Anti-spill and anti-adhesion joint of reel printing material as well as splicing method thereof

A technology of printed matter and connector, applied in the field of anti-overflow and anti-stick connector and splicing, which can solve the problems of pollution, quality accident, high tape pressure, etc., and achieve the effect of low cost, low use cost and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

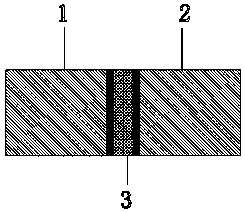

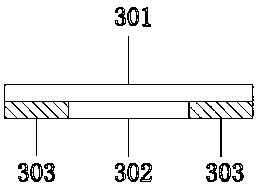

[0033] Such as figure 1 , 2 As shown in , 3, the anti-spill and anti-adhesion joint of reel printed matter described in this embodiment includes a front splicing part 1, a rear splicing part 2, and an adhesive layer 3; The roll direction is vertically arranged, and its center line coincides with the contact line between the front splicing part 1 and the rear splicing part 2. Anti-overflow adhesive layer 303, the length of the anti-overflow adhesive layer 303 is the same as the entire adhesive layer 3, the width is 1.5mm, the edge is aligned with the adhesive layer 3, and the anti-overflow adhesive layer 303 is uniformly distributed with micro 27.5g tipping base paper with a hole and cilia structure and a thickness of 0.03mm; the front splicing part 1 and the rear splicing part 2 are butted horizontally, and the two are in the same plane, and the adhesive layer 3 is bonded On the front of the reel print for easy identification of splices.

[0034] A method for splicing a spi...

Embodiment 2

[0040] Such as figure 1 , 2As shown in , 4, the anti-spill and anti-adhesion joint of the reel printed matter described in this embodiment, the reel printed matter is a reel cigarette label, including a front splicing part 1, a rear splicing part 2, and an adhesive layer 3; Layer 3 includes a substrate layer 301, an adhesive layer 302, and an anti-overflow adhesive layer 303 arranged on both sides of the adhesive layer 302. The length of the anti-overflow adhesive layer 303 is the same as that of the entire adhesive layer 3, The width is 2mm, the edge is aligned with the adhesive layer 3, and the anti-spill adhesive layer 303 adopts tipping paper base paper with a uniform distribution of micropores and cilia structure and a weight of 30g; the front splicing part 1 and the rear splicing part 2 of the joint Horizontal docking, the two are in the same plane, the adhesive layer 3 is glued to the front and back of the printed matter on the reel, and the two are symmetrical to each...

Embodiment 3

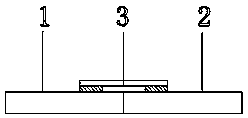

[0048] Such as figure 1 , 2 , 5, the dimensional parameters of the joint described in this embodiment are consistent with those in Example 1, the difference is that the front splicing part 1 and the rear splicing part 2 overlap each other, the rear splicing part 2 is located above the joint, and the adhesive layer 3 Pasted on the front, when the cigarette label is unwound and packaged, the cigarette package scraper will not scrape and tear the joint during the scraping process from back to front.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com