Patents

Literature

67results about How to "Easy automatic assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

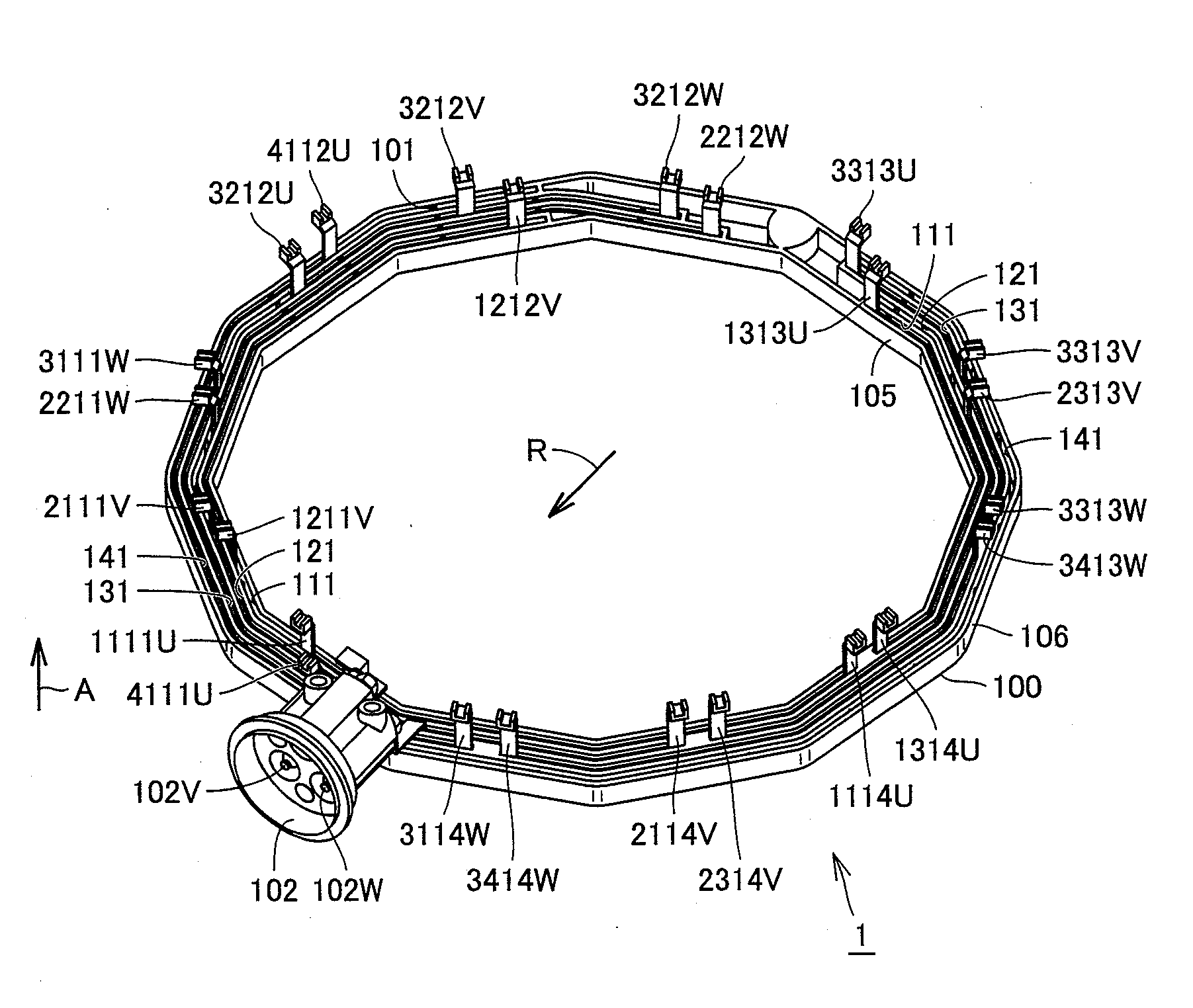

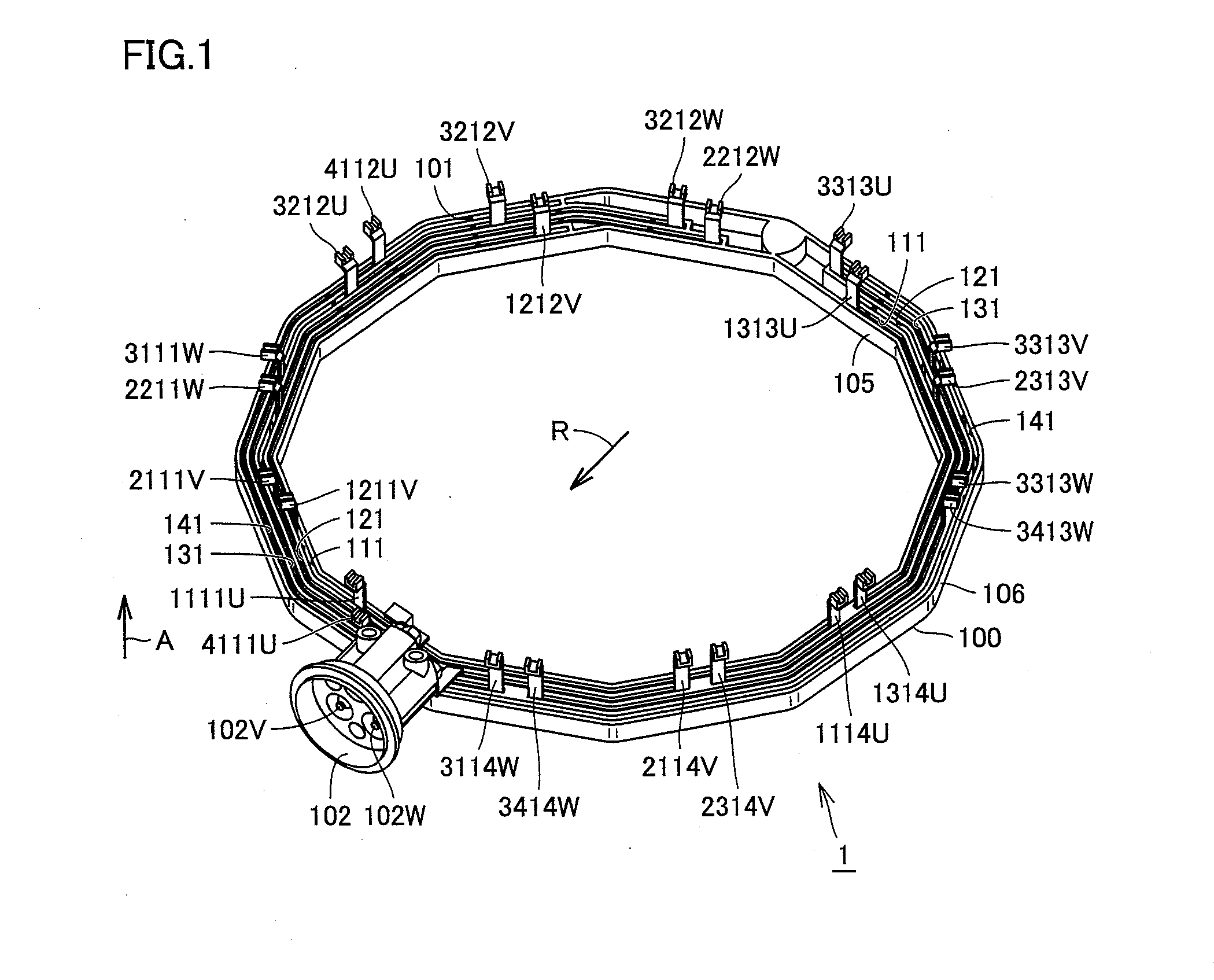

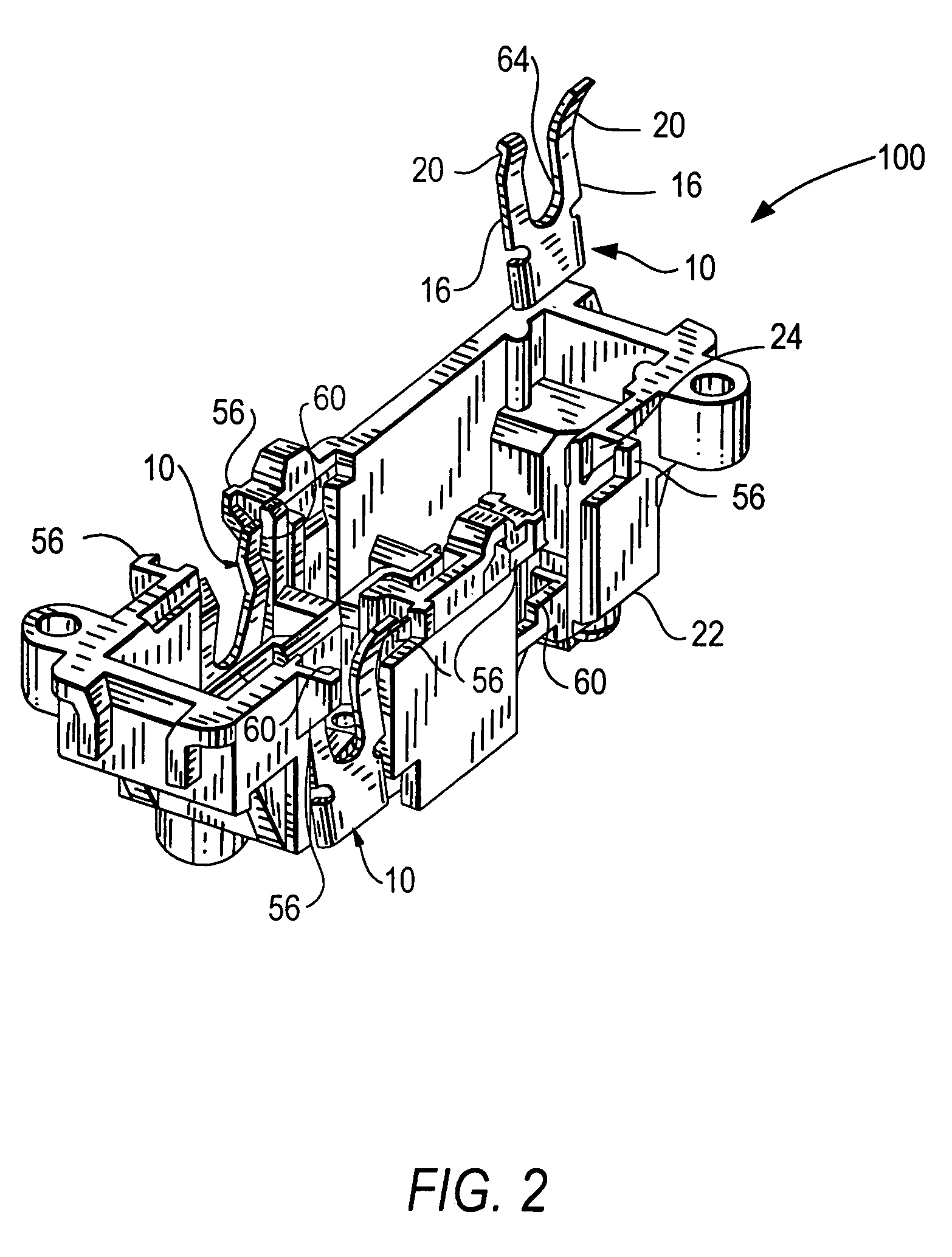

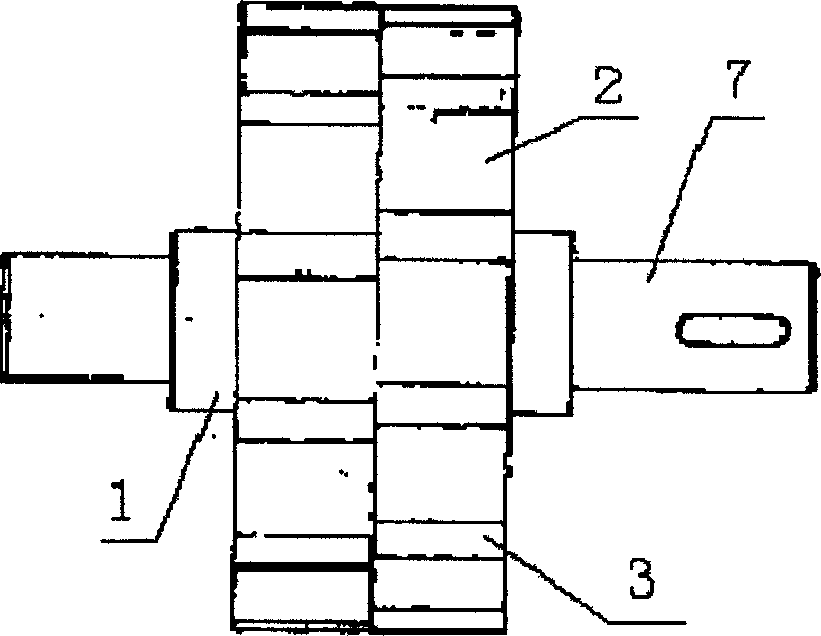

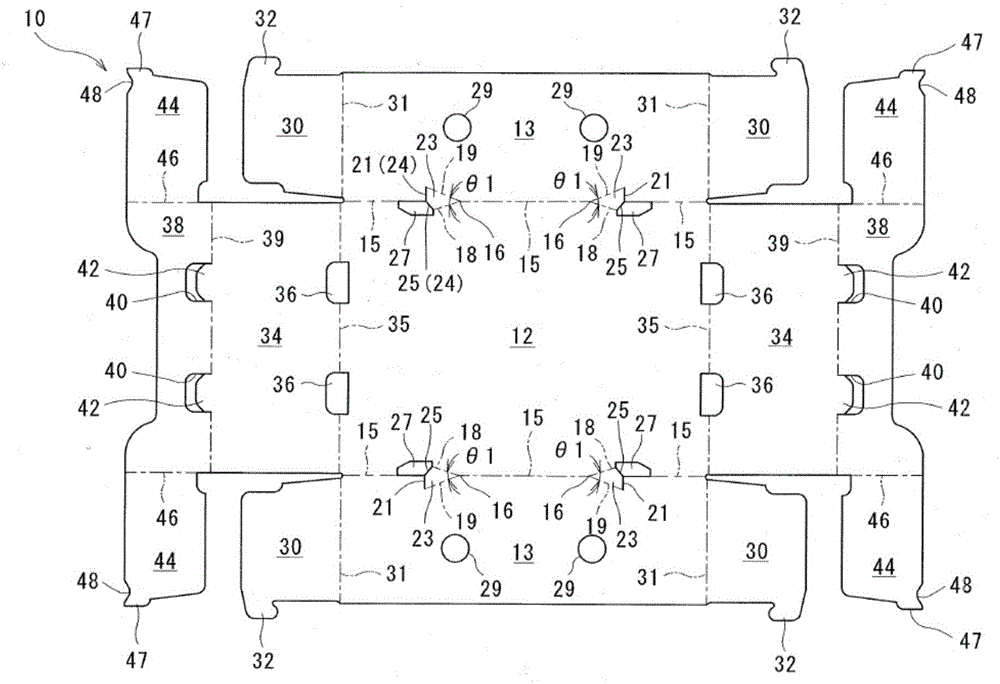

Terminal module for rotating electric machine, and rotating electric machine

InactiveUS20090039720A1Easy automatic assemblyEasy to assembleWindingsStructural associationElectric machineMechanical engineering

A terminal module for a rotating electric machine, allowing automatic assembling, is provided. The terminal module for a rotating electric machine includes a polygonal rail (100) provided with a groove, and a polygonal bus bar fitted in the groove.

Owner:TOYOTA JIDOSHA KK +3

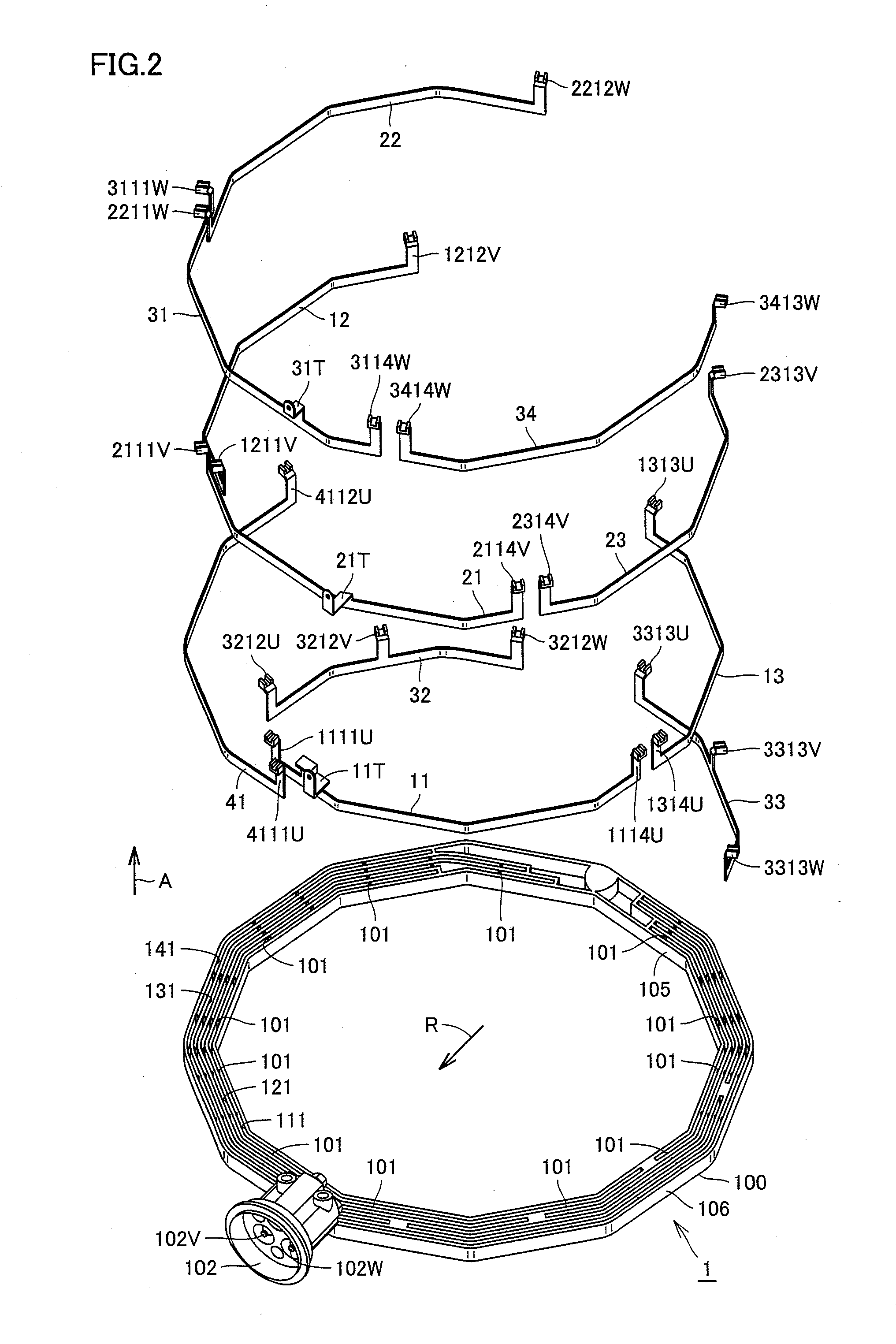

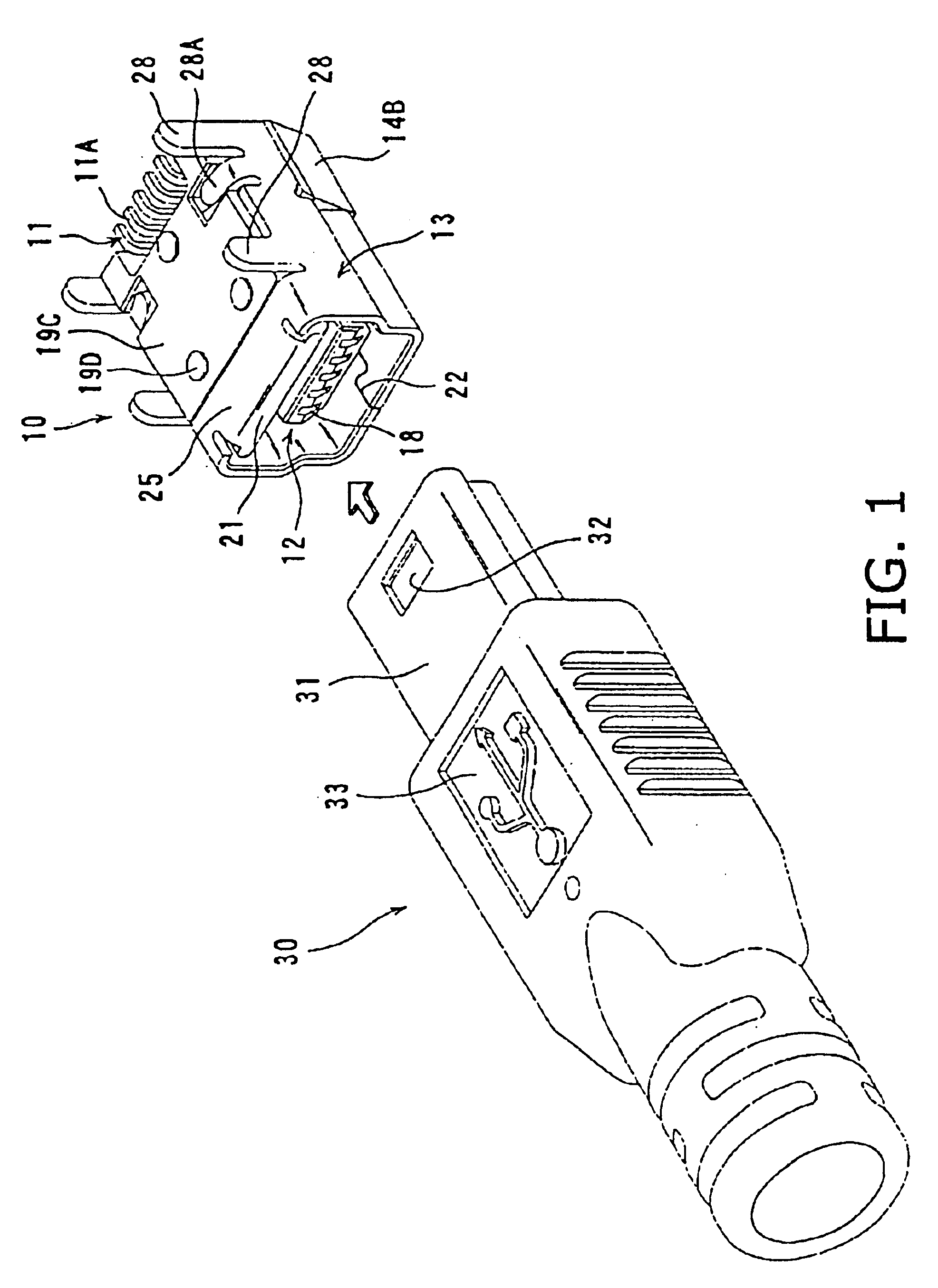

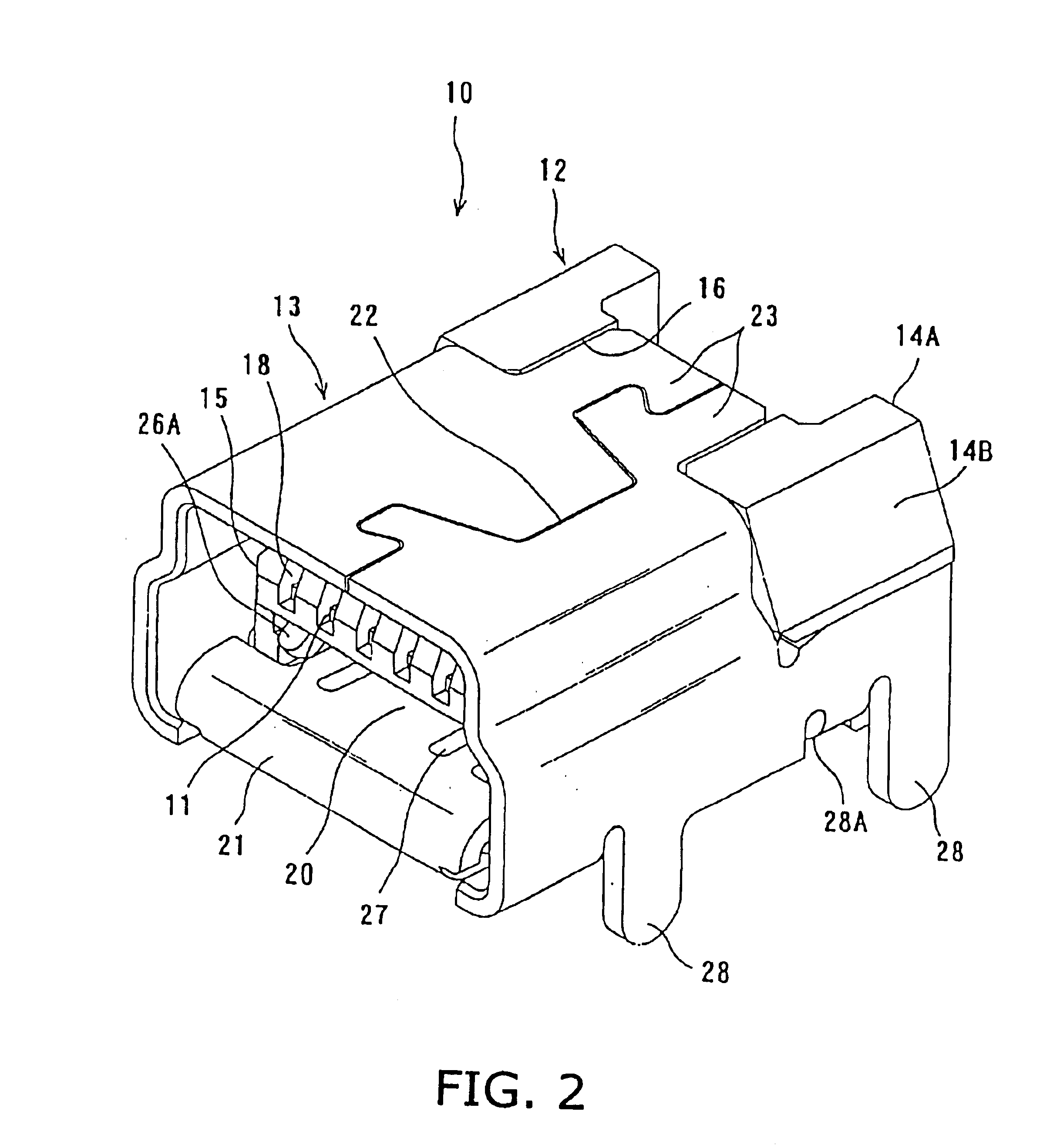

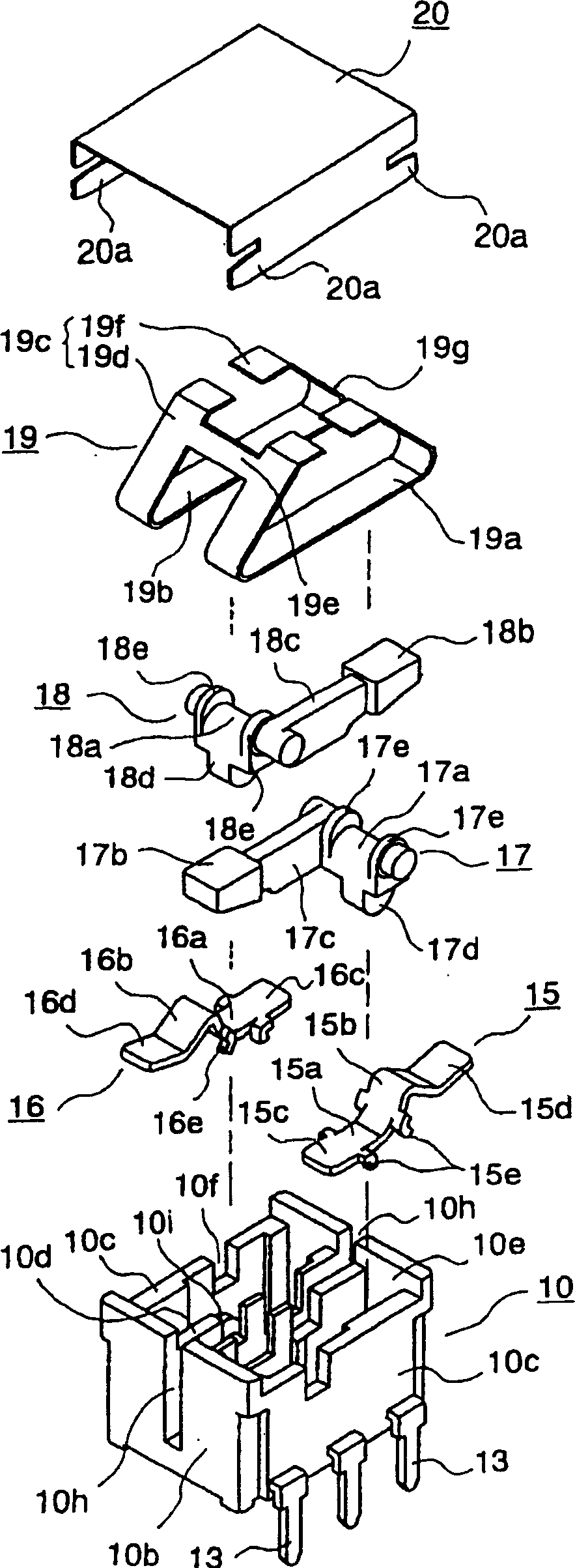

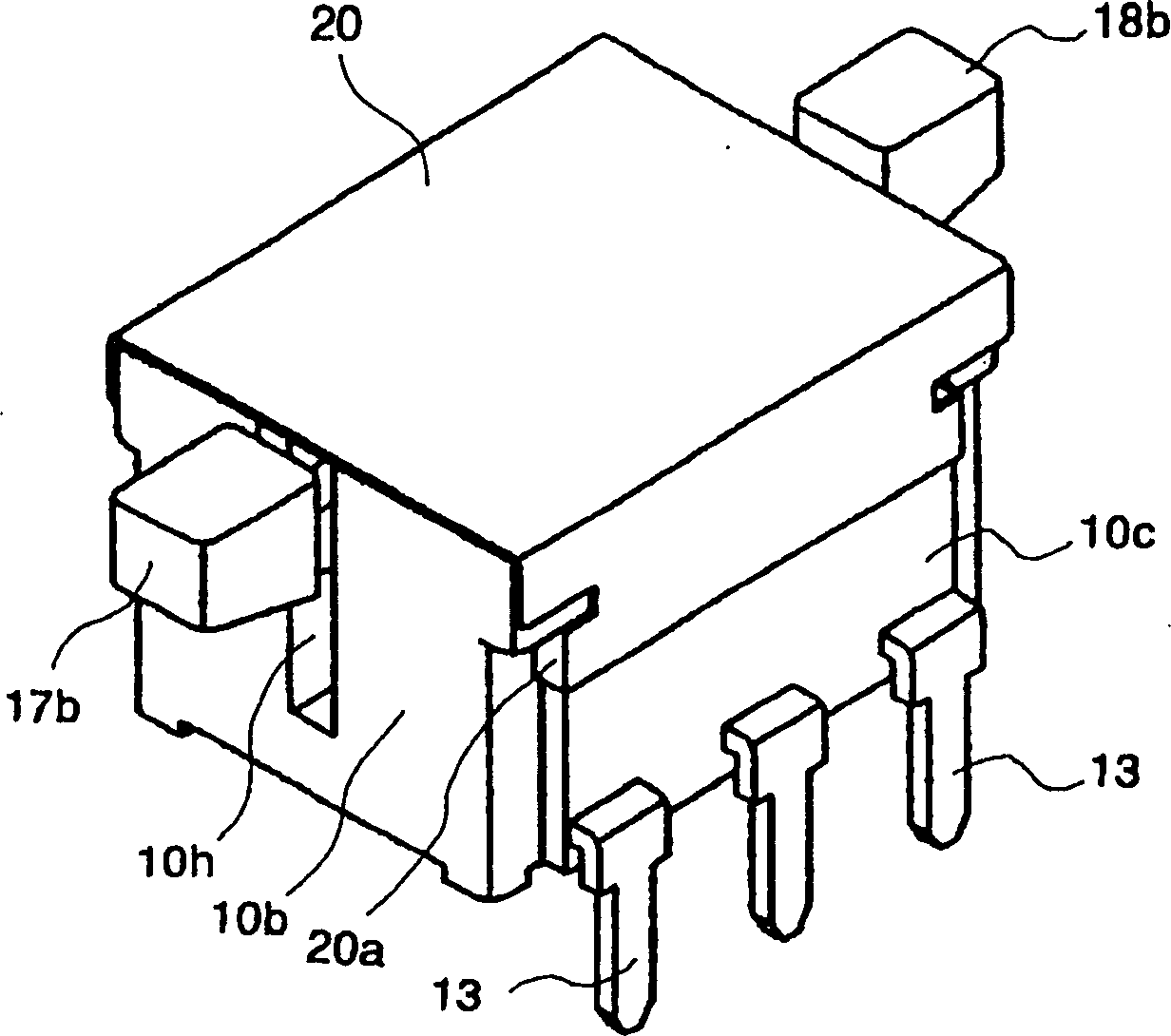

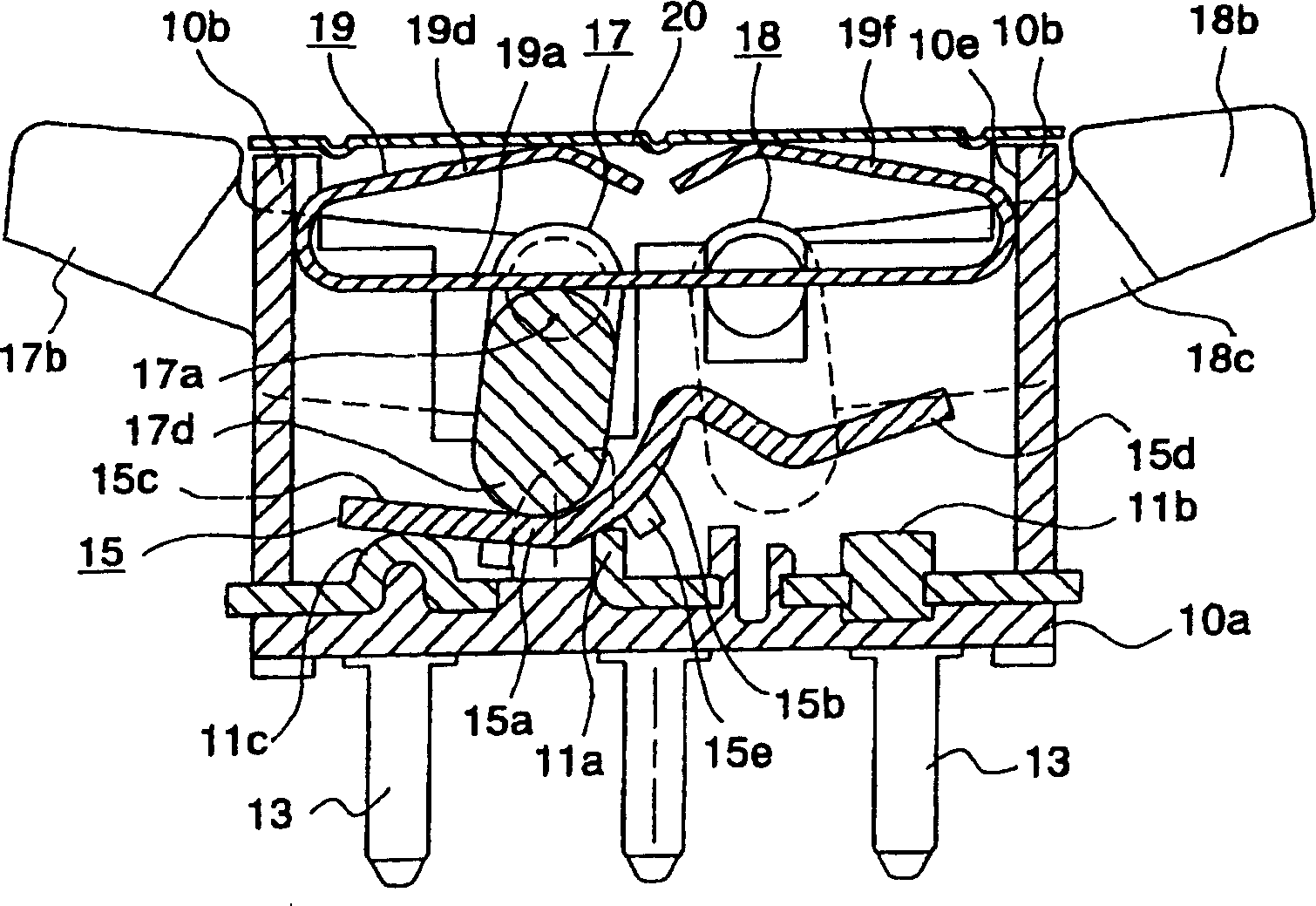

Electrical connector with lock and shield pieces in middle plane

InactiveUS6840806B2Smooth bootEfficient arrangementRotary current collectorNon-rotary current collectorMating connectionEngineering

An electrical connector comprises a housing (12) and a substantially rectangular case (13) made of a metal and enclosing the housing. The rectangular case includes at least one connection portion (28) on a side of a lower surface thereof for connection with a circuit board, a resilient lock piece (20) and a pair of shield pieces (26) between the upper and lower surfaces the rectangular case for engaging a mating connector. The upper surface of the case is made flat for easy assembling with the housing. The resilient lock piece has a bending portion (21), which is bent toward an inner of the rectangular case and the shield pieces are provided on sides of the resilient lock piece.

