Wire delivery mechanism of full automatic wire stripping machine

A fully automatic, winding mechanism technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of difficult quality assurance, slow speed, high scrap rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

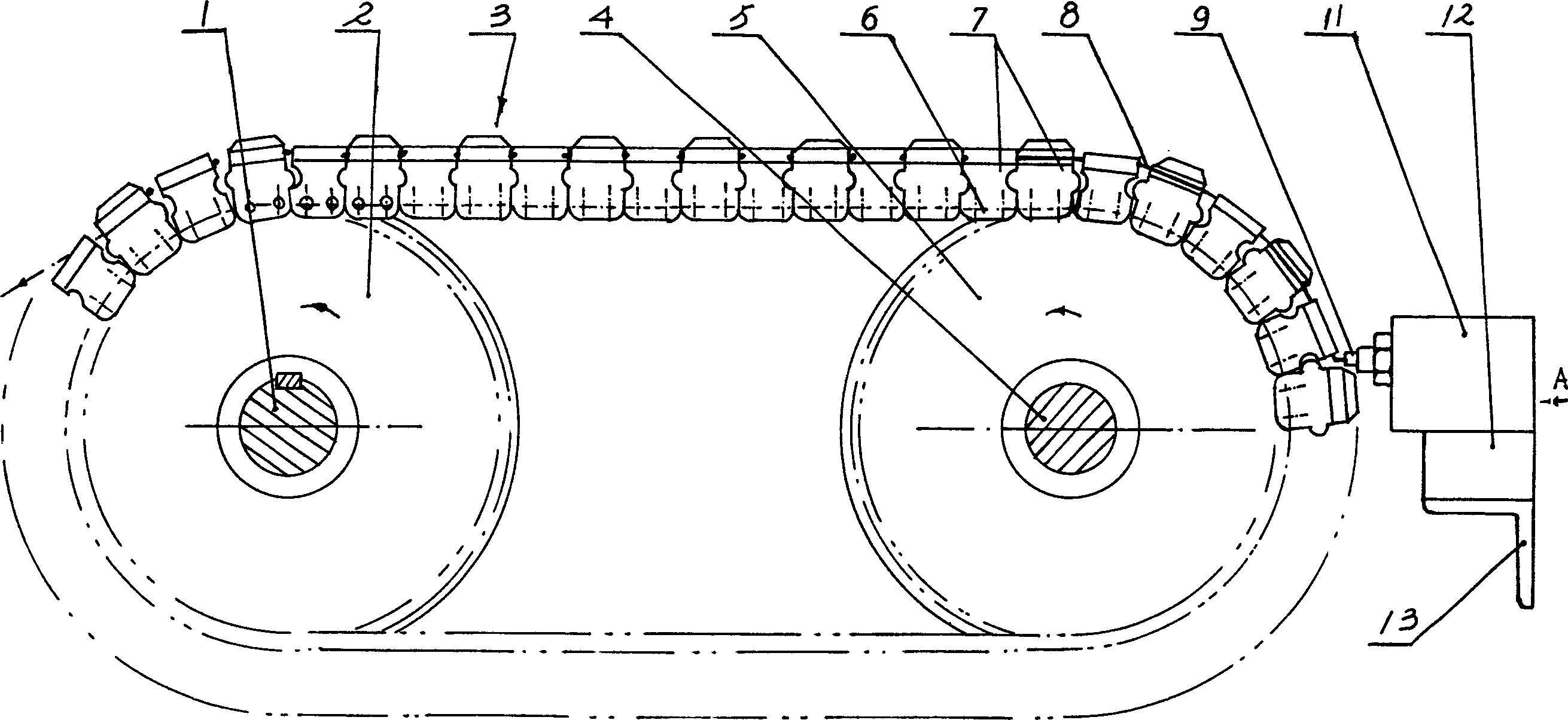

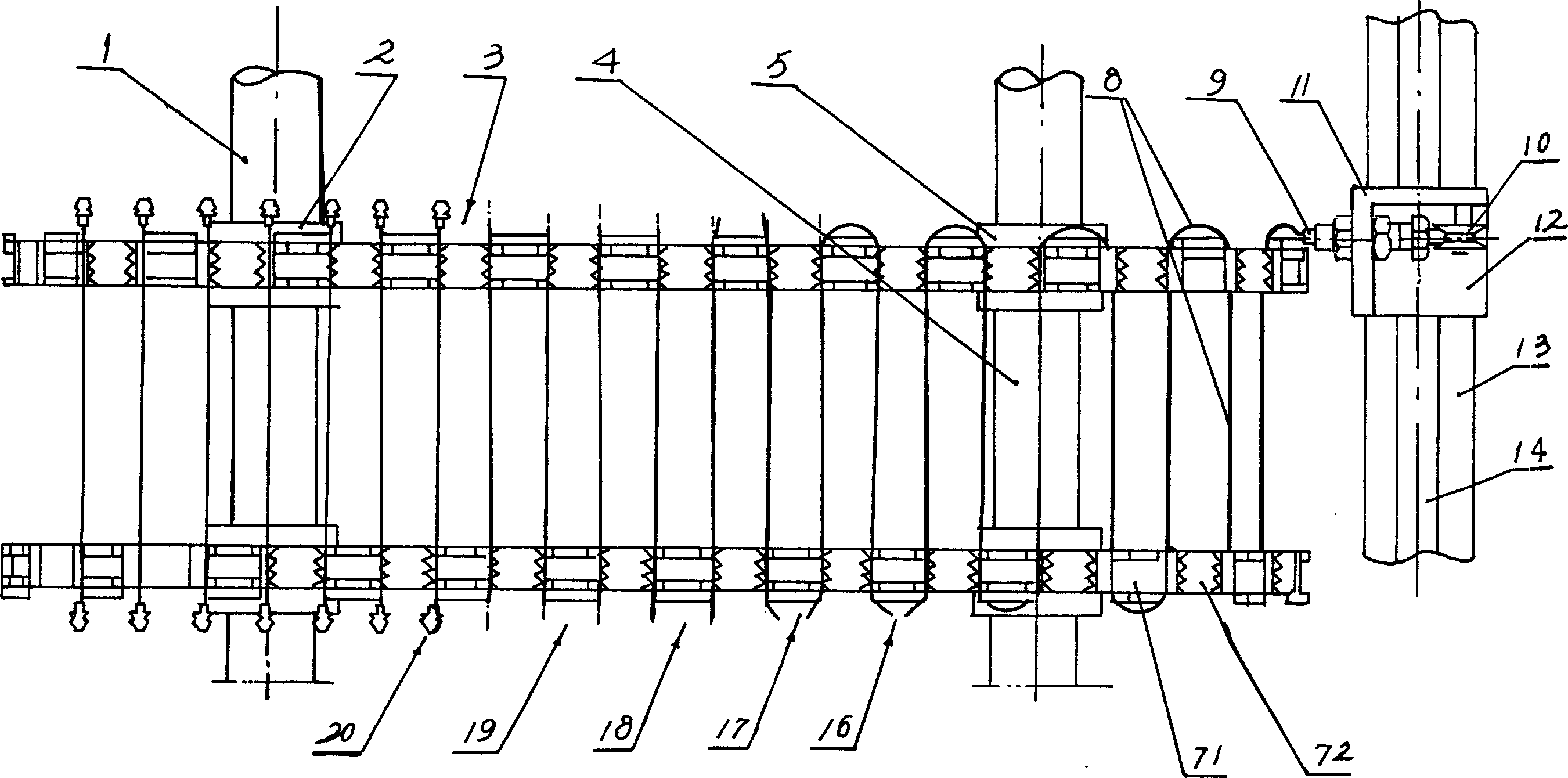

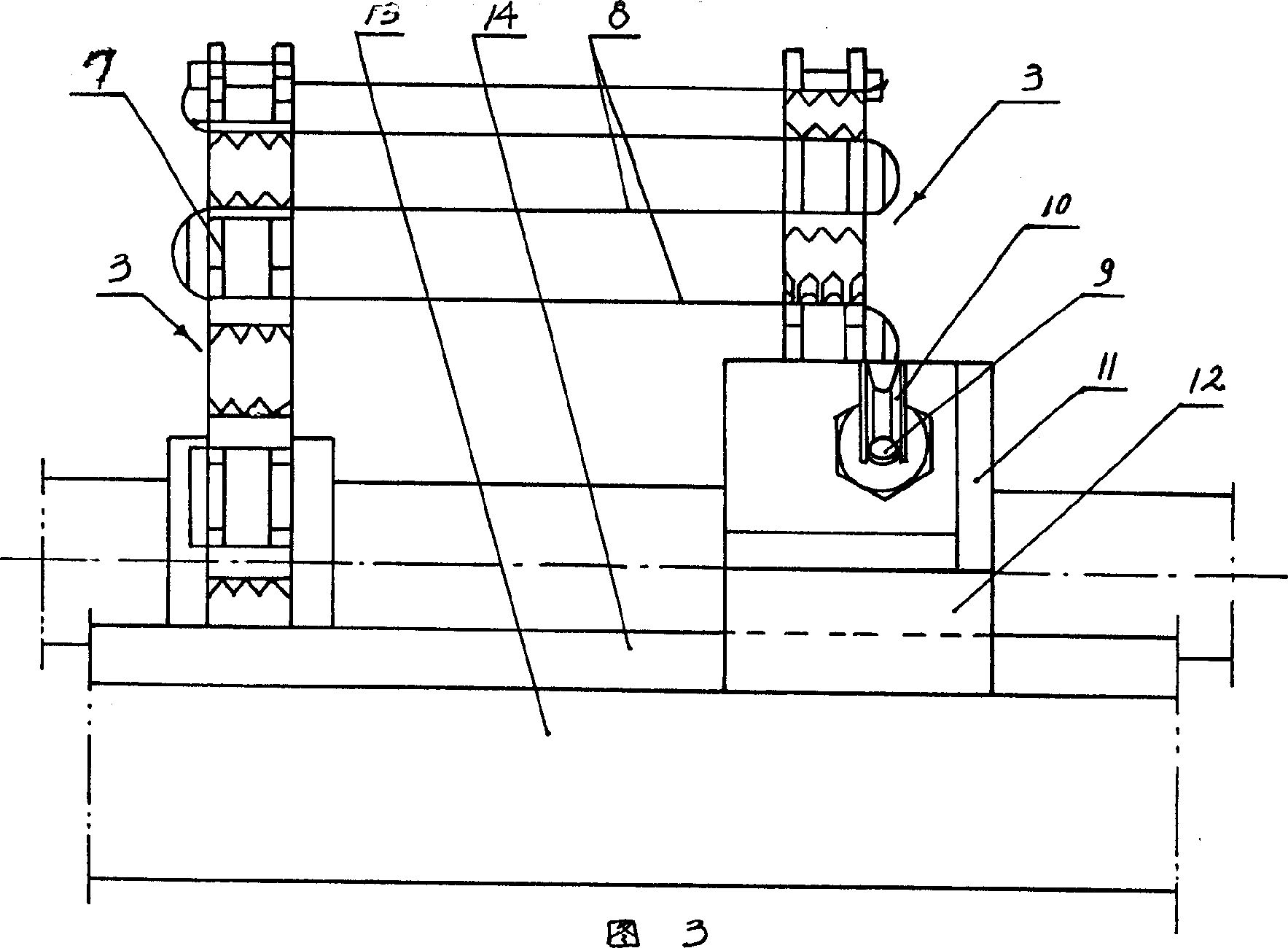

[0013] The invention relates to a wire feeding mechanism for a fully automatic wire stripping and punching machine, which belongs to processing equipment for wiring ends. The overall wire transmission mechanism is a set of mechanical transmission process, which has a driving shaft 1 and a driven shaft 4 installed in parallel in the wire stripping and punching machine, such as figure 1 , figure 2 As shown, the driving shaft 1 is driven by power, and there is a driving wheel 2 on the shaft, and a driven wheel 5 is installed on the driven shaft to transmit through the conveyor belt 3 to form a turning device. The key sending technology is that the conveyor belt 3 is not a common conveyor belt, but in There is a wire fixing block 7 on the conveyor belt. The wire fixing block has the functions of winding and clamping the wire. One end of the slewing device is equipped with a winding mechanism. The blocks hold the wires and run with the conveyor belt with the wires. Because the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com