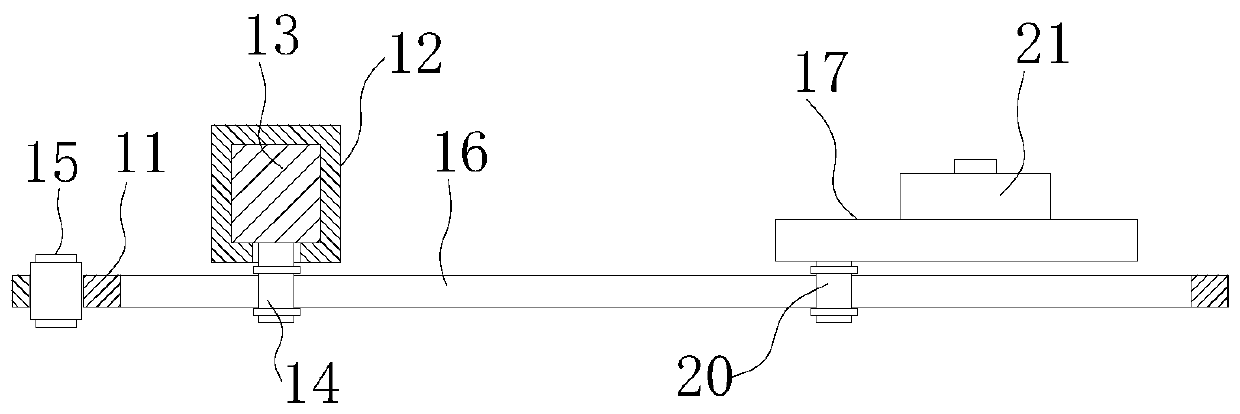

Fixed-length drawing composite technology and equipment

ActiveCN104401143ASubsequent processing is smoothFully understandTransfer printingInk transfer from master sheetEngineeringMechanical engineering

The invention discloses a fixed-length drawing composite technology and equipment. The fixed-length drawing composite technology can achieve fixed-length drawing of a laser film before composition and laser paper after stripping, so that control of laser graphic plate length on the laser film before the composition and laser graphic plate length on the laser paper after the stripping. A laser film fixed-length drawing system and a laser paper fixed-length drawing system are further arranged on a rack of the fixed-length drawing composite equipment; the laser film fixed-length drawing system carries out the fixed-length drawing on the laser film before the composition by controlling the conveying speed of the laser film before the composition to achieve the same laser graphic plate length after the composition; the laser paper fixed-length drawing system carries out the fixed-length drawing on the laser paper formed after the stripping by controlling the conveying speed of the laser paper formed after the stripping. Therefore, the fixed-length drawing composite technology and the equipment can produce the laser paper in the same laser graphic plate length, and smooth subsequent processing of the laser paper is ensured.

Owner:GUANGDONG JINMING MACHINERY

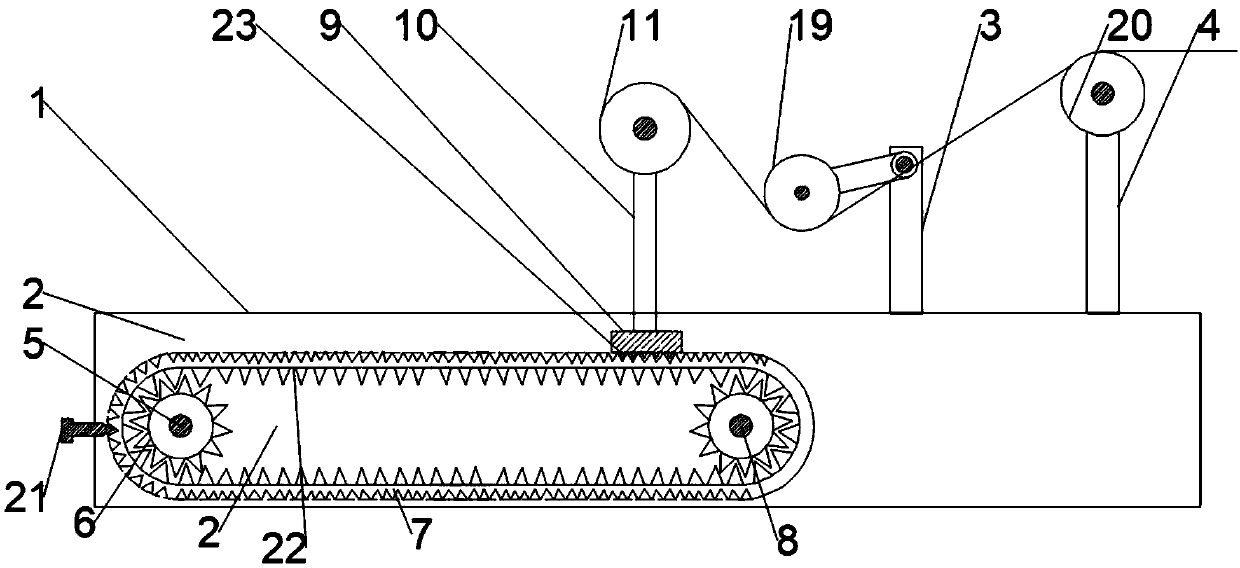

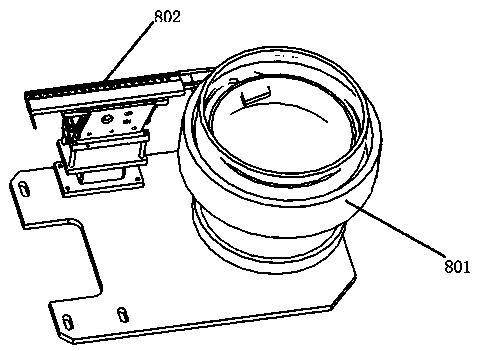

Adjustable unwinding device for cable production

ActiveCN107628478ASubsequent processing quality is goodModerate pressing forceFilament handlingCable/conductor manufactureDrive wheelEngineering

The invention discloses an adjustable unwinding device for cable production. The adjustable unwinding device comprises a base, wherein an installation groove is formed in the base, an adjusting rod and a vertical rod are installed on the top surface of the base, a driving wheel is installed in the installation groove, a rack is connected to the outer side of the driving wheel, a rectangular blockis connected to the rack, a support rod is installed on the top surface of the rectangular block, an unwinding wheel is installed on the top of the support rod, a mounting hole is formed in the top ofthe adjusting rod, a rotating gear is installed on the top of the adjusting rod by virtue of a rotary shaft, a steering handle is fixedly connected to one end of the rotary shaft, a rotary rod is connected to the outer side of the rotating gear, an adjusting wheel is installed at the bottom of the rotary rod, and a pulley is installed on the top of the vertical rod. The position of the unwindingwheel is adjusted, and the pressing force of the adjusting wheel on a cable is changed, so that the cable tension is proper, the subsequent processing of the cable is smooth, the rate of finished products is high, and the applicability is wide.

Owner:江西瑞金金字电线电缆有限公司

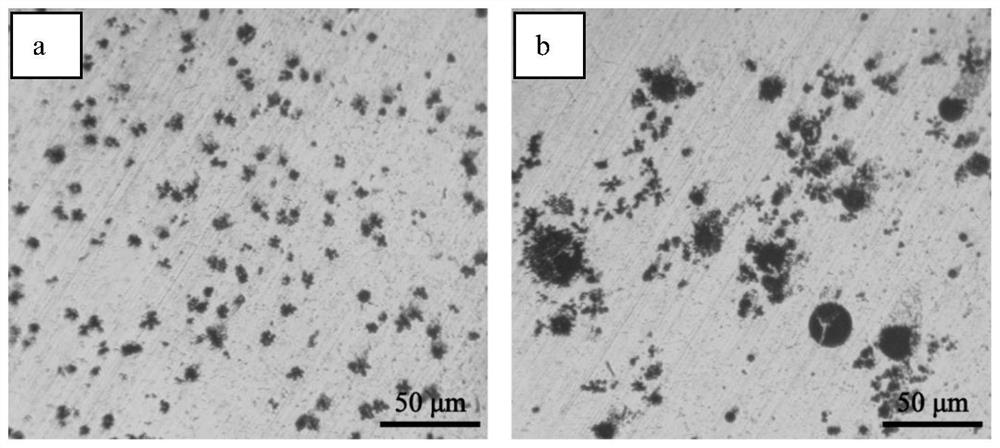

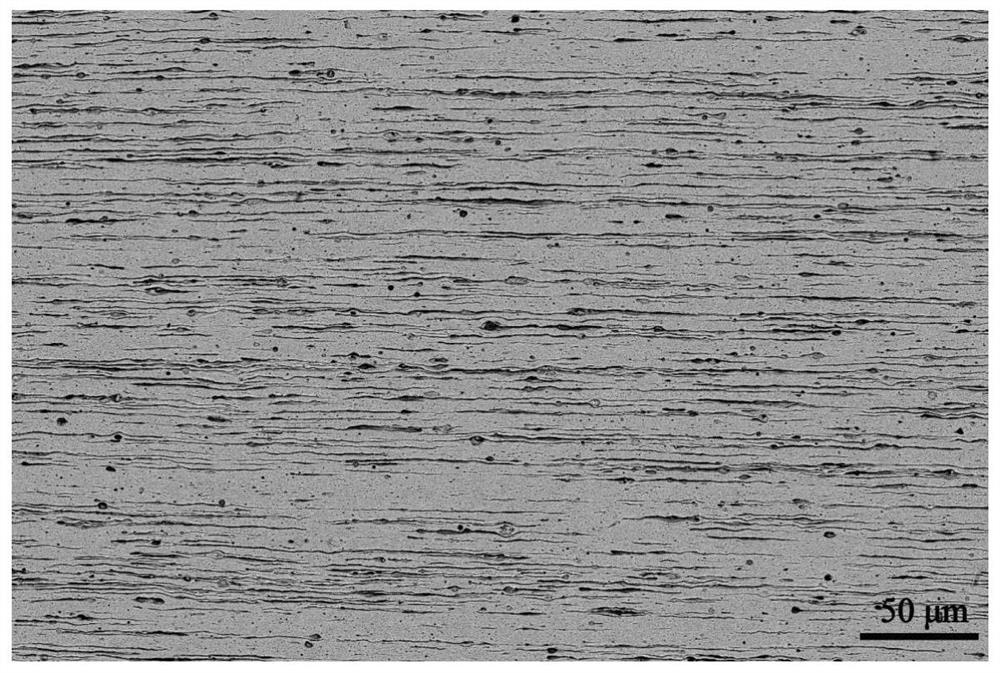

Cu-Fe-Cr-Mg electromagnetic shielding material and preparation method thereof

InactiveCN112111670AInhibition of segregationSuppress generationMagnetic/electric field screeningHeat stabilityAlloy

The invention provides a Cu-Fe-Cr-Mg electromagnetic shielding material. The Cu-Fe-Cr-Mg electromagnetic shielding material comprises the following components, in percentage by mass, including 5%-15%of Fe, 0.01%-0.5% of Cr, 0.01%-0.5% of Mg and the balance of Cu. The invention further provides a preparation method of the Cu-Fe-Cr-Mg electromagnetic shielding material. Elements are prevented frombeing burnt and oxidized by smelting under argon; Fe phases are crushed through electromagnetic stirring, segregation of the Fe phases and formation of large-particle spherical Fe phases are inhibited, and the Fe phases are distributed more uniformly; Mg reduces the solid solubility, pores and shrinkage cavities of Fe in copper; Cr is dissolved in the Fe phases, so that the strength and the thermal stability of the Fe phases are improved; and the tensile strength of a finished alloy reaches 600-1050 MPa, the softening temperature reaches 450 DEG C or above, the electric conductivity reaches 55-70% IACS, and the electromagnetic shielding effect reaches 80-170 dB.

