Dry-type air-core reactor preparation mould provided with air gaps of fixed size and sample preparation method

A hollow reactor, fixed size technology, applied in the field of preparing molds and samples for dry hollow reactors with fixed size air gaps, can solve the problems of slow vacuum bubbling process, deep bubble staying, and retained bubbles, etc. Avoid insulation deformation damage, ensure accuracy, and ensure the effect of correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

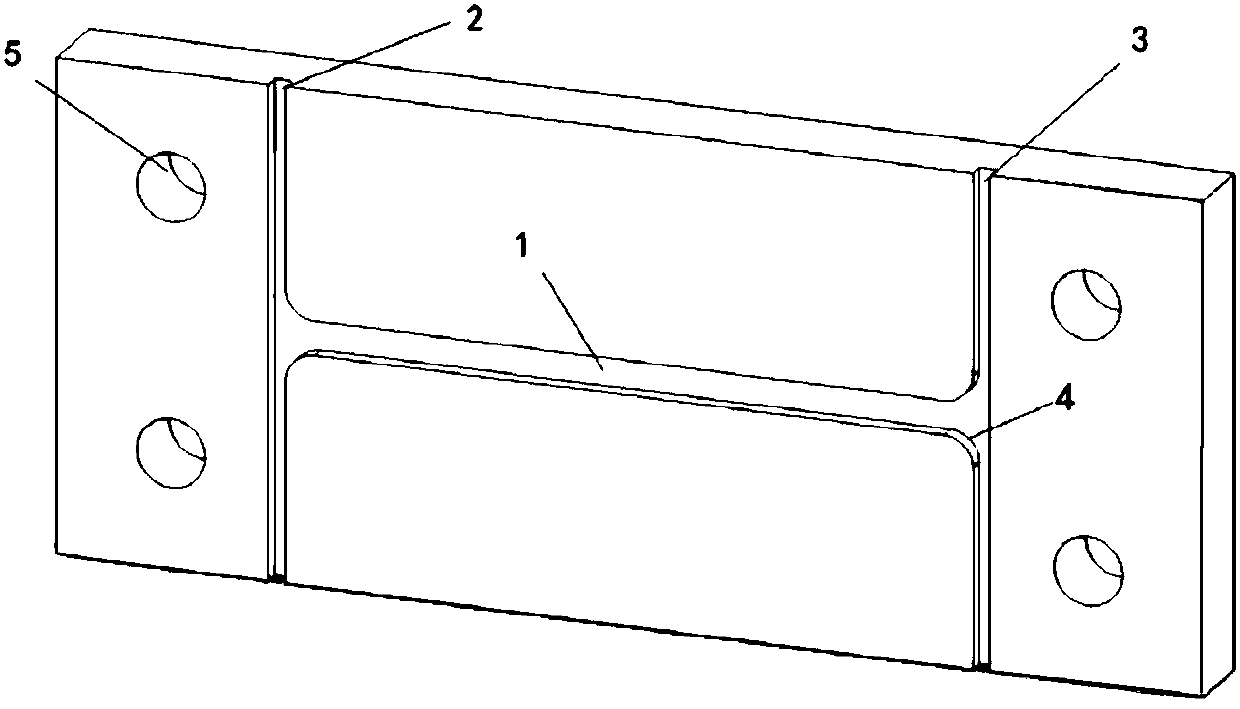

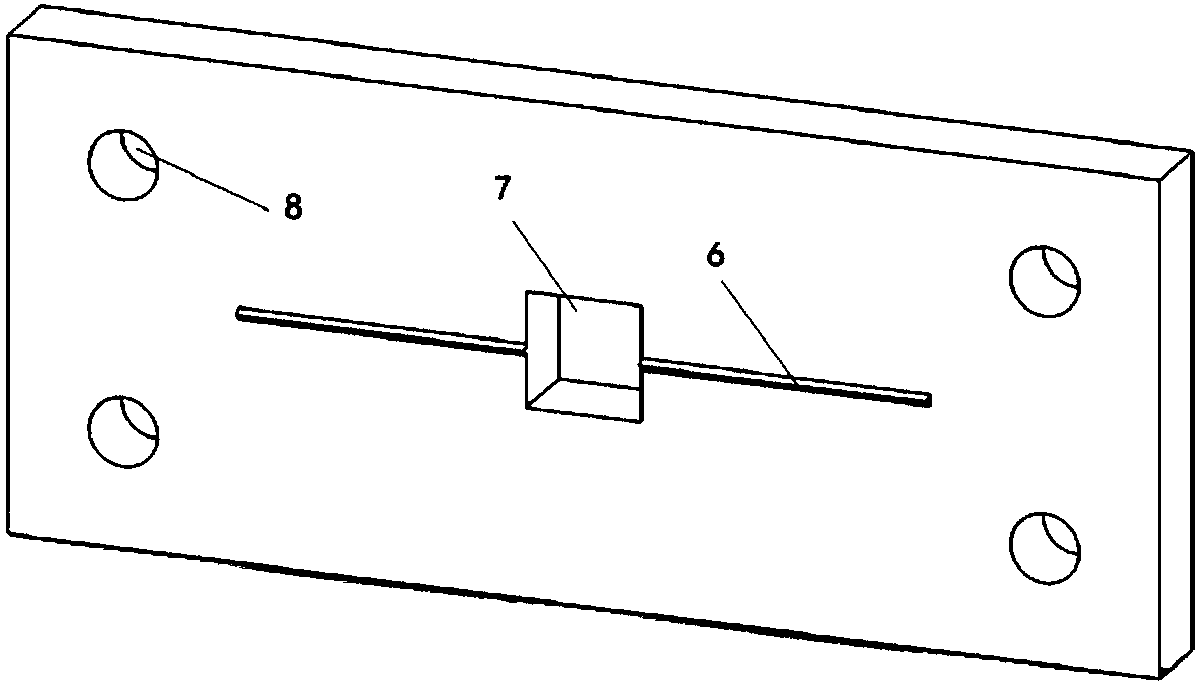

[0055] The invention proposes a dry-type air-core reactor with a fixed size air gap preparation mold and sample preparation method. The mold can realize the adjustment of the air gap width by replacing the gap sheets with different thicknesses. This model can effectively simulate the existence of air gaps between turns The inter-turn insulation structure of the dry-type air-core reactor in the case can be used for the research and test of the insulation and dielectric properties in the case of defects between the turns.

[0056] 1. PTFE mold

[0057] Such as figure 1 The bottom plate of the polytetrafluoroethylene mold used to make the sample is shown. The mold structure size parameter is 200×86×15mm, and a length of 120mm, width of 5.9mm, and depth of 2.9mm are milled out in the center of the long side of the mold. Merge groove 1, mill out the first through groove 2 and the second through groove 3 with a width of 2.9mm and a depth of 2.9mm at both ends of the groove, and mer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com