Owner:HIROSE ELECTRIC GROUP

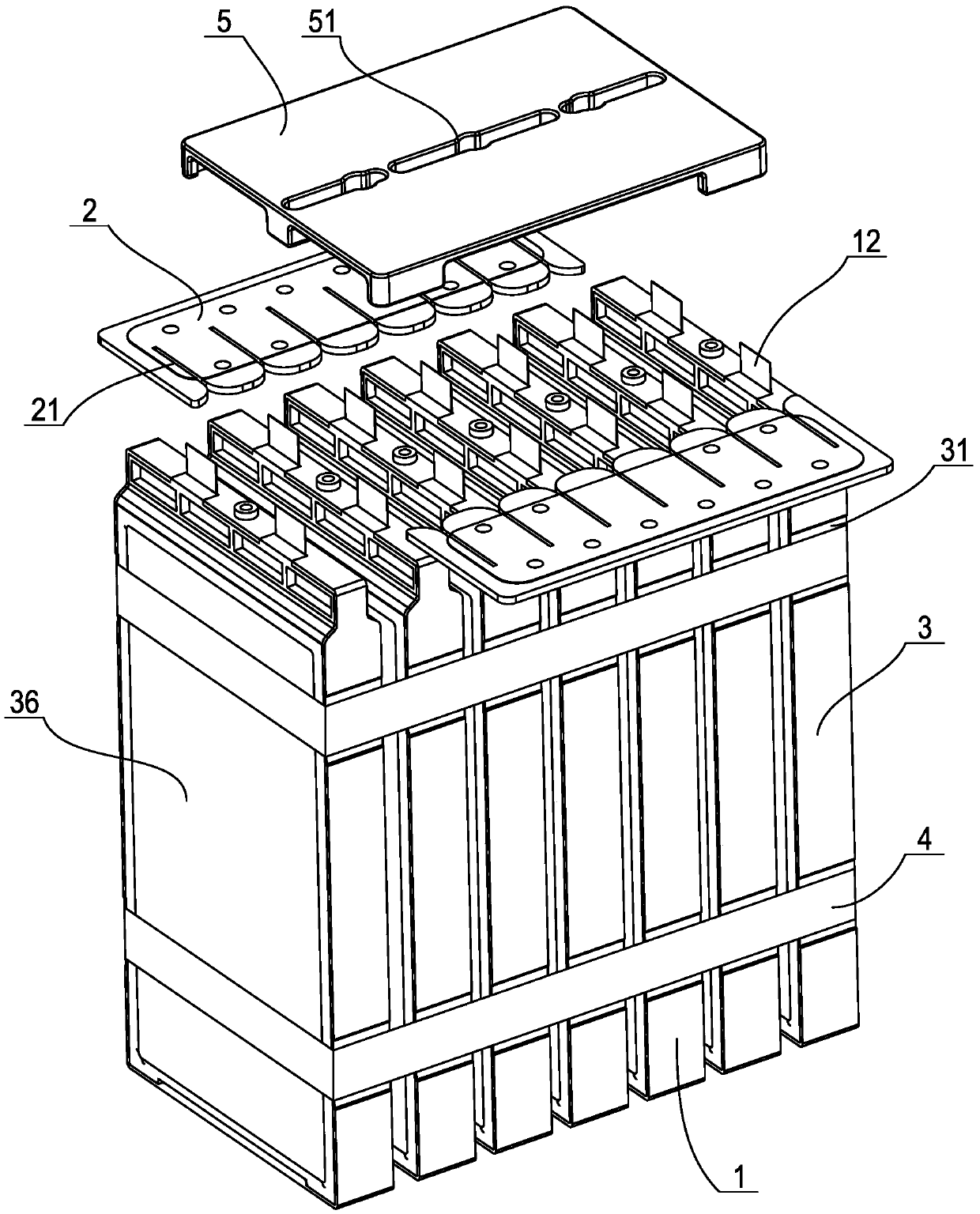

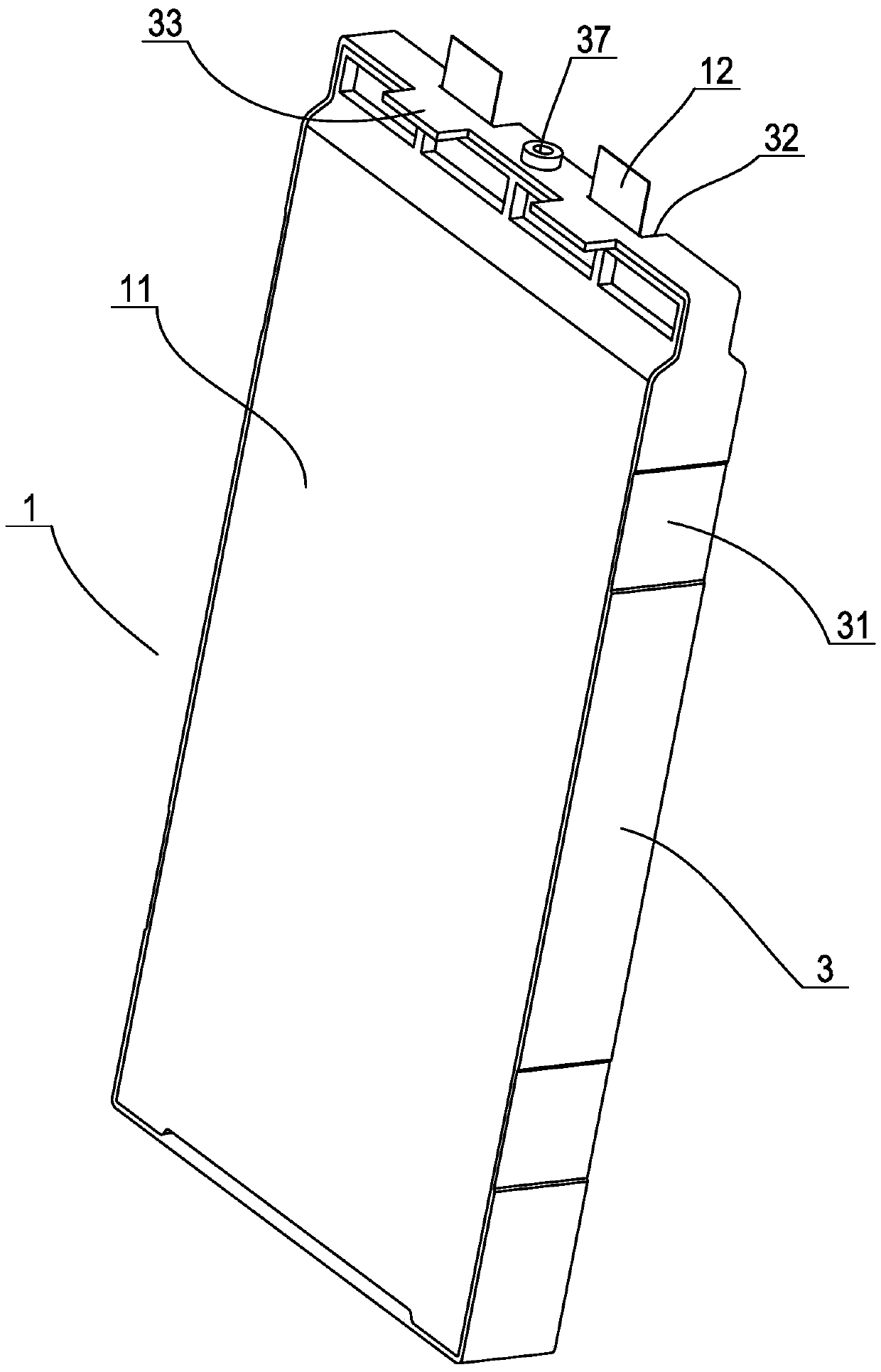

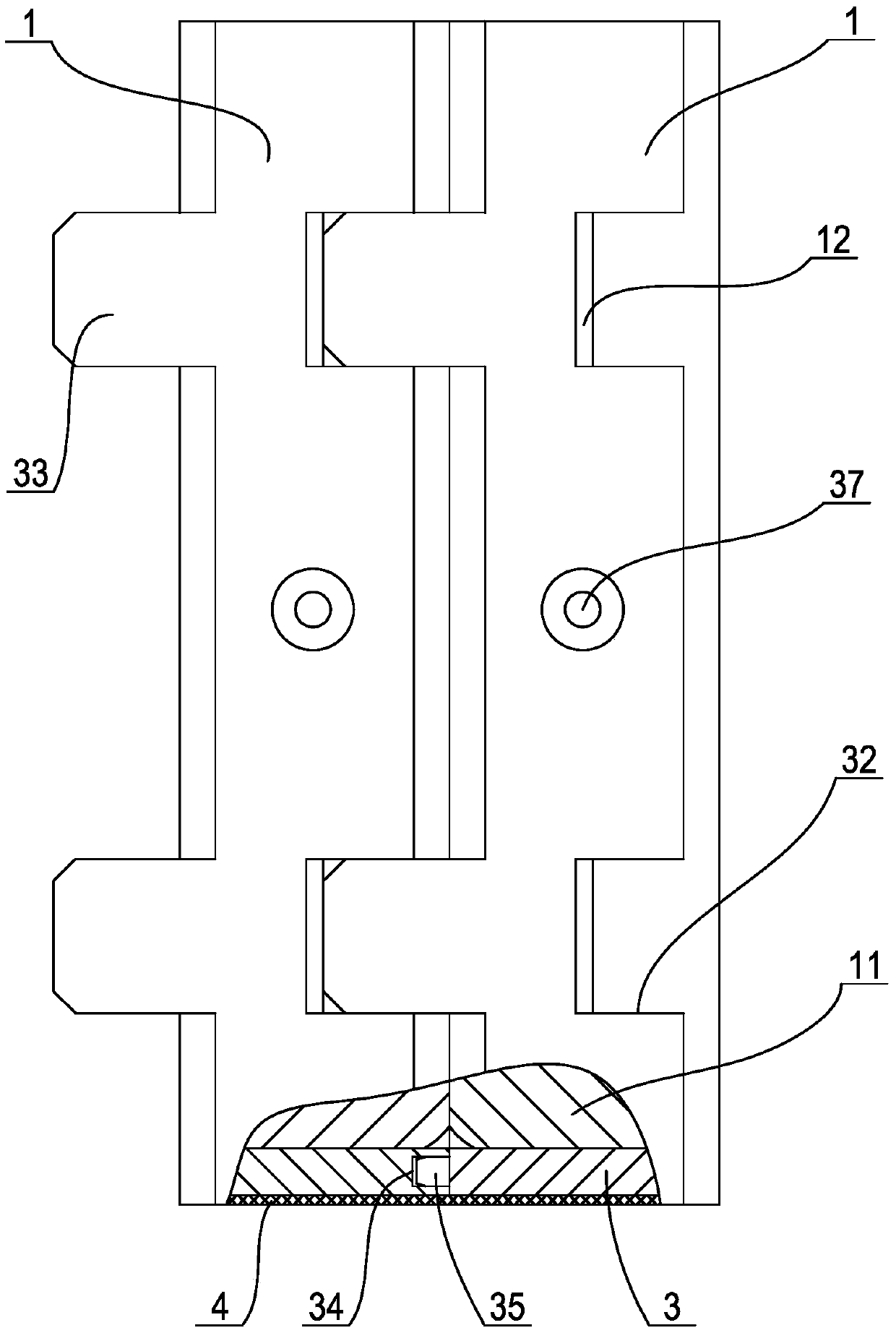

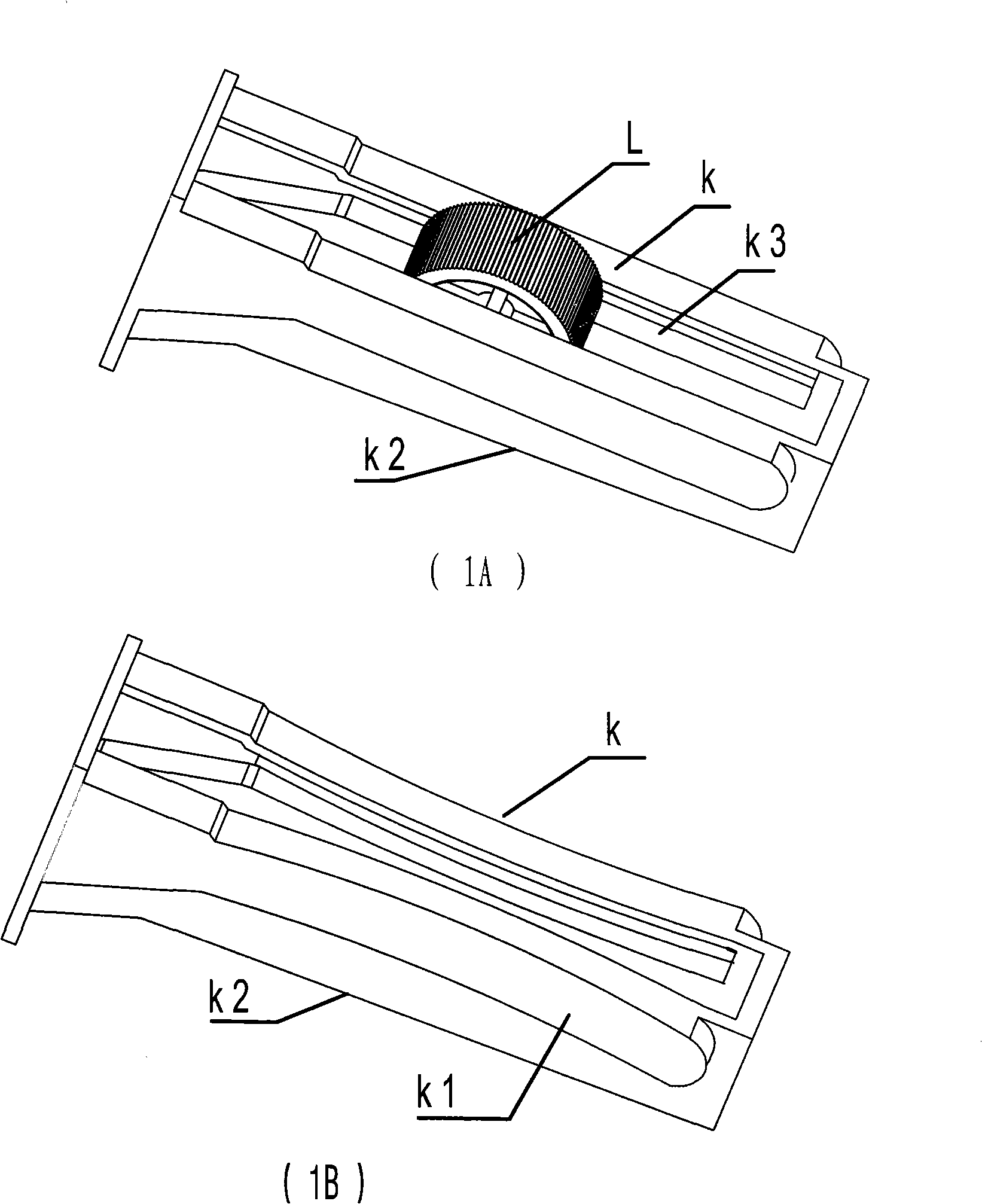

Convenient-to-assemble automatically power battery module and electric motor car

ActiveCN105514498AHigh strengthImprove protectionFinal product manufactureCell component detailsPower batteryElectrical battery

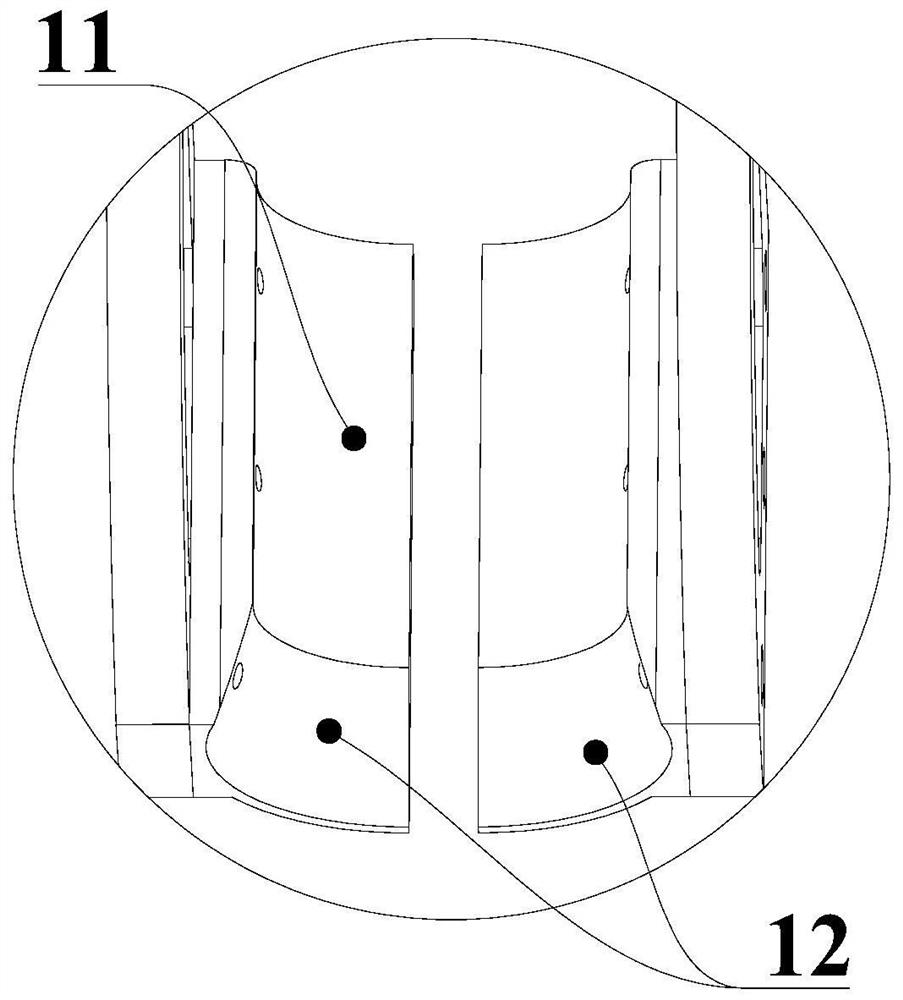

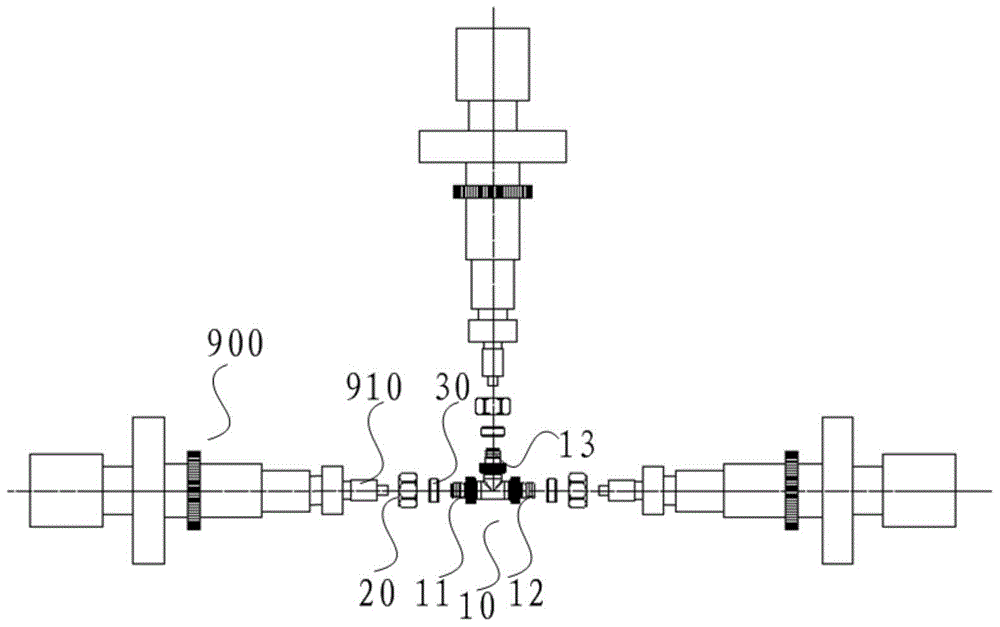

The invention discloses a convenient-to-assemble automatically power battery module and an electric motor car. The electric motor car adopts the power battery module; the power battery module comprises a plurality of soft pack battery cells; positive electrode lugs of each soft pack battery cell are connected via a bus bar, correspondingly, negative electrode lugs of the soft pack battery cell are connected via another bus bar; the two bus bars are arranged oppositely side by side; electrode lug grooves are formed in edges on the opposite sides of the two bus bars at intervals respectively; bell mouths, which are larger and larger gradually, are formed in corners at the opening of the electrode lug grooves; the electrode lugs of the soft pack battery cells are clamped in the corresponding electrode lug grooves of the bus bars on two sides sequentially, extend out of the upper ends of the bus bars, and then bend to cling to and be connected to the upper surfaces of the bus bars. The convenient-to-assemble automatically power battery module is simple in integral structure, the soft pack battery cells can be connected with the bus bars conveniently, automatic assembly can be realized, the assembly efficiency is high, the outline after packing is regular, and the soft pack battery cells are low in damage possibility.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

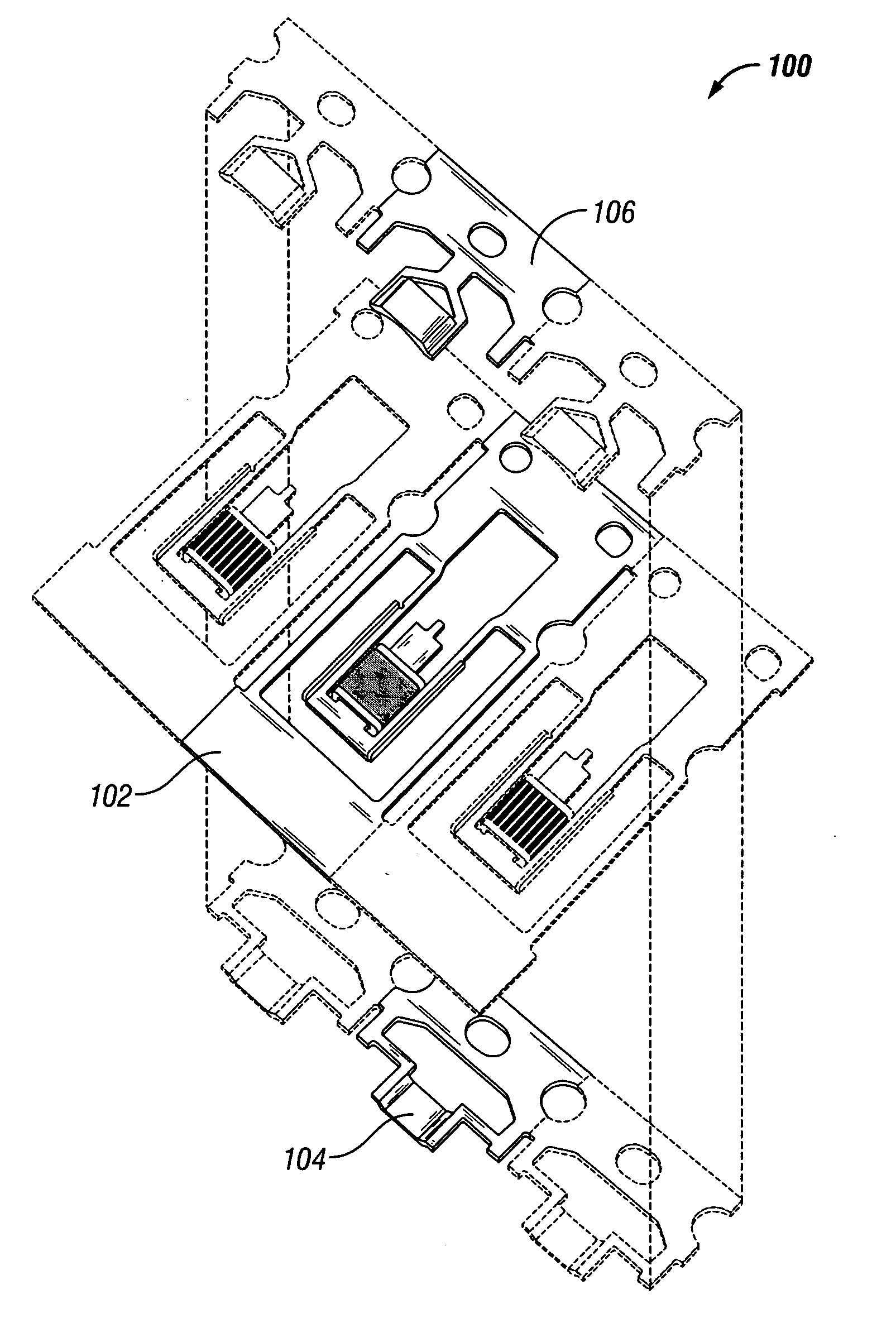

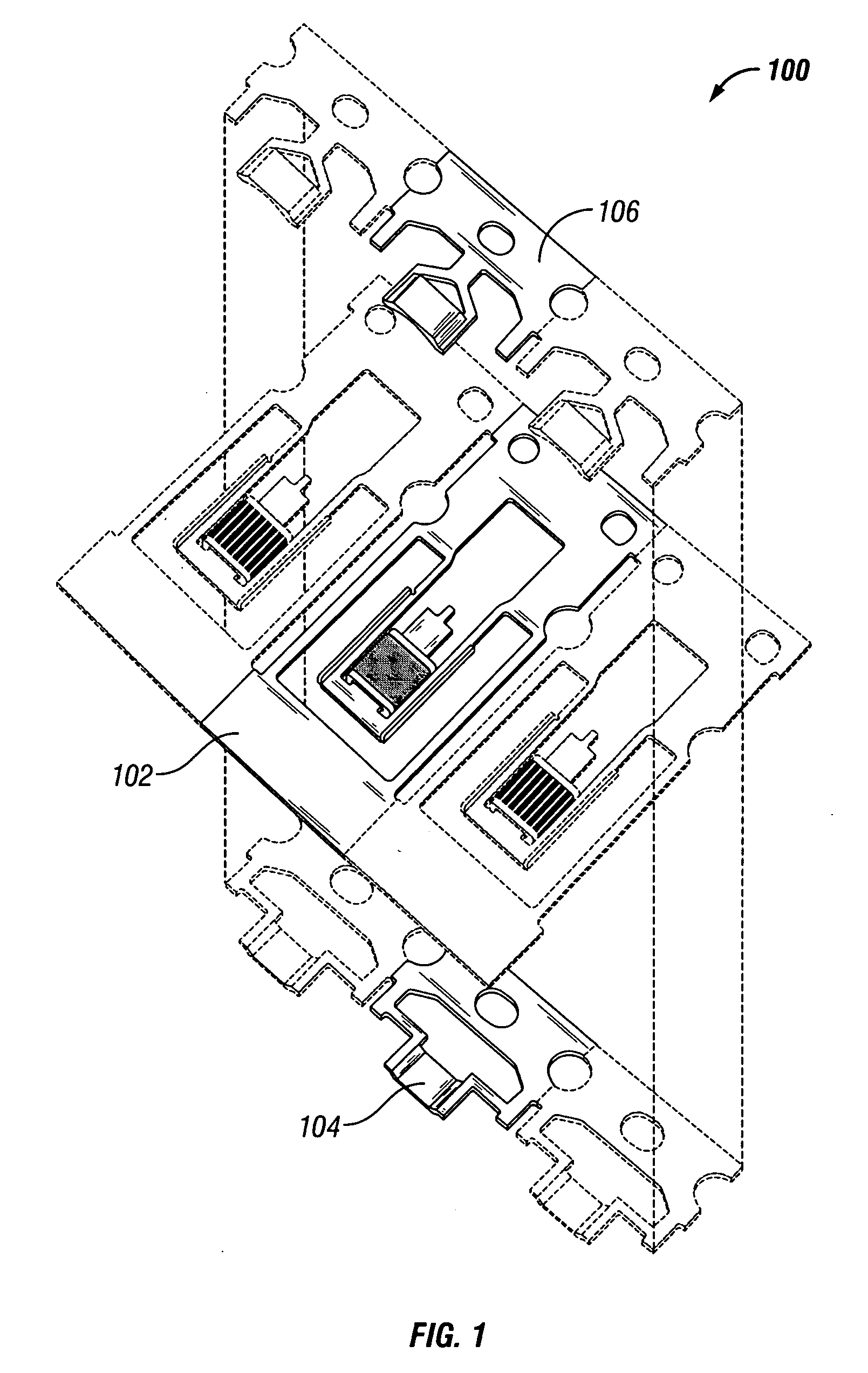

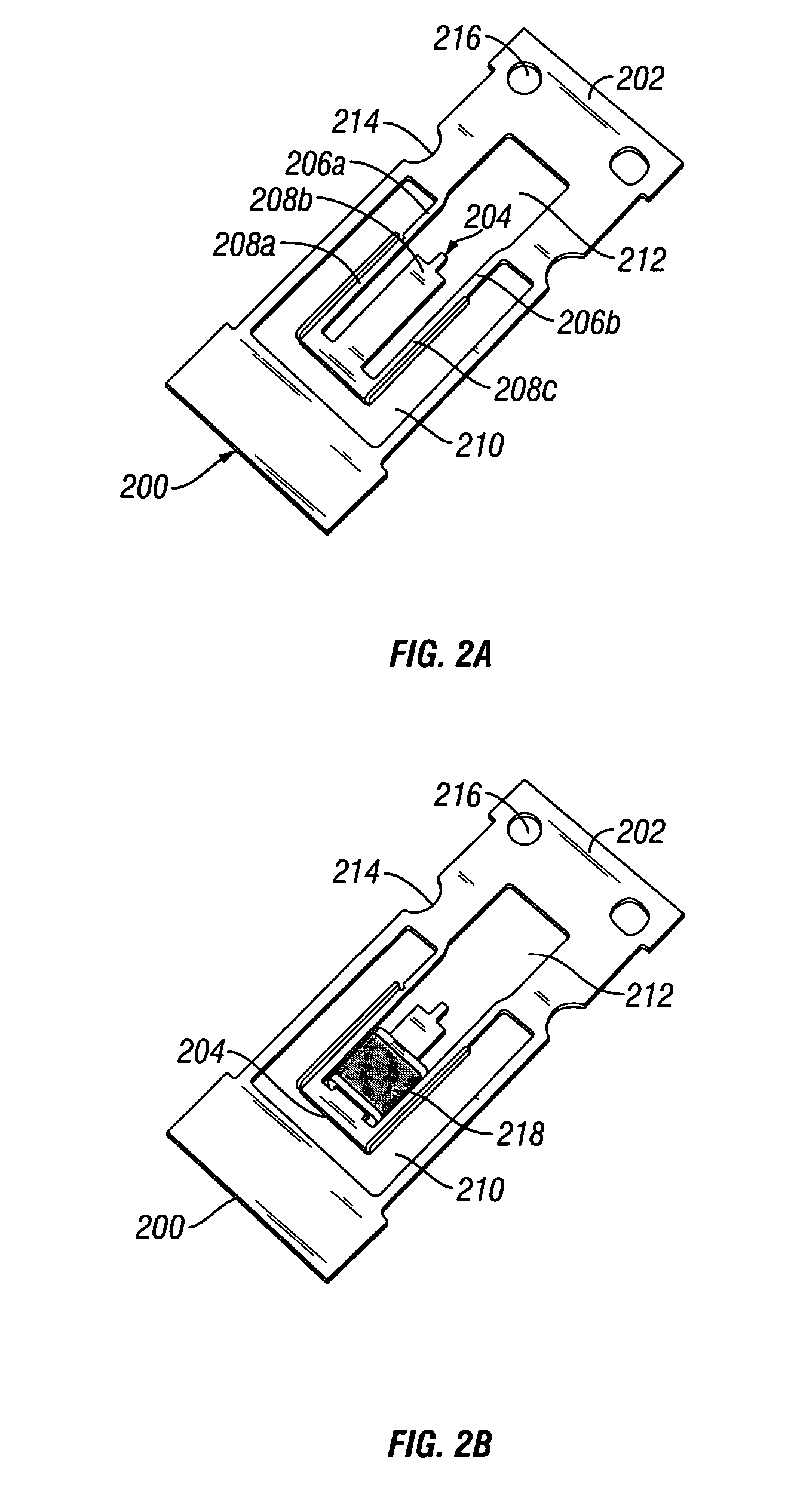

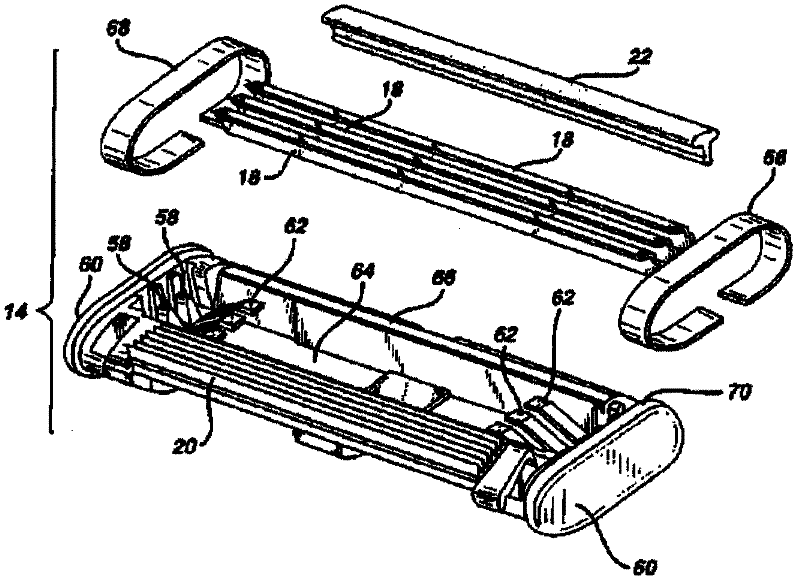

Method and system for assembling electroacoustic transducers

Method and system are disclosed for facilitating automatic assembly of electroacoustic transducers for listening devices, such as hearing aids. The method and system provide the components of the electroacoustic transducer in the form of carriers. Each carrier includes a frame surrounding a preformed component. The preformed component is attached to the frame by at least one strut that holds the component in a fixed position within the frame. The frame may then be used as a guide or reference for mounting other components (whether provided on component carriers or not) to the preformed component. Some components, instead of being in a carrier, may be preassembled as a subassembly and then mounted to other components that are in a carrier. Several carriers may be connected sequentially in a strip and run through an assembly line to facilitate automatic assembly of multiple electroacoustic transducers in parallel.