Owner:JIANGXI UNIV OF SCI & TECH +1

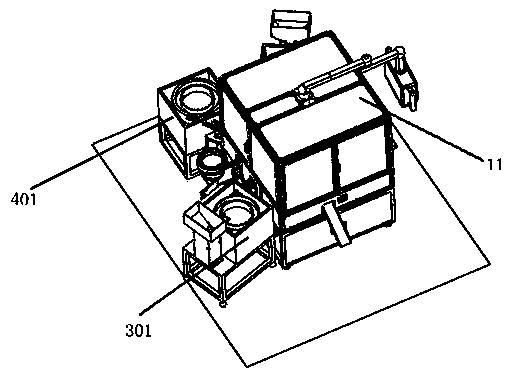

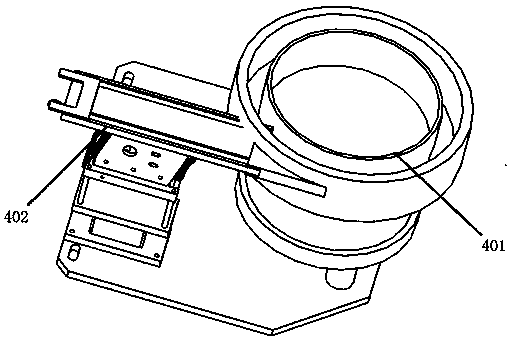

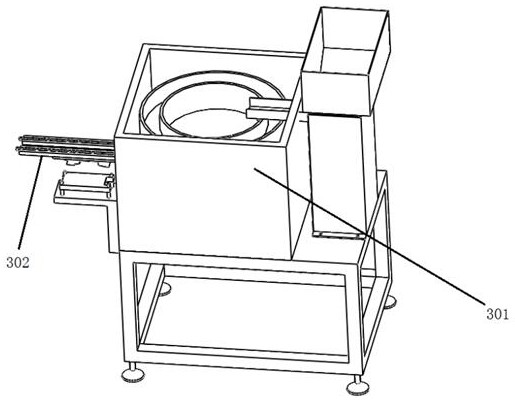

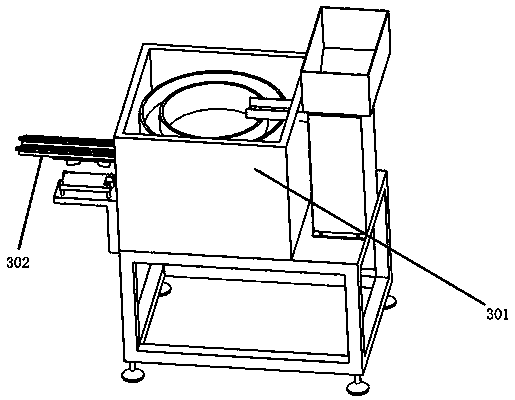

Mesh pad automatic assembly system for C-type card automatic assembly

InactiveCN109366117AImprove automationAvoid stackingAssembly machinesMetal working apparatusEngineeringAutomation

The invention relates to a mesh pad automatic assembly system for C-type card automatic assembly. The mesh pad automatic assembly system comprises a mesh pad supplying assembly, a mesh pad conveying assembly and a mesh pad feeding assembly, wherein the mesh pad supplying assembly comprises a mesh pad spiral vibration feeding machine; the mesh pad conveying assembly comprises a mesh pad conveying belt; the mesh pad feeding assembly comprises a mesh pad top plate which is positioned at the discharge port of the mesh pad conveying belt, a mesh pad placing seat for containing the mesh pad is arranged on the mesh pad top plate, the mesh pad placing seat is driven by a mesh pad translation cylinder to move in a reciprocating mode along the horizontal direction of the mesh pad top plate, and a mesh pad clamping jaw is further arranged above the mesh pad top plate. The mesh pad automatic assembly system has the advantages that the mesh pad supplying assembly, the mesh pad conveying assembly and the mesh pad feeding assembly are coordinated, so that the single mesh pad can be sequentially pushed to the assembling position, the mesh cushion is sleeved on bolts, preparation is made for subsequent riveting, manual placement is not needed, a good foundation is provided for the follow-up automatic assembly of the C-shaped clamp, and automation is facilitated.

Owner:江苏中伟业通讯设备有限公司

Shell making method for impeller wax molds for hydraulic retarder of heavy vehicle

InactiveCN106825401AAvoid fragmentationRoasting went wellLiquid resistance brakesFoundry mouldsWaxImpeller

The invention relates to a shell making method for impeller wax molds for a hydraulic retarder of a heavy vehicle. The shell making method is implemented by sequentially processing a surface layer, a transition layer and a reinforcement layer on the surface of a wax mold module assembled by the wax molds. The shell making method has the advantages as follows: a shell is steadier and firmer by adding the surface layer, the transition layer and the reinforcement layer on the surface of the wax mold module, the shell cracking phenomenon is avoided, and smooth roasting is ensured.

Owner:JIANGSU TANGCHEN AUTOMOBILE PARTS

Preparation method of 996 aluminum oxide ceramic substrate

ActiveCN114538899APromote densificationPromote growthAuxillary shaping apparatusClay mixing apparatusOxide ceramicSlurry

The invention relates to the technical field of ceramic substrates, and provides a preparation method of a 996 aluminum oxide ceramic substrate, which comprises the following steps: (1) preparing a sintering aid; (2) preparing slurry; (3) tape casting and stamping; (4) discharging glue; and (5) sintering. The formula and the process of the aluminum oxide ceramic are optimized, the content of aluminum oxide is increased to 99.6%, and the sintering temperature is reduced while the electrical property and the mechanical property of the aluminum oxide ceramic are improved. The problems that 99 porcelain products produced in the prior art are poor in quality stability and the sintering porcelain forming temperature is too high are solved.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

Sheep tail grease fancy soap and production method thereof

The invention belongs to the field of preparation of fancy soaps and in particular relates to a sheep tail grease fancy soap and a production method thereof. The sheep tail grease fancy soap is prepared from the following components in percentage by weight: 20 percent to 27 percent of sheep tail grease, 20 percent to 27 percent of olive oil, 10 percent to 14 percent of coconut oil, 5 percent to 10 percent of Shea butter and 30 percent to 33 percent of sodium hydroxide with the concentration of 30 percent to 35 percent. The production method of the sheep tail grease fancy soap comprises the following steps: refining the sheep tail fat, blending compound grease, carrying out saponification reaction and molding and so on, so as to prepare the sheep tail grease fancy soap; the sheep tail grease fancy soap has the beneficial effects that the sheep tail grease fancy soap has strong cleaning powder, is moderate and moist and can be used for inhibiting skin inflammations; the sheep tail grease fancy soap has low production cost and no goaty flavor and the problems that the sheep tail grease is difficultly used in the preparation of the fancy soaps and the like are solved.

Owner:内蒙古高雅乐生物科技有限责任公司

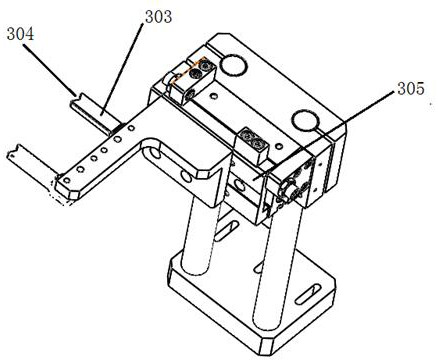

Gasket supplying system for C clamp automatic assembly

InactiveCN109604983AImprove automationSubsequent processing is smoothMetal working apparatusEngineeringAutomation

The invention relates to a gasket supplying system for C clamp automatic assembly. The system comprises a gasket supplying assembly, a gasket conveying assembly and a gasket feeding assembly; the gasket supplying assembly comprises a gasket spiral vibration supplying machine; the gasket conveying assembly comprises a gasket conveying belt, the gasket feeding assembly comprises a gasket top plate,the gasket top plate is provided with a U-shaped opening allowing a gasket to pass through, a gasket clamping jaw is arranged above the gasket top plate, and is jointly formed by a pair of gasket subjaw bodies, the upper ends of the two gasket sub jaw bodies are connected through a gasket clamping jaw fixed base, and the two gasket sub jaw bodies are movably connected with the gasket clamping jawfixed base. The system has the advantages that through cooperation of the gasket supplying assembly, the gasket conveying assembly and the gasket feeding assembly, a single gasket can be pushed to the assembling position in sequence, manual placing is not needed, the good foundation is provided for automatic assembly of C clamps in sequence, and automation is conveniently achieved.

