BOPP thin-film production technology for capacitor with multi-layered compound structure

A multi-layer composite, production method technology, applied in the application, household appliances, other household appliances, etc., to reduce film rupture factors, reduce production costs, and improve dielectric strength.

Active Publication Date: 2013-05-15

HUBEI LONGCHEN TECH CO LTD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002]Existing BOPP films for capacitors all adopt single-layer production technology, and the feeding system uses the raw material self-weight feeding or vacuum suction method, which cannot separate the granular raw materials The low-molecular powder produced in the process of manufacturing, packaging, feeding, and transportation will produce too much volatile matter in the process of casting, longitudinal drawing, and horizontal drawing, which will pollute the membrane surface and cause the film to be broken in the horizontal drawing. Many low-molecular materials lead to a decrease in mechanical strength; because it is a single-layer structure, only a single formula of a single raw material can be used, and it is difficult to meet the requirements of subsequent processing characteristics and end-use characteristics of the film at the same time (sufficient surface roughness and Sufficient dielectric strength and temperature resistance), not only the production cost is high, but also the product quality is poor; at the same time, the single-layer structure cannot avoid and reduce the horizontal tensile film and product withstand voltage and temperature resistance caused by raw metal ash and other impurities The performance is degraded, and there is no secondary structure, the tensile stress of the product is relatively concentrated, and it is easy to break, causing the product to be scrapped in subsequent processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Login to View More