Owner:SONION NEDERLAND

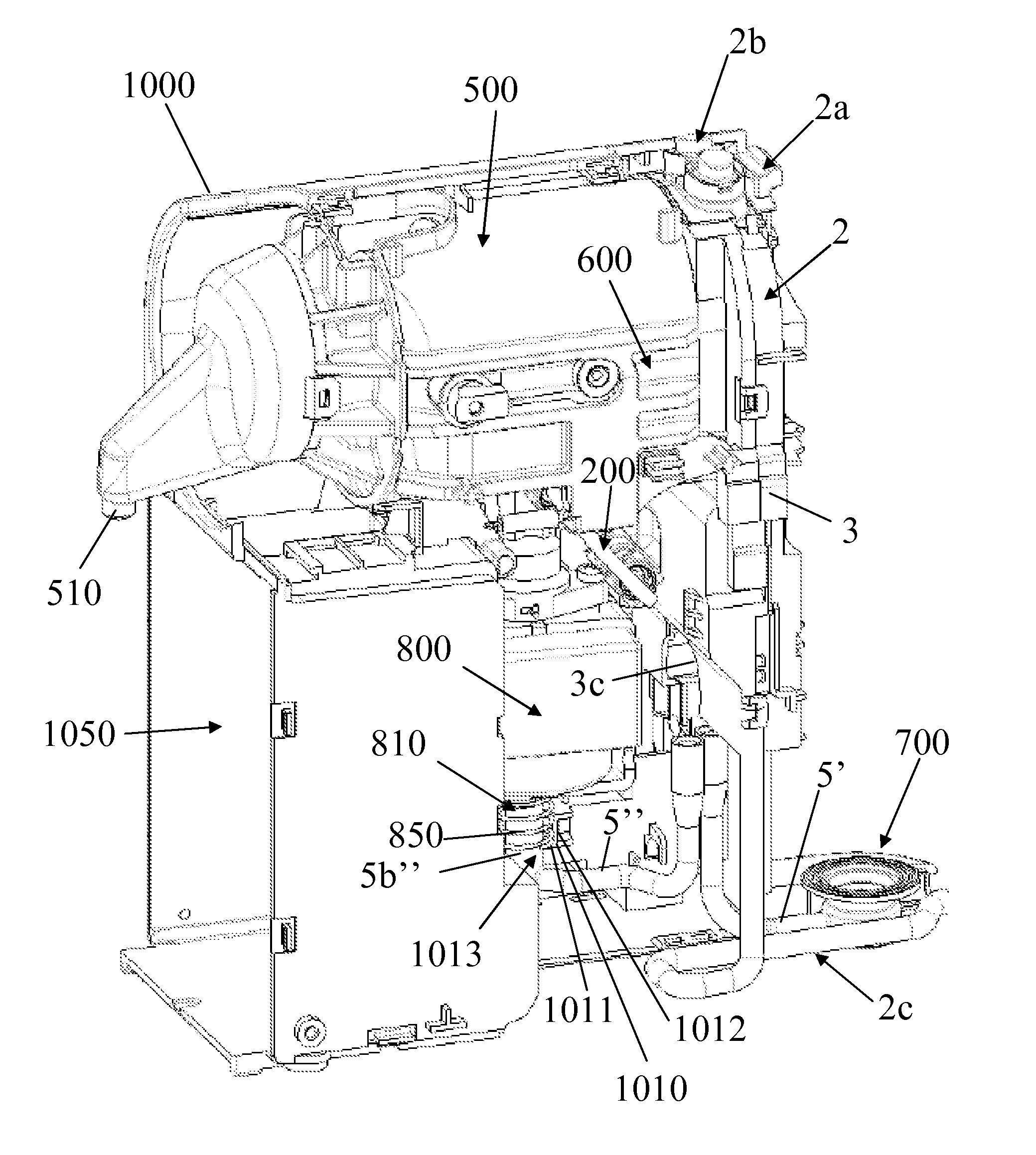

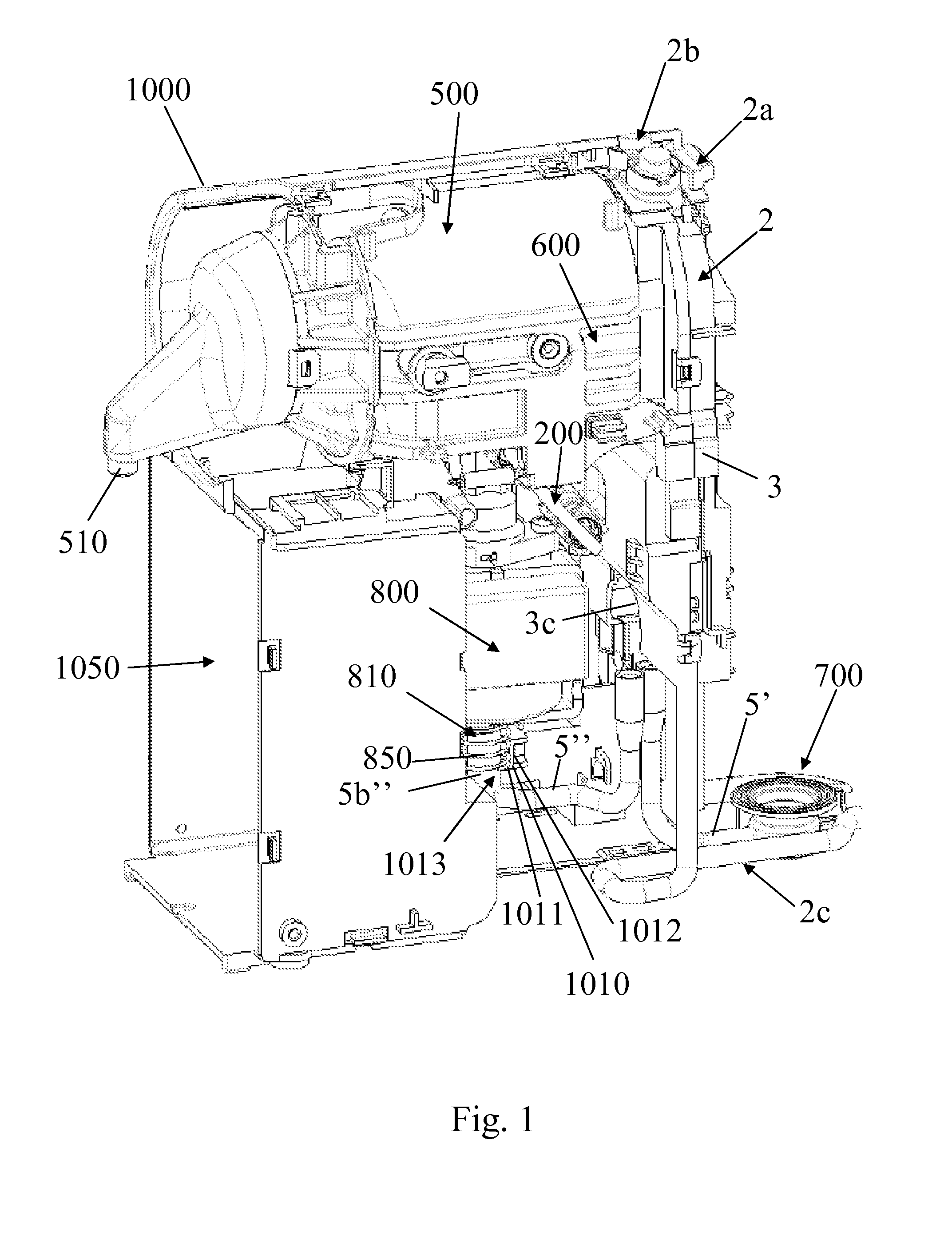

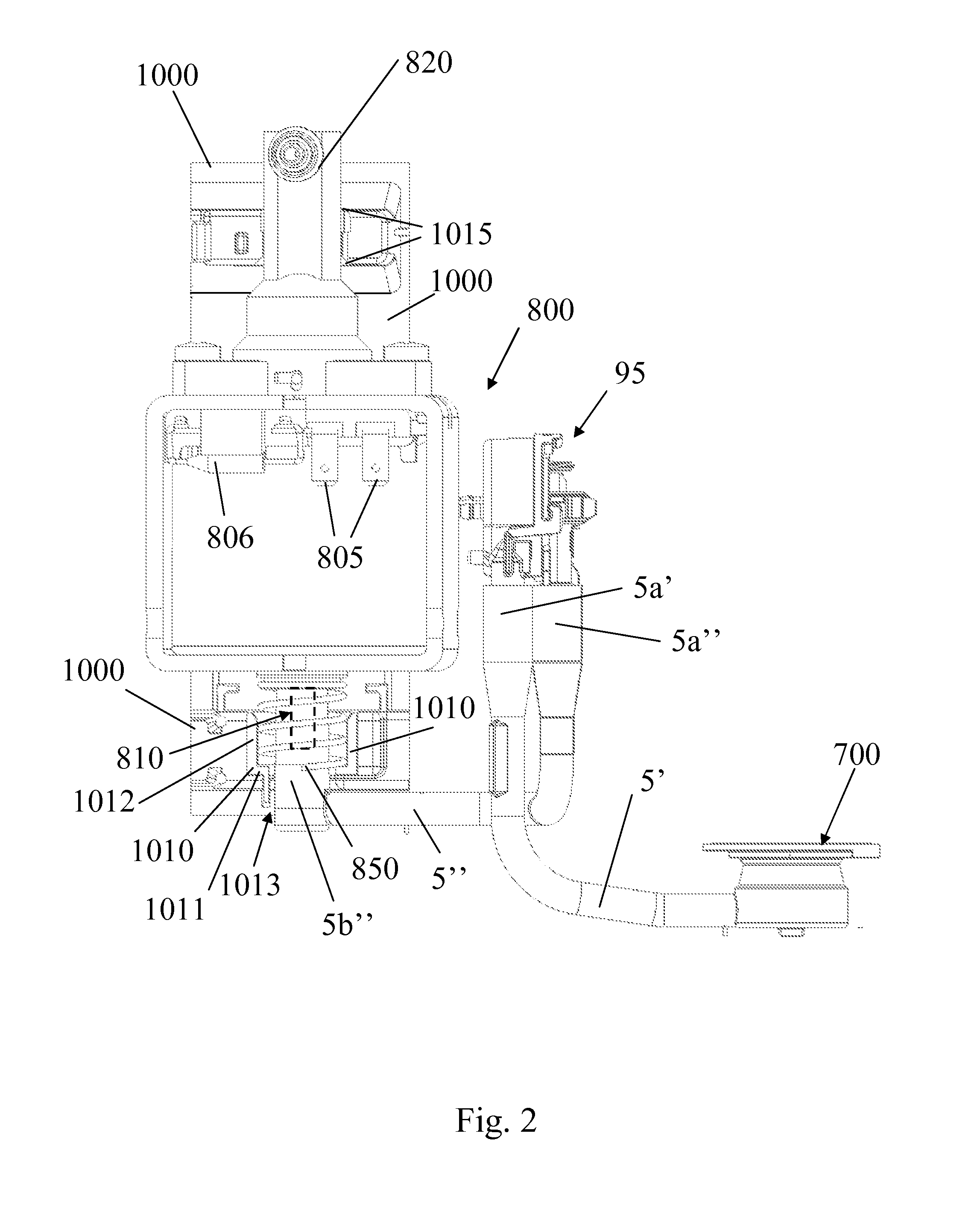

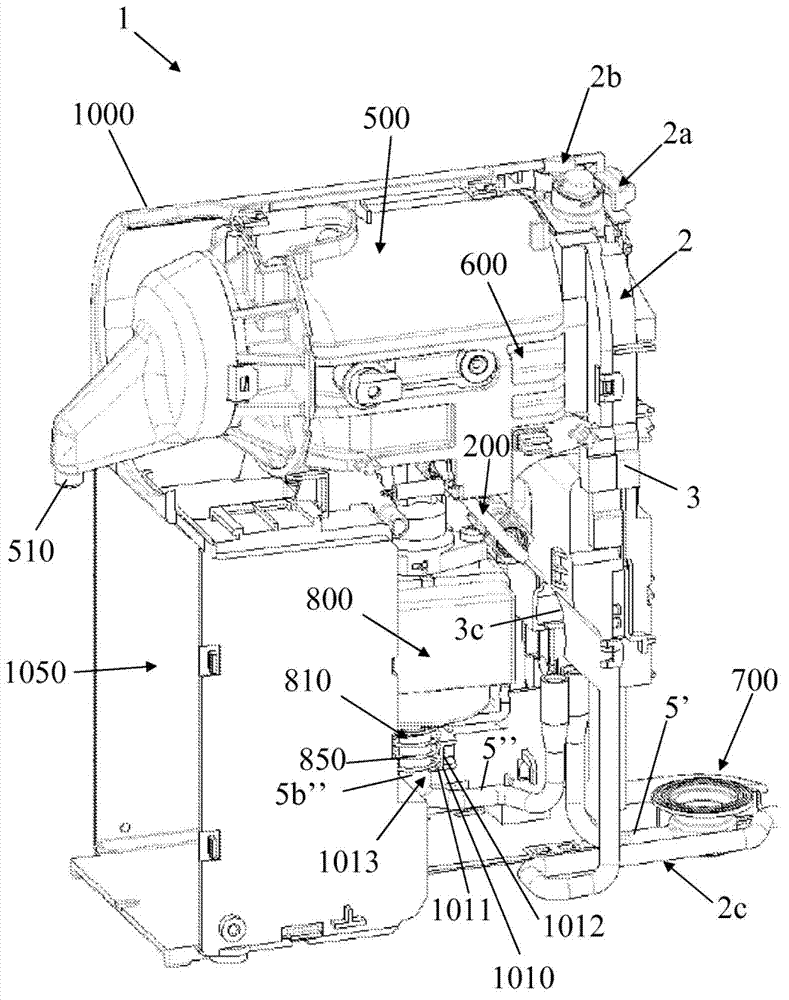

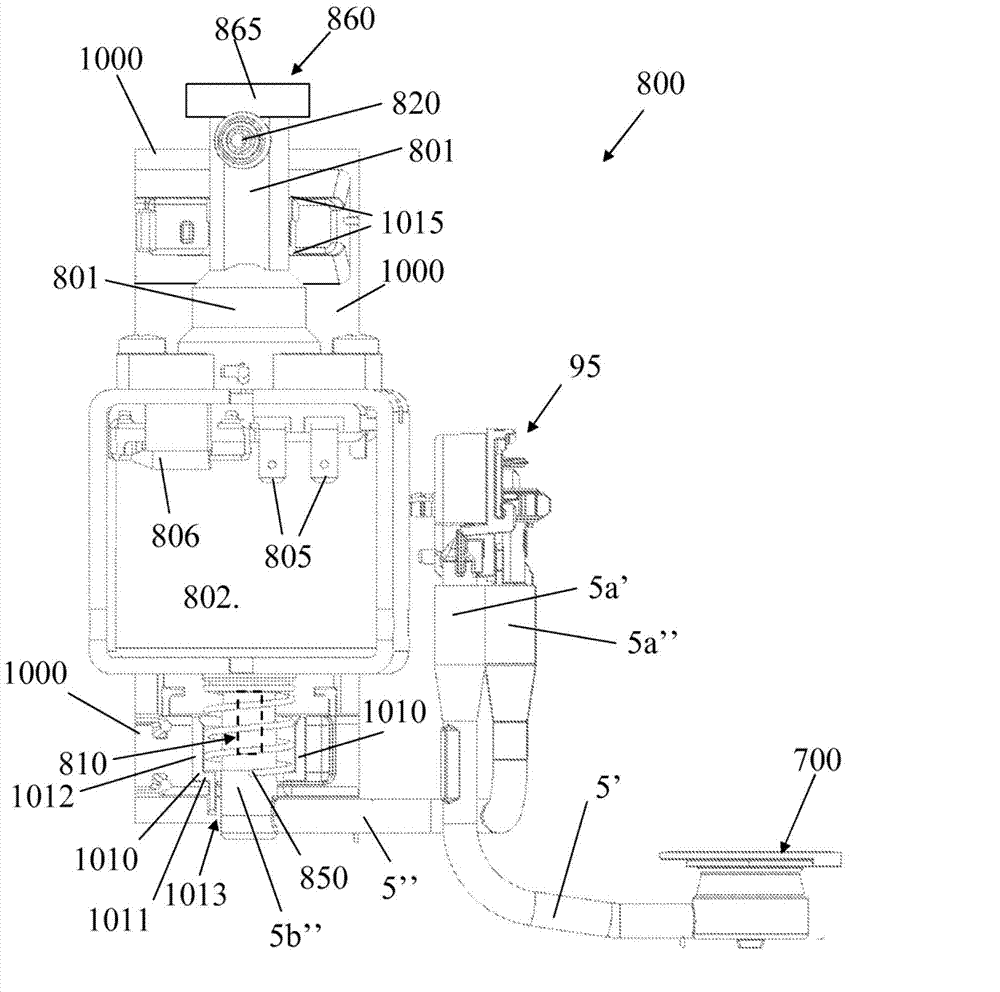

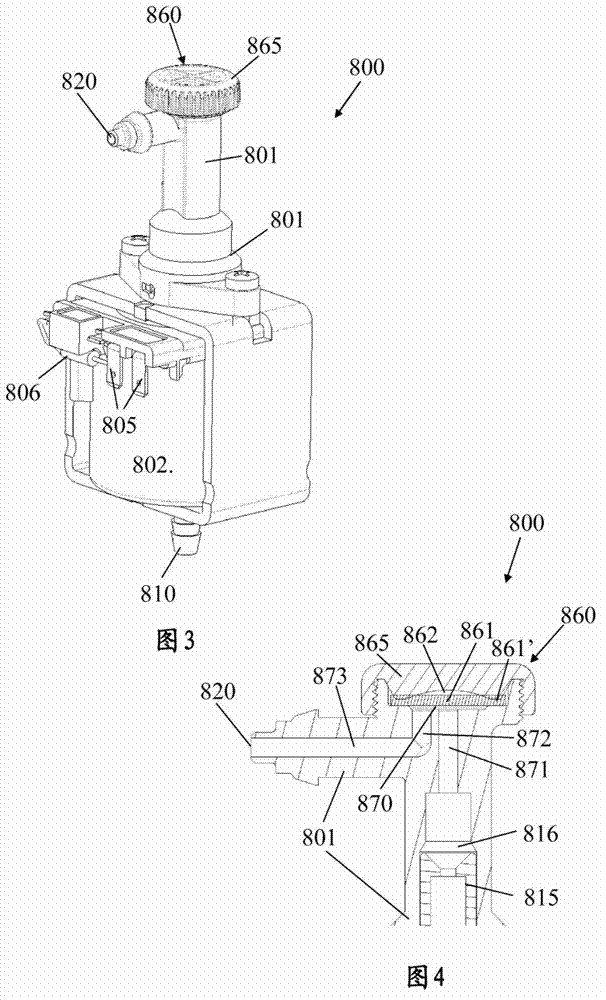

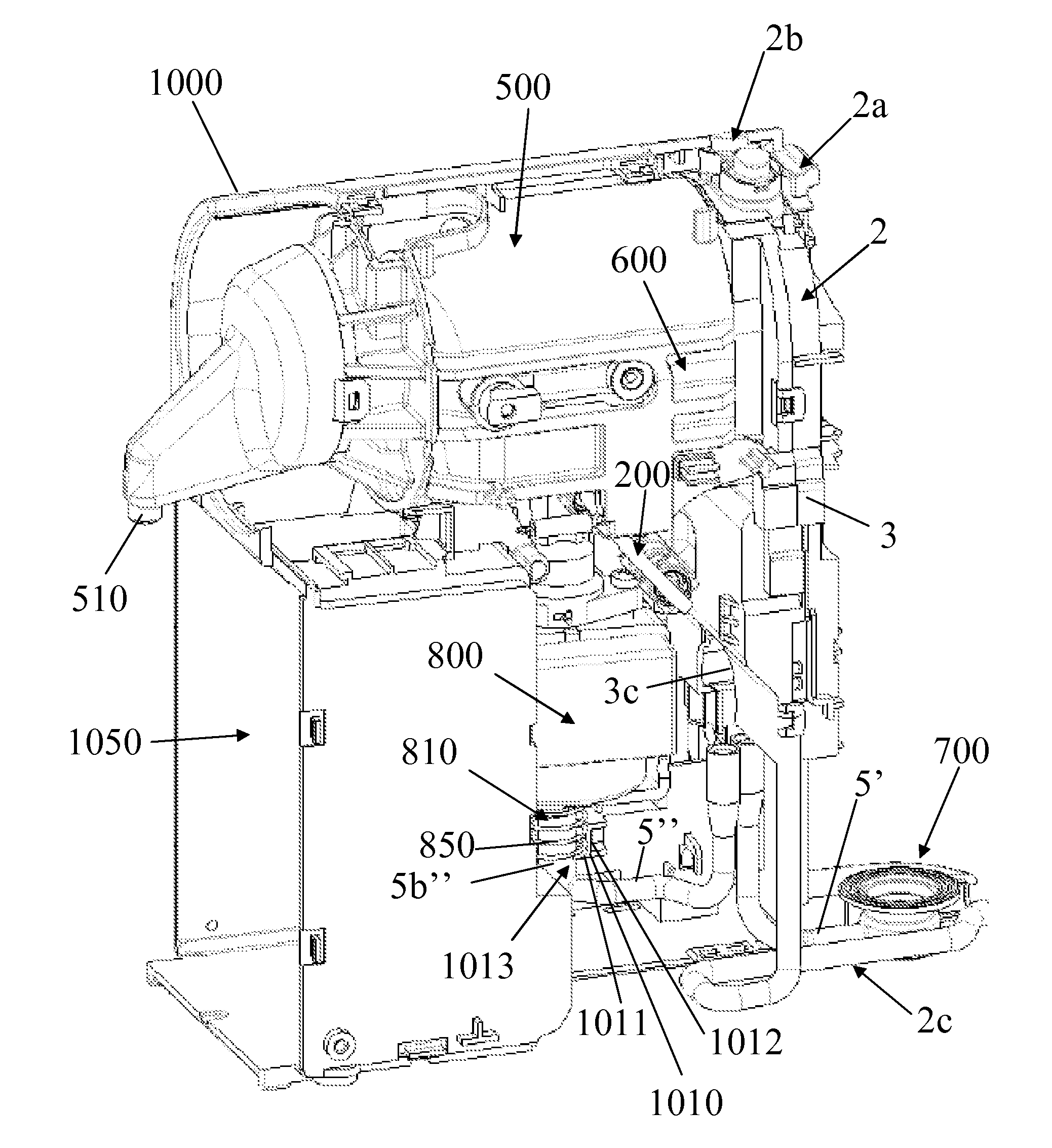

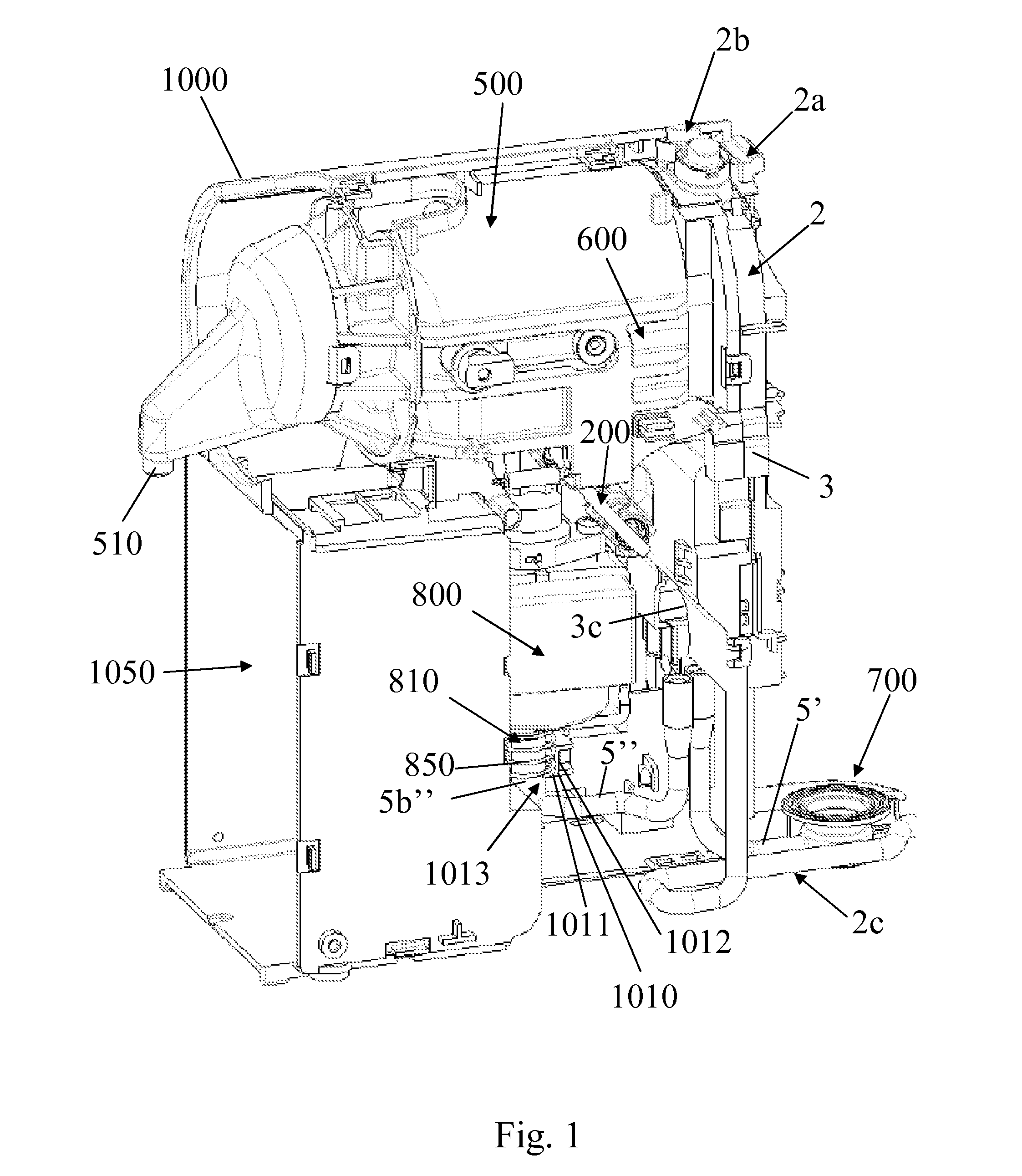

Pump mount in a beverage preparation machine

ActiveUS20110308396A1Easy to installReducing and preventing transmissionBeverage vesselsLiquid dispensingMachine partsEngineering

A beverage preparation machine that includes a housing, a pump which vibrates during use and which is mounted in the housing, and a dampener for preventing or reducing the transmission of vibrations from the pump to other machine parts. The damper includes a spring on which the pump is mounted in the housing.

Owner:SOC DES PROD NESTLE SA

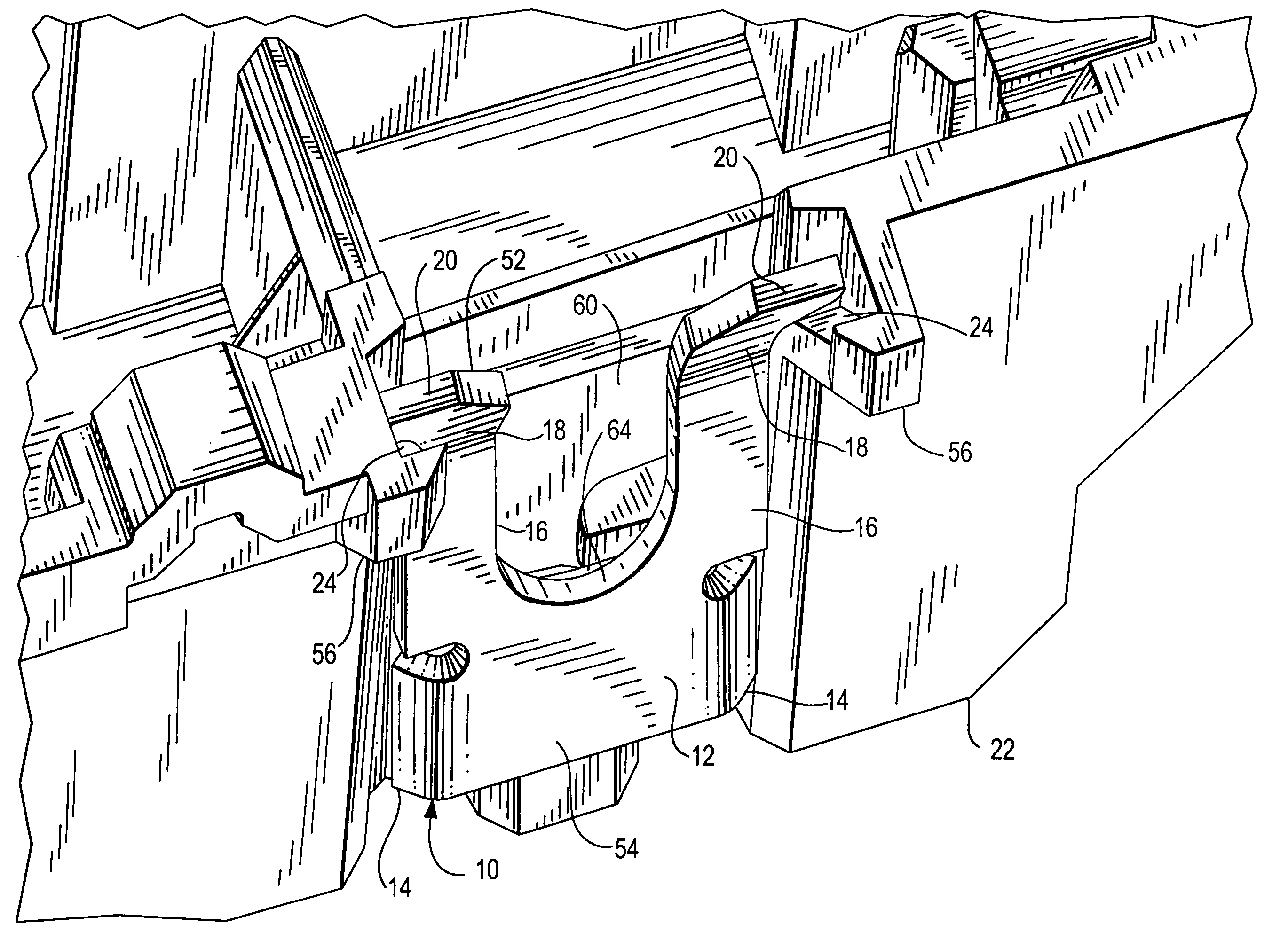

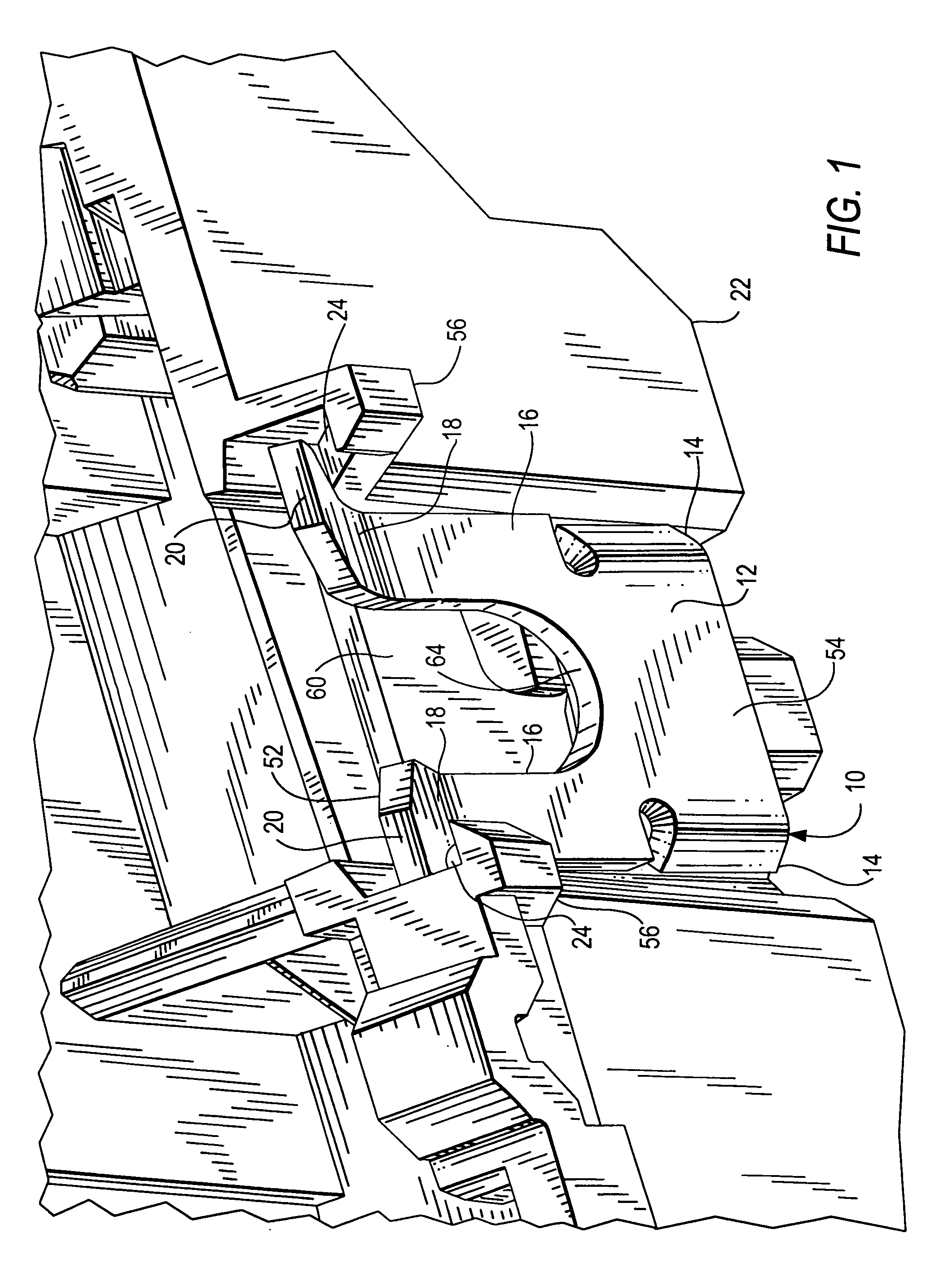

Drop in clamp for wiring terminations

ActiveUS7175485B1Easily inserted into and “ droppedReduce complexityElectric connection structural associationsClamped/spring connectionsEngineeringMechanical engineering

An improved clamp that can be inserted into a wiring device independent of a wiring termination assembly thereby reducing the complexity and cost of the manufacture of the wiring device. The clamp has a pair of legs spaced apart forming an opening to allow the wiring termination assembly to be inserted therebetween. The wiring device includes support members to support the clamp legs so to permit the clamp to pivot about the support member independently of the wiring termination assembly.