Owner:江苏中伟业通讯设备有限公司

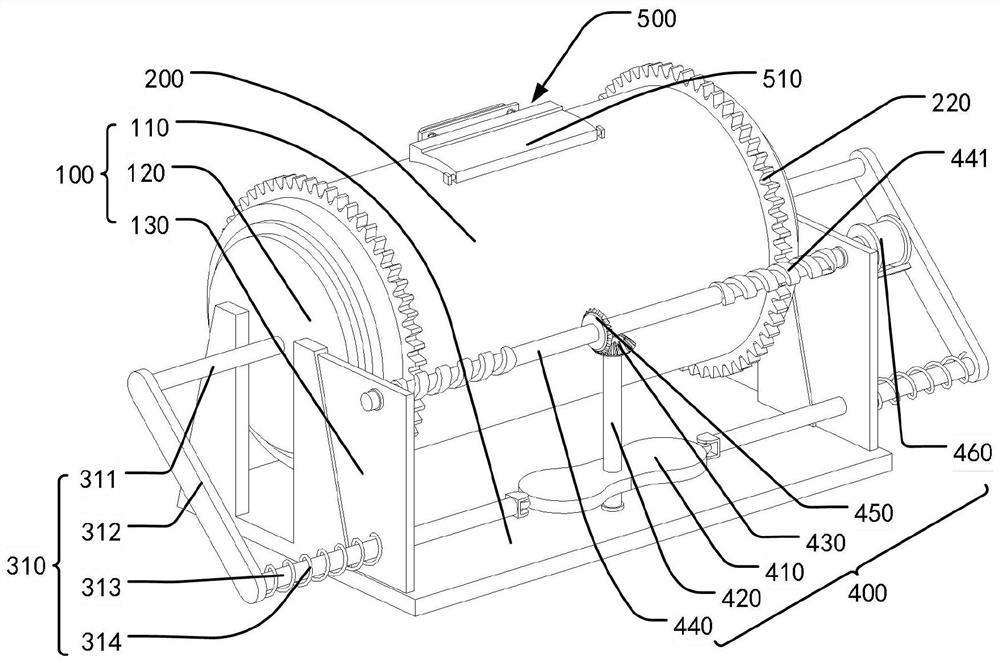

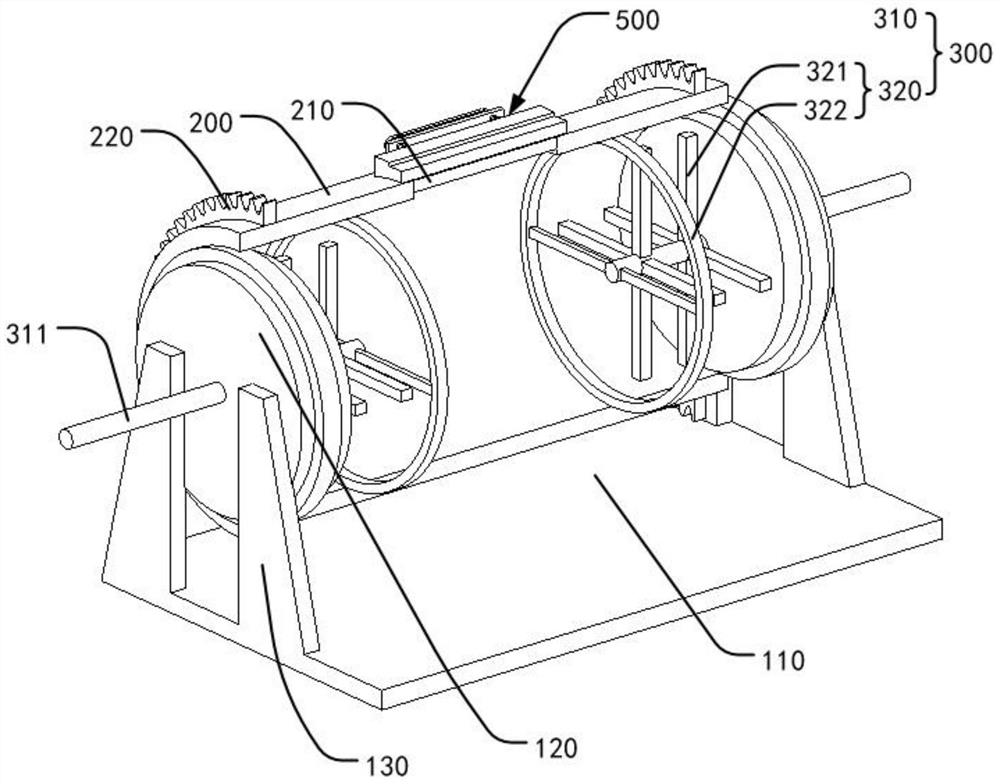

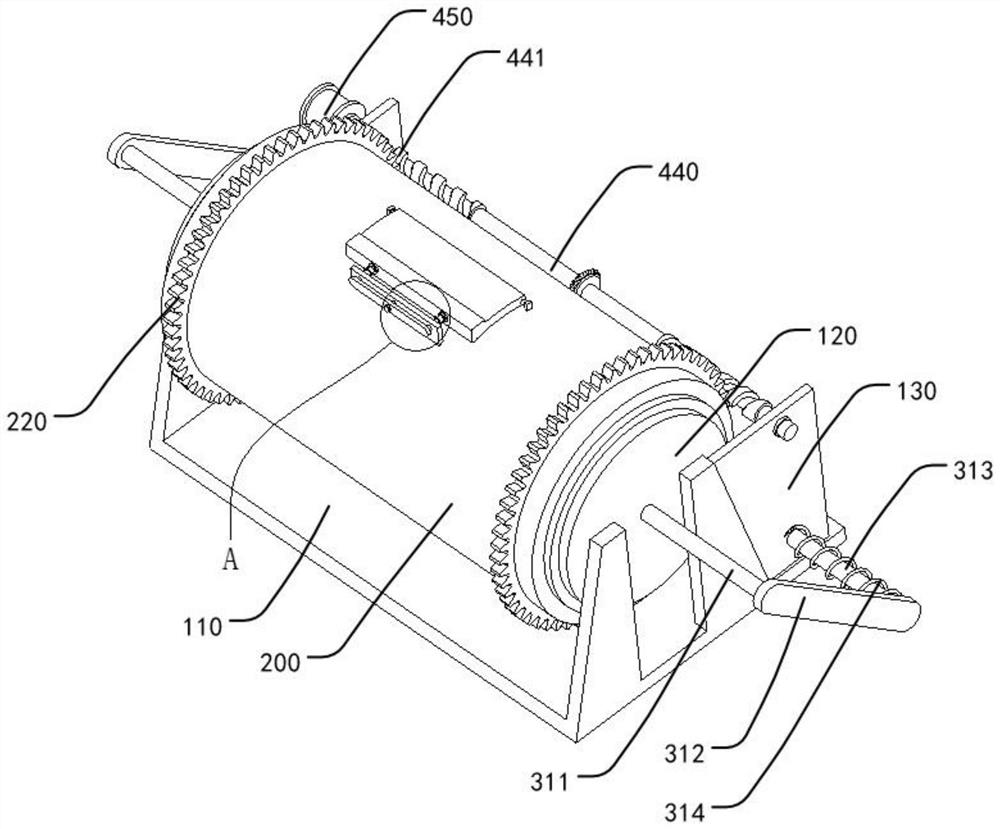

Stirring device

PendingCN114832693AStir wellSubsequent processing is smoothRotating receptacle mixersShaking/oscillating/vibrating mixersRotational axisReciprocating motion

The invention discloses a stirring device. The stirring device comprises a base, a rotating barrel and a stirring assembly. The base comprises a bottom plate and two round seat plates, and the two round seat plates are fixed on the bottom plate; the two ends of the rotating barrel are rotationally connected with the two round base plates correspondingly, and the rotating barrel can rotate. The rotary barrel and the two round seat plates define a containing cavity; the stirring assembly comprises a first transmission part and a first stirring part, the first transmission part is installed on the base and connected with the first stirring part, and the first stirring part is located in the containing cavity; the first transmission part drives the first stirring part to reciprocate in the containing cavity in the axial direction of the rotating barrel. According to the mixing device, materials in the containing cavity are mixed in the circumferential direction through rotation of the rotating barrel, and then the materials in the containing cavity can be mixed in the axial direction through reciprocating motion of the stirring component in the containing cavity in the axial direction of the rotating shaft, so that the materials in the containing cavity can be uniformly mixed in an all-around mode, and mixed materials with high conformity are obtained; and subsequent processing and use are facilitated.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Food having reduced breakage rate and preparation method thereof

PendingCN106259733AValid packageReduce breakageDough treatmentBakery productsAdditive ingredientBreakage rate

The present invention relates to food. The food consists of baking food based flour and / or starch. The baking food comprises at least one first zone and at least one second zone being in contact with the first zone, the second zone comprises shaping accessory ingredients with an amount of 0.5-15 wt% of the total weight of the flour and / or starch based on the baking food, the glass-transition temperature of the shaping accessory ingredients is lower than 0 DEG C; and the second zone exists in the amount of at least 1 wt% of the total weight of the food. The addition of the shaping accessory ingredients can effectively lower breakage rates of multi-zone food and especially multi-zone baking food with crisp textures.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

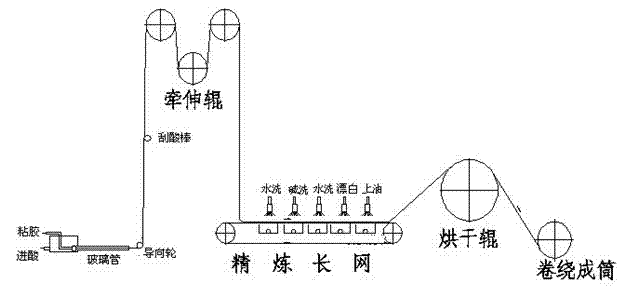

High-speed flat yarn spinning production system

InactiveCN103614797AIncrease resistanceIncrease spinning speedFilament/thread formingArtificial filaments from viscoseWinding machineYarn

The invention provides a high-speed flat yarn spinning production system. The system is characterized by comprising a spinning nozzle, an acid inlet box, a glass tube, a guide wheel, an acid scraping rod and a drawing roller, wherein an acid inlet is formed in one end on the acid inlet box; an acid outlet is formed in the other end of the acid inlet box; the spinning nozzle is positioned in the acid inlet box; the acid outlet is connected with an inlet of the glass tube; an outlet at the other end of the glass tube is connected with the guide wheel; the acid scraping rod is arranged above the guide wheel and is perpendicular to the glass tube; the drawing roller is arranged above the glass tube; an after-treatment device, a drying device and a winding machine are arranged below the drawing roller; a spinning solution passes through a spinning hole of the spinning nozzle under pressure, the injected viscose trickle and an acid bath in the acid inlet box are reacted and molded, the strands and the acid bath enter the glass tube, the strands which are solidified and molded in the glass tube sequentially pass through the guide wheel and the acid scraping rod, enter an after-treatment process through the drawing roller, are subjected to after-treatment and are dried and are wound into a drum.

Owner:YIBIN GRACE +2

Recovery processing and purification method for waste metal

InactiveCN110564967AGuarantee processing qualityImprove the economic benefits of processingProcess efficiency improvementPurification methodsEconomic benefits

The invention discloses a recovery processing and purification method for waste metal. The recovery processing and purification method for the waste metal comprises the following steps: pretreatment,forging and briquetting, smelting, mold forming and detection. The recovery processing and purification method for the waste metal has the following advantages: the waste metal is recovered and purified through the technical processes of pretreatment, forging and briquetting, smelting, mold forming and the like, the technical flow is shortened, the treatment time is reduced, the turnover and circulation of the metal are accelerated, and the utilization efficiency for the metal is increased; and different impurities in the waste metal are removed by charging different reaction gases, a good effect is achieved, and the smooth progress of the subsequent processing procedure is guaranteed, so that the processing energy consumption is reduced, the processing cost is saved, the processing quality for the waste metal is guaranteed, and the processing economic benefits of the waste metal are increased.