Abstract

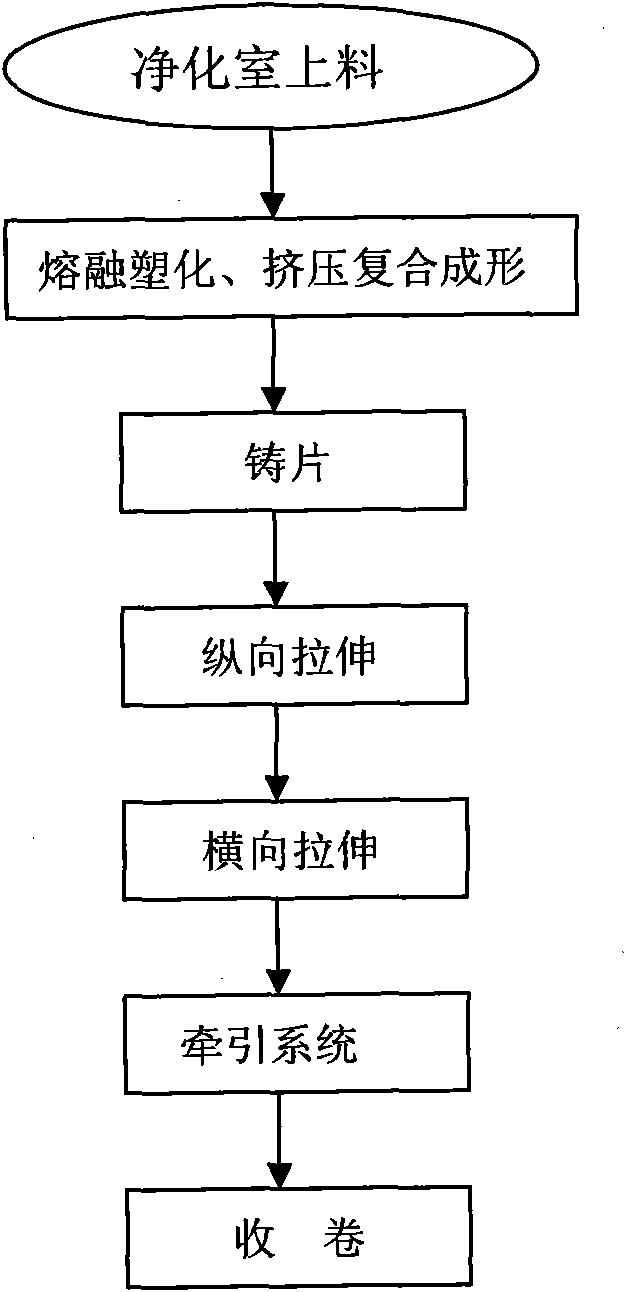

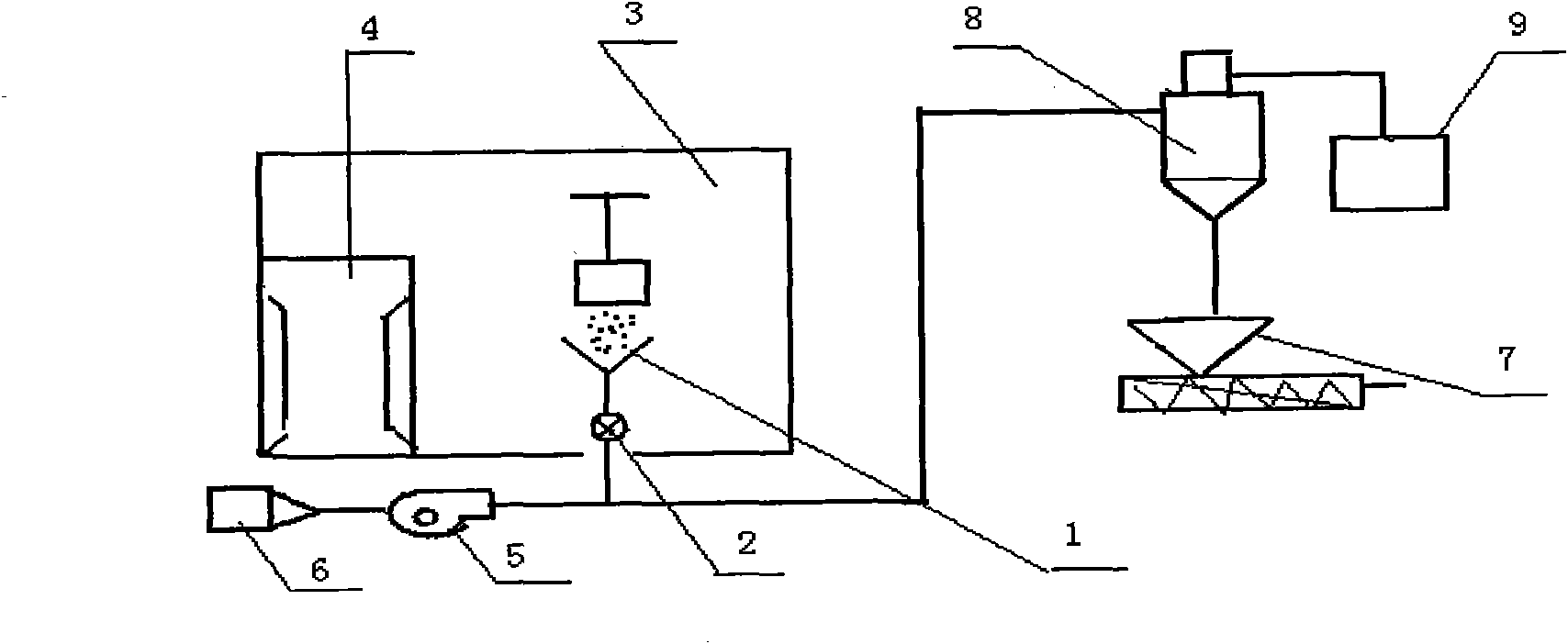

The invention discloses a BOPP (Biaxially-oriented Polypropylene) thin-film production technology for a capacitor with a multi-layered compound structure, which solves the problems that the low molecular powder in pellet materials can not be separated during the conventional thin film production process, and the product structure is simple. The thin-film production technology is characterized in that the thin film adopts a multi-layered compound structure, Beta crystal polypropylene raw materials is arranged in the surface layer, and Alpha crystal polypropylene raw materials are arranged in the inner layer. The main technological process adopts the following steps of removing the low molecular powder in the polypropylene raw materials through a blower and a cyclone separator and delivering the polypropylene raw materials into a hopper of an extruding machine; smelting, plasticizing and squeezing out the pellet materials through extruding machines that are arranged in parallel, conveying the pellet materials to a clothes rack shaped multi channel die head, and converging the pellet materials in an outlet die cavity to form the multi-layered compound structure; performing vertical and horizontal stretching and drawing and conducting surface treatment to achieve the thin film with designed thickness; and rolling the finished thin film into a cylinder through a double-station rolling machine. The product has little low molecular content, high mechanical strength, good dielectric property and heat resistance properties and high voltage resistance properties, and can be widely applied to produce different types of capacitors.

Description

1. Technical field [0001] The invention belongs to the production technology of BOPP film for capacitors, and in particular relates to a production method of BOPP film for capacitors with multilayer composite structure. 2. Background technology [0002] Existing BOPP films for capacitors all adopt single-layer production technology, and the feeding system uses raw material self-weight feeding or vacuum suction, which cannot separate the low-molecular powder produced during the manufacturing, packaging, feeding, and transportation of granular raw materials. materials, so that excessive volatiles are produced during casting, longitudinal drawing, and transverse drawing, which will pollute the membrane surface and cause transverse drawing to break the film. The finished product contains more low-molecular materials, resulting in a decrease in mechanical strength; because it is a single-layer structure , can only use a single formula of a single raw material, it is difficult to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C69/00B29C47/10B29C47/12B29C47/06B29C47/92B29C55/12B29K23/00B29L7/00B29C48/30B29C48/92

Inventor 潘旭祥林锦鸿吴忠平

Owner HUBEI LONGCHEN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com