Inner hole spraying device of hardware product

A technology of spraying device and products, applied in the direction of spraying device, etc., can solve the problem of inability to guarantee the efficiency and quality of spraying of inner holes of hardware, and achieve the effect of reducing labor intensity and improving efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

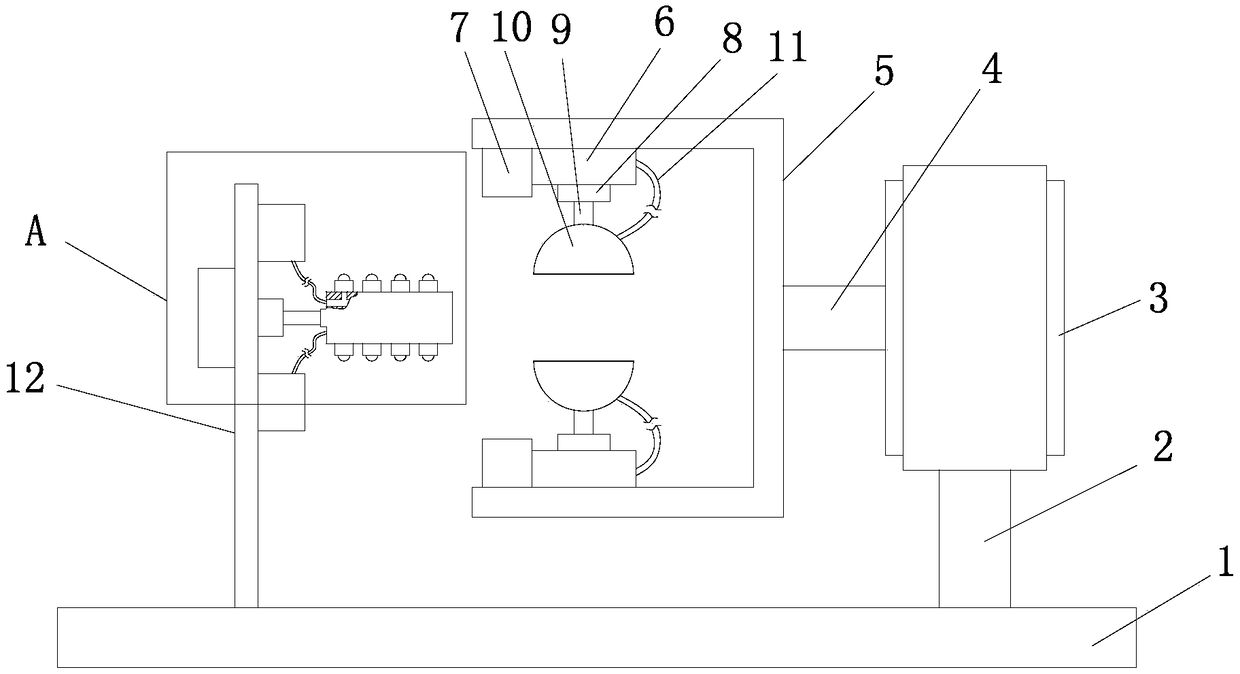

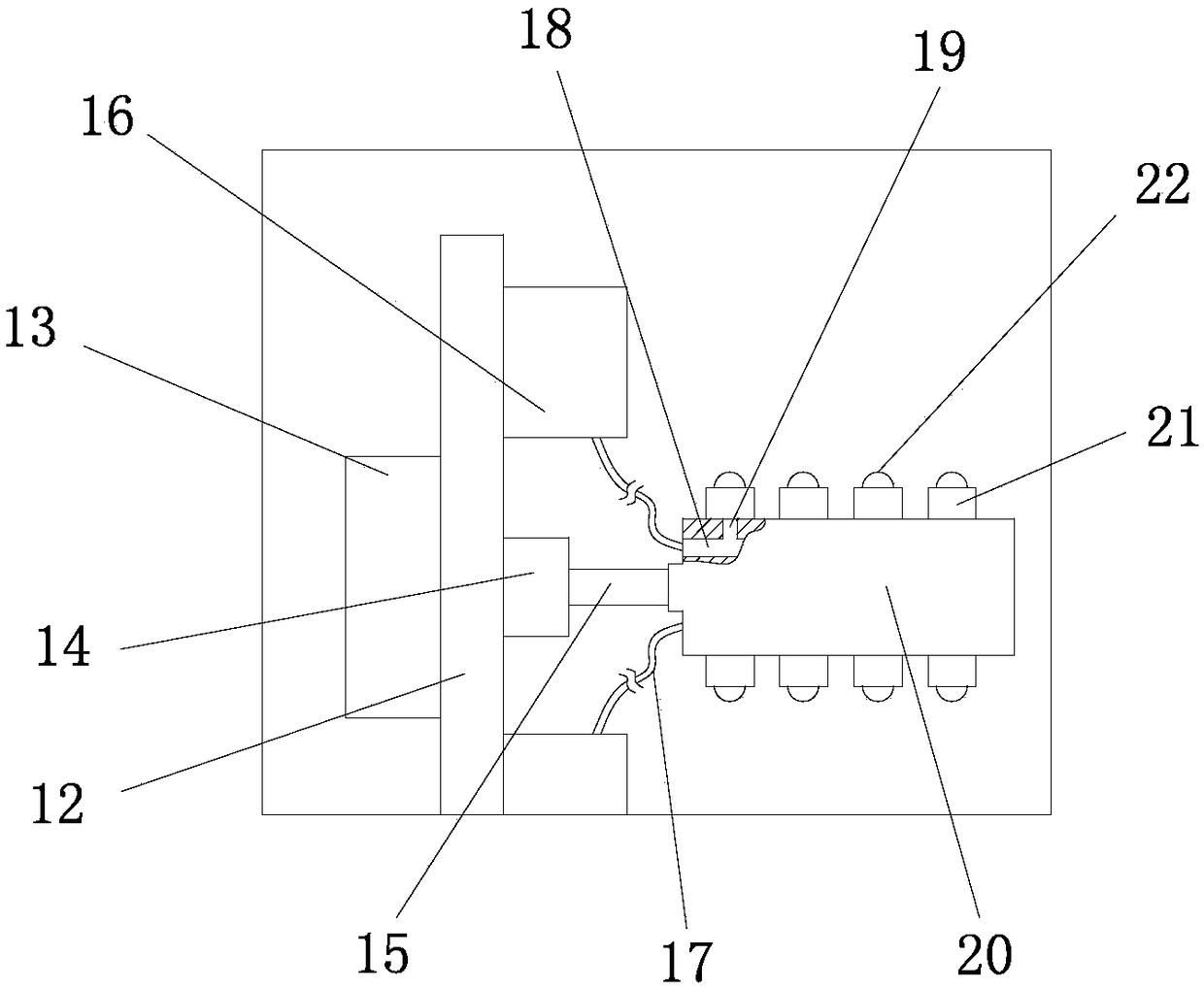

[0017] Such as Figure 1-2 As shown, a metal product inner hole spraying device provided by the present invention includes a base 1, a motor bracket 2 is installed on the upper end of the base 1, a motor 3 is installed on the upper end of the motor bracket 2, and one side of the motor 3 A rotating shaft 4 is installed, and the side of the rotating shaft 4 away from the motor 3 is equipped with a rotating frame 5, and the inner wall of the rotating frame 5 on the opposite side in the vertical direction is equipped with a first piston 8, and the first piston 8 A first piston shaft 9 is installed on the side away from the swivel frame 5, a suction cup 10 is installed on the side of the first piston shaft 9 away from the first piston 8, and a first hydraulic pump is also provided on the side of the compressor 6 7. An installation shaft 12 is installed on the upper end of the base 1 and on one side of the rotating frame 5, and a nozzle mounting seat 21 is installed on the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com