Owner:江苏绿塔环境工程有限公司

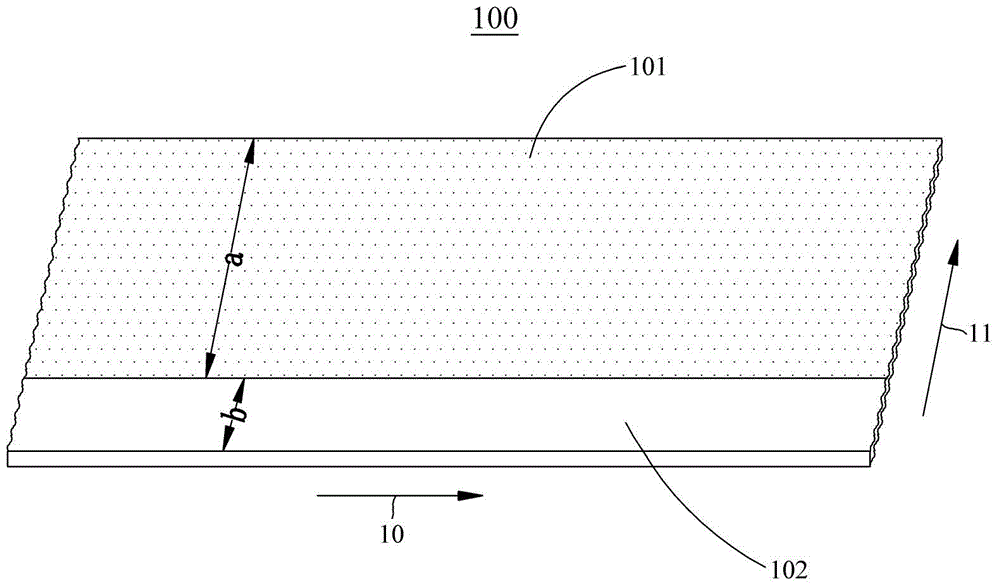

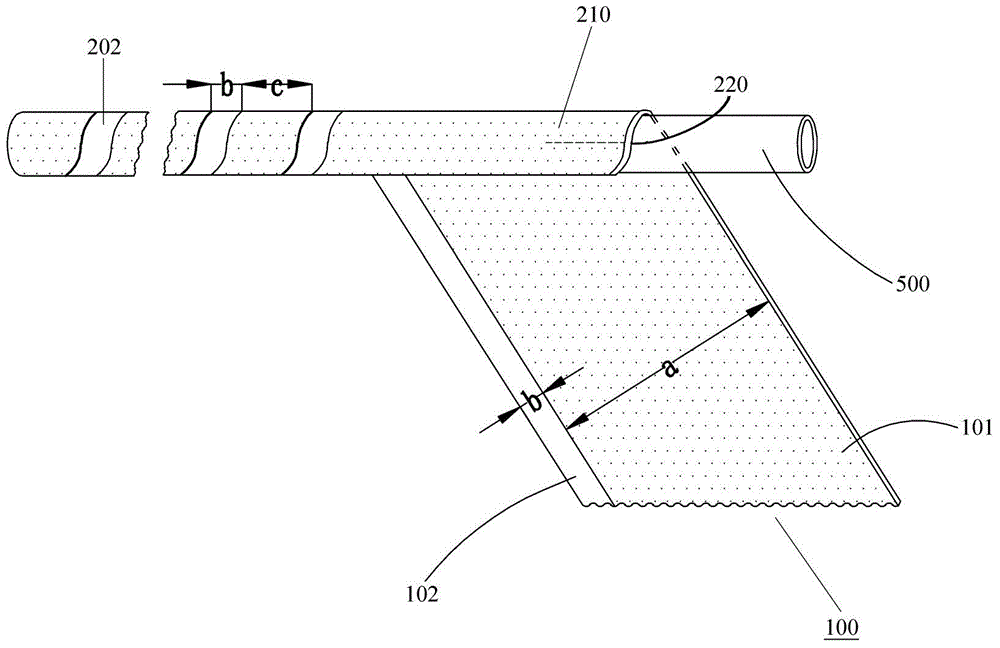

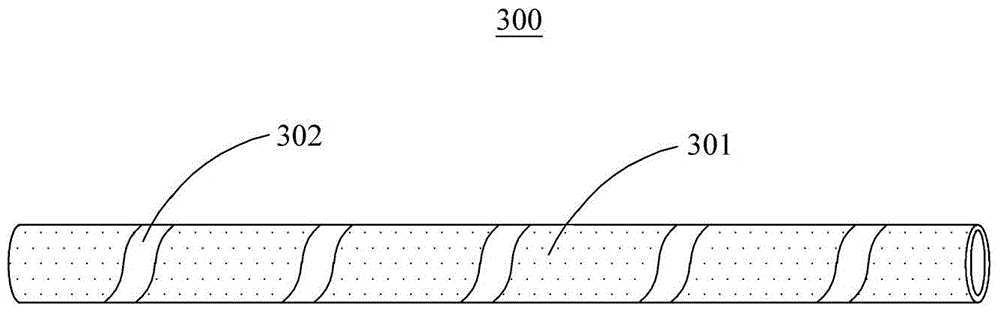

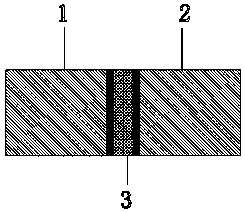

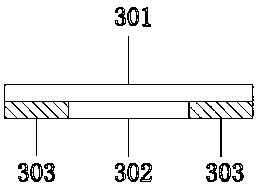

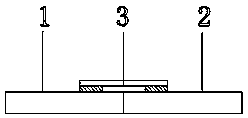

Anti-spill and anti-adhesion joint of reel printing material as well as splicing method thereof

The invention provides an anti-spill and anti-adhesion joint of a reel printing material as well as a splicing method thereof, and relates to the field of auxiliary supplies for production of reel printing materials. Through the change of a reel product joint and the improvement of a joint splicing method, the joint is prevented from overflowing adhesive under extrusion, the quality of the reel product and the stability of the subsequent processes are guaranteed and the production efficiency is improved to a certain degree; meanwhile, the joint operation time is shortened by virtue of the method simply, and the method is suitable for on-line operation. Through setting of the simple structure layer and low cost, the problems in the traditional printing industry are solved, the quality of the reel printing materials is improved, and succession of the subsequent processing of the reel printing materials, particularly reel cigarette labels is benefited; furthermore, the existing process isbasically not changed and the use cost is low.

Owner:YUNNAN TONGPRINT

An adjustable pay-off device for cable production

ActiveCN107628478BSubsequent processing quality is goodModerate pressing forceFilament handlingCable/conductor manufactureRotational axisDrive wheel

Owner:江西瑞金金字电线电缆有限公司

A fixed-length drawing composite process and its equipment

ActiveCN104401143BSubsequent processing is smoothEnsure consistencyTransfer printingInk transfer from master sheetOptoelectronicsFixed length

The invention discloses a fixed-length drawing composite technology and equipment. The fixed-length drawing composite technology can achieve fixed-length drawing of a laser film before composition and laser paper after stripping, so that control of laser graphic plate length on the laser film before the composition and laser graphic plate length on the laser paper after the stripping. A laser film fixed-length drawing system and a laser paper fixed-length drawing system are further arranged on a rack of the fixed-length drawing composite equipment; the laser film fixed-length drawing system carries out the fixed-length drawing on the laser film before the composition by controlling the conveying speed of the laser film before the composition to achieve the same laser graphic plate length after the composition; the laser paper fixed-length drawing system carries out the fixed-length drawing on the laser paper formed after the stripping by controlling the conveying speed of the laser paper formed after the stripping. Therefore, the fixed-length drawing composite technology and the equipment can produce the laser paper in the same laser graphic plate length, and smooth subsequent processing of the laser paper is ensured.

Owner:GUANGDONG JINMING MACHINERY

Wood carbonization treatment method

ActiveCN100534740CAvoid defectsQuality improvementWood treatment detailsCarbonizationSaturated water vapor

A carbonization process for increasing the quality of wood by continuous gradient heating method includes such steps as heating to 120-140 deg.C, eating to 160-240 deg.C, spraying atomized water for slowly cooling to 100 deg.C, filling the saturated steam at 100 deg.C to return the water content back to 4-6%, and cooling to 15-30 deg.C.

Owner:ZHEJIANG SHIYOU TIMBER

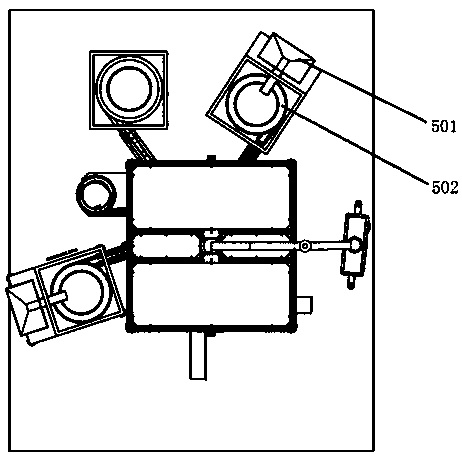

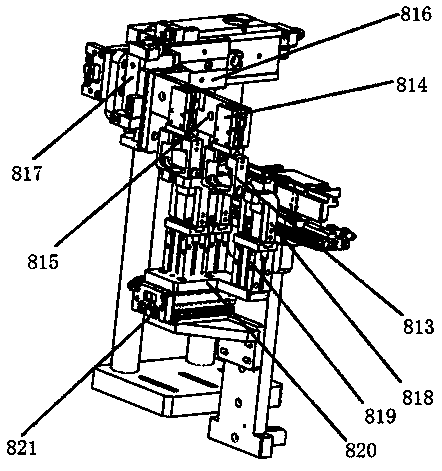

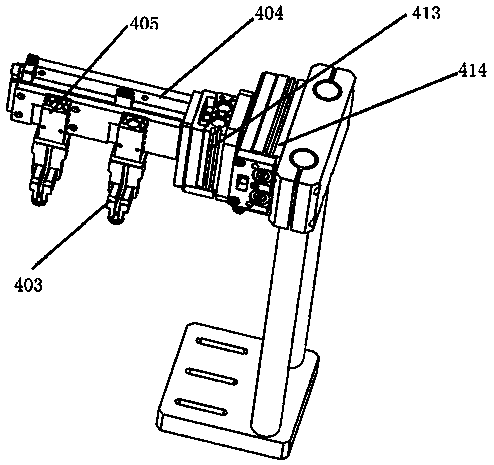

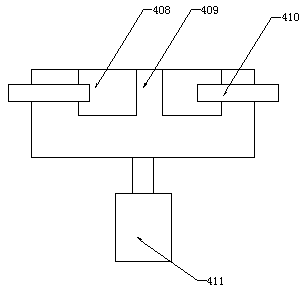

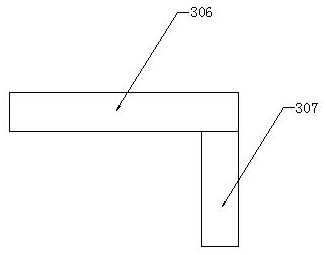

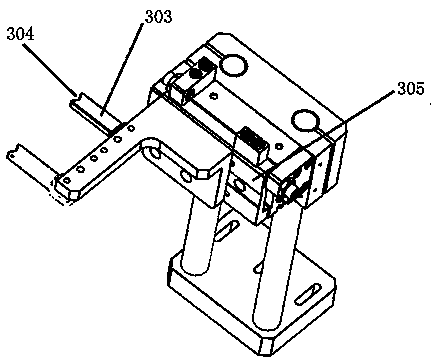

A nut feeding system for automatic assembly of c-type cards

ActiveCN109604984BImprove automationSubsequent processing is smoothMetal working apparatusStructural engineeringMachine

The invention relates to a nut feeding system for C-shaped card automatic assembly. The nut feeding system comprises a nut feeding component, a nut conveying component and a nut sending component; thenut feeding component comprises a nut spiral vibration feeding machine; the nut conveying component comprises a nut conveying bracket; the nut conveying bracket is provided with a nut conveyor belt;the nut sending component comprises a nut ejection plate arranged at a discharge hole of the nut conveyor belt; the nut ejection plate is provided with a U-shaped opening through which a nut passes; anut push plate is further arranged above the nut conveyor belt; and the front end of the nut push plate is provided with a V-shaped opening matched with the nut. The nut feeding system has the advantages that through matching of the nut feeding component, the nut conveying component and the nut sending component, single nuts are sequentially pushed to an assembly device without manual placement,a good foundation is provided to subsequent C-shaped card automatic assembly, and realization automation is facilitated.

Owner:江苏中伟业通讯设备有限公司

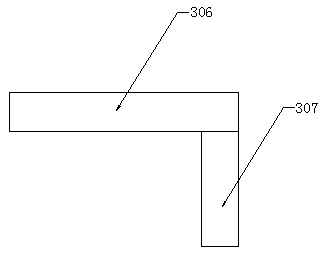

Ball discharge mechanism used for steel ball production

PendingCN110102480AImplement automatic filteringEasy outflowGradingEngineeringMechanical engineering

The invention relates to a ball discharge mechanism used for steel ball production. The ball discharge mechanism comprises a ball discharge frame arranged in an inclined manner. The ball discharge frame comprises a bottom plate and upper side plates arranged on the two sides, in the long axis direction, of the bottom plate. A ball discharge passageway for steel balls to roll is formed by the bottom plate and the upper side plates together. The ball discharge mechanism has the beneficial effects that according to the ball discharge mechanism, by means of cooperation of kidney-shaped screening through holes in a screening section, automatic screening is achieved when steel balls of two different specifications pass, the phenomenon of ball mixing is avoided, and it is ensured that subsequentmachining is smoothly conducted; and by forming the screening through holes, when the steel balls pass, outflow of liquid, such as fine grinding fluid and cleaning fluid, left on the surfaces of the steel balls is also facilitated when the steel balls pass.

Owner:JIANGSU LIXING GENERAL STEEL BALL

Nut feeding system for C-shaped card automatic assembly

The invention relates to a nut feeding system for C-shaped card automatic assembly. The nut feeding system comprises a nut feeding component, a nut conveying component and a nut sending component; thenut feeding component comprises a nut spiral vibration feeding machine; the nut conveying component comprises a nut conveying bracket; the nut conveying bracket is provided with a nut conveyor belt;the nut sending component comprises a nut ejection plate arranged at a discharge hole of the nut conveyor belt; the nut ejection plate is provided with a U-shaped opening through which a nut passes; anut push plate is further arranged above the nut conveyor belt; and the front end of the nut push plate is provided with a V-shaped opening matched with the nut. The nut feeding system has the advantages that through matching of the nut feeding component, the nut conveying component and the nut sending component, single nuts are sequentially pushed to an assembly device without manual placement,a good foundation is provided to subsequent C-shaped card automatic assembly, and realization automation is facilitated.