Owner:LEVITON MFG

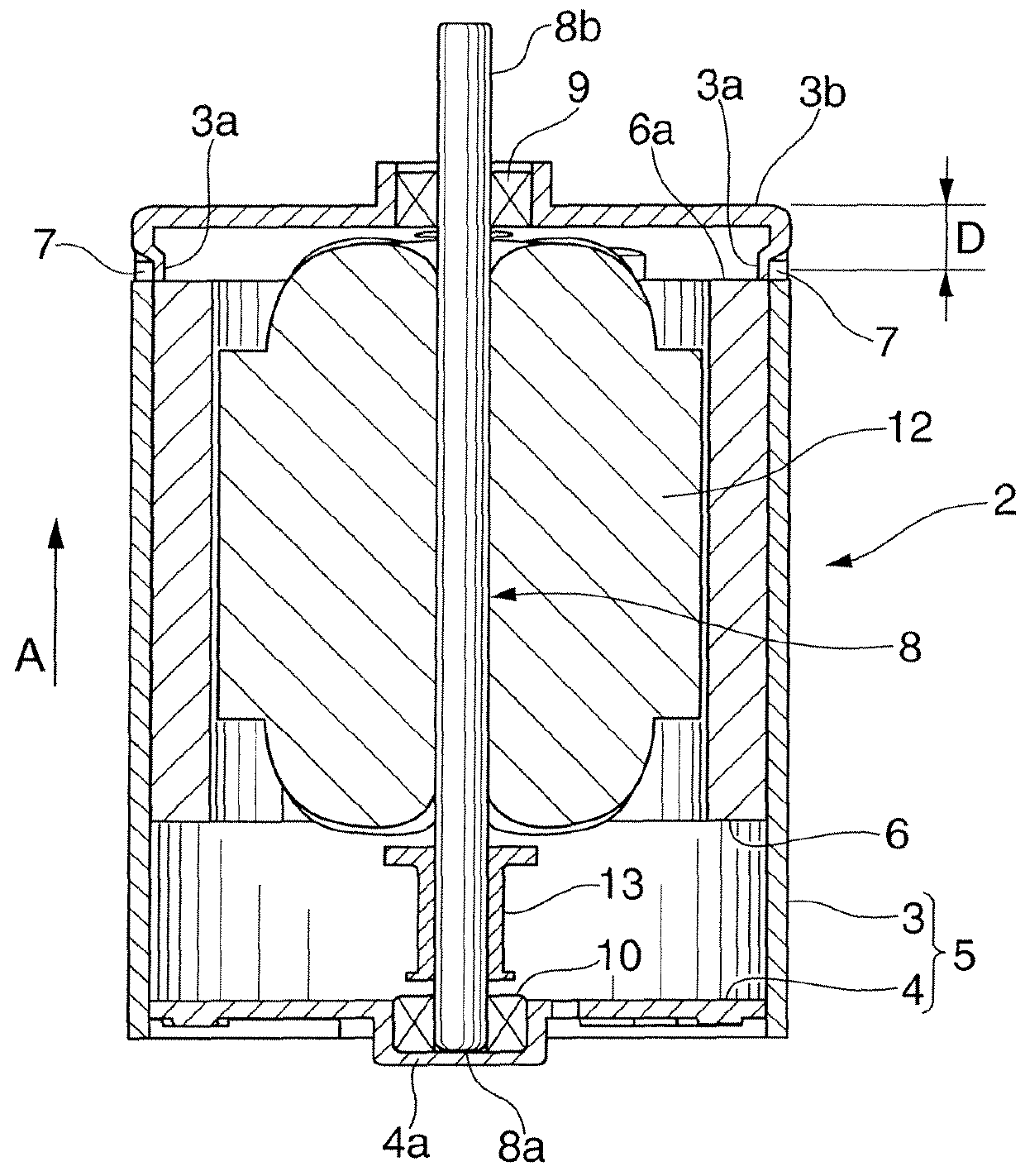

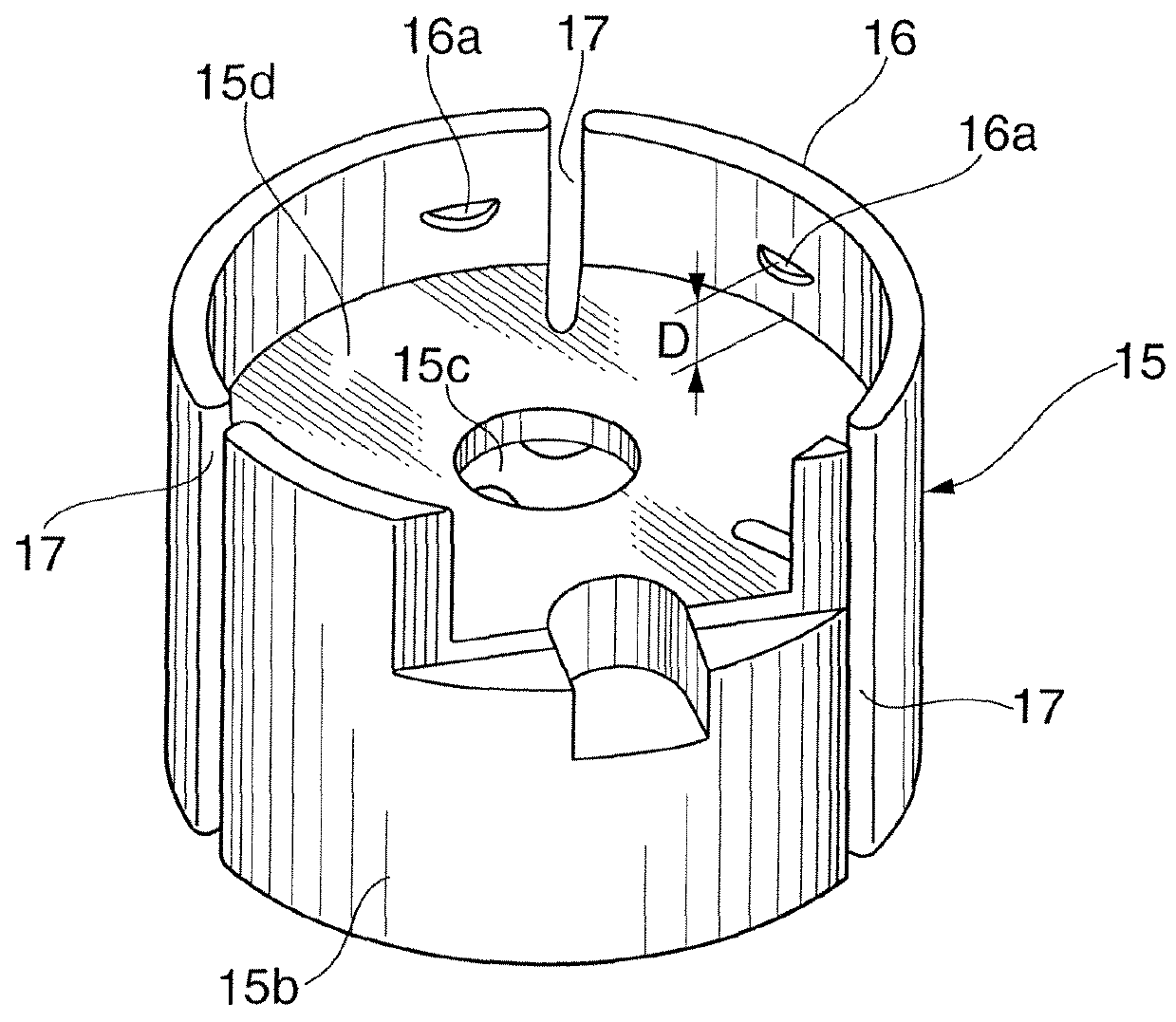

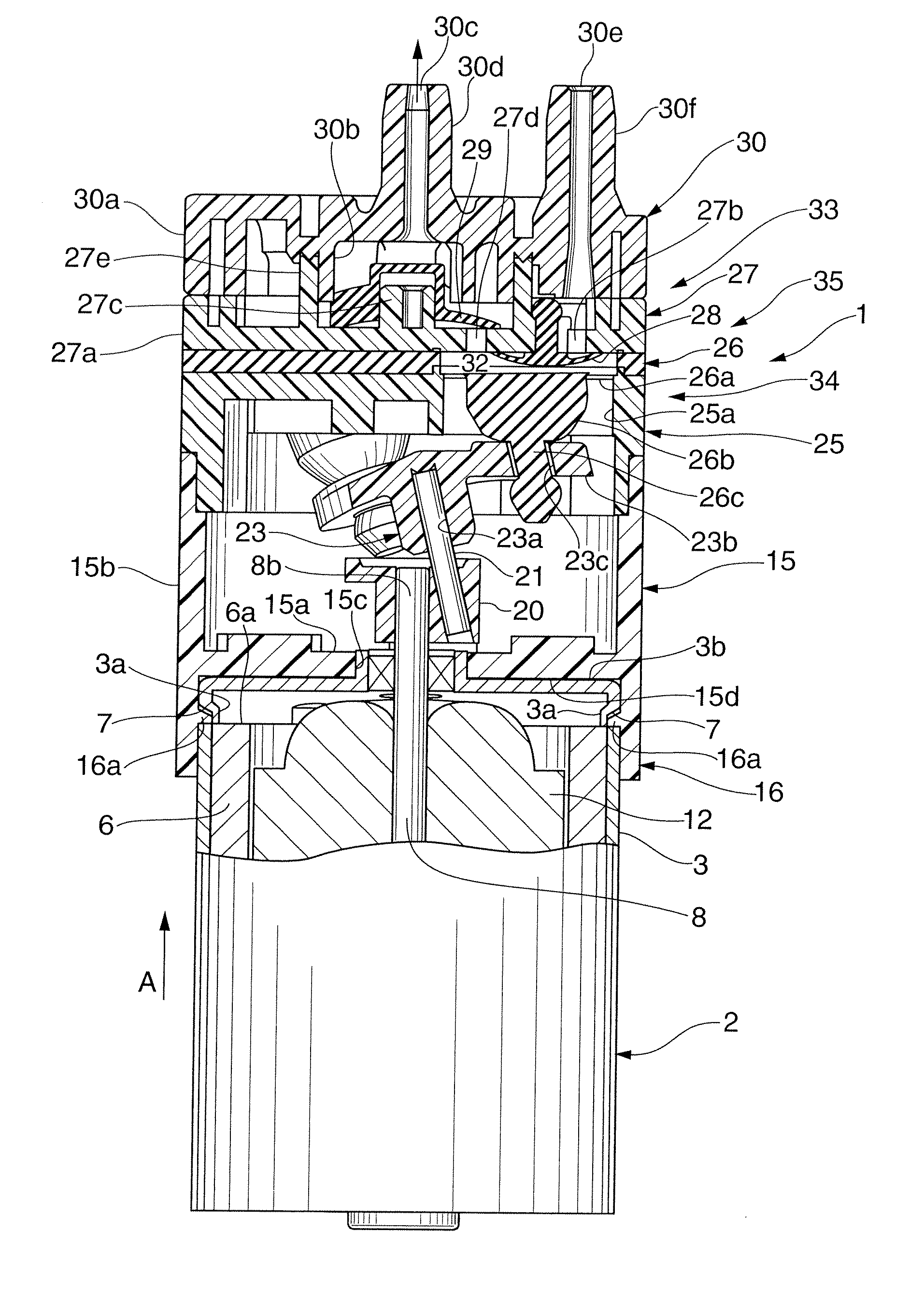

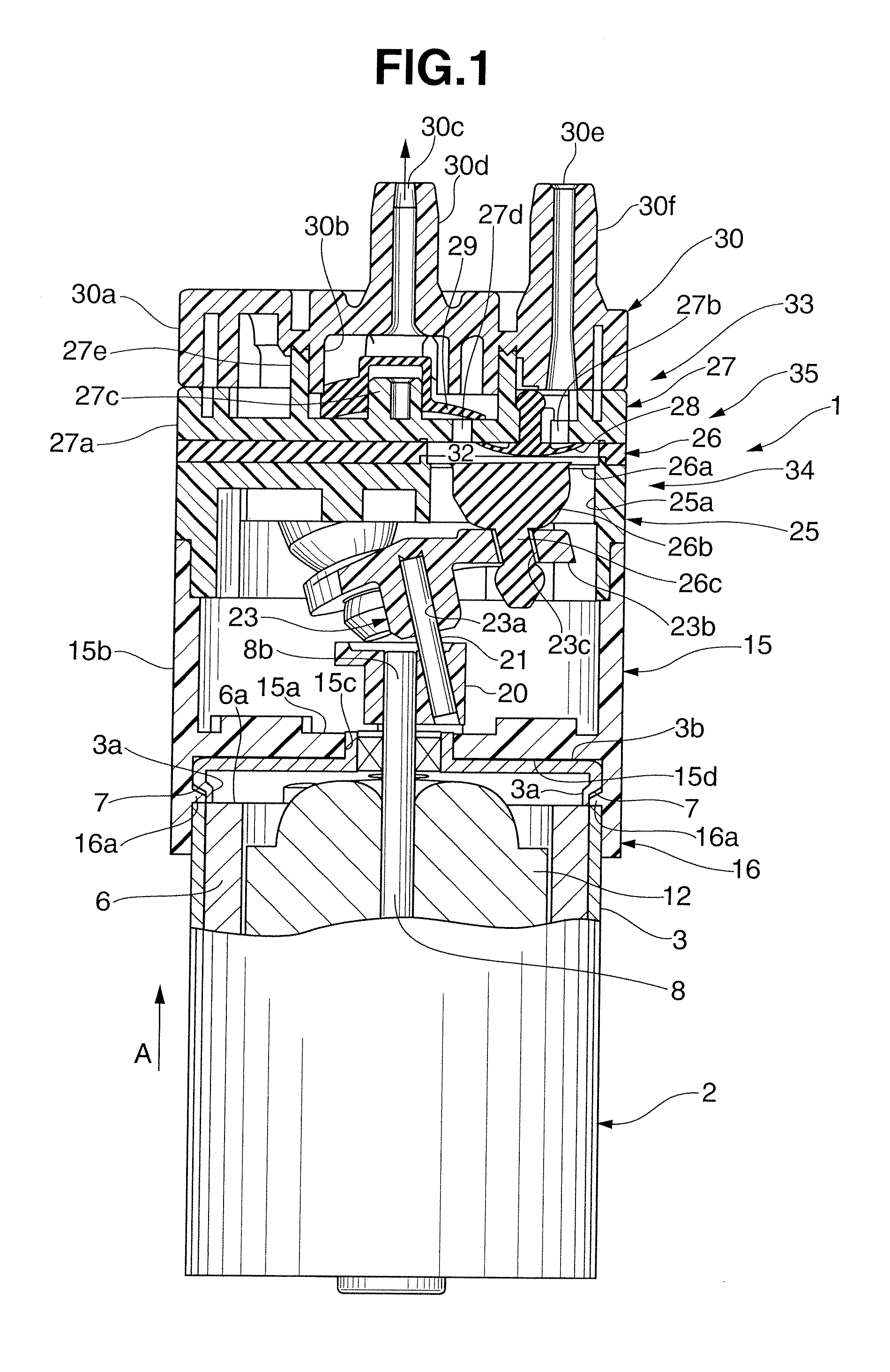

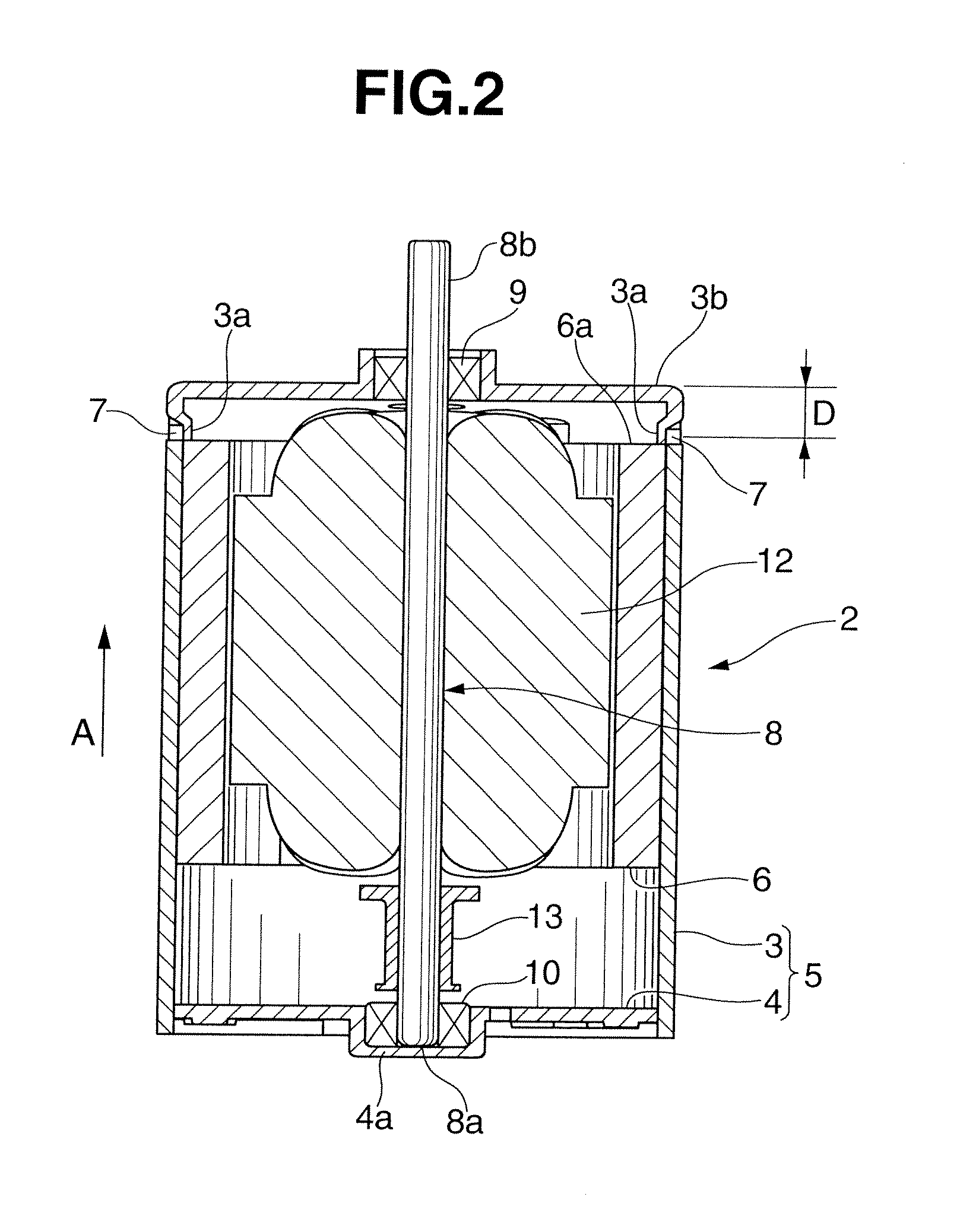

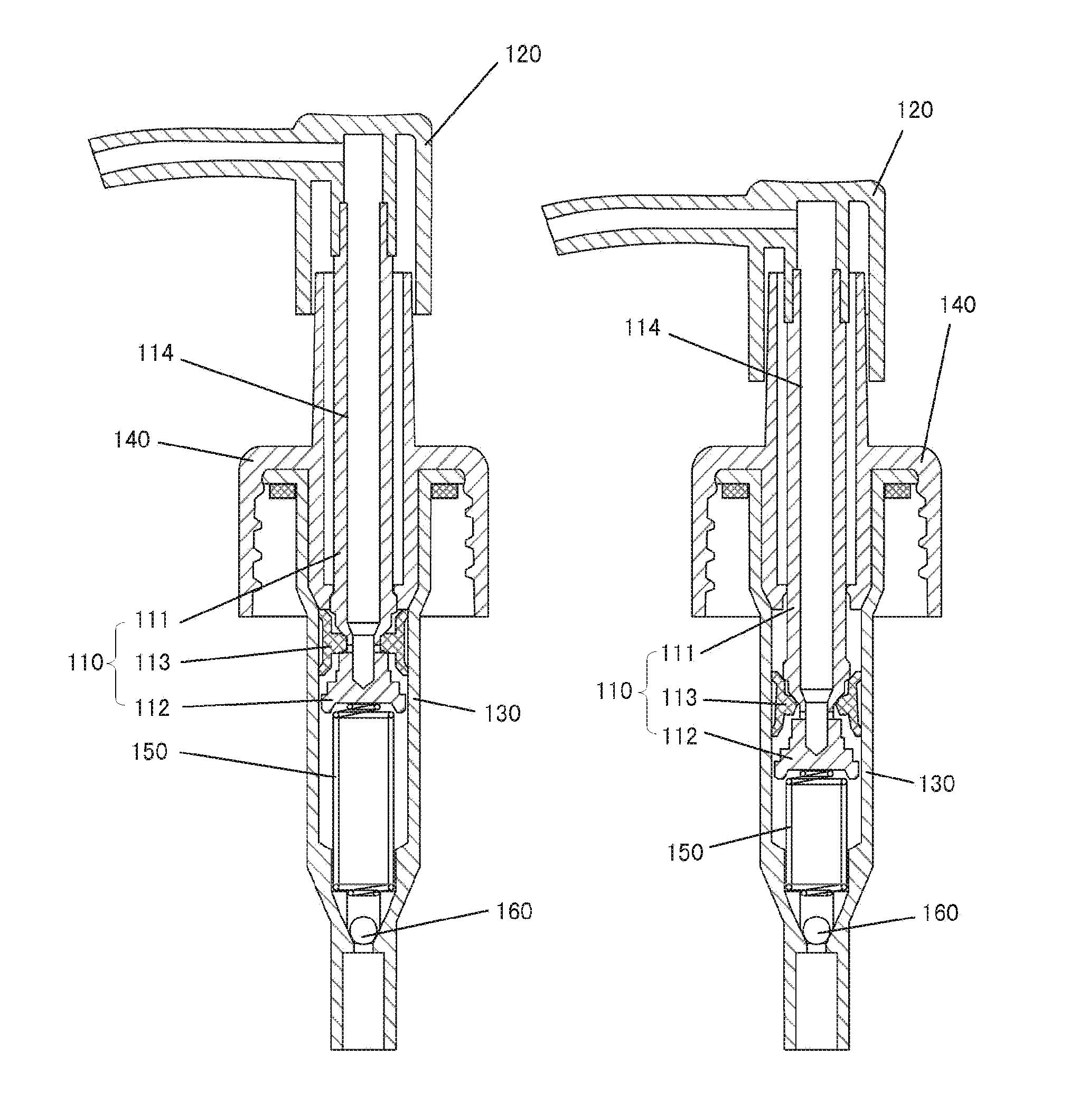

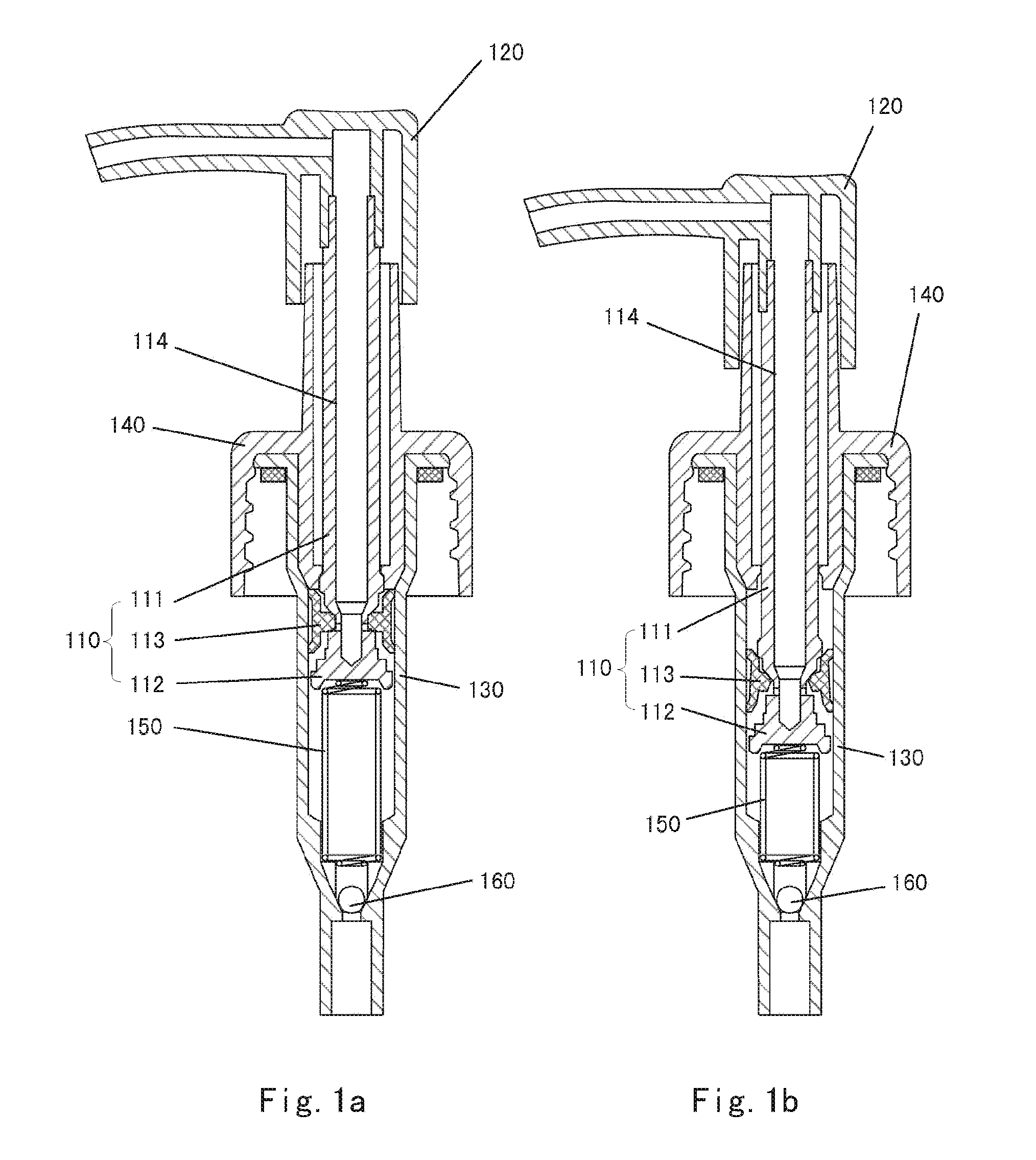

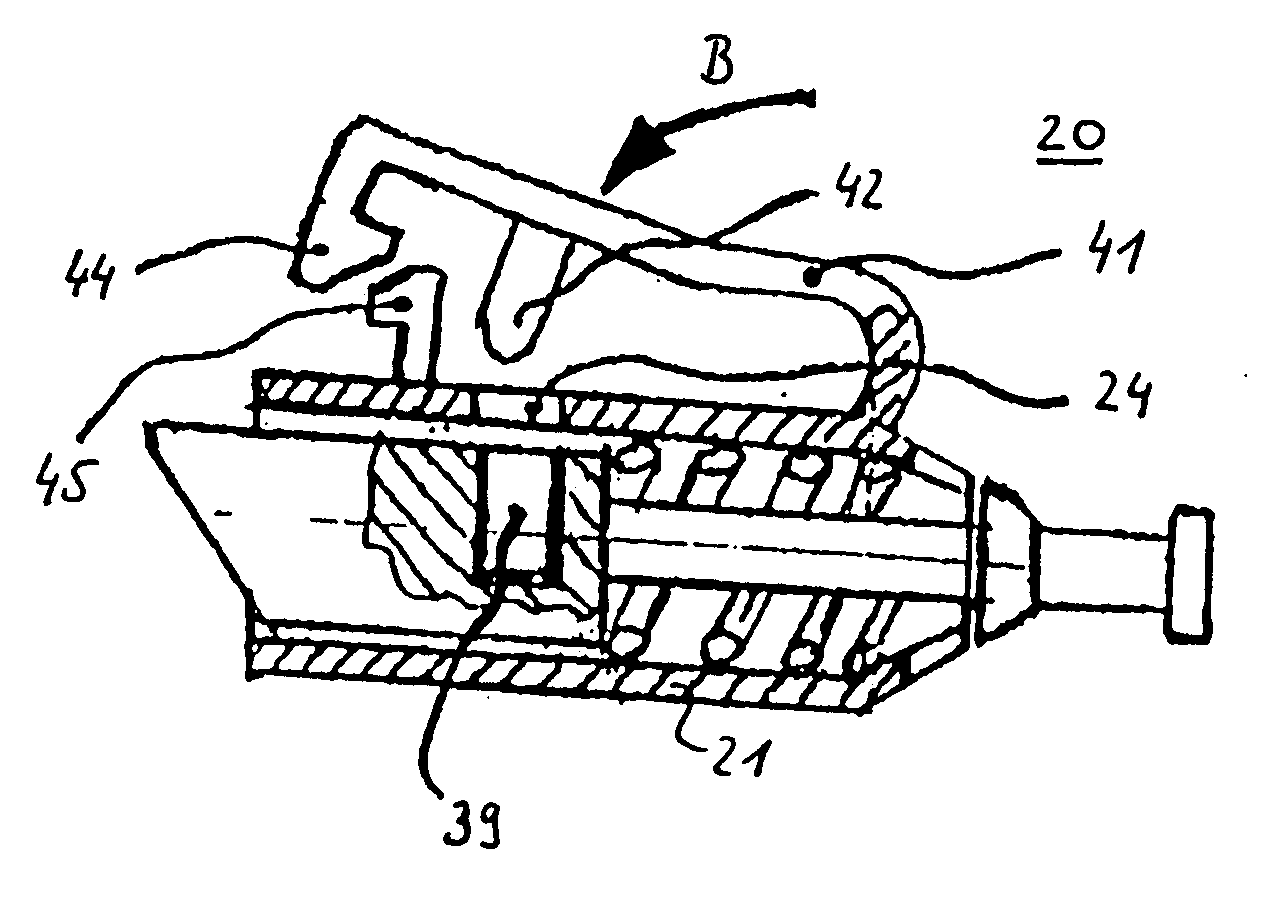

Diaphragm pump

ActiveUS9341176B2Reduce in quantityEasily introducedPositive displacement pump componentsFlexible member pumpsDiaphragm pumpPump chamber

Owner:OKEN LTD

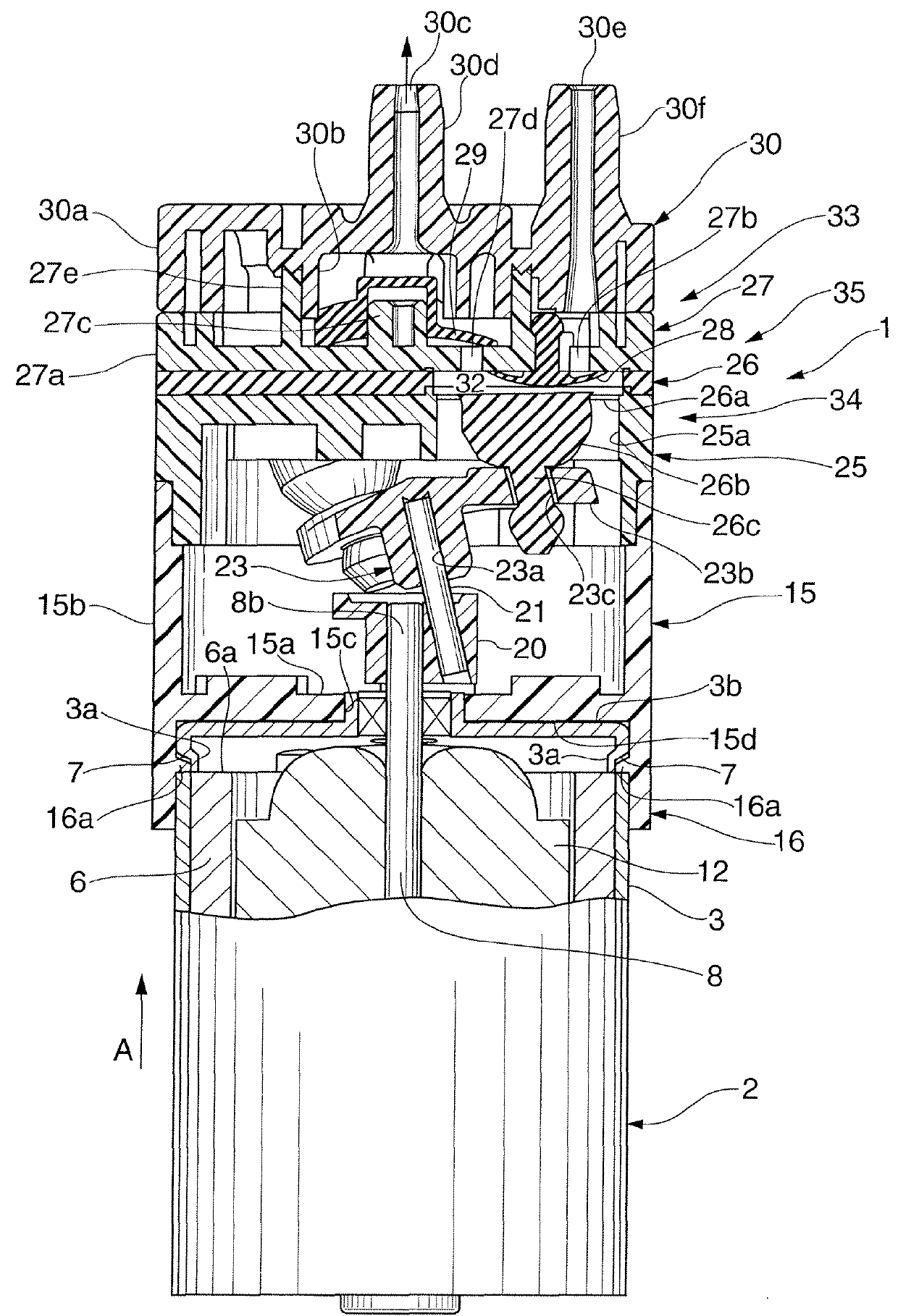

Diaphragm pump

ActiveUS20130034452A1Reduce in quantityEasily introducedPositive displacement pump componentsFlexible member pumpsDiaphragm pumpPump chamber

A diaphragm pump includes a motor having a recess in an outer circumferential portion, a crank which rotates together with a motor output shaft, a driving member including a driving element which reciprocates in accordance with the crank rotation, and a diaphragm which forms a pump chamber which expands and contracts in accordance with the reciprocating driving element. The pump also includes a suction passage which draws a fluid into the pump chamber, a discharge passage which discharges the fluid, a suction valve formed in the suction passage to regulate a reverse flow of the fluid to the suction passage, a discharge valve formed in the discharge passage to regulate a reverse flow of the fluid to the pump chamber, and an elastically deformable cylindrical member which holds the diaphragm and includes a projection which engages with the recess of the motor.