Owner:江苏中伟业通讯设备有限公司

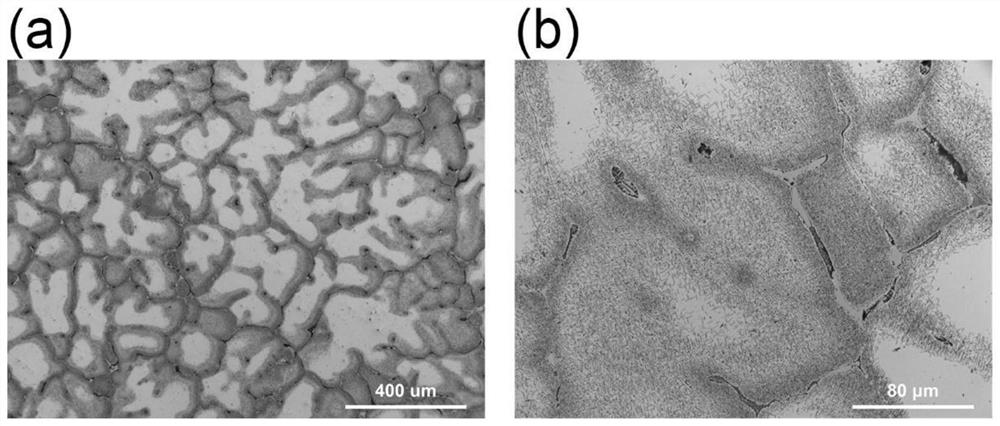

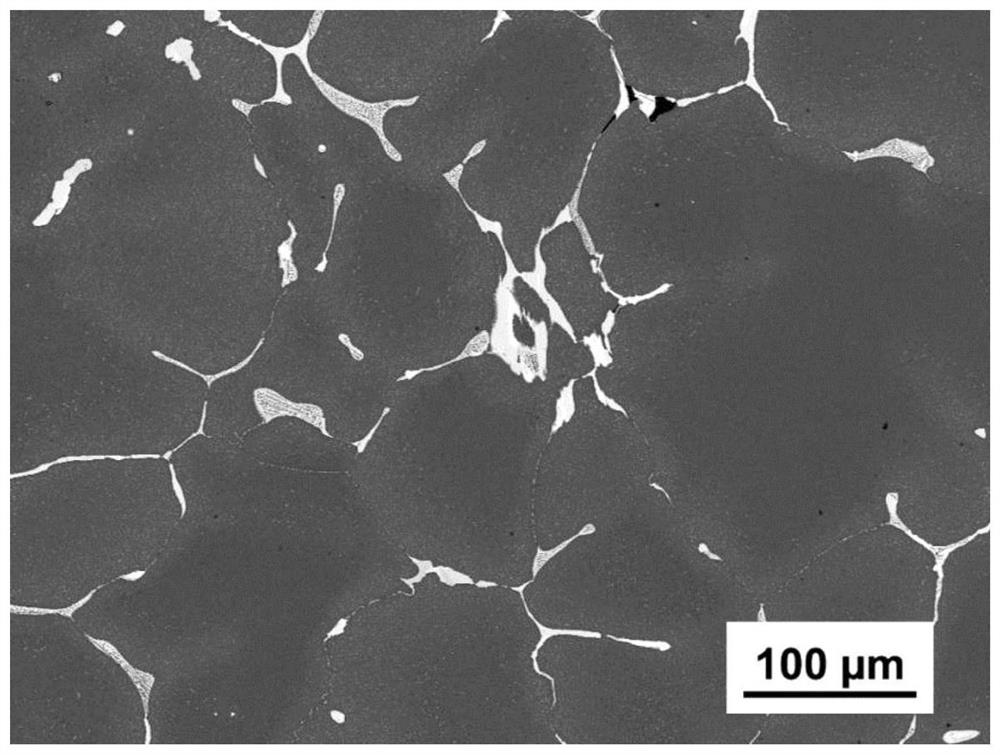

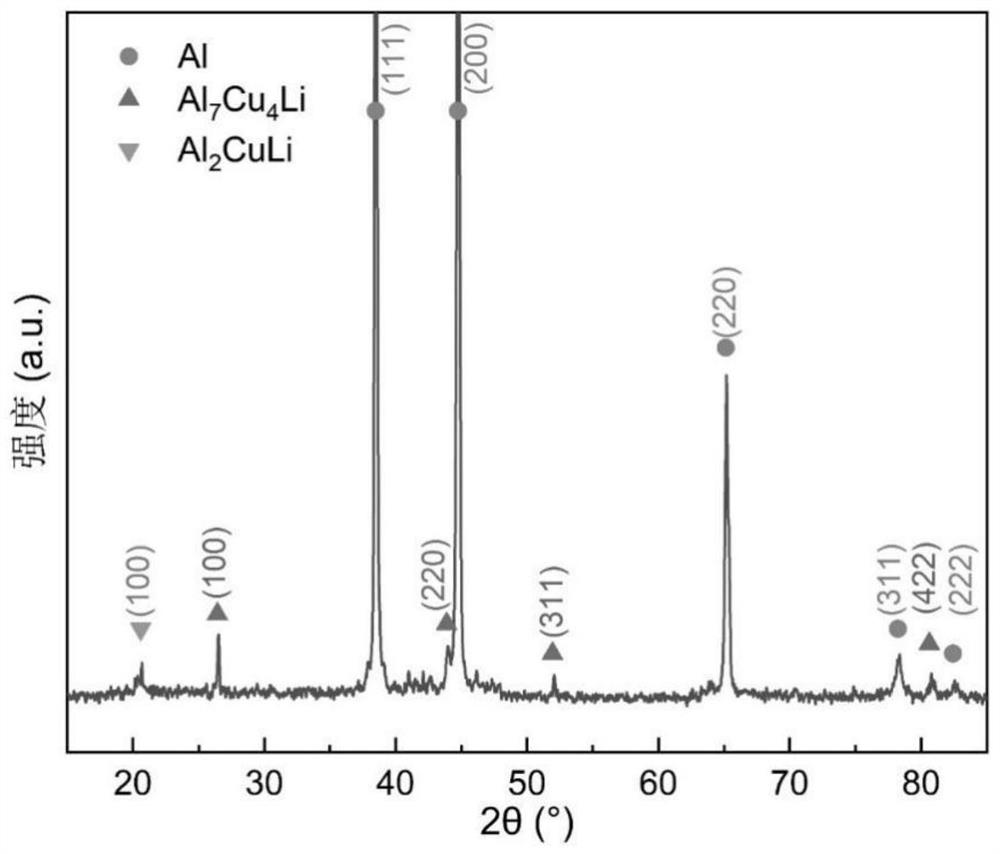

Aluminum-lithium alloy and heat treatment process thereof

PendingCN114561578AElimination of low melting point phasesSubsequent processing is smoothProcess efficiency improvementIngotAluminium-lithium alloy

The invention provides an aluminum-lithium alloy and a heat treatment process thereof, the aluminum-lithium alloy is an alloy with a high Cu / Li ratio, and the heat treatment process is two-stage homogenization heat treatment. The first-stage homogenization heating rate of the two-stage homogenization heat treatment is 8-12 DEG C / min, the homogenization temperature is 465-480 DEG C, the heat preservation time is 14-18 h, the second-stage homogenization heating rate is 3-5 DEG C / min, the homogenization temperature is 490-505 DEG C, and the heat preservation time is 20-30 h; after two-stage homogenization heat treatment, the volume fraction of residual phases in the aluminum-lithium alloy does not exceed 0.7%, and the residual phases are Al-Cu-Fe-Mn phases with high melting points, so that low-melting-point phases in an aluminum-lithium alloy ingot are eliminated to the greatest extent, a uniform fire state structure with uniformly distributed alloy elements is obtained, and the subsequent processing performance is improved.

Owner:CENT SOUTH UNIV

A lithium battery rolling automatic edge correction device

InactiveCN103178238BEnsure consistent stackingReduce labor intensityElectrode manufacturing processesBall screwPole piece

The invention discloses a lithium battery rolling automatic centering and deviation correcting device. The device comprises a base platform, as well as a first pressing roller, a second pressing roller, a third pressing roller, a material receiving roller, an analog to digital (A / D) conversion module, a programmable controller and a stepping motor, which are arranged on the base platform, wherein the first pressing roller, the second pressing roller, the third pressing roller and the material receiving roller are sequentially arranged from left to right and movably connected with the base platform; a photoelectric sensor which is connected with the A / D conversion module is arranged on the first pressing roller and connected with the stepping motor through the programmable controller; and a ball screw transmission mechanism is arranged between the stepping motor and the material receiving roller. By using the lithium battery rolling automatic centering and deviation correcting device, the deviation of pole pieces in a rolling process can be corrected, the consistency of pole piece lamination is ensured, the smoothness of subsequent processing is ensured, production efficiency is indirectly improved, and the labor intensity of an operator is reduced. The lithium battery rolling automatic centering and deviation correcting device has the characteristics of simple structure, convenience in use and the like, and is suitable for popularization.