Owner:OKEN LTD

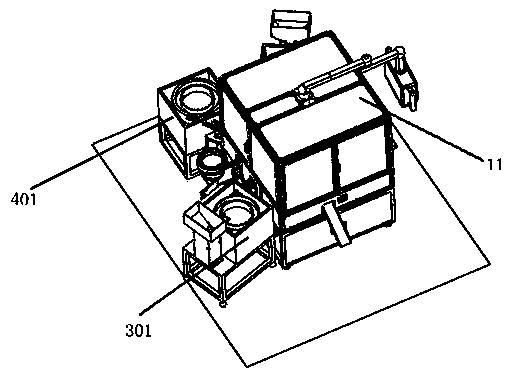

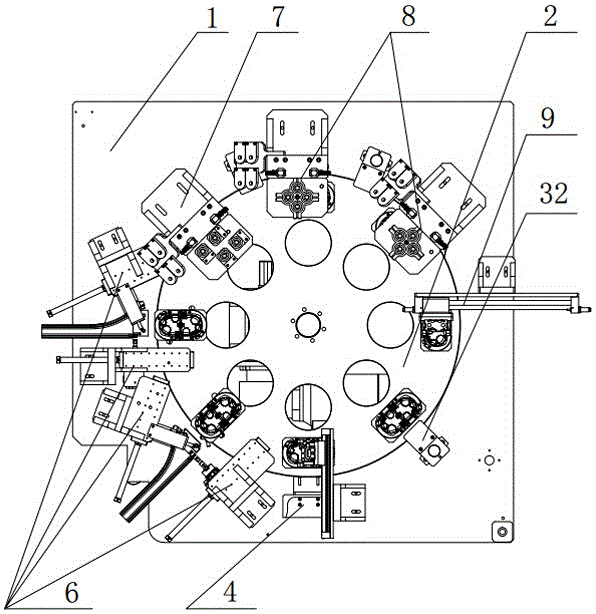

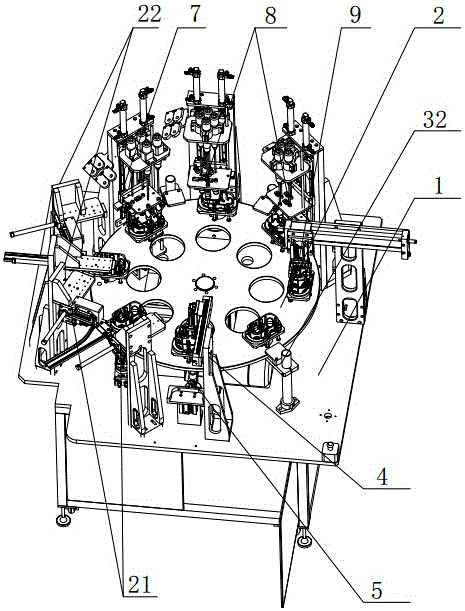

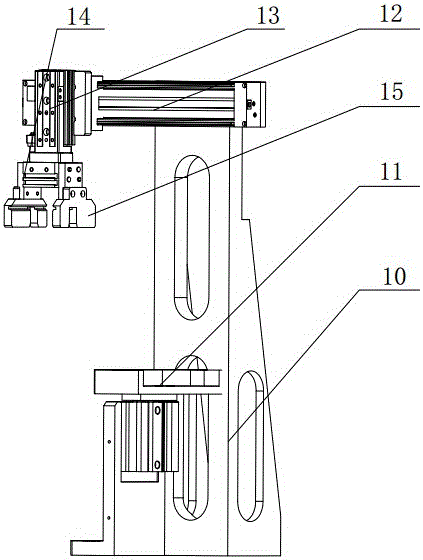

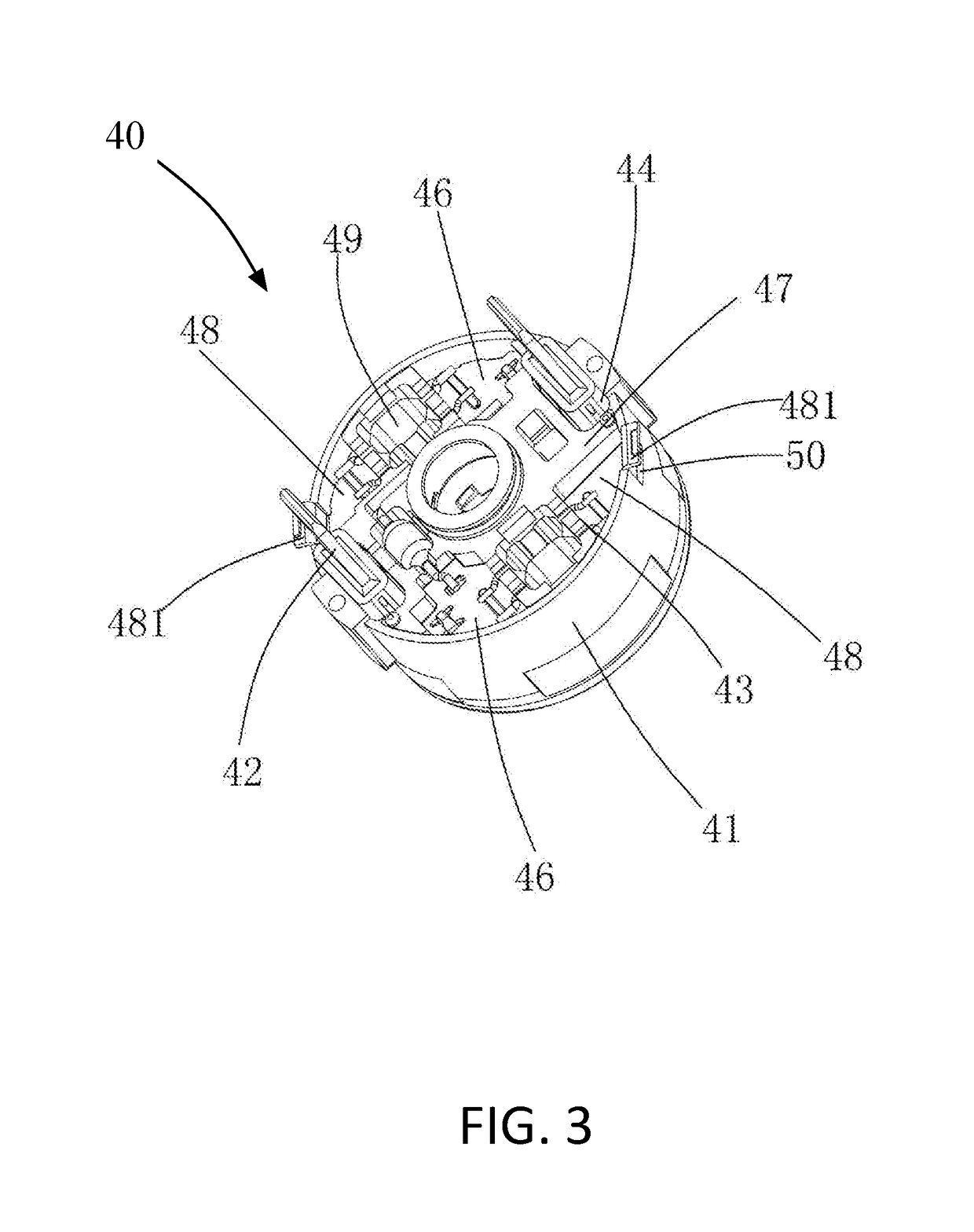

C-shaped clamp automatic assembling system

PendingCN109366118AImplement automatic assemblyReduce manual laborAssembly machinesMetal working apparatusBolt connectionC shaped

The invention relates to a C-shaped clamp automatic assembling system. The C-shaped clamp automatic assembling system comprises an assembling platform, wherein the assembling platform is disc-shaped,the assembling platform is driven by a rotary driving mechanism to rotate, a plurality of assembling seats are distributed on the assembling platform in parallel along the circumference direction of the assembling platform, a nut placement process, a gasket placement process, a C-shaped clamping frame placement process, a primary detection process, a bolt connection process, a secondary detectionprocess, a mesh pad placement process and a riveting pressure process are sequentially arranged on the outer side of the circumference of the assembling platform. The C-shaped clamp automatic assembling system has the advantages that the plurality of assembling seats, the nut placement process, the gasket placement process, the C-shaped clamp frame placement process, the primary detection process,the bolt connection process, the secondary detection process, the mesh pad placement process and the riveting and pressing process are coordinated, so that the automatic assembly of the C-shaped clamp is realized, the manual labor is reduced, and the working efficiency is improved.

Owner:江苏中伟业通讯设备有限公司

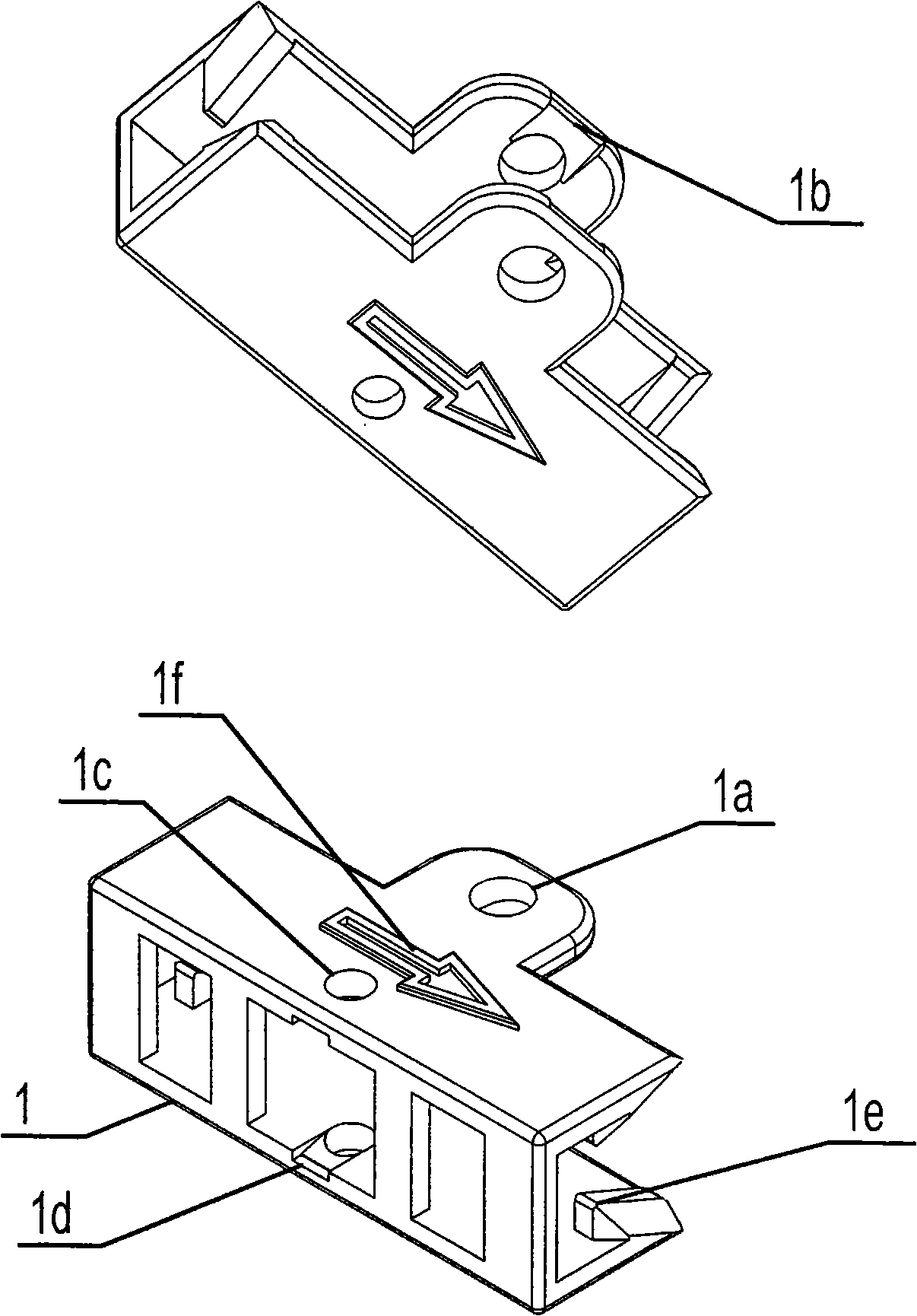

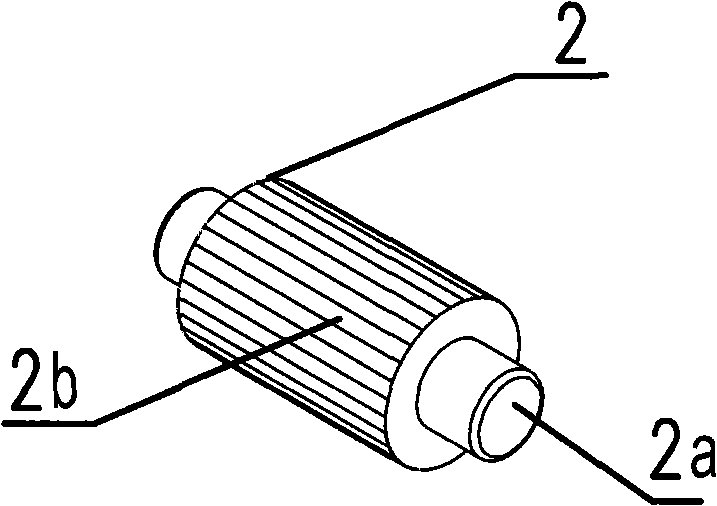

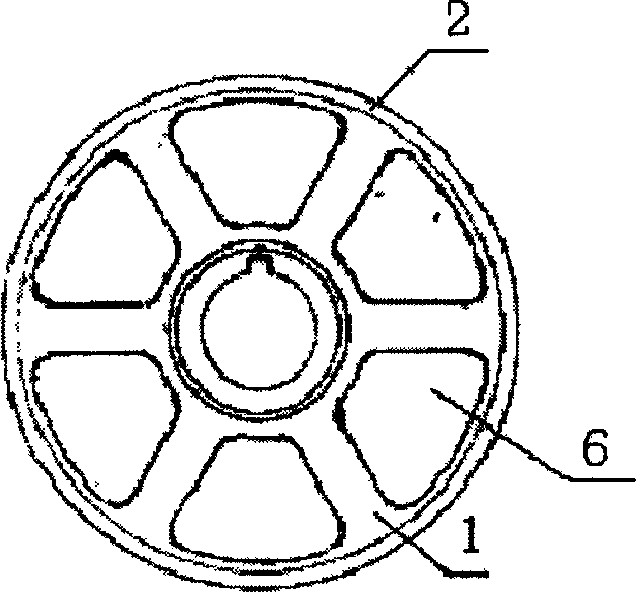

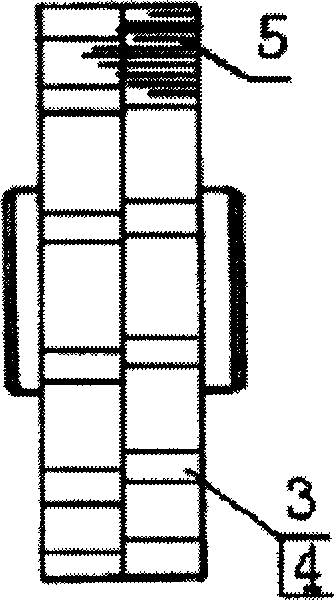

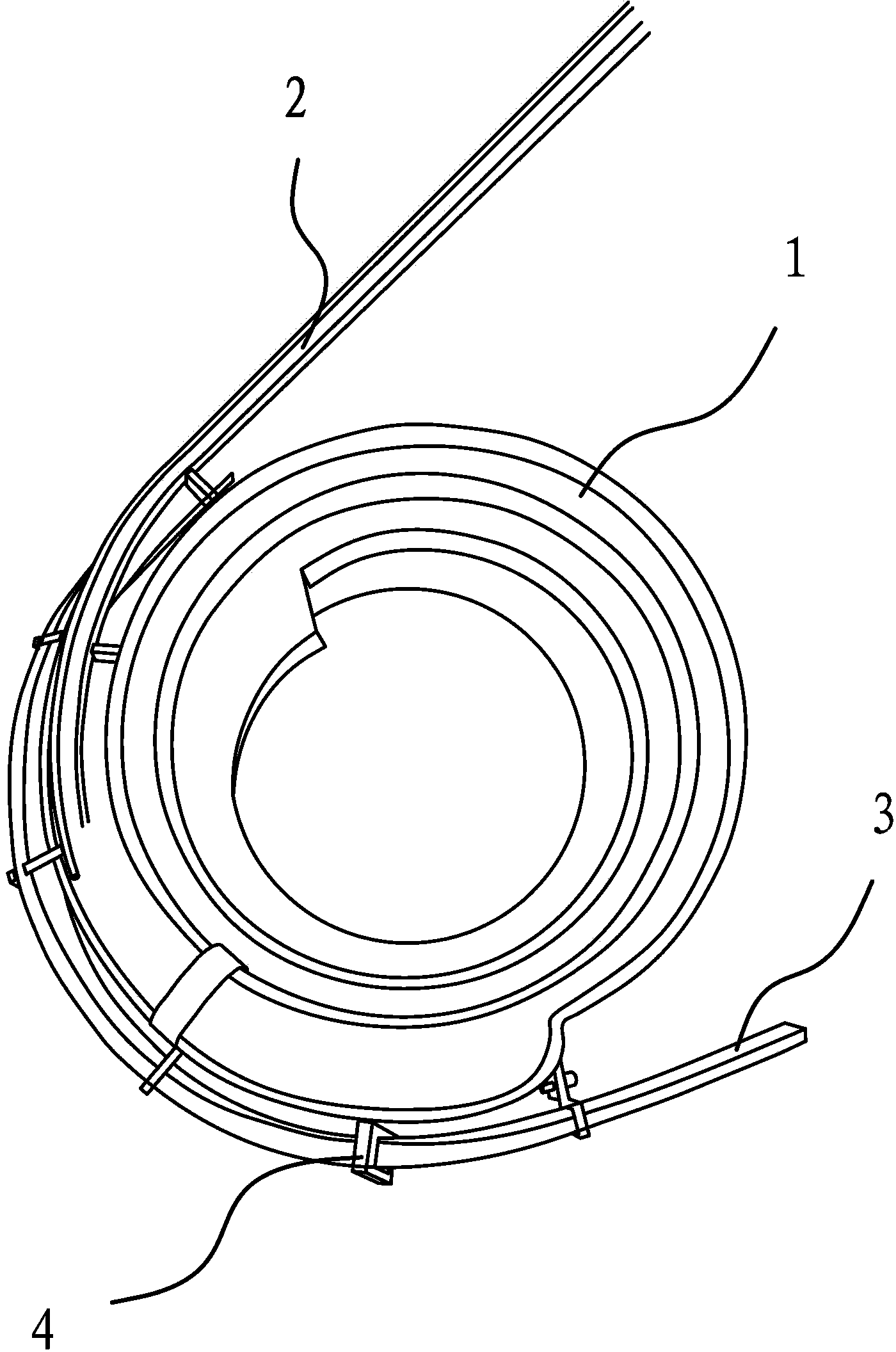

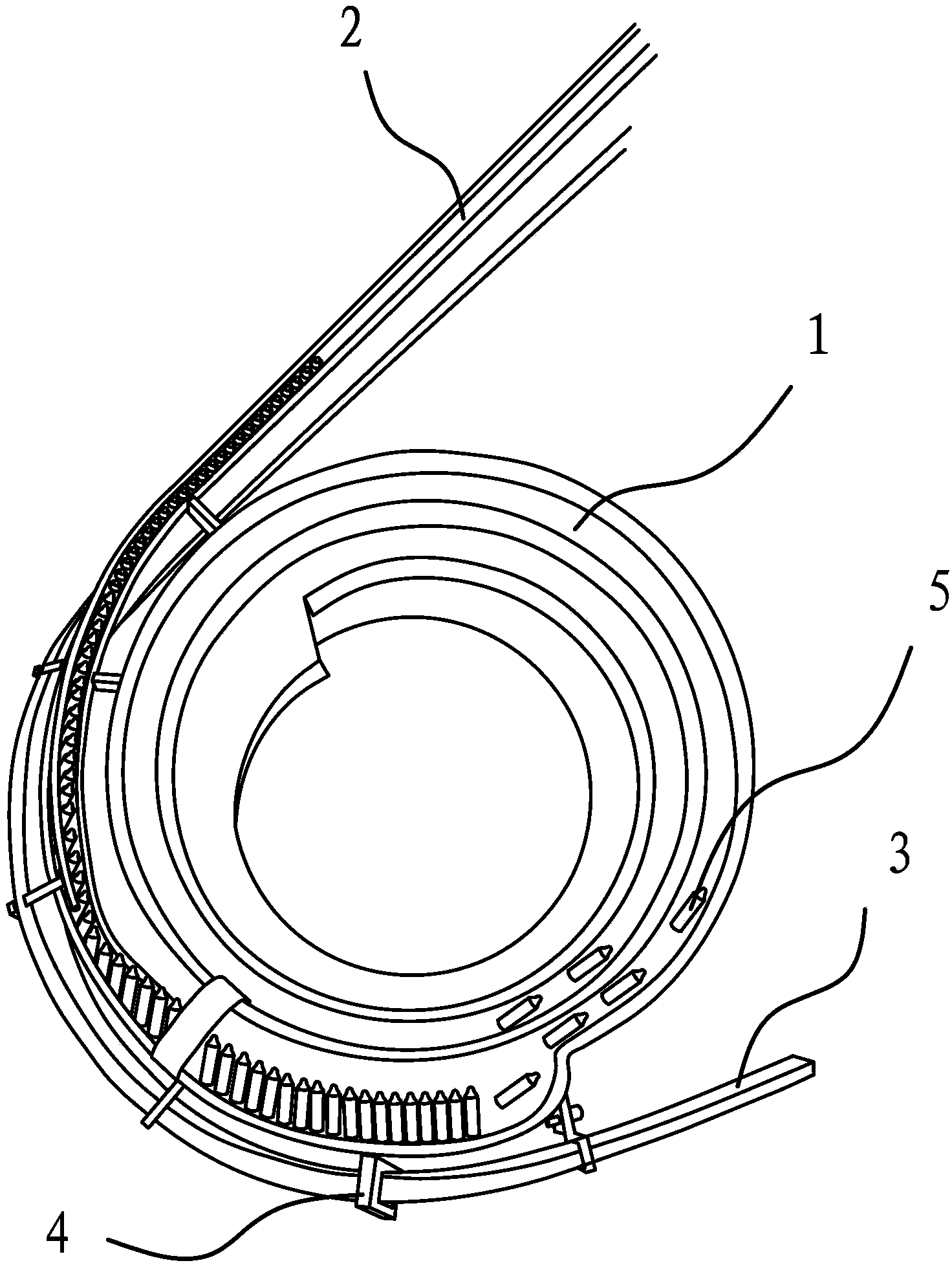

Cam type infusion regulator

InactiveCN101569769AChange the cross-sectional areaInfusion speed regulation and controlIntravenous devicesCamGuide tube

A cam type infusion regulator consists of a shell 1, a supporting wheel 2 and a regulating wheel 3. The shell has a structure of a U-shaped groove, two pairs of axle holes (1a, 1c) are correspondingly drilled on the upper side and the lower side, and axial lines of the two pairs of the axle holes (1a, 1c) are parallel with each other and perpendicular with each other; the supporting wheel 2 is arranged in the axle hole 1c on the lower part of the shell; the regulating wheel 3 is arranged in the axle hole 1a on the upper part of the shell; the surface 3c of the regulating wheel has a cam shape, the distance between the surface 3c of the regulating wheel and an axle center changes in an involute mode, and the curvature change of the surface 3c of the regulating wheel meets the regulating and control requirements on the infusion speed; an infusion conduit is arranged between the regulating wheel 3 and the shell 1 and the supporting wheel 2; and during use, fingers twist the regulating wheel 3, the change of the distance between a curved surface 3c of the regulating wheel and a supporting wheel 3 on the bottom of the shell extrudes or releases the conduit, and changes the sectional area of the conduit to achieve the aim of regulating and controlling the infusion speed. Compared with the prior infusion regulator, the cam type infusion regulator has the characteristics of small size, material conservation, capability of self-assembly, improvement on the efficiency, convenient use, reliable regulation and stable speed.

Owner:张亚平

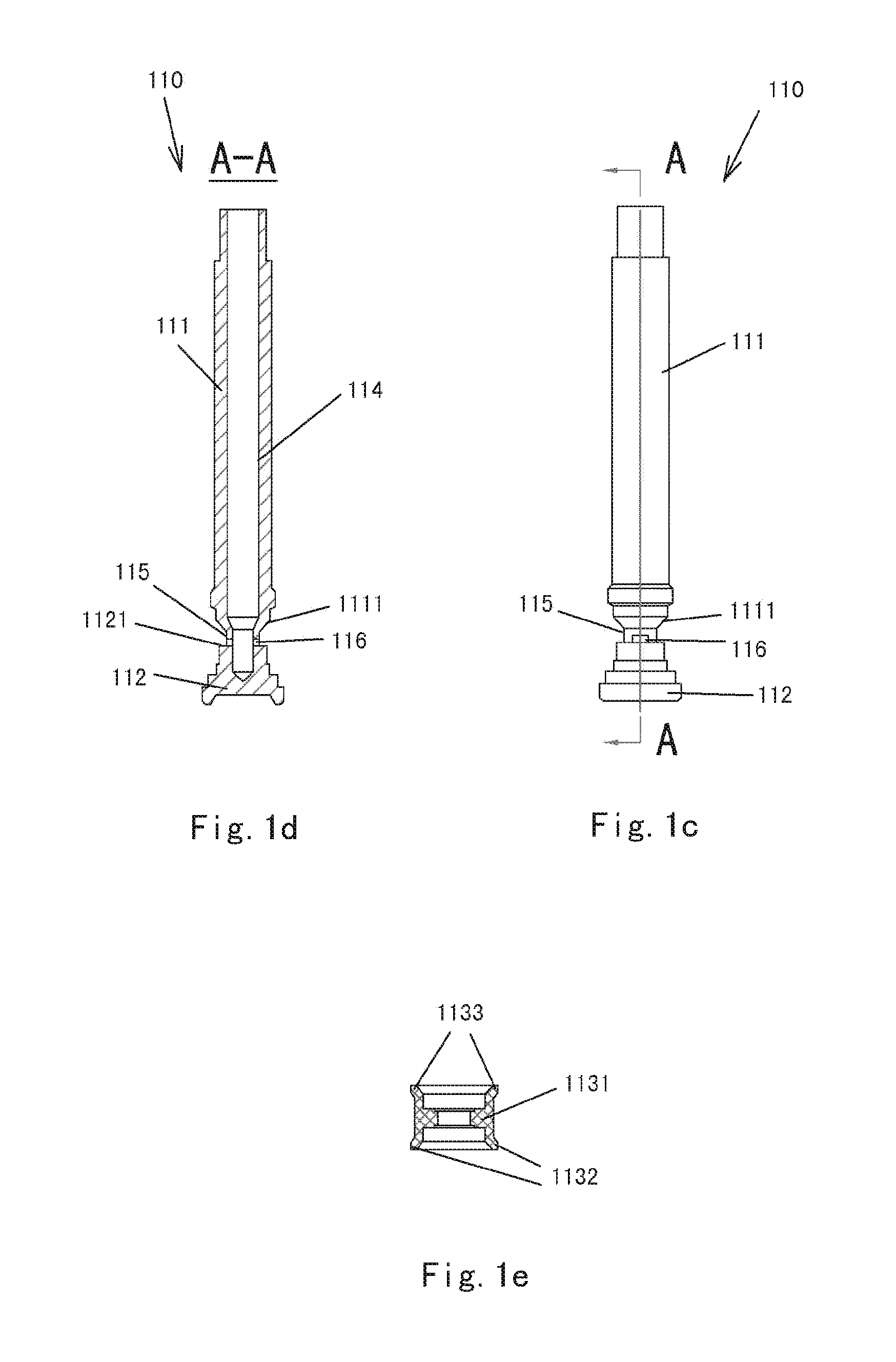

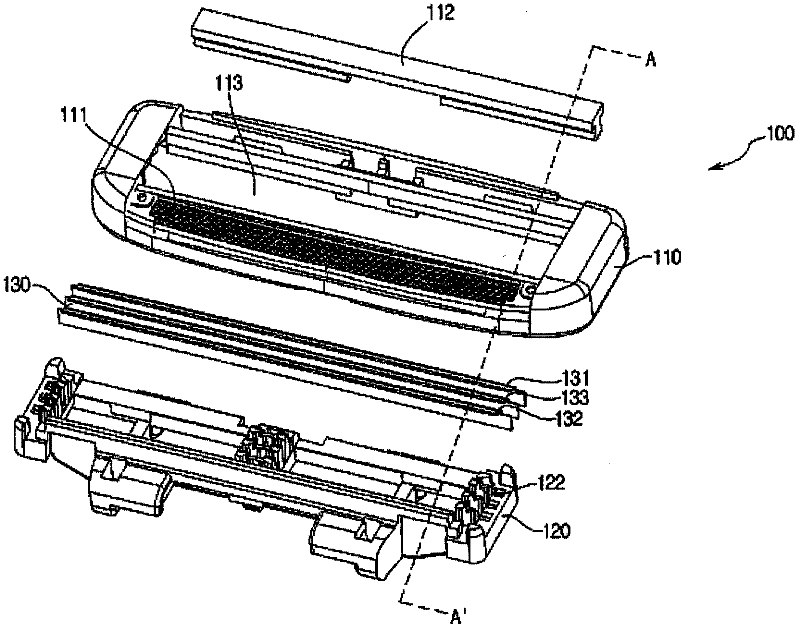

Liquid pump using elastomeric piston, piston assembly and manufacturing method thereof

InactiveUS20140314600A1Improved product precision and qualityEasy automatic assemblyPiston ringsPositive displacement pump componentsElastomerEngineering

The invention provides a liquid pump using an elastomeric piston. The liquid pump has a piston assembly (10), which comprises: a piston rod (11); a piston head (12); a piston engaging portion (15) which is between the piston rod and the piston head in a necking shape; and a piston (13) made of an elastomeric material and sleeved around the piston engaging portion between the piston rod and piston head. The piston rod and piston head are formed separately and then assembled together. The piston engaging portion (15) is composed of a piston-engaging-portion formation part of at least one of the piston rod and the piston head. The invention also provides a method of manufacturing the piston assembly (10). The invention further provides a piston assembly (10) for a liquid pump. The piston assembly has a piston (13) which is provided with an annular notch (133) formed on the periphery of an upper end of the piston (13) where an annular inner flange (131) is formed. The piston assembly and its manufacture method are helpful to improving product precision and quality and facilitate automated assembly, and are specially used for the liquid pumps using an elastomeric piston.

Owner:DING YAO WU

Reduction of pump nuisance

Owner:SOC DES PROD NESTLE SA

Permanent-magnet generator rotor and its manufacturing method

InactiveCN1808847ASmall magnetic circuit lossLarge effective air gap areaMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetEngineering

This invention discloses one permanent generating motor rotor and its process method, which adopts straight bar rare earth magnetic steel paralleling to the motor rotor surface to make each steel vertical axis line parallel to the permanent magnetic motor rotor axis line; the rotor is composed of rotor axis, rotor outer ring, radio rotor and two blocks of straight rare earth magnetic steel; the radio rotor is fixed on the axis and the rotor outer ring is fixed on the rotor surface and the rare earth magnetic steel is fixed on the rotor outer ring surface.

Owner:XINAN TOOLS GUIZHOU PROV

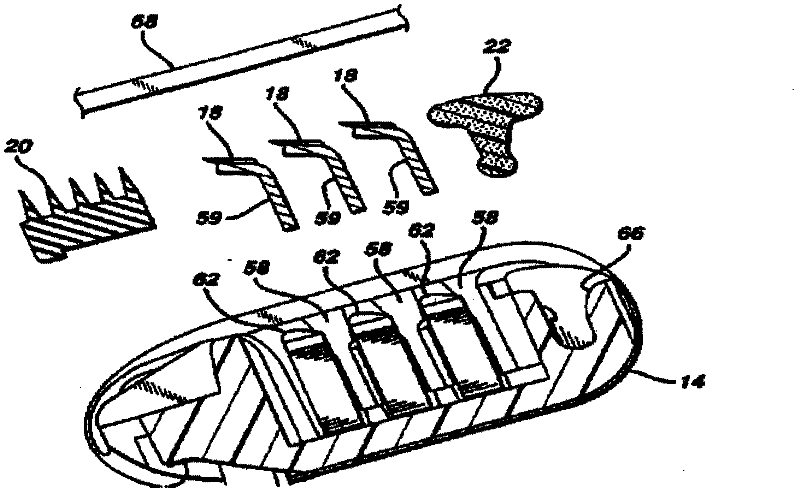

Unitary shaving razor cartridge

InactiveCN102232011AAvoid deformationEasy automatic assemblyMetal working apparatusEngineeringRazor Blade

The present invention relates to a shaving razor cartridge, comprising: one or more curved razor blades, an upper housing comprising an exposing portion for exposing the edges of the razor blades to the outside, and a guard; and a lower housing coupled to the upper housing, having a blade mounting portion for supporting the razor blades, wherein the bottoms of said one or more razor blades are supported at both ends and the center of the blade mounting portion, and both ends of said razor blades have notches such that the tops of the razor blades are supported and vertically connected to both ends of the upper housing. As the notches are formed at both ends of the razor blades to enable the razor blades to be accommodated in the space between the blade mounting portion and the upper housing, the necessity of a clip for fixing razor blades is eliminated, and the deformation of the razor blades can be prevented, thus making products slim and small-sized, and enabling the automatic assembly of cartridges of a variety of shapes and reducing production costs.

Owner:DORCO CO LTD

Automatic feeding device of bulb of holiday lamp

InactiveCN103350887AIncrease productivityEasy automatic assemblyJigging conveyorsConveyor partsMechanical engineeringMechanical vibration

The invention provides an automatic feeding device of a bulb of a holiday lamp and belongs to the technical field of mechanical vibration feeding. The automatic feeding device of the bulb of the holiday lamp solves the problems that an existing vibration feeding machine cannot change the material conveying state. The automatic feeding device of the bulb of the holiday lamp comprises a vibration feeding tray. The automatic feeding device of the bulb of the holiday lamp is characterized in that a conveying track used for enabling the bulb of the holiday lamp which is horizontally placed to be in a vertical state is connected to a discharge outlet of a hopper of the vibration feeding tray, and a magnetic body which extends in parallel with the conveying track is arranged on the periphery of the conveying track. The automatic feeding device of the bulb of the holiday lamp has the advantages that the horizontal conveying state of the bulb of the holiday lamp can be converted into the vertical conveying state.