Owner:JIANGSU TENPOWER LITHIUM

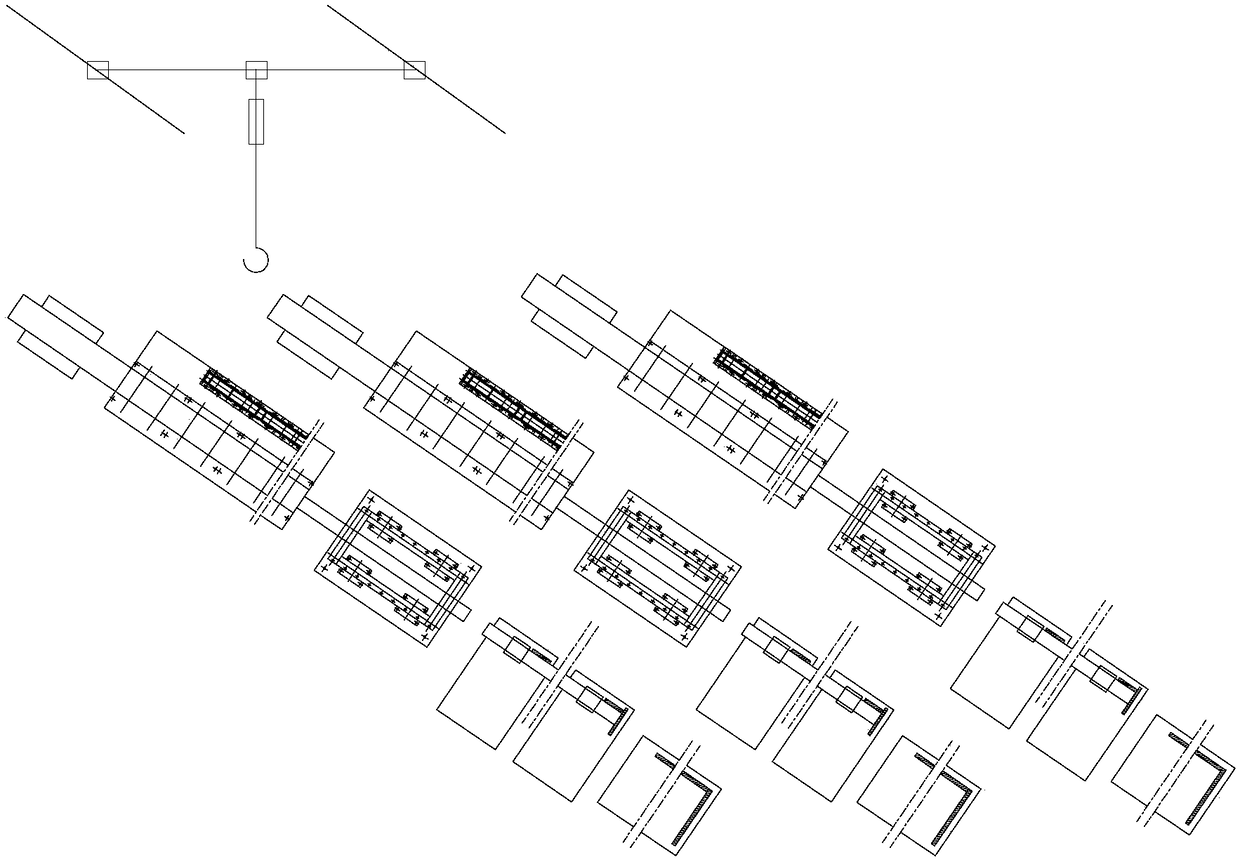

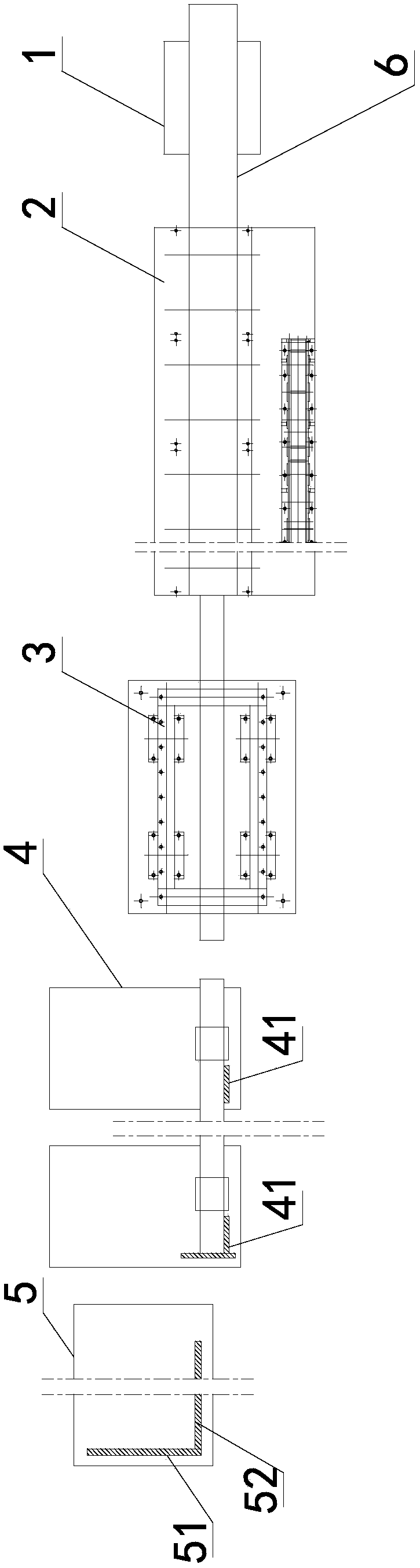

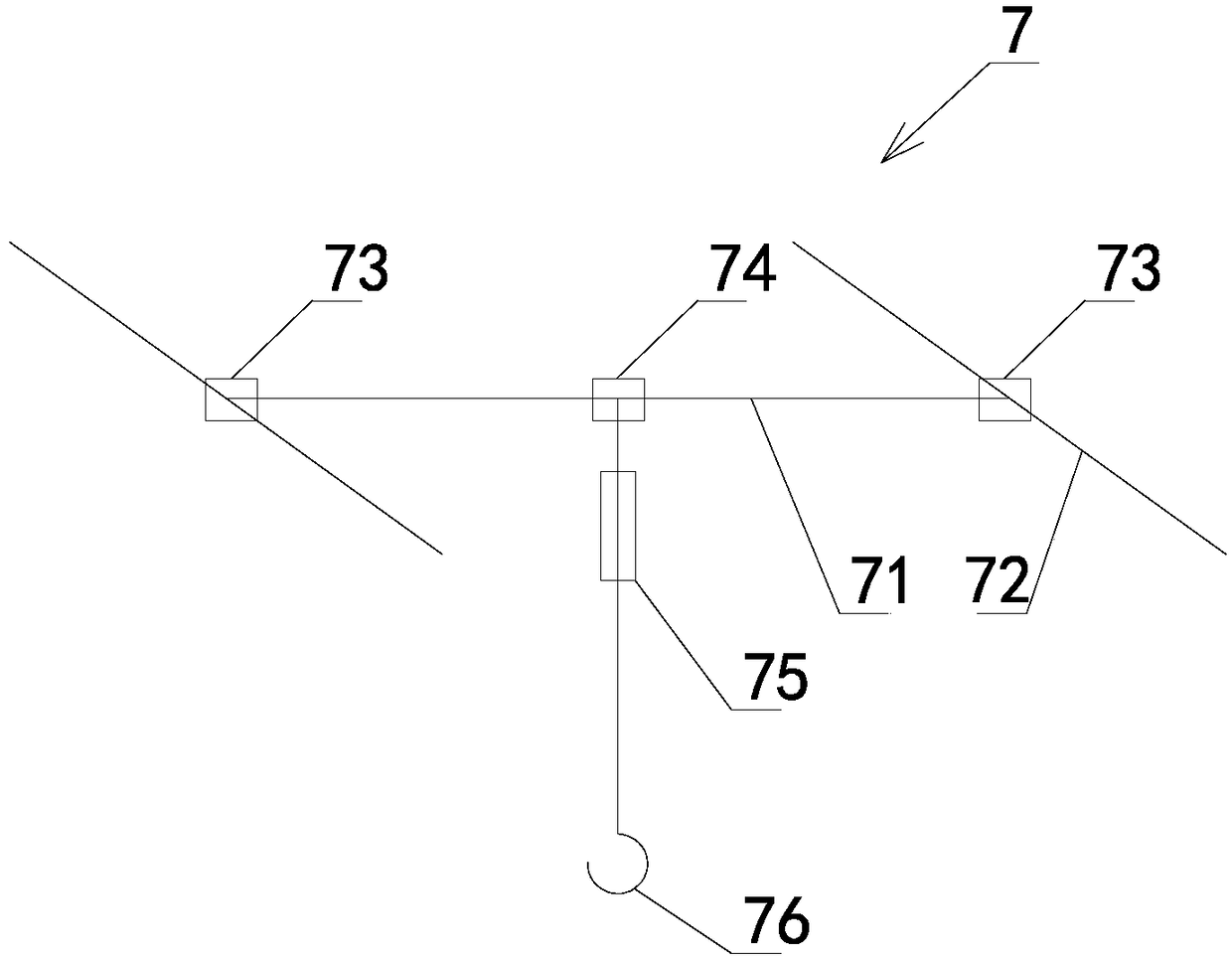

Keel production system

InactiveCN108860763AEliminate channelSmall footprintOther manufacturing equipments/toolsBundling machine detailsEngineeringUtilization rate

The invention discloses a keel production system. The keel production system comprises a travelling crane and multiple keel production devices which are arranged side by side, wherein each keel production device comprises a feeding mechanism, a bending mechanism, a shearing mechanism, a packaging mechanism and a stacking mechanism which are arranged in sequence; the travelling crane comprises a supporting beam, a moving mechanism, a lifting mechanism and a pothook; the moving mechanism is connected to the supporting beam; one end of the lifting mechanism is connected to the moving mechanism; the other end of the lifting mechanism is connected to the pothook; an installing frame is arranged at a feeding port side of the bending mechanism; and the shearing mechanism is arranged at a discharging port side of the bending mechanism. The keel production system can be applied to the technical field of a production device, can effectively overcome the defects in the prior art and can effectively improve the production efficiency; further, the floor space required can also be reduced; and the utilization rate of plants is increased.

Owner:BEIJING NEW BUILDING MATERIAL

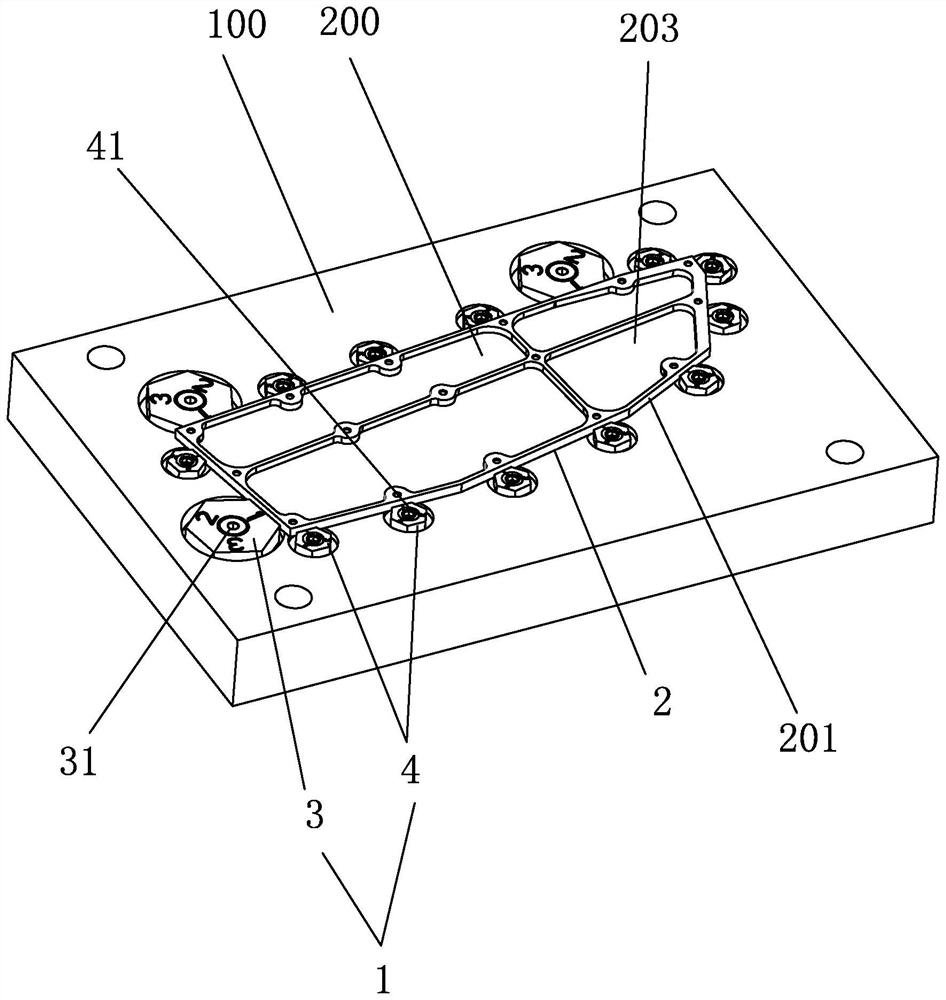

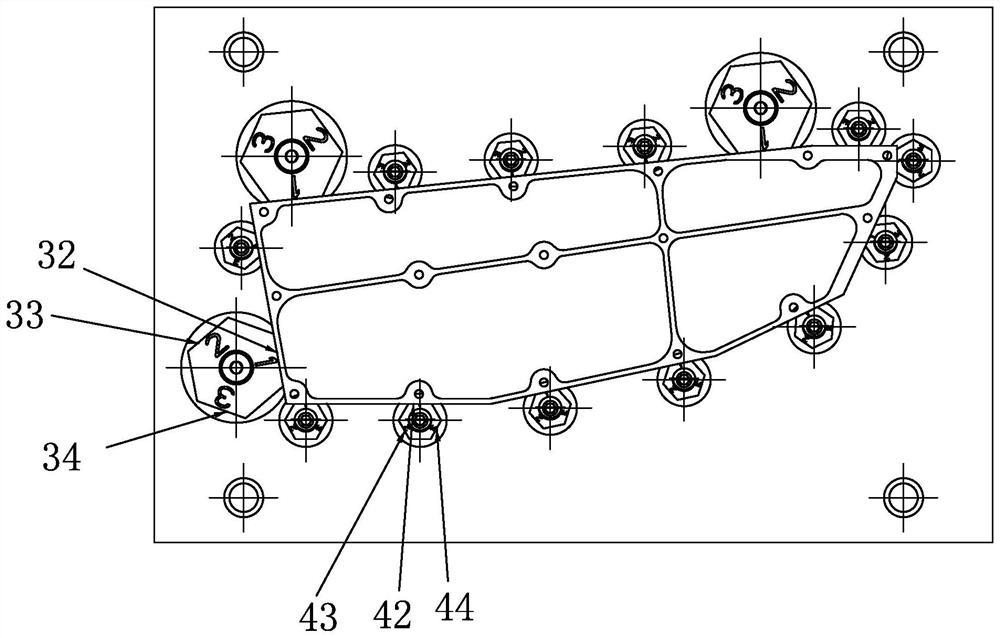

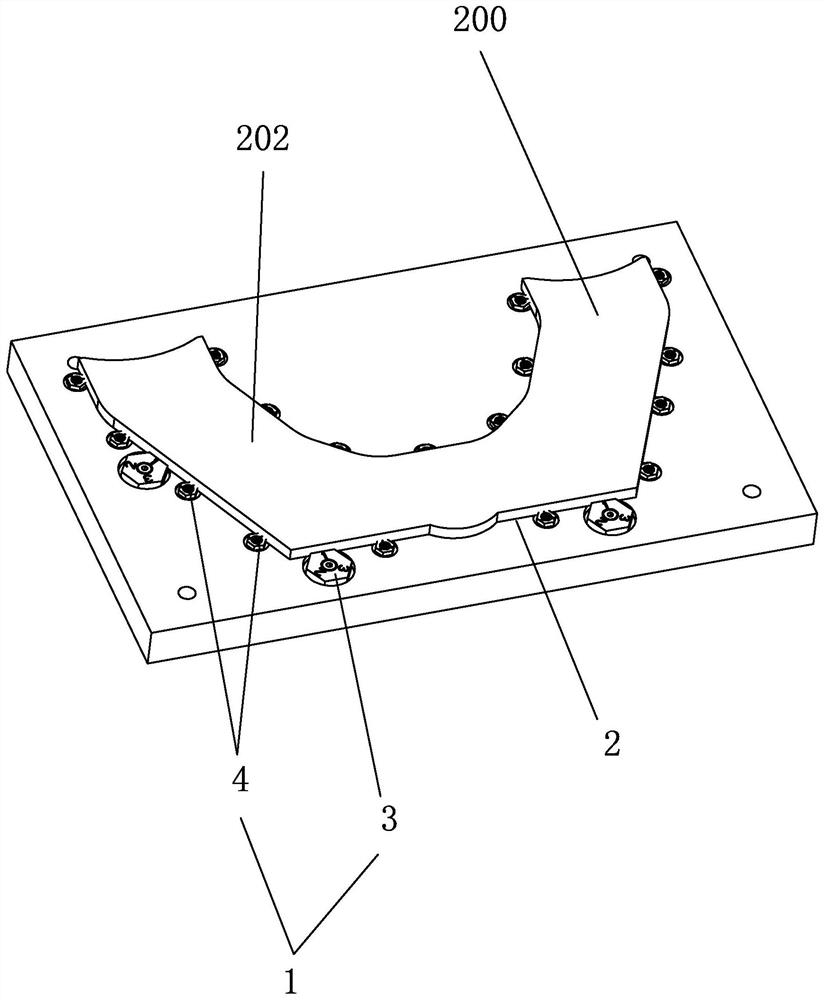

Machining tool and machining process for thin-wall plate parts

ActiveCN114603375AShorten the timeImprove clamping efficiencyMilling equipment detailsPositioning apparatusMachining processMachine tool

The invention discloses a machining tool for thin-wall plate parts, which comprises a tool base plate and a multi-precision mode positioning mechanism arranged on the tool base plate, a discharging cavity is arranged in the middle of the multi-precision mode positioning mechanism, and the multi-precision mode positioning mechanism can adjust the outer contour surface of the discharging cavity according to the machining precision requirement. The invention further discloses a machining process of the thin-wall plate type part, the multi-precision mode positioning mechanism arranged on the tool base plate is used for locking the part of the same specification, and the characteristic that the multi-precision mode positioning mechanism can adjust the outer contour face of the discharging cavity is utilized; in different machining procedures such as rough machining, semi-finish machining and finish machining, the workpiece can be accurately positioned, the clamping precision does not need to be frequently adjusted, the tool positioning workload is optimized, and the clamping and machining efficiency is remarkably improved.

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

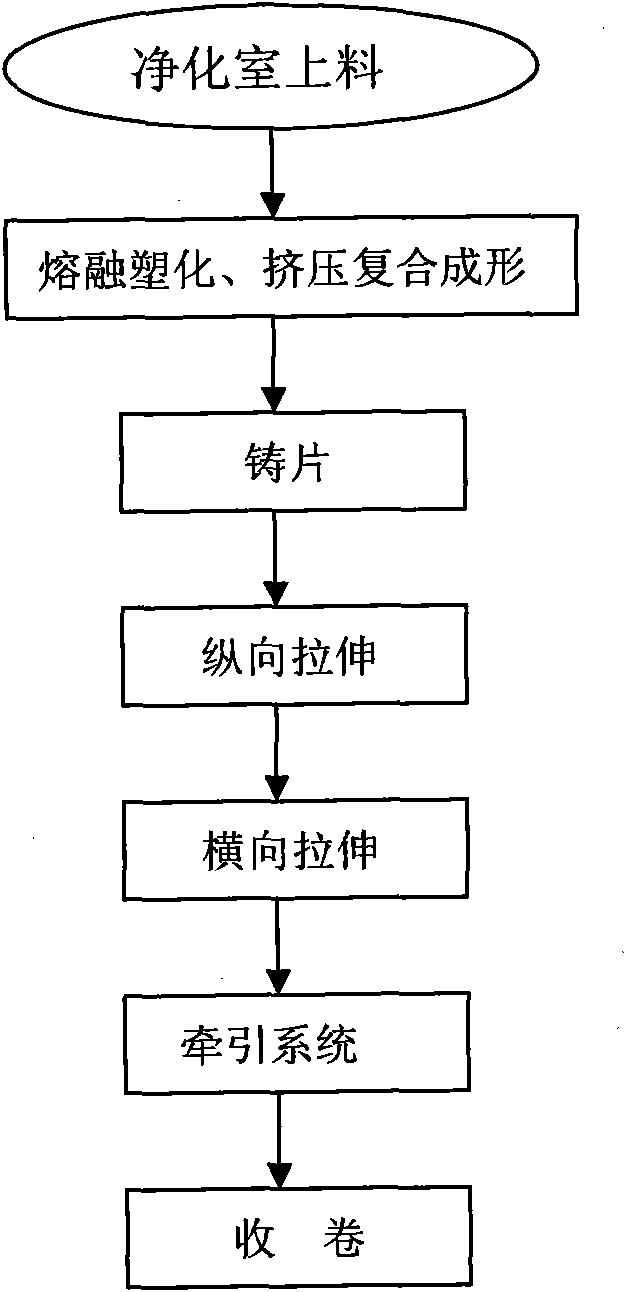

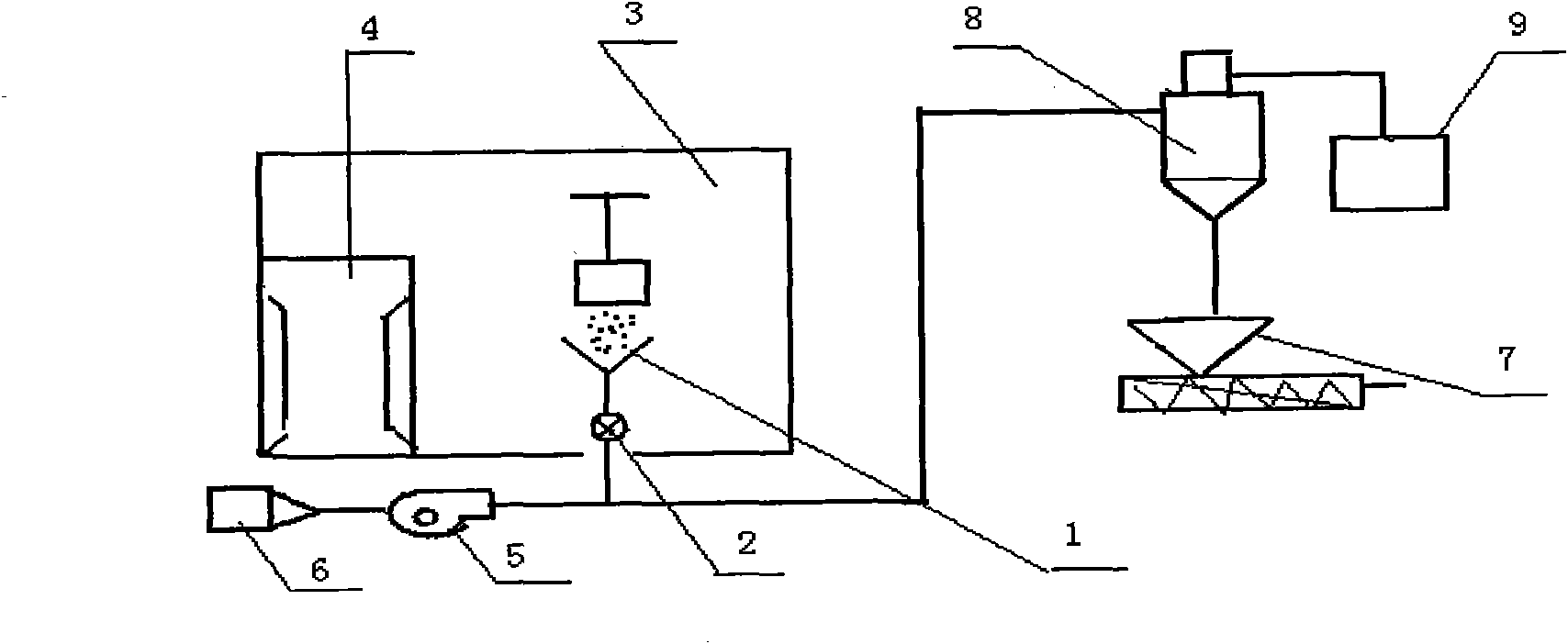

BOPP thin-film production technology for capacitor with multi-layered compound structure

ActiveCN102049859BTake advantage ofHigh mechanical strengthFlat articlesDielectricTypes of capacitor

The invention discloses a BOPP (Biaxially-oriented Polypropylene) thin-film production technology for a capacitor with a multi-layered compound structure, which solves the problems that the low molecular powder in pellet materials can not be separated during the conventional thin film production process, and the product structure is simple. The thin-film production technology is characterized in that the thin film adopts a multi-layered compound structure, Beta crystal polypropylene raw materials is arranged in the surface layer, and Alpha crystal polypropylene raw materials are arranged in the inner layer. The main technological process adopts the following steps of removing the low molecular powder in the polypropylene raw materials through a blower and a cyclone separator and delivering the polypropylene raw materials into a hopper of an extruding machine; smelting, plasticizing and squeezing out the pellet materials through extruding machines that are arranged in parallel, conveying the pellet materials to a clothes rack shaped multi channel die head, and converging the pellet materials in an outlet die cavity to form the multi-layered compound structure; performing vertical and horizontal stretching and drawing and conducting surface treatment to achieve the thin film with designed thickness; and rolling the finished thin film into a cylinder through a double-station rolling machine. The product has little low molecular content, high mechanical strength, good dielectric property and heat resistance properties and high voltage resistance properties, and can be widely applied to produce different types of capacitors.