Owner:HAINING WENSHUO TECH CONSULTING CO LTD

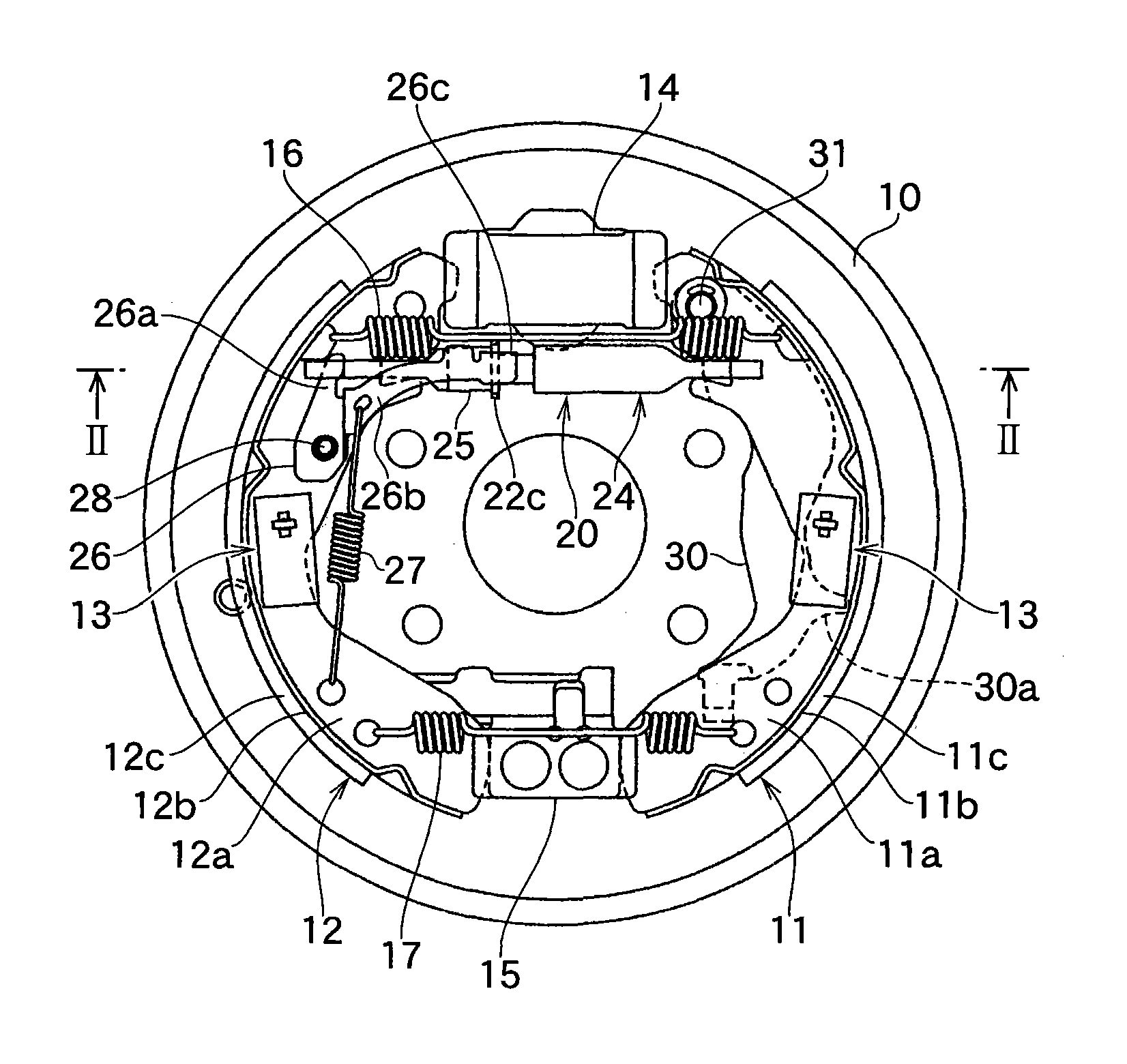

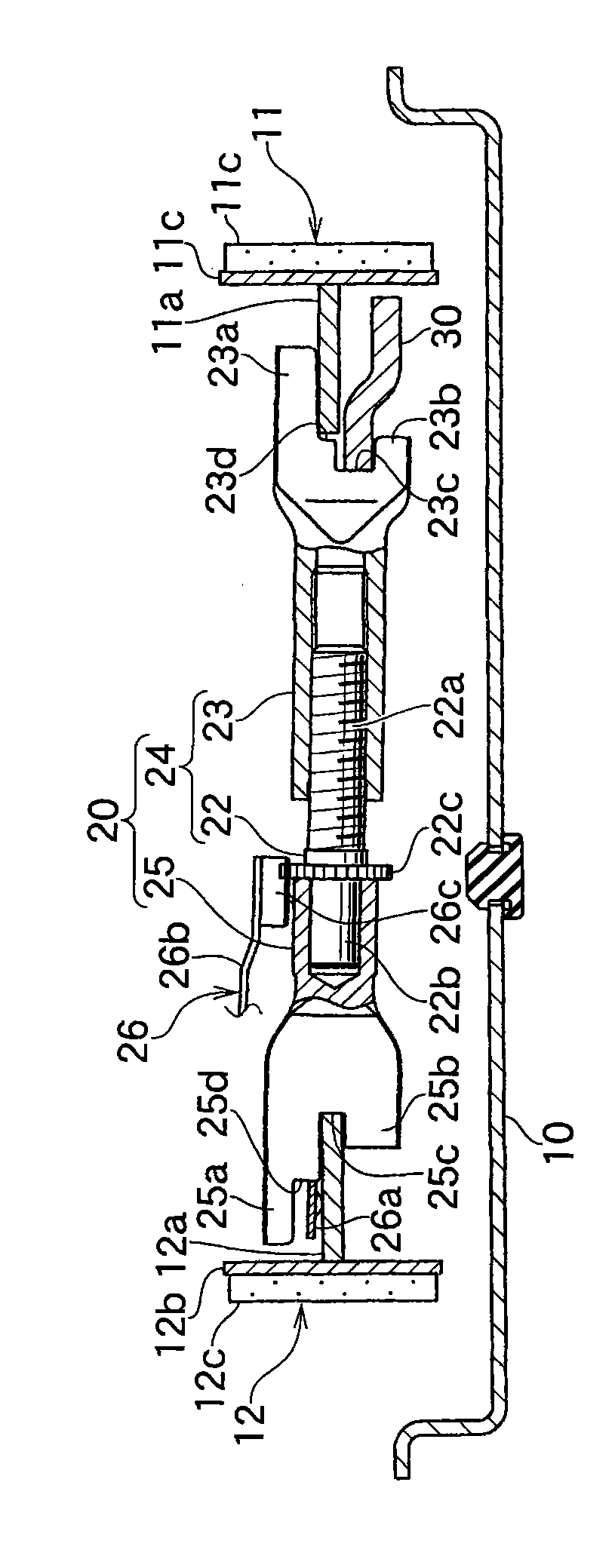

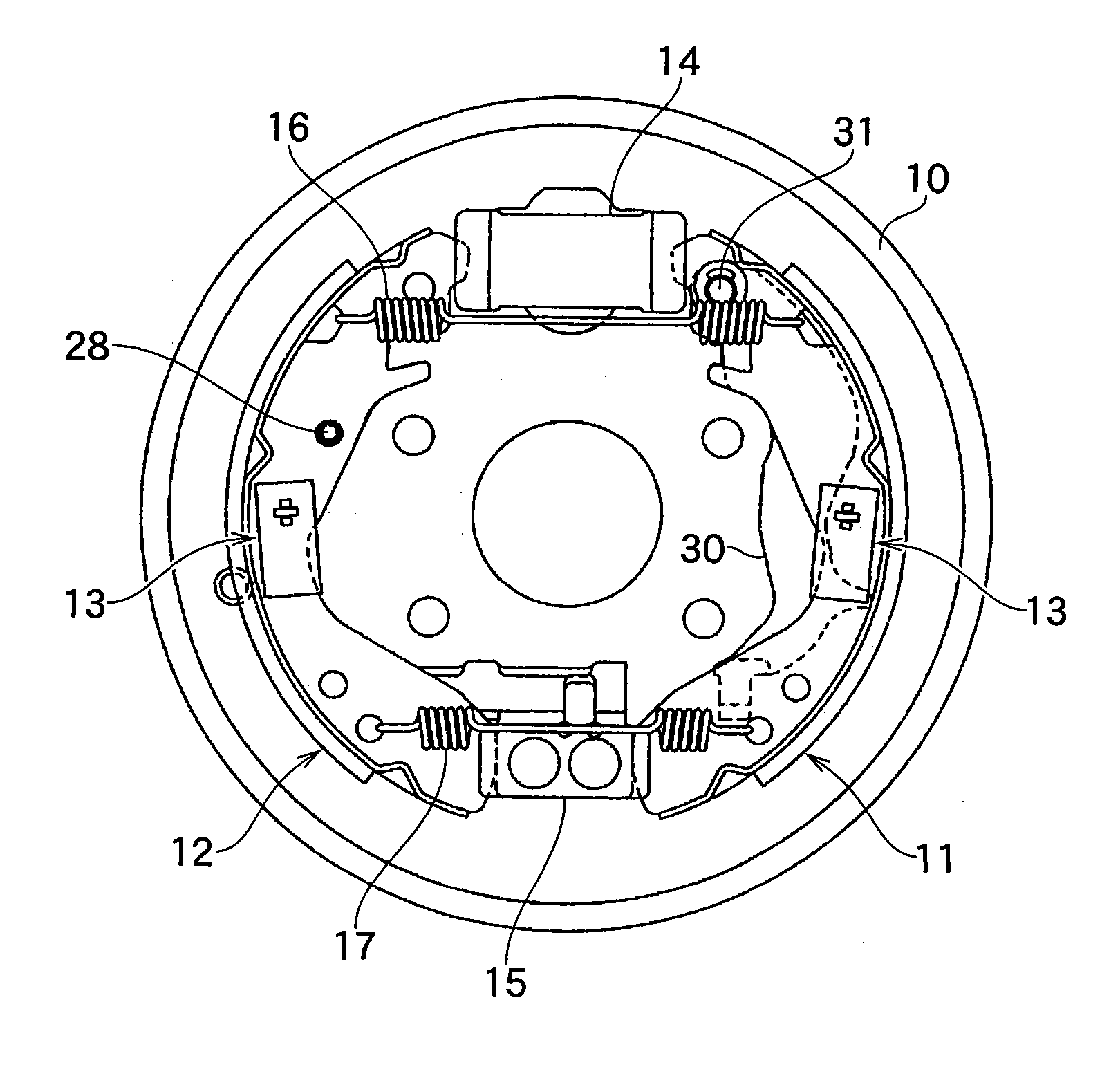

Automatic adjustment device for shoe clearance

InactiveCN102261407AEasy automatic assemblyDrum brakesSlack adjustersEngineeringMechanical engineering

The invention relates to an automatic adjustment device for shoe gaps. An object of the present invention is to provide a drum brake device in which a support unit can be assembled in a state where a brake shoe is placed on a back plate. A drum brake device, which has an incremental automatic shoe gap adjustment device, the device has the following structure, wherein the support assembly can be moved from the opposite direction to the back plate relative to a pair of brake shoes Assemble.

Owner:NISSHINBO BRAKE INC

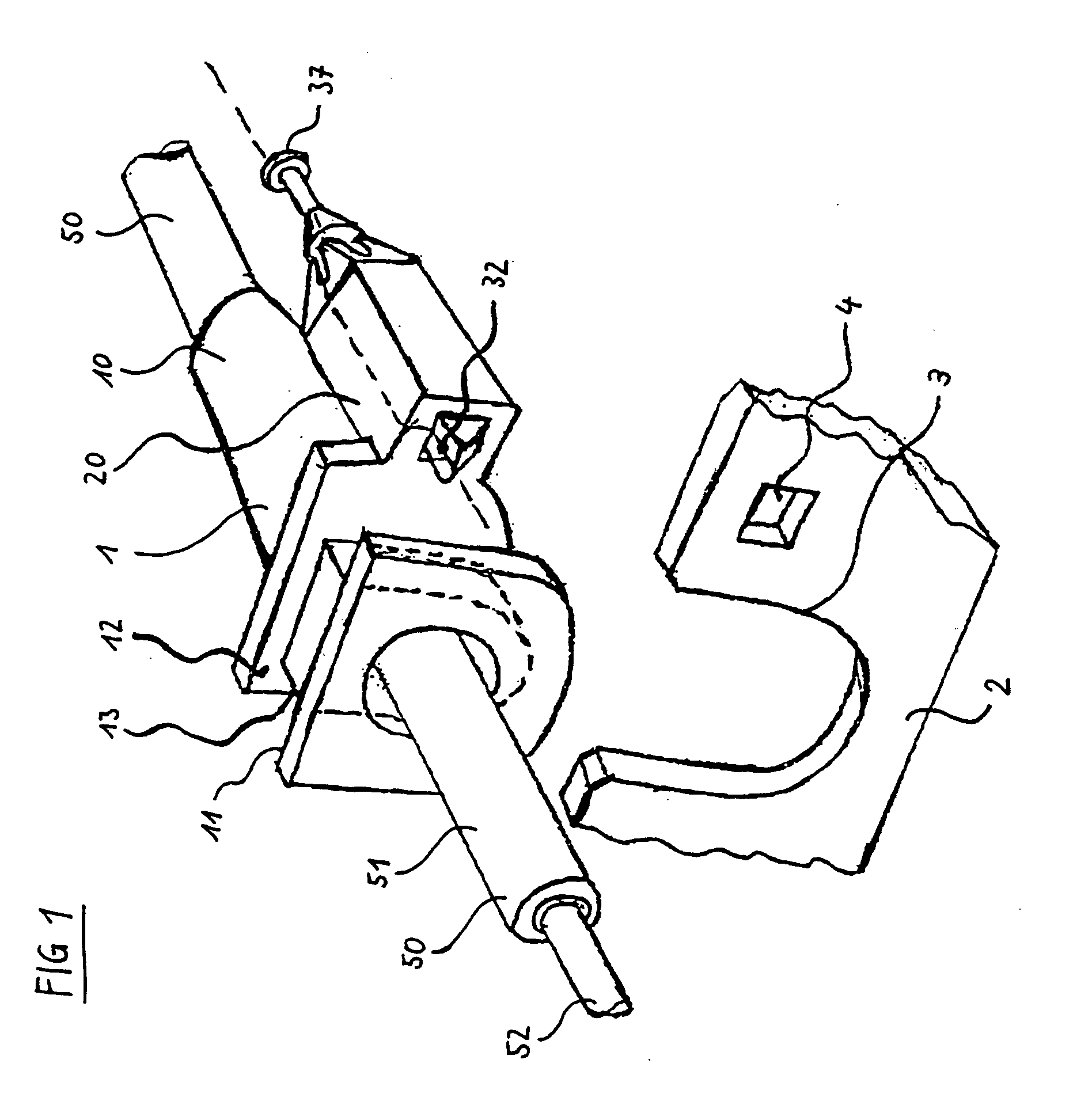

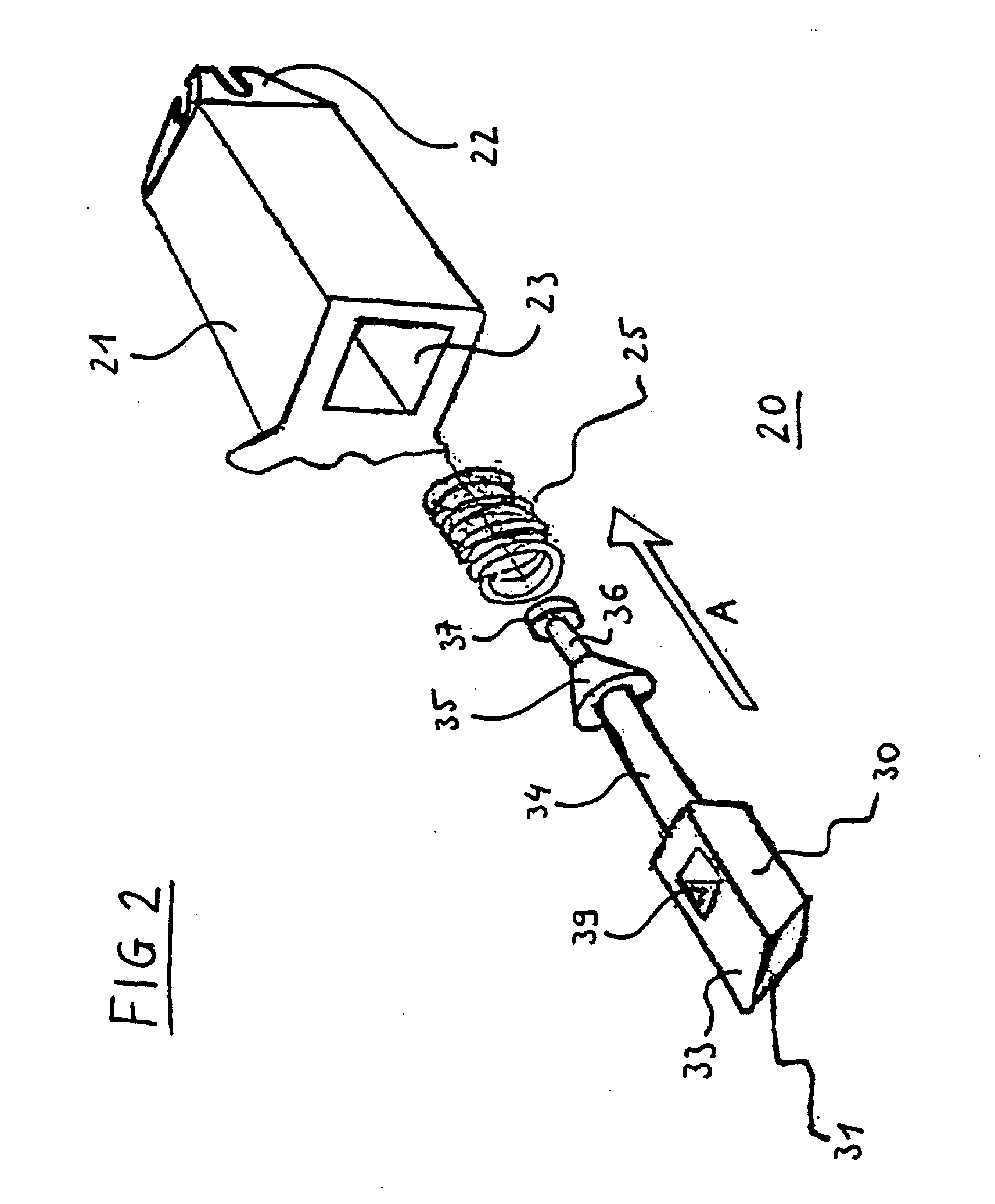

Mounting element for a bowden cable

InactiveUS20050160866A1Easy to masterCost-efficiently be producedRoad vehiclesShaft for linear movementBowden cableEngineering

The present invention relates to a mounting element 1 for a bowden cable 50, particularly for the automotive engineering, comprising a mounting body 10 with a at least partially circumferential mounting slot 13, wherein the mounting slot 13 can be brought into engagement with an essentially U-shaped seat 3 within a support structure by sliding; a latching element 20, for latching the mounting body 10 with the support structure 2, wherein the latching element 20 comprises a displaceable latch 30, a spring 25 and a latching housing 21, which is open at opposed sides; wherein the latch 30 comprises a snap element 35, so that the latch 30 is latchable with the latching housing 21 by insertion of the latch 30 into the latching housing 21.

Owner:FICO TRIAD

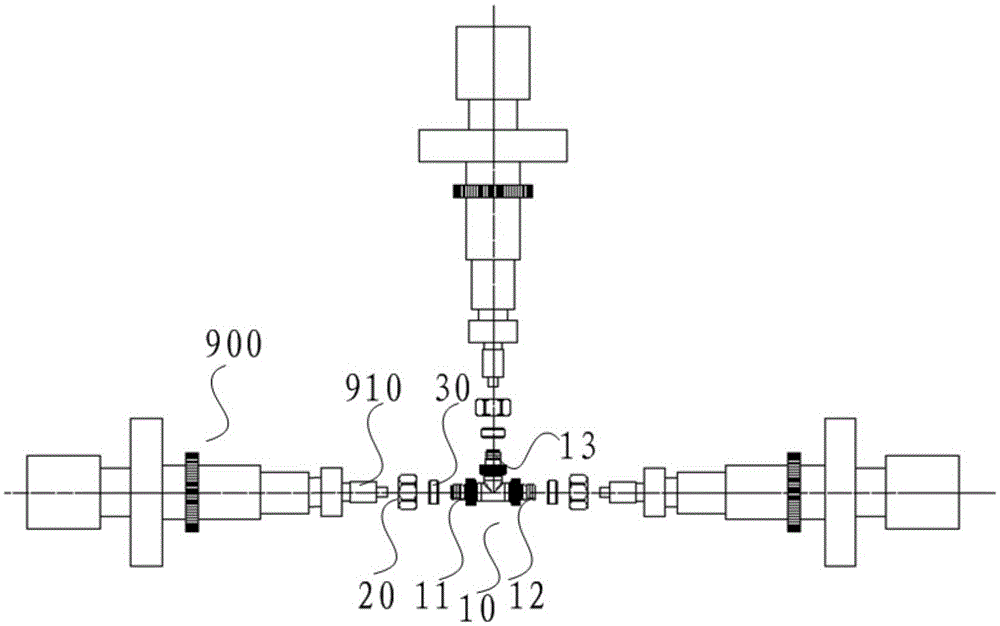

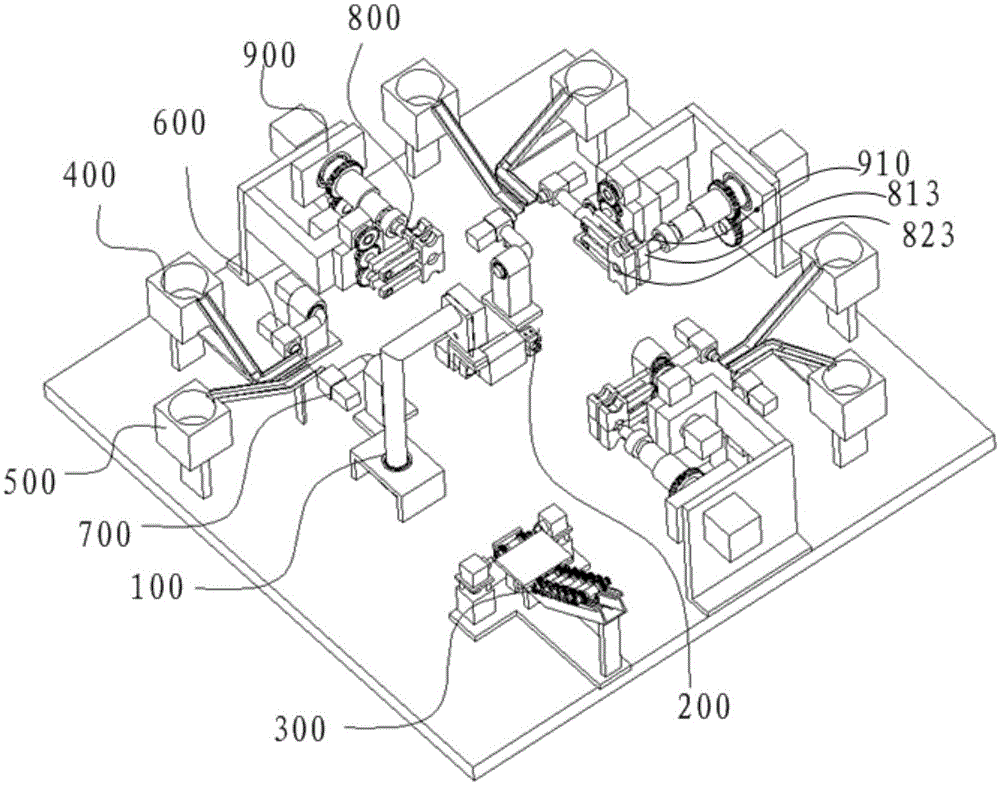

Assembling device and method for tee pipes

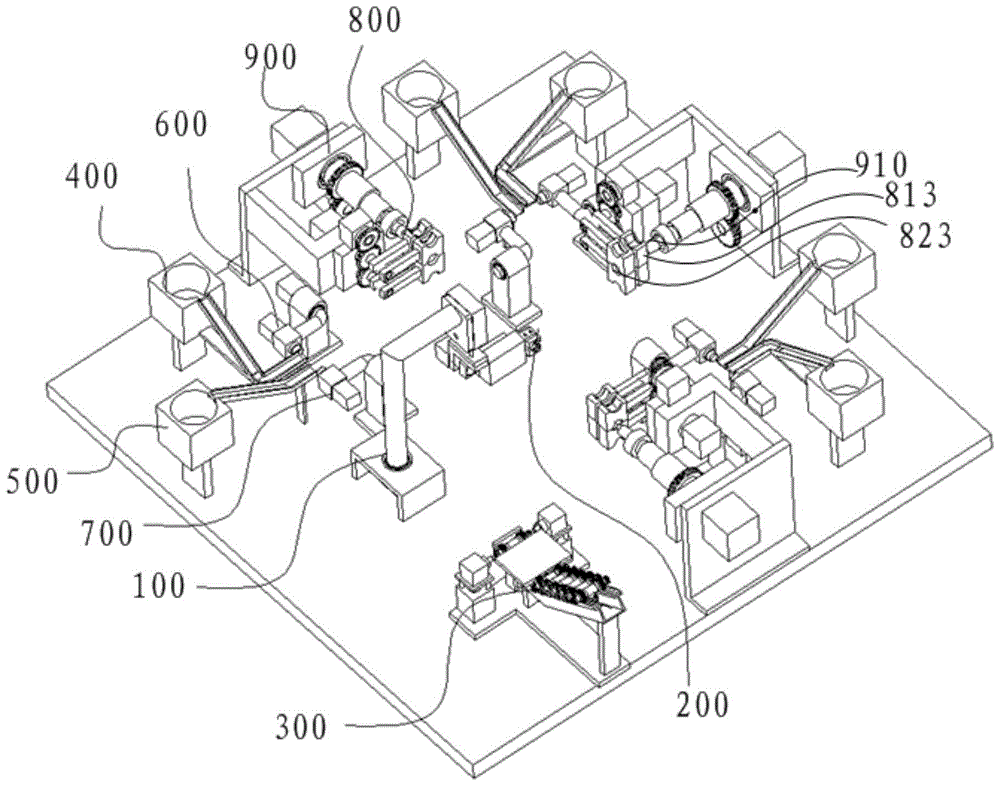

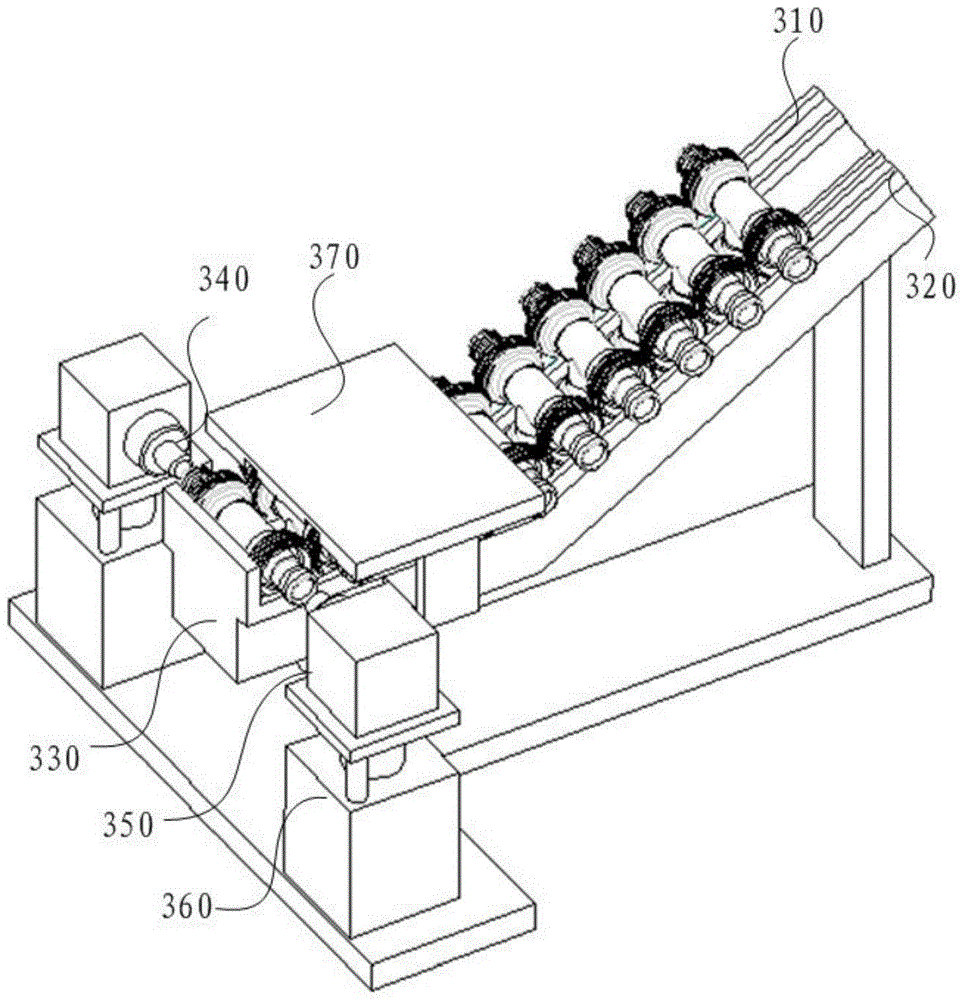

ActiveCN105014375AEasy to assembleRealize automated assemblyAssembly machinesManipulatorManufacturing engineering

The invention discloses an assembling device and method for tee pipes. The assembling device for the tee pipes comprises a controller, a pipe mechanical arm, a pipe assembling position, a first assembling mechanism, a second assembling mechanism and a third assembling mechanism, wherein the first assembling mechanism, the second assembling mechanism and the third assembling mechanism are arranged around the pipe assembling position. The pipe mechanical arm, the first assembling mechanism, the second assembling mechanism and the third assembling mechanism are electrically connected with the controller. The tee pipe assembling method includes the following steps that the pipe mechanical arm grabs the tee pipes and conveys the tee pipes to the assembling position. Nuts and pipe sleeves are put in the first assembling mechanism, the second assembling mechanism and the third assembling mechanism so that the nuts, the pipe sleeves and the axes of corresponding joints can be located on the same straight line. The nuts and the pipe sleeves are screwed into the three joints of the three tee pipes through the first assembling mechanism, the second assembling mechanism and the third assembling mechanism to complete assembling of the tee pipes. According to the assembling device and method for the tee pipes, the tee pipes are automatically assembled, and the assembling time is effectively shortened.

Owner:RIFENG ENTERPRISE GRP CO LTD +1

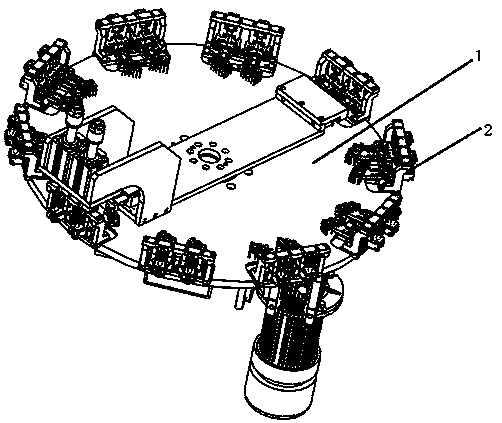

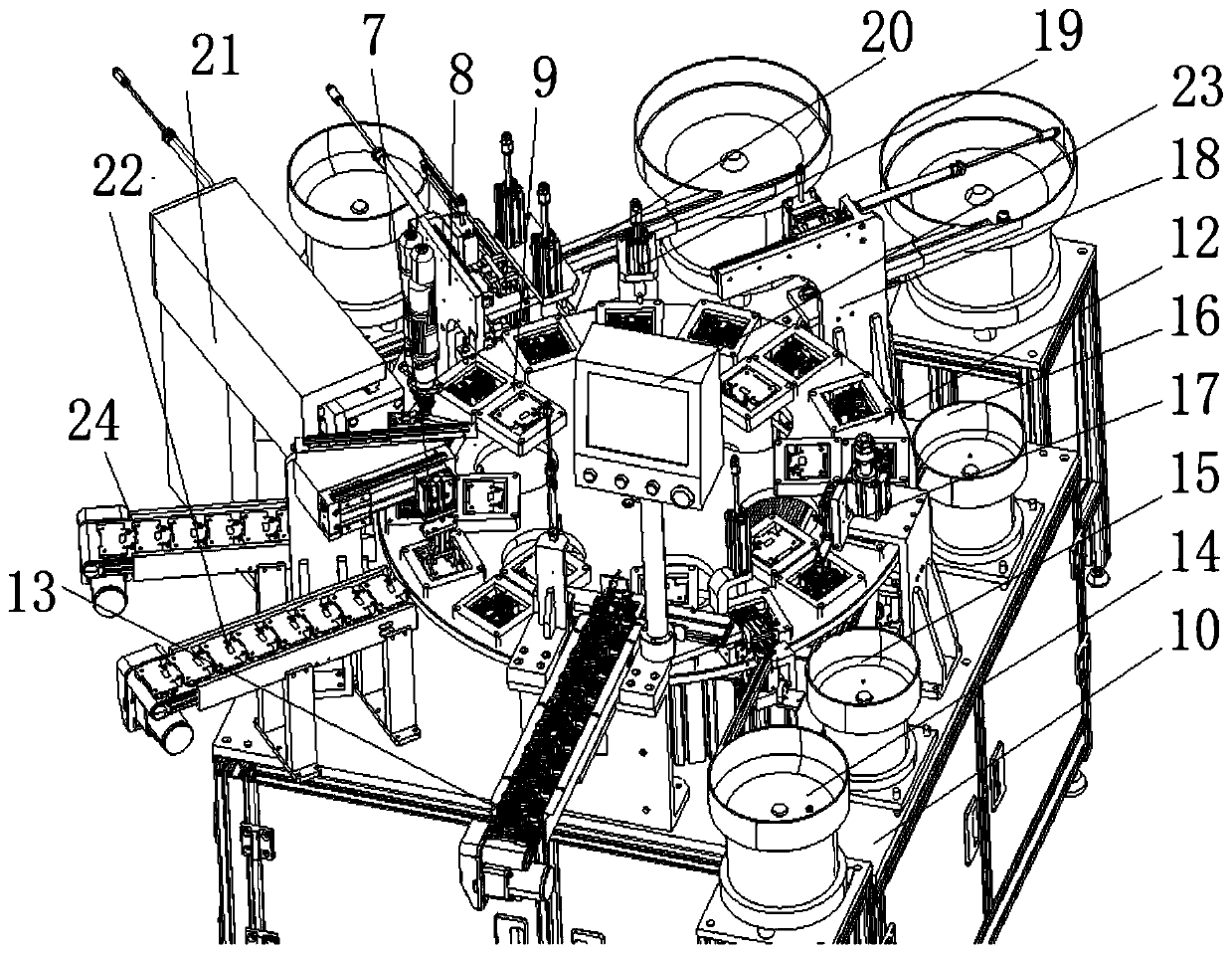

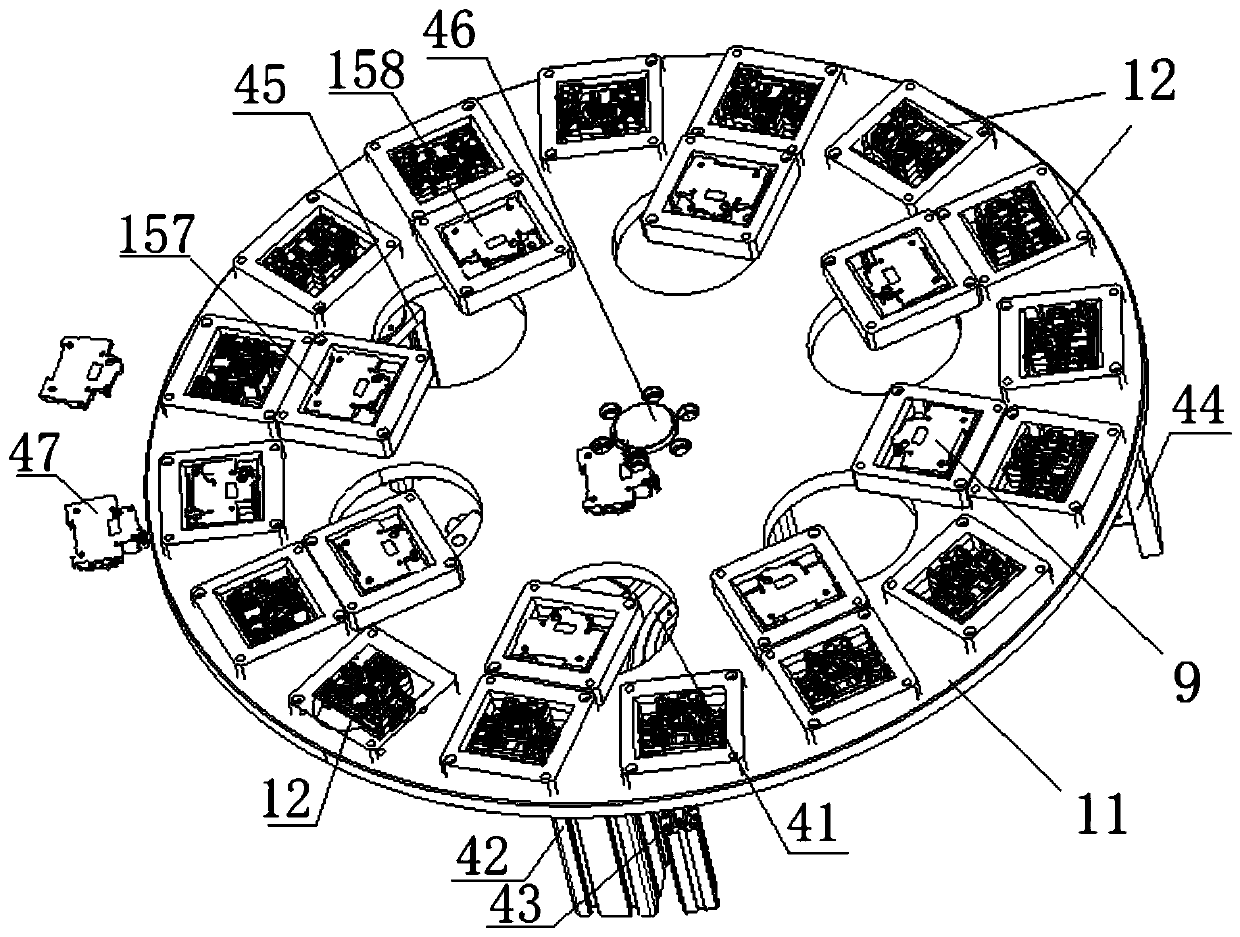

Automatic assembling and locking system for miniature circuit breaker

ActiveCN111482802AFacilitate automatic assembly and inspectionReduce equipment and manpower investmentAssembly machinesMetal working apparatusBase stationAutomation