Owner:HUBEI LONGCHEN TECH CO LTD

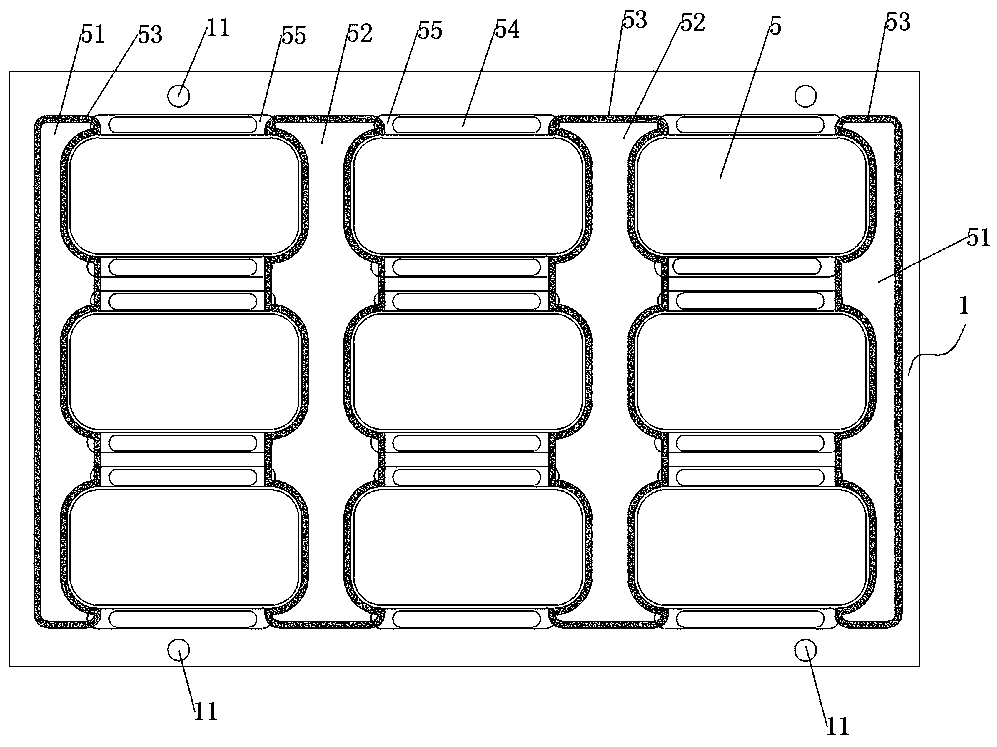

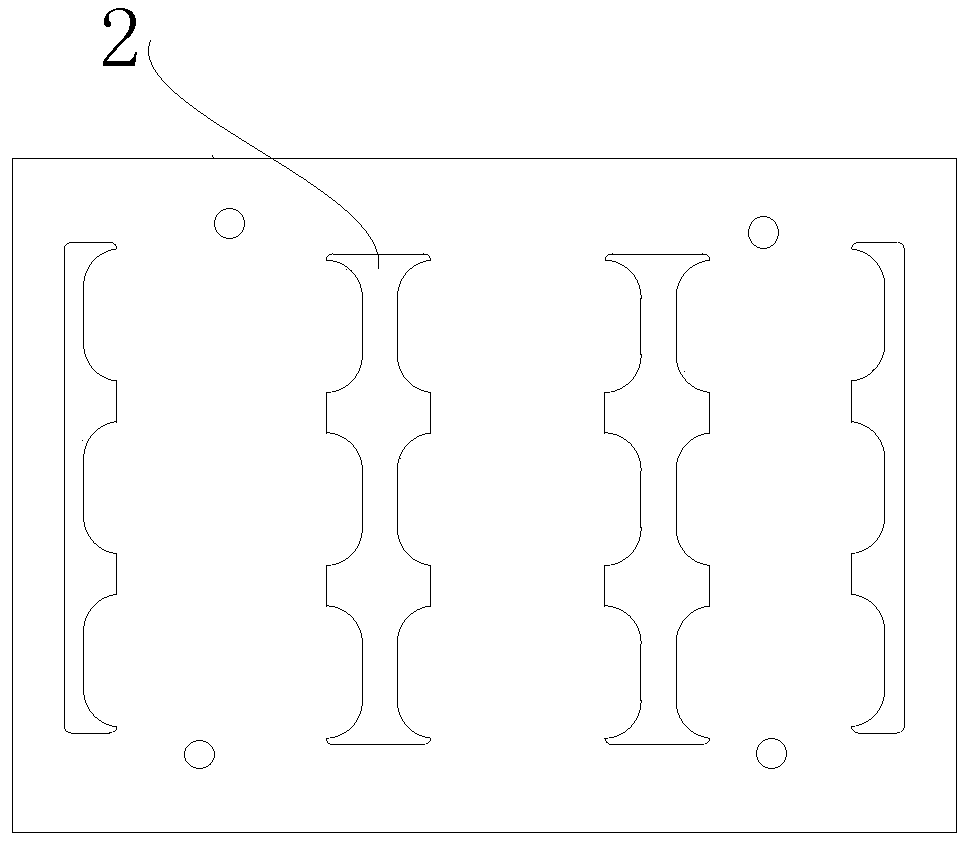

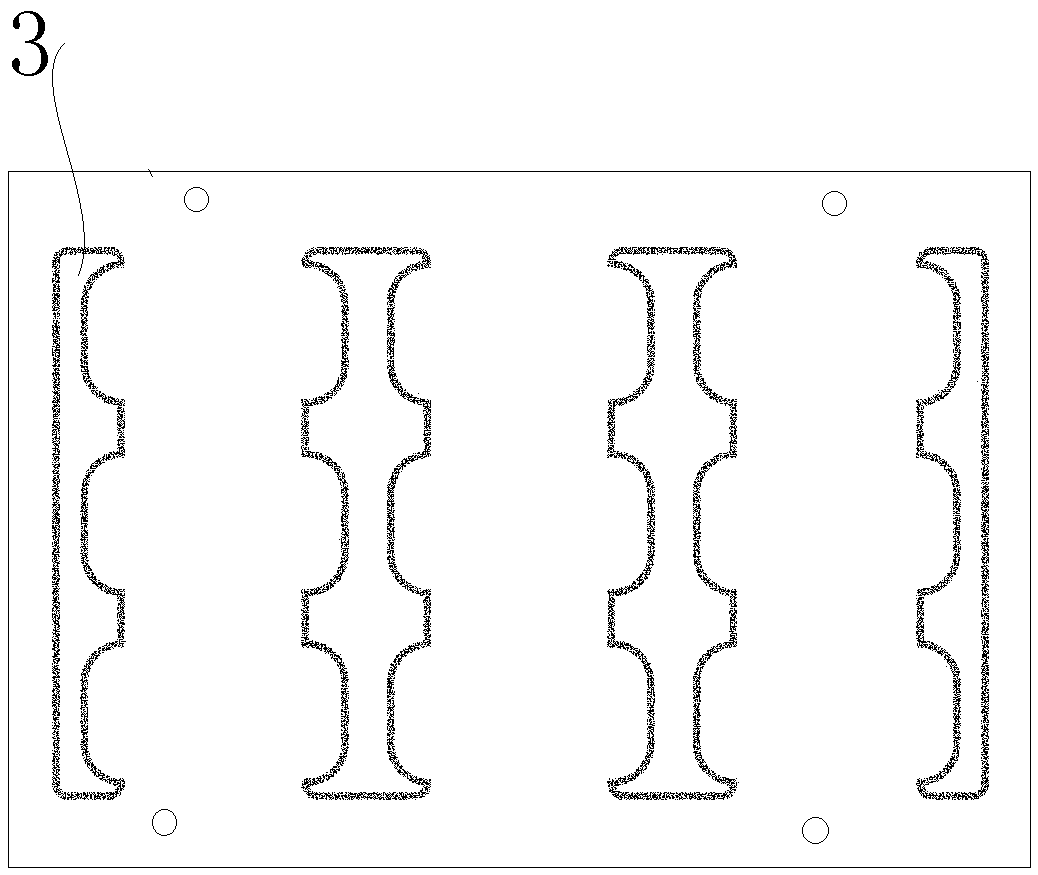

Insulating material stamping forming mold and stamping machining method

PendingCN110883862AHigh vibration frequencyGuarantee molding qualityMetal working apparatusPunchingEngineering

The invention provides an insulating material stamping forming mold and a stamping machining method. The stamping forming of insulating materials can be achieved, and the occurrence of unevenness or burrs in cutting edges can be reduced. The insulating material stamping forming mold comprises a mold body I, a mold body II, a mold body III and a mold body IV, the mold body I, the mold body II, themold body III and the mold body IV are separately installed on a punching machine I, a punching machine II, a punching machine III and a punching machine IV, cutters I corresponding to areas I to be machined and areas II to be machined and having the same shape with the areas I to be machined and the areas II to be machined are separately arranged on an upper mold of the mold body I, cutters II corresponding to slitter edges I and having the same shape with the slitter edges I are arranged on an upper mold of the mold body II, cutters III corresponding to areas III to be machined and having the same shape with the areas III to be machined are arranged on an upper mold of the mold body III, and cutters IV corresponding to slitter edges II and having the same shape with the slitter edges IIare arranged on an upper mold of the mold body IV. The stamping forming method of the insulating materials comprises the steps that material falling is carried out, specifically, punching operation iscarried out on a material plate by the punching machines, and parts are separately from the material plate.

Owner:无锡积捷光电材料有限公司

Machining platform capable of moving with multi-degree-of-freedom

PendingCN111975394AMeet the needs of multi-degree-of-freedom adjustmentBroad market spaceLarge fixed membersPositioning apparatusElectric machineMulti degree of freedom

The invention discloses a machining platform capable of moving with multi-degree-of-freedom, and belongs to the technical field of machining equipment. A X-directional driving lead screw assembly drives a first sliding table to slide on a base seat along the X direction, a Y-directional driving lead screw assembly drives a second sliding table to slide on the first sliding table along the Y direction, and a Z-directional driving lead screw assembly drives a cross beam to slide on a vertical plate along the Z direction. An output shaft of a rotating motor is fixedly connected with a working head so as to make the working head rotate circumferentially, as a result, the working head can move in the X direction, Y direction, Z direction and circumferential direction, the requirement of adjustment of the multi-degree-of-freedom of the working head can be met, fastening bolts are screwed into threaded holes of rectangular fixing blocks and adjustment threaded holes of a working table successively, and the rectangular fixing blocks distributed circumferentially are utilized to fix ring-shaped work pieces together, so that subsequent machining processes are carried out smoothly.

Owner:扬州市江都区凯润机械厂

A water-cooled cooling forging press

ActiveCN109719251BSimple quenchingReduced risk of deformationHandling devicesHeating/cooling devicesThermodynamicsProcess engineering

The invention relates to the technical field of presses and aims to provide a water cooling forging press capable of cooling a panel. A technical scheme adopted by the invention is as follows: the water cooling forging press comprises a conveying device for conveying the panel and a forging device for forging the panel. A water cooling device is also arranged behind the discharge side of the forging device along the panel conveying direction. The water cooling device comprises a row of cooling water spray heads distributed below the panel along the width direction of the panel, and the coolingwater spray heads face the panel; a collecting tank opened in the top is formed below the cooling water spray heads, a water pump is arranged in the bottom of the collecting tank, and the water pumpcommunicates to the cooling water spray heads through pipelines. The water cooling forging press provided by the invention can cool the forged panel with water, so that follow-up processing steps arecarried out smoothly.

Owner:嵊州市因康机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com