The invention discloses an automatic assembling and locking system for a miniature circuit breaker. The automatic assembling and locking system is characterized in that a turntable assembly is arranged in the middle of a table top of a rack, sixteen base stations and eight upper cover stations are uniformly distributed on the turntable assembly in an indexing manner, each of the sixteen base stations is provided with a base jig for conveying bases; each of the eight upper cover stations is provided with an upper cover jig; a base conveying mechanism, an adjusting nut conveying mechanism, a nutinput part, a nut detection unit, an arc extinguishing cover conveying mechanism, an arc extinguishing cover detection assembly, an arc guide plate and contact supporting plate press-fitting conveying mechanism, a secondary press-fitting assembly, a screw locking mechanism, an upper cover feeding mechanism and a finished product discharging mechanism are arranged close to related stations; the turntable assembly comprises an output shaft, a turntable is fixed at the upper end of the output shaft; and three supporting frames are arranged below the turntable, and all the supporting frames jointly support the turntable to rotate upwards through balls in all ball supports. The automatic assembling and locking system for the miniature circuit breaker is novel in structure, stable in finished product quality and high in automation degree.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

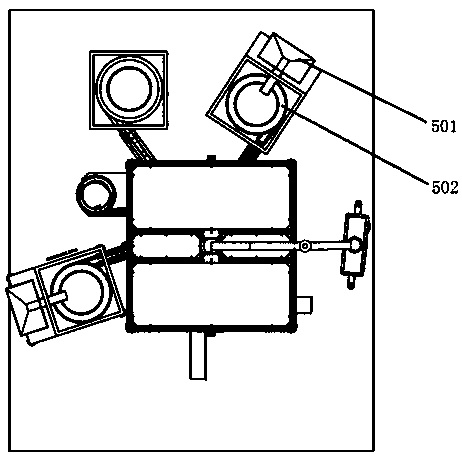

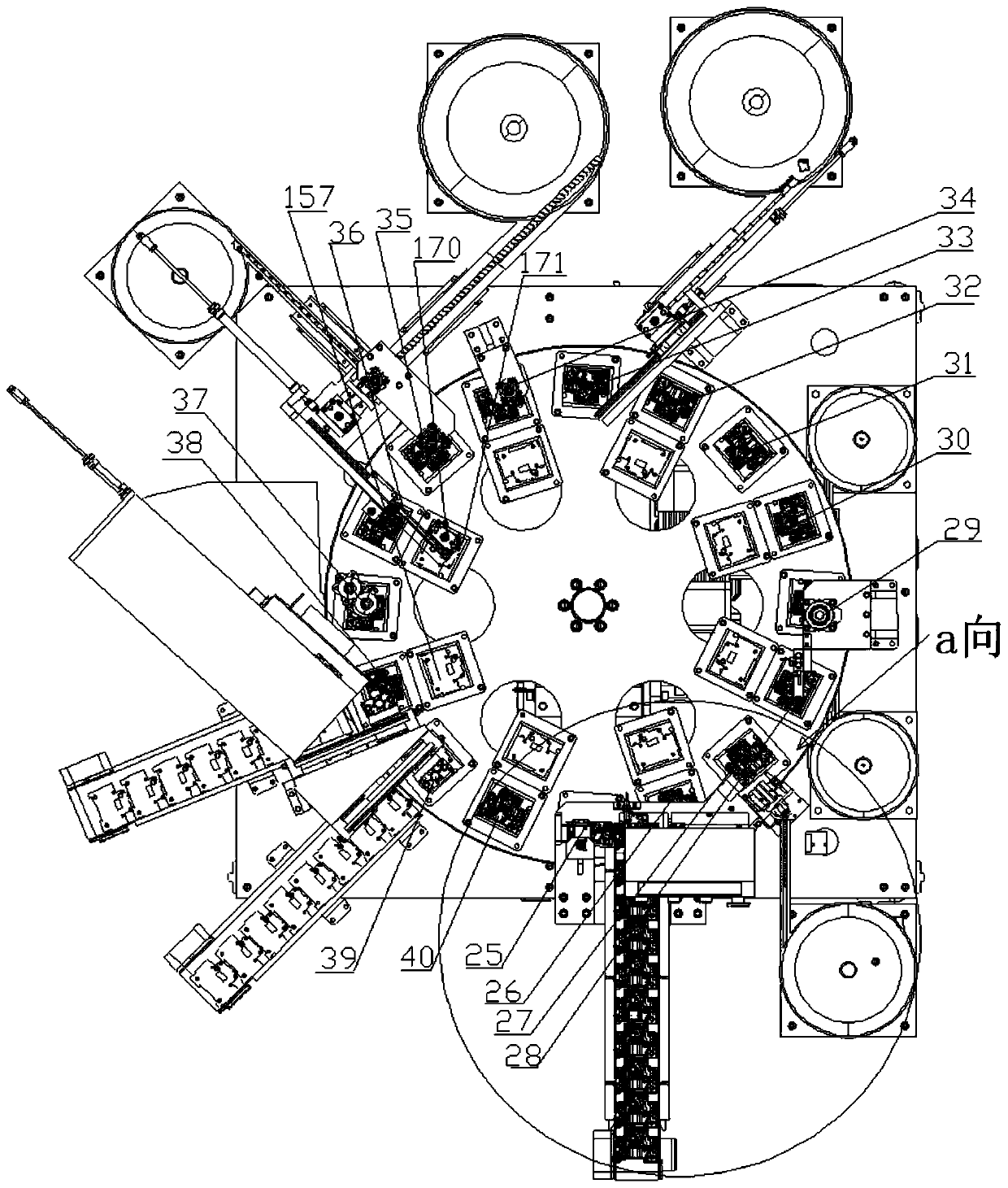

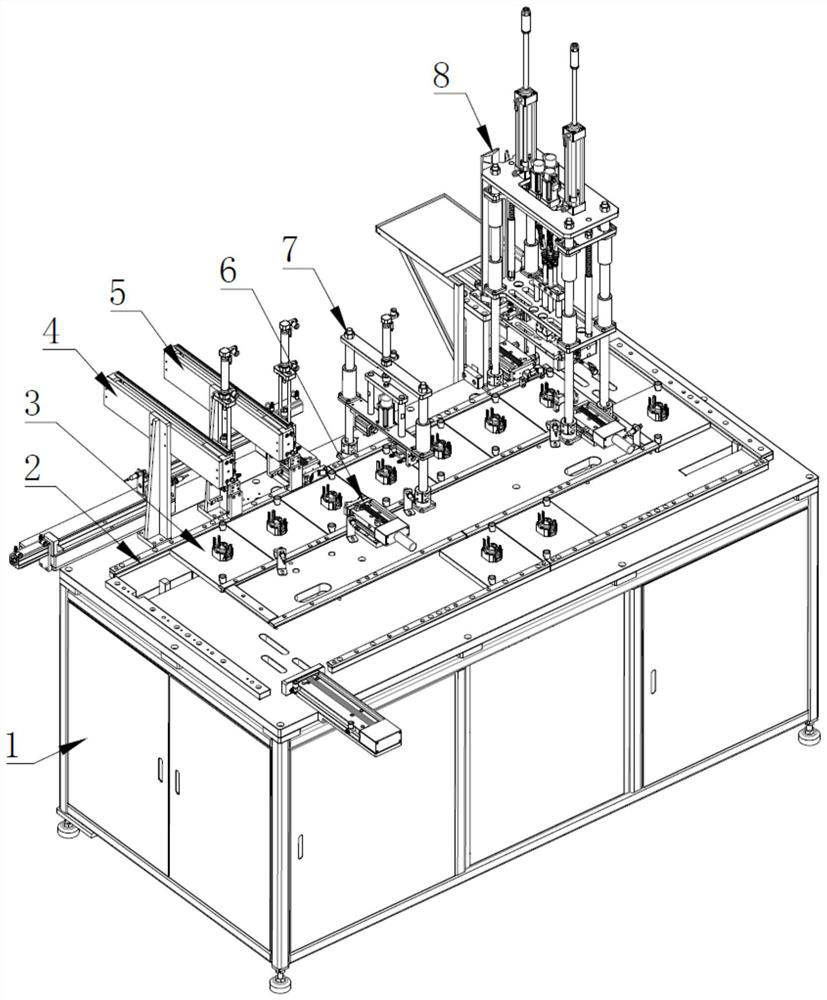

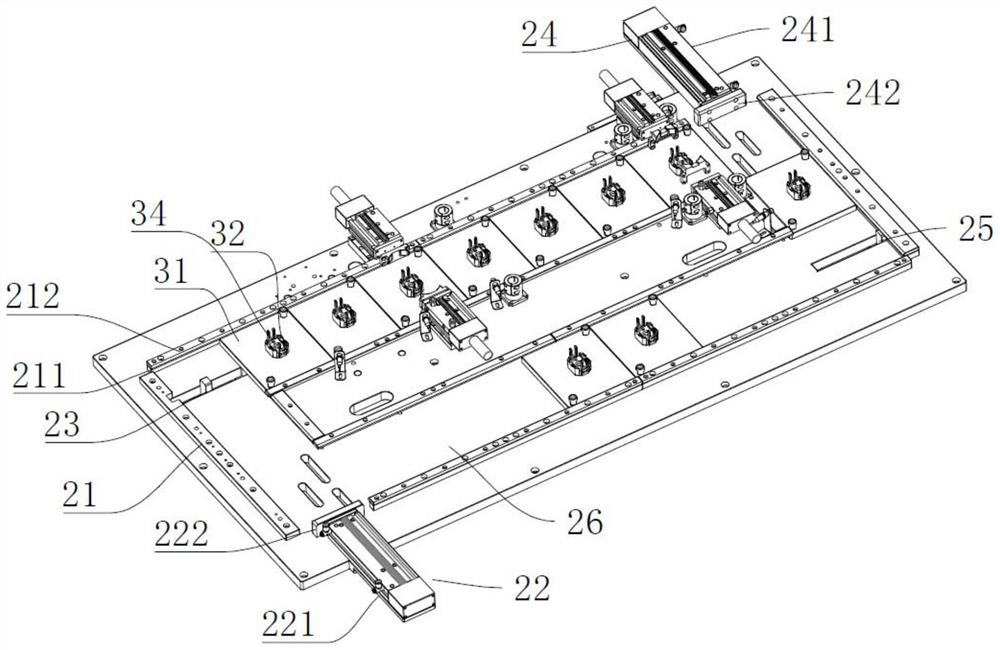

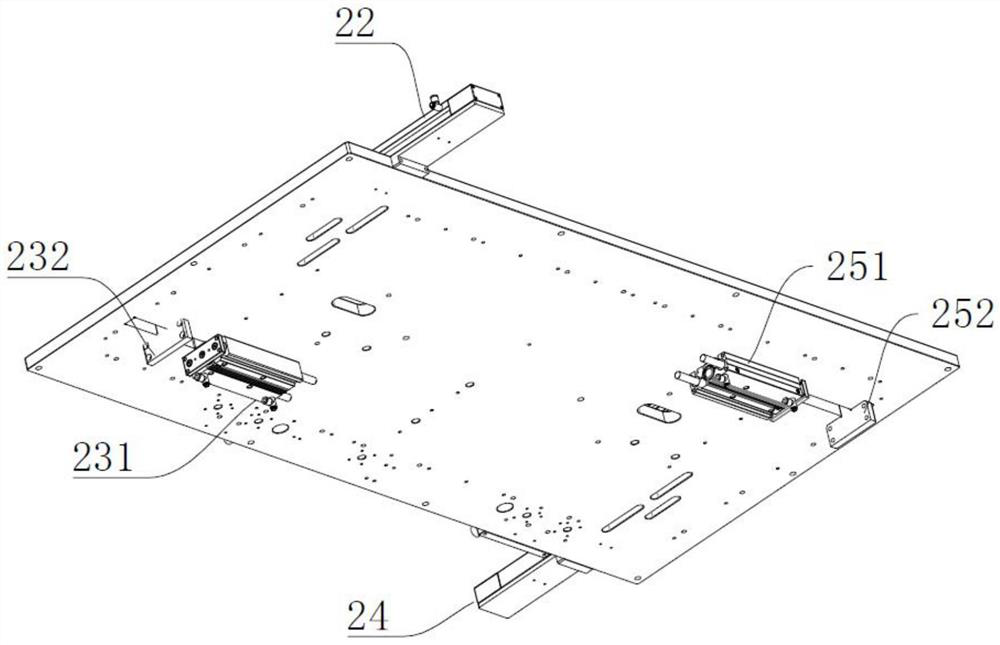

Switch cassette assembling machine

ActiveCN106584100AImprove assembly efficiencyGood product consistencyAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of assembling of switch cassettes, in particular to a switch cassette assembling machine. The switch cassette assembling machine comprises a controller, a workbench (1), a rotary platform (2), a first power mechanism, a clamp assembly (3), a feeding mechanism (4), a rotary mechanism (5), an iron buckle placement mechanism (6), a first screw installing mechanism (7), a second screw installing mechanism (8) and a discharging mechanism, wherein the first power mechanism, the feeding mechanism (4), the rotary mechanism (5), the iron buckle placement mechanism (6), the first screw installing mechanism (7), the second screw installing mechanism (8) and the discharging mechanism are all electrically connected with the controller. The switch cassette assembling machine is high in assembling efficiency, and assembled switch cassettes are high in consistency.

Owner:NINGBO KINGS INDAL

Switch device

InactiveCN1477660AEasy to assembleImprove reliabilityTumbler/rocker switch detailsSwitches with two operating positionsSwitching signalRestoring force

A switch device includes two switch elements, both elements being disposed in a case and given restoring force by a common leaf spring; a cover which closes a top opening of the case; and an operating knob having two projections for selectively activating the switching elements. The leaf spring includes a compressed portion which is resiliently compressed by the cover, a pair of pressing strips which resiliently presses against each shaft of a pair of drivers of the switching elements. The operating knob presses a protruding receiver of each of the drivers, thereby selectively tilting a pair of conductive plates to output a switch ON signal.

Owner:ALPS ALPINE CO LTD

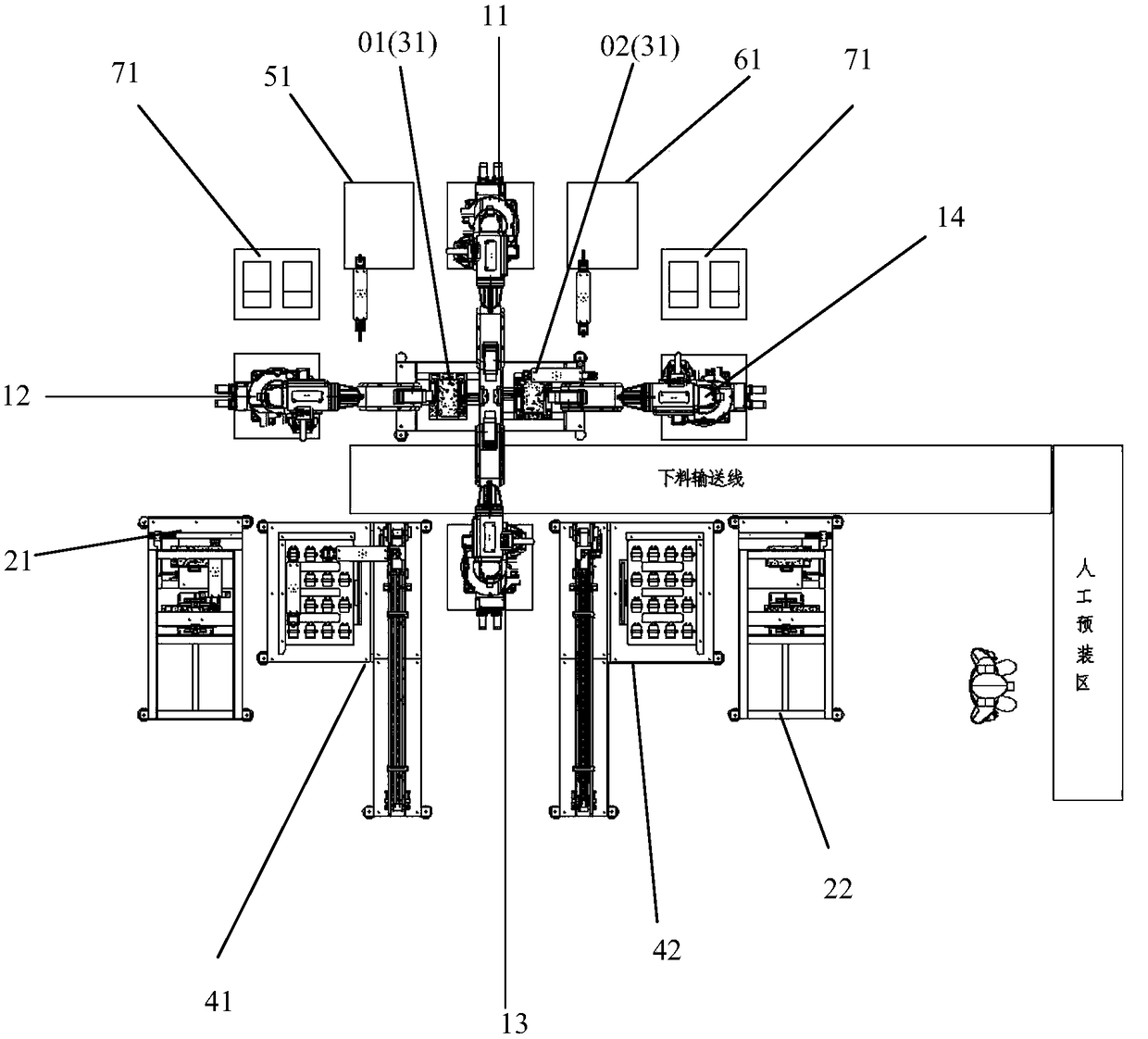

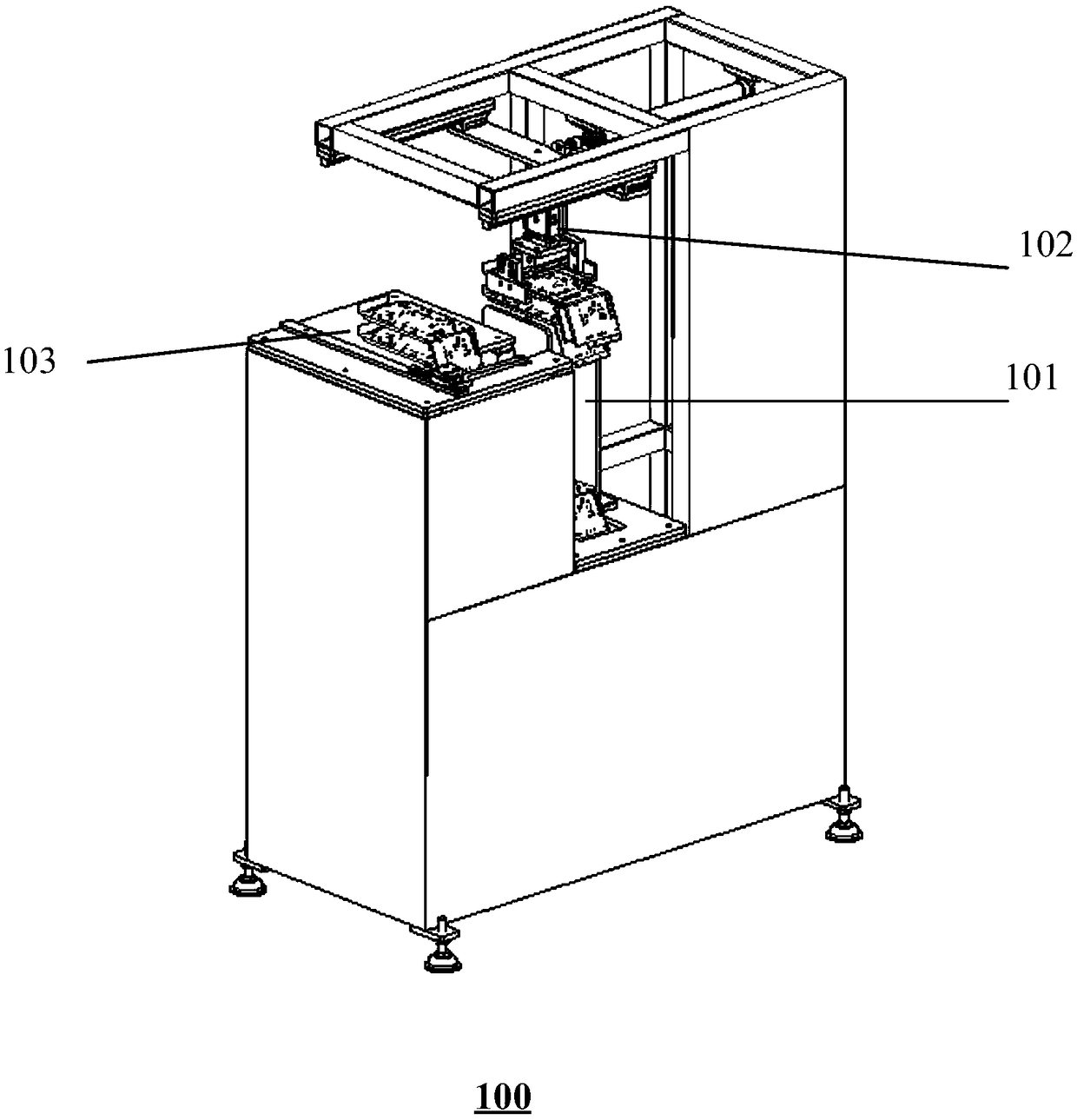

Automatic assembling system and method

InactiveCN108994602AImplement automatic assemblyIncrease productivityAssembly machinesCapacitanceEngineering

The invention provides an automatic assembling system and method which are used for improving electric appliance box production efficiency and quality, reducing the labor intensity of workers and saving person cost. The automatic assembling system comprises a control subsystem and a mechanical assembly subsystem, the mechanical assembly subsystem comprises a sheet metal part feeding device, a capacitance feeding device, an operation positioning device and a robot; and the control subsystem and the mechanical assembly subsystem are in communication connection, and the control subsystem is usedfor controlling mechanical assembly subsystem to conduct assembly operation on sheet metal parts.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

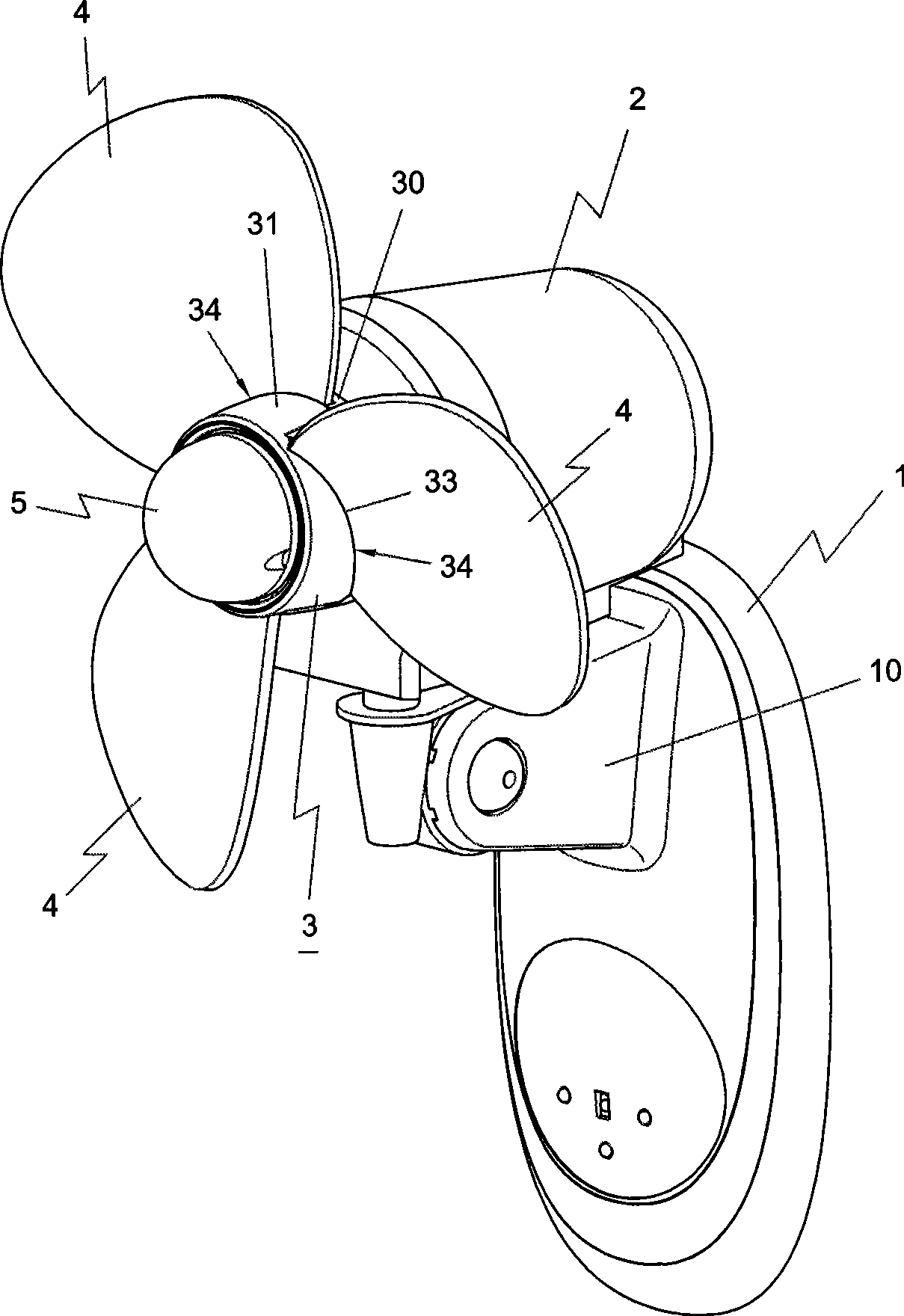

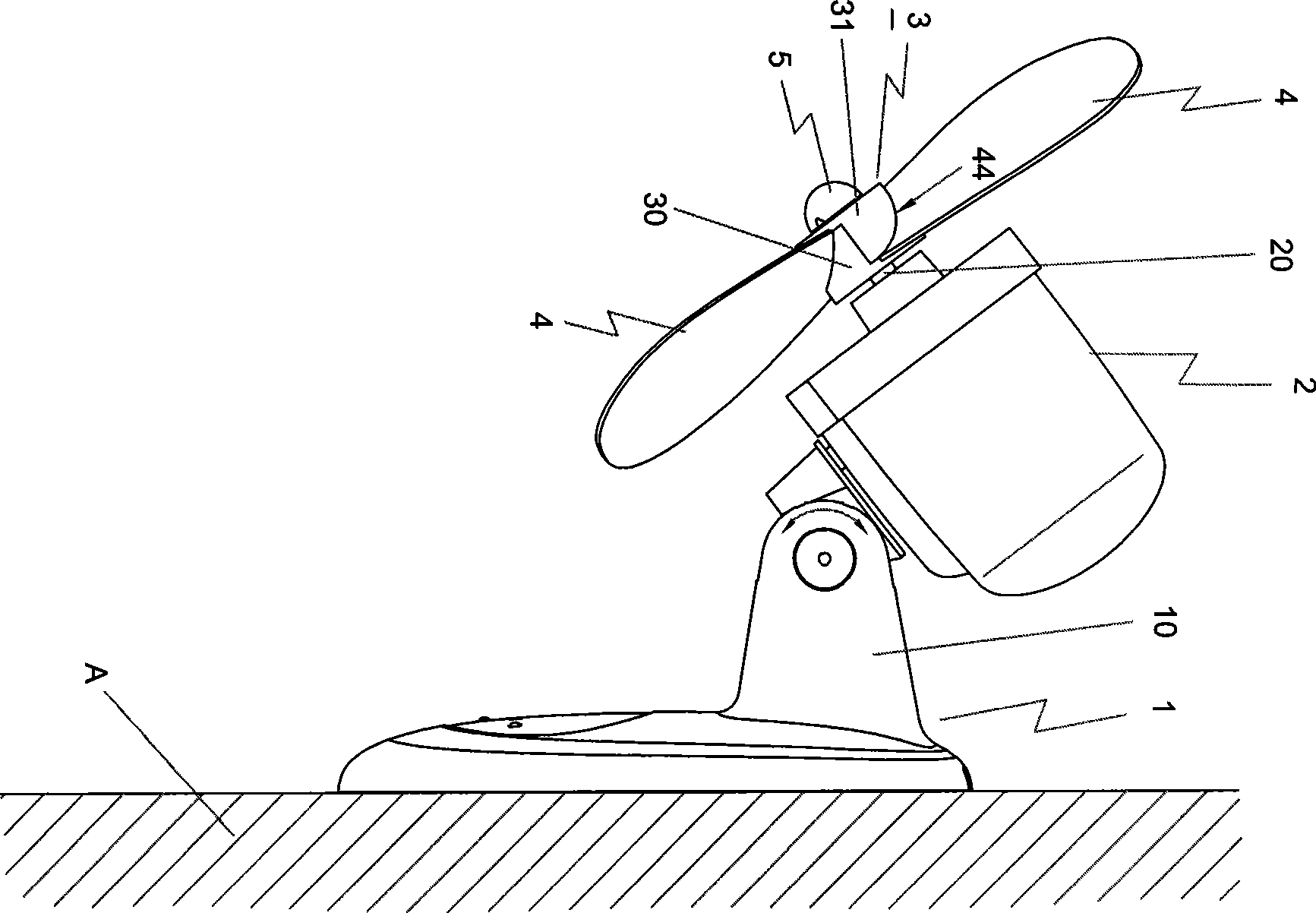

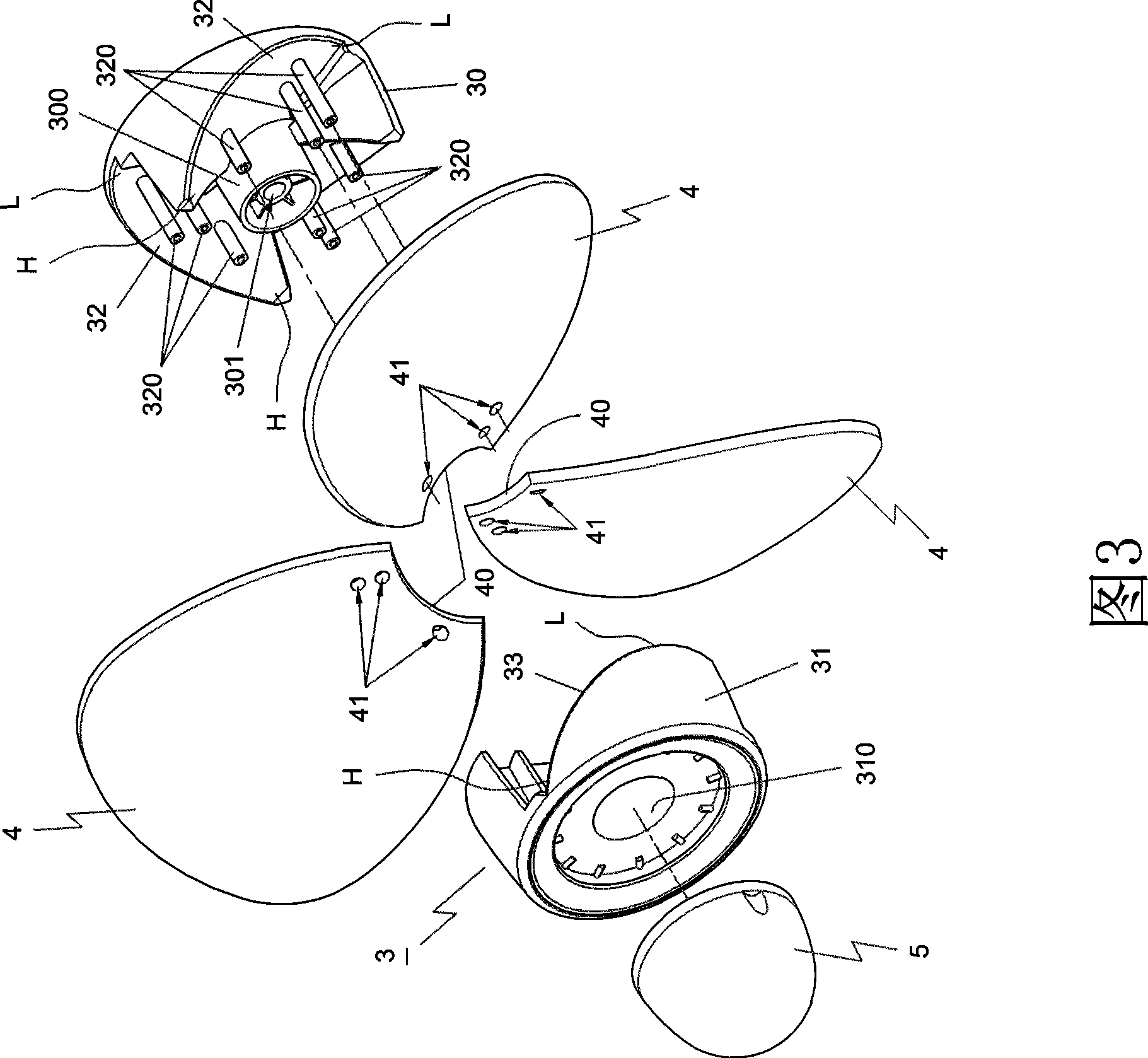

Electric fan

InactiveCN101440817AReduce volumeEasy automatic assemblyPump componentsPump installationsAir volumeSafety design

The invention discloses an electric fan, which comprises a base, a motor machine set, fan blade seats and fan blades, wherein the base is provided with a connecting seat and the motor machine set; the motor machine set is arranged on the connecting seat of the base and provided with a mandrel; the fan blade seats are provided with first components and second components which are corresponding and provided with combination seats and combination sleeves respectively, the combination seats are provided with shaft holes, the first components and the second components are provided with a plurality of curved surfaces respectively, the curved surfaces of the second components are of a corresponding shape, the curved surfaces of the first components are provided with a plurality of protruded pillars, and the first components and the second components form fan blade accommodating grooves when the first components and the second components are mutually combined; the fan blades are provided with a plurality of the fan blade accommodating grooves matched with a plurality of the fan blade seats, and the fan blades are made of a foaming or flexible material into a plane shape and are provided with grooves and a plurality of holes; and the first components and the second components of the fan blade seats are combined with the fan blades to form the electric fan. The electric fan does not need to arrange a safety net, namely, the electric fan has safety design, can save manufacturing cost, can not resist air-out effect and improve air output.

Owner:TUNG ELECTRIC +1

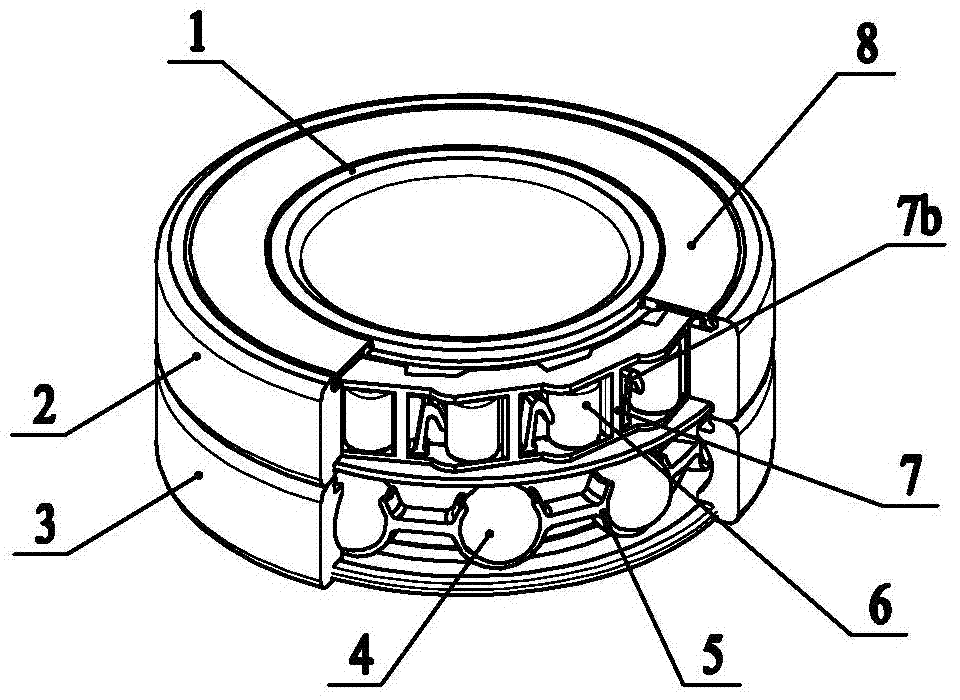

Self-resetting double-sealing reverse locking composite bearing

ActiveCN103527626AGuaranteed concentricityLow manufacturing costBall and roller bearingsBearing componentsSmooth surfaceBall (bearing)

The invention relates to a self-resetting double-sealing reverse locking composite bearing. An inner ball groove with an arc-shaped cross section is formed in the first end of the surface of the outer circumference of an inner ring, and a smooth surface is arranged at the second end of the surface of the outer circumference of the inner ring. An outer ball groove with an arc-shaped cross section is formed in the surface of the inner circumference of a first outer ring. A plurality of sets of curve faces connected end to end are arranged on the surface of the inner circumference of a second outer ring, one end of each curve face is an arc section, the other end of each curve face is a linear section, and the arc sections and the linear sections are in smooth transition connection. A ribbon retainer is arranged between the first end of the inner ring and the first outer ring, and balls are arranged in the ball bags of the ribbon retainer; a self-resetting retainer is arranged between the second end of the inner ring and the second outer ring, rolling columns are arranged in the mounting window holes of the self-resetting retainer, cantilever limit blocks are arranged on the mounting window hoes, one end of each cantilever limit block is fixed to the self-resetting retainer, and a bent portion capable of being elastically bent towards one sides of the rolling columns is arranged at the other end of each cantilever limit block. The self-resetting double-sealing reverse locking composite bearing is simple in structure, ingenious in design and convenient and reliable to assemble.

Owner:WUXING HUAYANG ROLLING BEARING JIANGSU LITTLESWAN GROUP

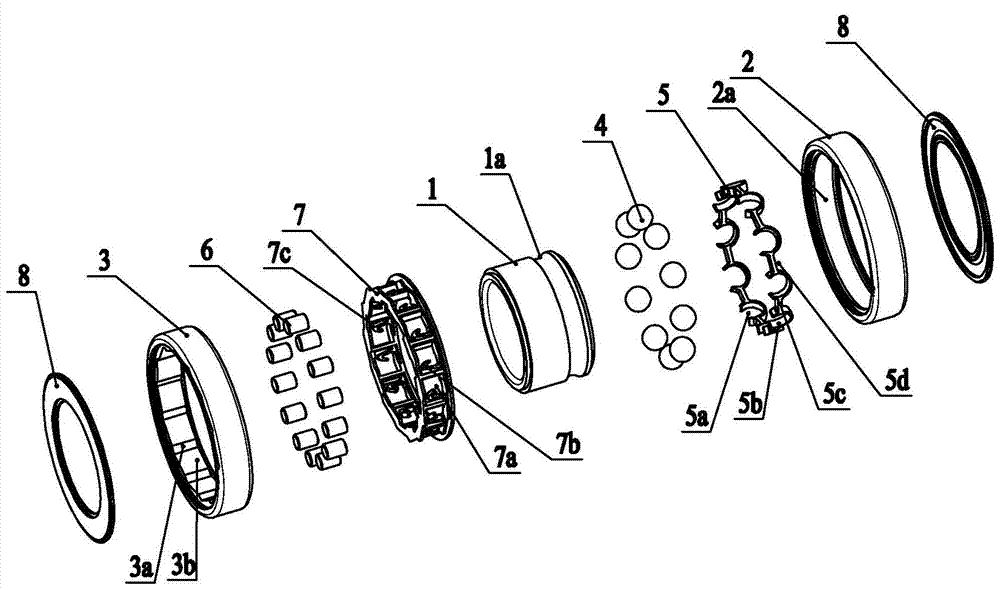

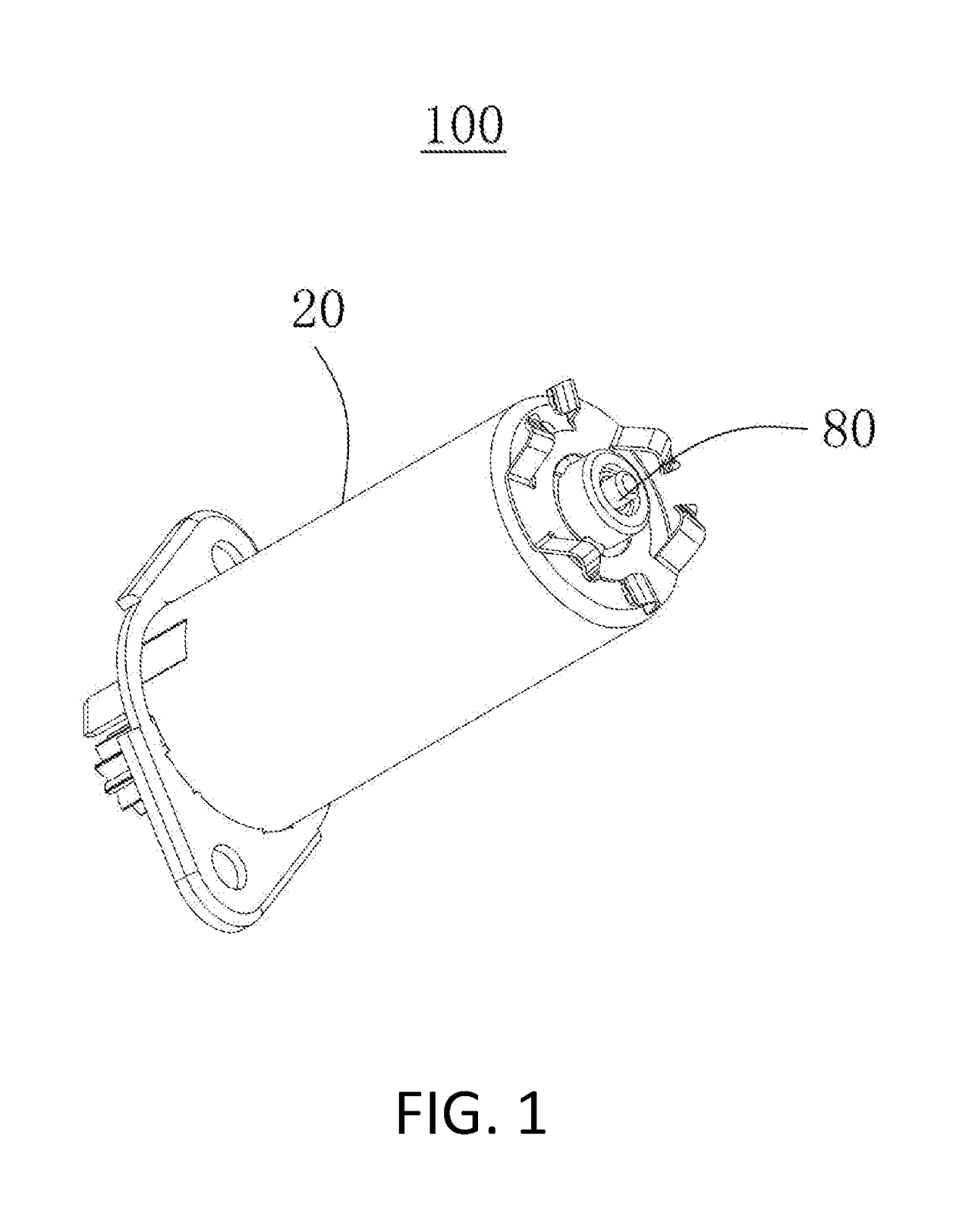

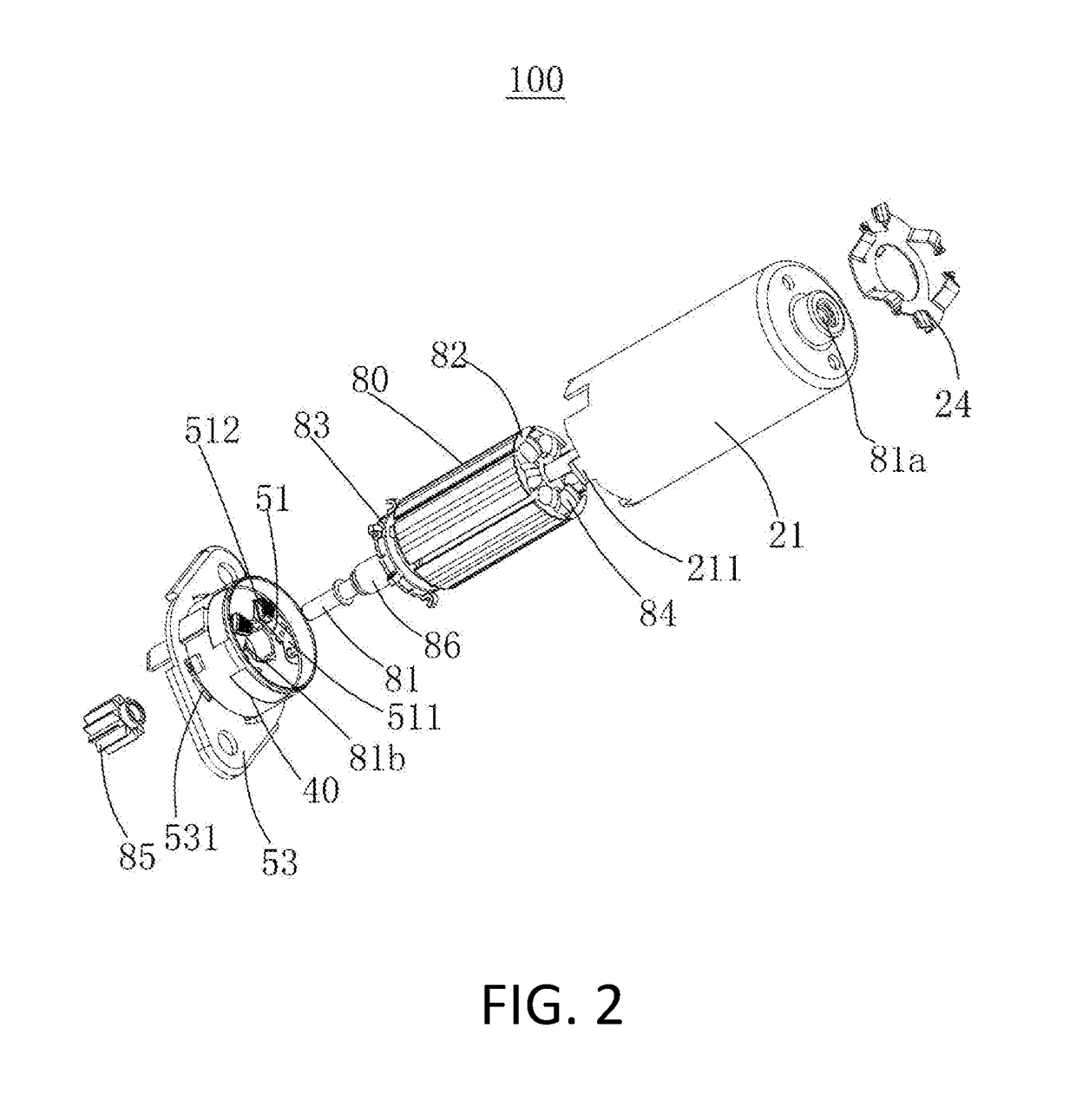

Motor, end cap and manufacturing method thereof

ActiveUS20190020240A1Simple structureLow costAssociation with control/drive circuitsRotary current collectorElectrical conductorElectric power

An electric motor, an end cap thereof and a manufacturing method of the end cap are provided. The end cap includes an insulating body and a filter circuit board mounted to the insulating body. The filter circuit board includes at least two power conductors for receiving an external power source, an insulating support frame integral with the at least two power conductors, and at least one filter element. One end of the at least one filter element is connected to a corresponding power conductor, and the other end of the at least one filter element is grounded.

Owner:JOHNSON ELECTRIC SA

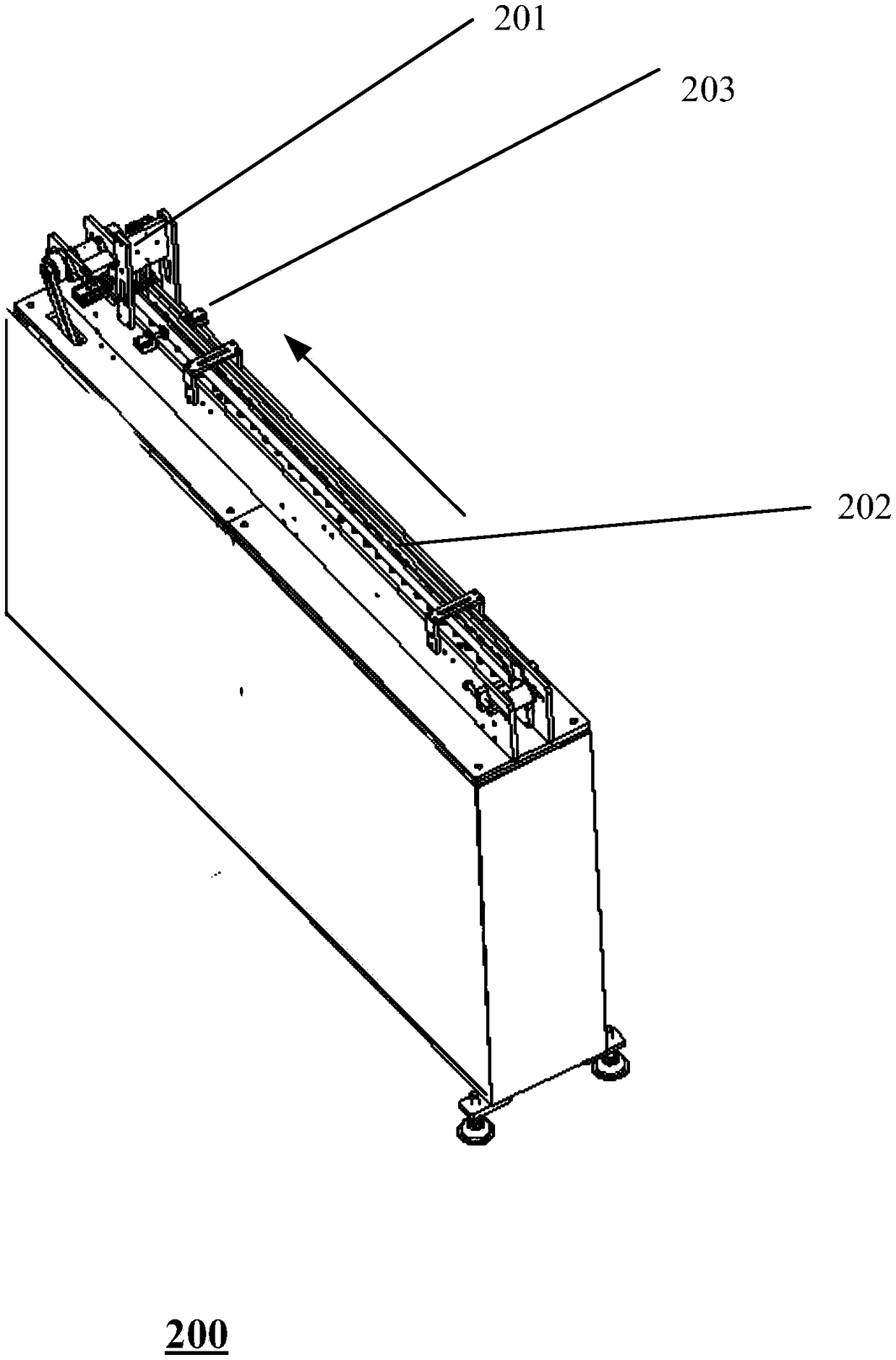

Automatic assembling technology for motor end cover seal

InactiveCN113857851AImprove assembly accuracyHigh degree of automationAssembly machinesManufacturing dynamo-electric machinesElectric machineryIndustrial engineering

The invention relates to the technical field of motor assembling, in particular to an automatic assembling technology for a motor end cover seal. A rack, a rectangular-ambulatory-plane conveying device arranged on the surface of the rack, a motor assembling jig capable of being conveyed to the rectangular-ambulatory-plane conveying device, as well as a seal feeding device, an end cover feeding device, an end cover correcting device, an end cover rotating and pressing device and a screw locking device which are mounted on the rack, located on one side of the rectangular-ambulatory-plane conveying device and sequentially arranged are included. Seal piece feeding, end cover feeding, end cover correcting, end cover rotating and pressing and end cover screwing and locking are sequentially carried out, the overall assembling precision is high, the automation degree is high, manpower is saved, stability and reliability are achieved, and the technology is suitable for assembling of motor end covers on a large scale.

Owner:DONGGUAN DIRECT DRIVE TECH LTD

Pump mount in a beverage preparation machine

ActiveUS8863648B2Reducing and preventing transmissionReduce vibrationBeverage vesselsLiquid dispensingMachine partsEngineering

A beverage preparation machine that includes a housing, a pump which vibrates during use and which is mounted in the housing, and a dampener for preventing or reducing the transmission of vibrations from the pump to other machine parts. The damper includes a spring on which the pump is mounted in the housing.

Owner:SOC DES PROD NESTLE SA

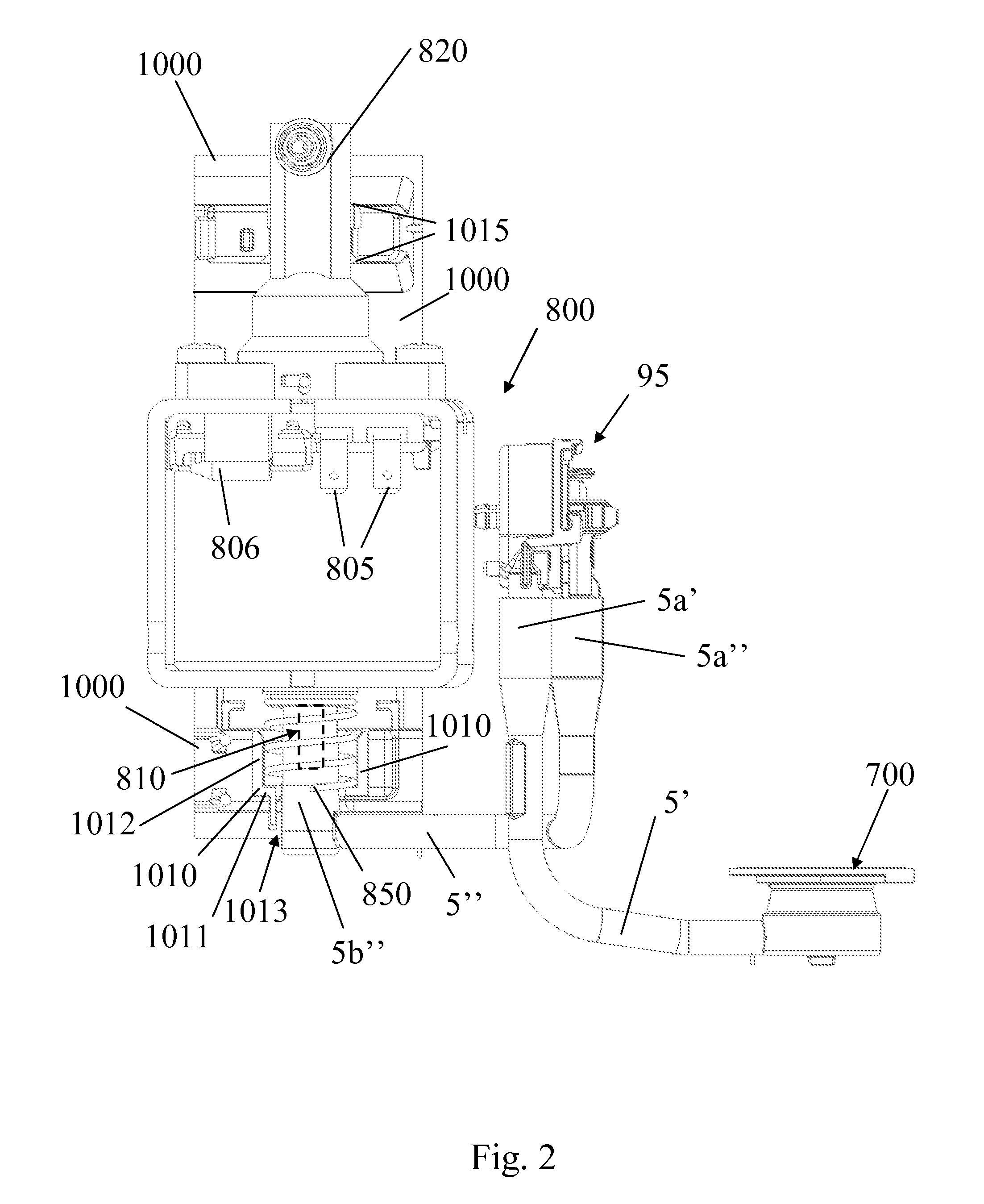

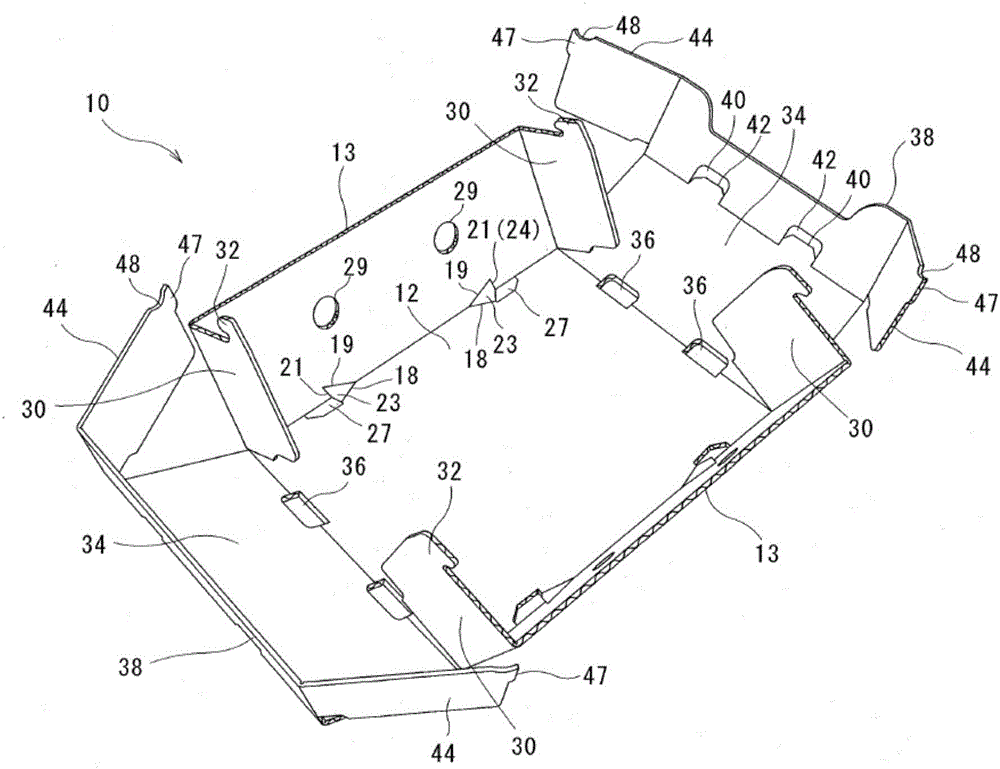

Locking structure, container utilizing locking structure, and assembling device for container

ActiveCN105813944AAvoid distractionsEasy to lockBox making operationsPaper-makingStructural engineeringBranching points

In the present invention, there is a first inclined line (18) which extends over a first wall (12) toward a third wall (44) side from a branching point (16) on a folding line (15) between the first wall (12) and a second wall (13), a second inclined line (19) which extends over the second wall (13) toward the third wall (44) side from the branching point (16), and a cutout part (24) which extends from the tip of the first inclined line (18) to the tip of the second inclined line (19), and between the abovementioned elements is a locking-receiving part (23) which will extend at a slope over the first wall (12) and second wall (13) at assembly. A locking part (48) for engaging with the cutout part (24) side of the locking-receiving part (23) is provided on the third wall (44), which will be disposed along the inner surface of the second wall (13).

Owner:UNION CORP

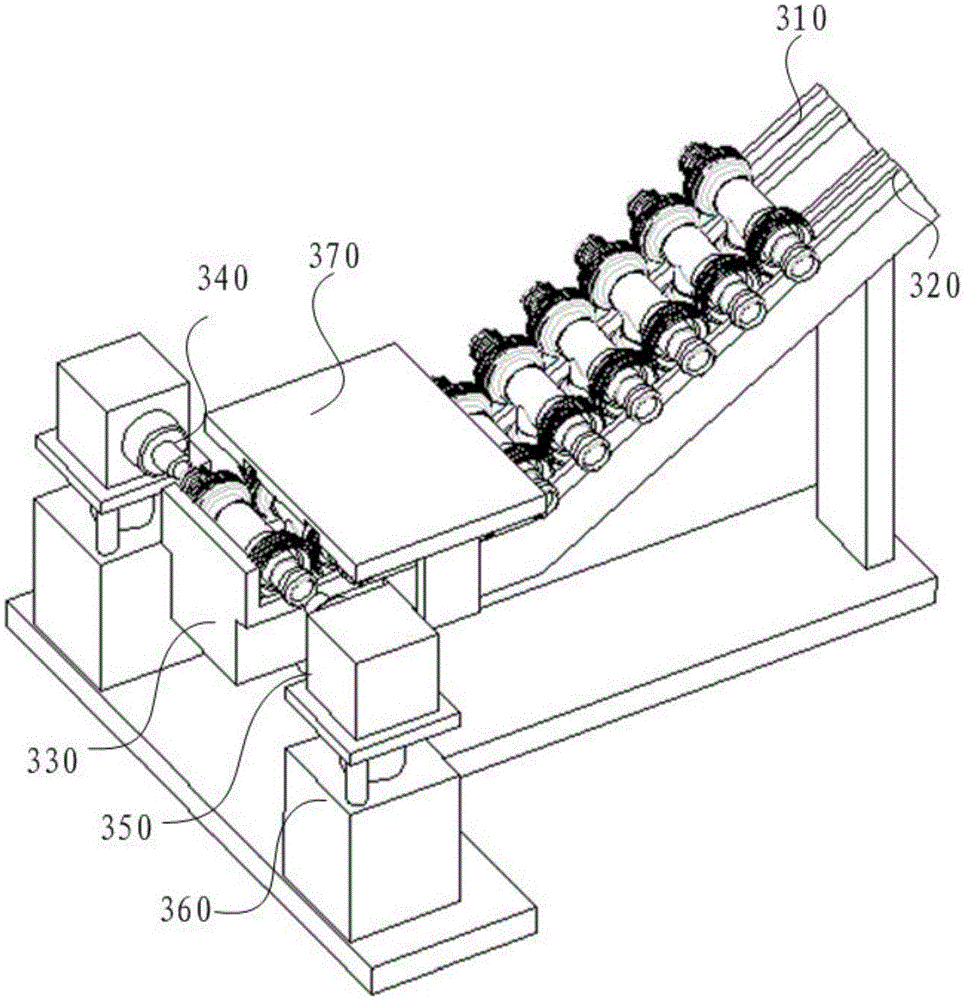

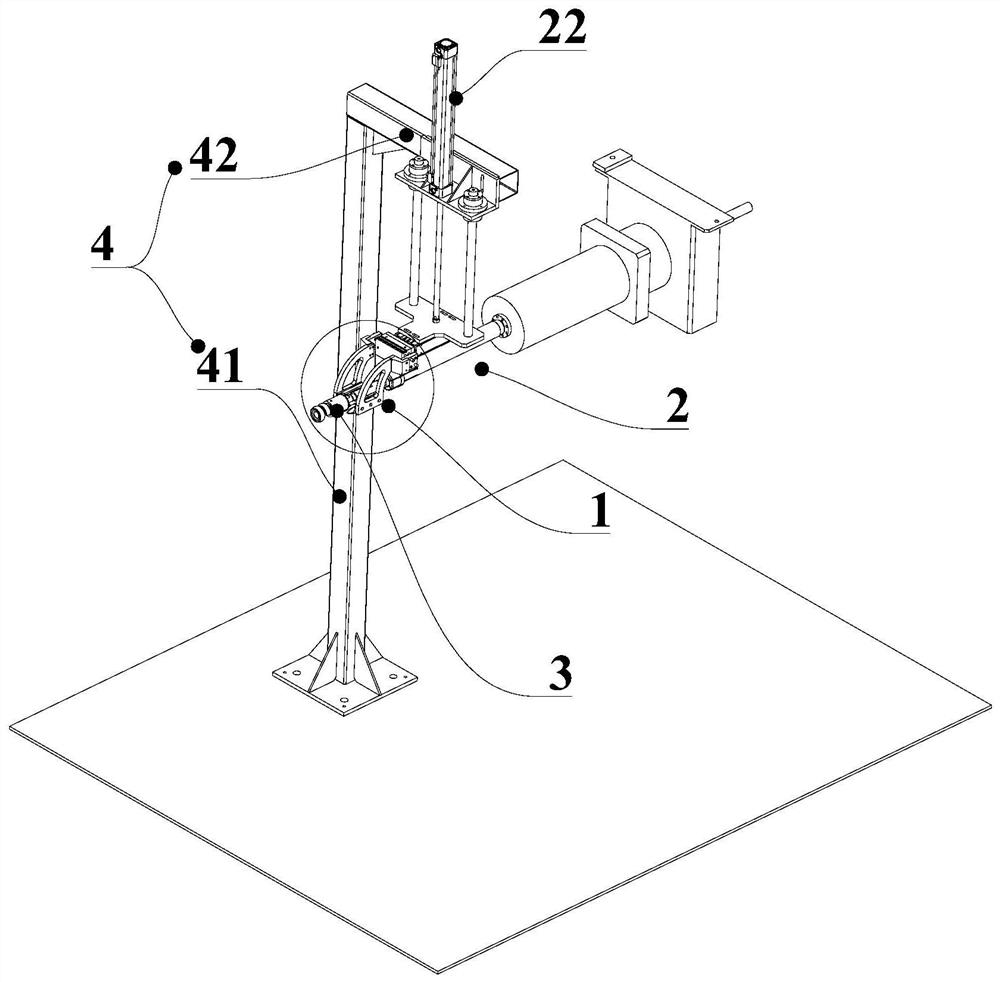

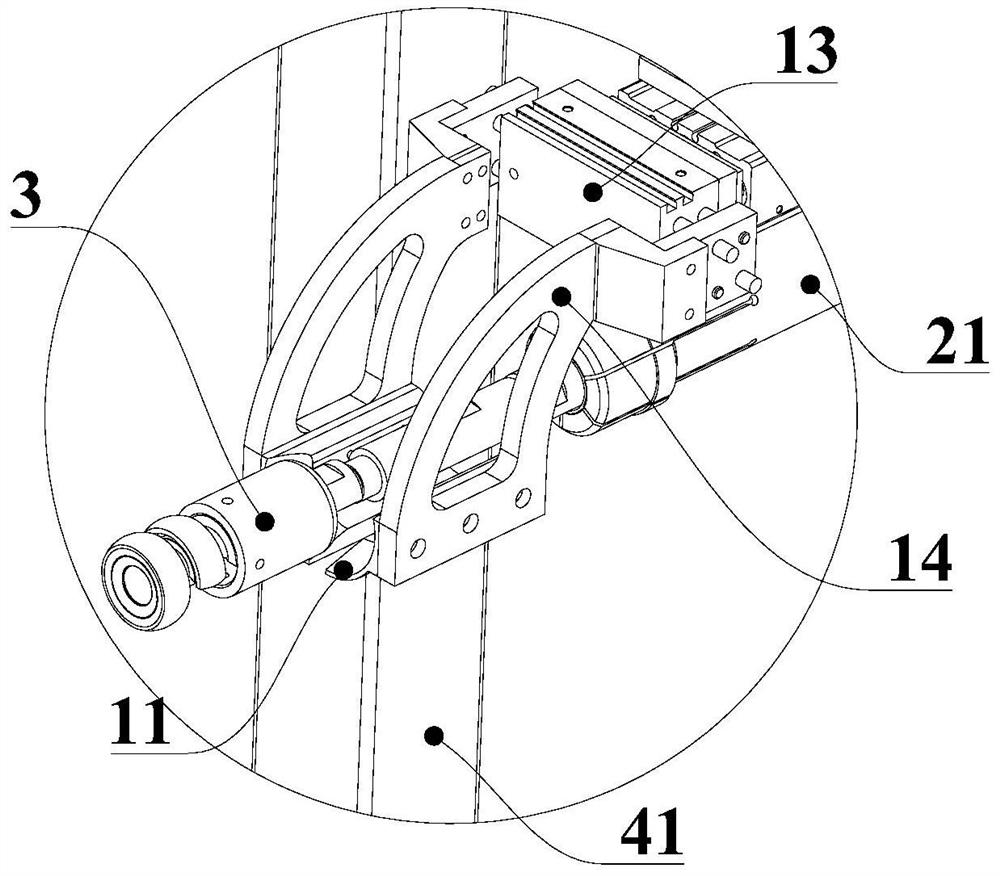

Supporting device of internal expansion core rod for bent pipe and bent pipe machining system

The invention provides a supporting device for an internal expansion core rod for a bent pipe. The supporting device is characterized by comprising a lifting support and a driving unit for driving the lifting support to move, the driving unit can at least adjust the position along the axial direction and the vertical direction of the matching position of a pipe and the internal expansion core rod, and the lifting support can support the internal expansion core rod from the lower part. The invention further provides a bent pipe machining system comprising the supporting device. The supporting device of the internal expansion core rod for the steel bent pipe and the bent pipe machining system have the advantages that the internal expansion core rod is straightened through the lifting support, automatic assembly of the pipe is facilitated, and therefore the internal expansion core rod and the pipe can be continuously driven to move relatively to a designated position, dependence on manual straightening can be avoided, the working efficiency and safety are improved, the labor cost is reduced, moreover, the equipment transformation cost is low, only one supporting device needs to be additionally arranged in an existing pipe bending machine, the internal expansion core rod does not need to be replaced, and the service life is long.

Owner:BAOLONG ANHUI AUTO PARTS

Equipment and method for assembling three-way pipe fittings

ActiveCN105014375BRealize automated assemblyExtraction went wellAssembly machinesManipulatorManufacturing engineering

The invention discloses an assembling device and method for tee pipes. The assembling device for the tee pipes comprises a controller, a pipe mechanical arm, a pipe assembling position, a first assembling mechanism, a second assembling mechanism and a third assembling mechanism, wherein the first assembling mechanism, the second assembling mechanism and the third assembling mechanism are arranged around the pipe assembling position. The pipe mechanical arm, the first assembling mechanism, the second assembling mechanism and the third assembling mechanism are electrically connected with the controller. The tee pipe assembling method includes the following steps that the pipe mechanical arm grabs the tee pipes and conveys the tee pipes to the assembling position. Nuts and pipe sleeves are put in the first assembling mechanism, the second assembling mechanism and the third assembling mechanism so that the nuts, the pipe sleeves and the axes of corresponding joints can be located on the same straight line. The nuts and the pipe sleeves are screwed into the three joints of the three tee pipes through the first assembling mechanism, the second assembling mechanism and the third assembling mechanism to complete assembling of the tee pipes. According to the assembling device and method for the tee pipes, the tee pipes are automatically assembled, and the assembling time is effectively shortened.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com