Locking structure, container utilizing locking structure, and assembling device for container

一种锁定结构、容器的技术,应用在刚性/半刚性容器的制造、容器、刚性容器等方向,能够解决提高成本、复杂机制、自动组装困难等问题,达到加强组装操作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

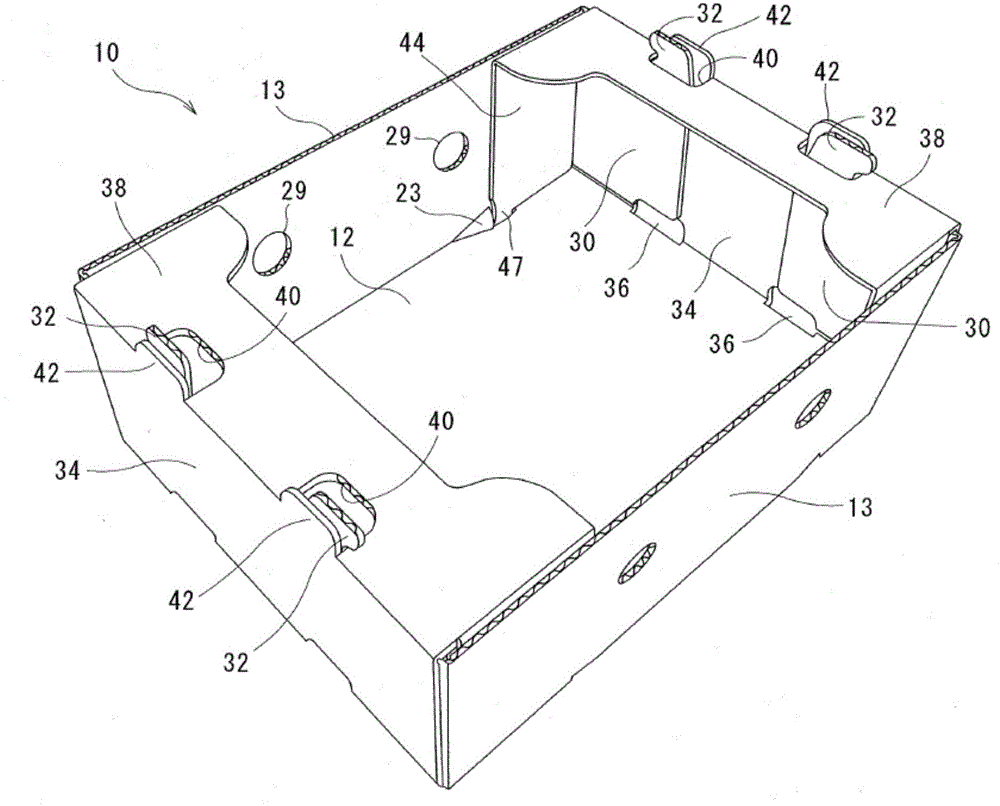

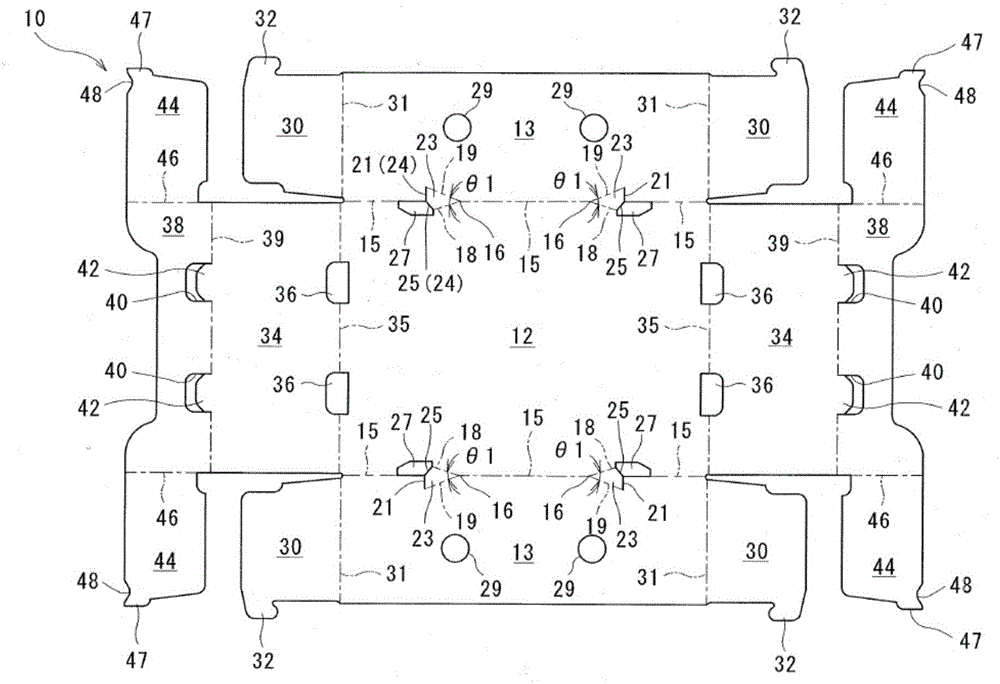

[0045] figure 1 The file box 10 of the first embodiment is shown, which is formed using corrugated cardboard and has the locking structure of the present invention. The file box 10 forming a container is a box including: a bottom panel (first panel) 12 ; side panels (second panel) 13 ; and end panels 34 . The upper end of the file box 10 is opened, and the upper end opening is partially covered by the closing flap 38 . The corrugated board has a well-known structure in which a central core of corrugated shape is placed between a front liner and a back liner.

[0046] Such as figure 2 As shown, a pair of side panels 13 , 13 are attached to the long sides (opposite sides) of the rectangular bottom panel 12 and a pair of end panels 34 , 34 are attached to the short sides (opposite sides) of the rectangular bottom panel 12 .

[0047] The side panels 13 have a rectangular plate shape, are formed continuously with the bottom panel 12, and are folded at right angles with respect ...

no. 2 example

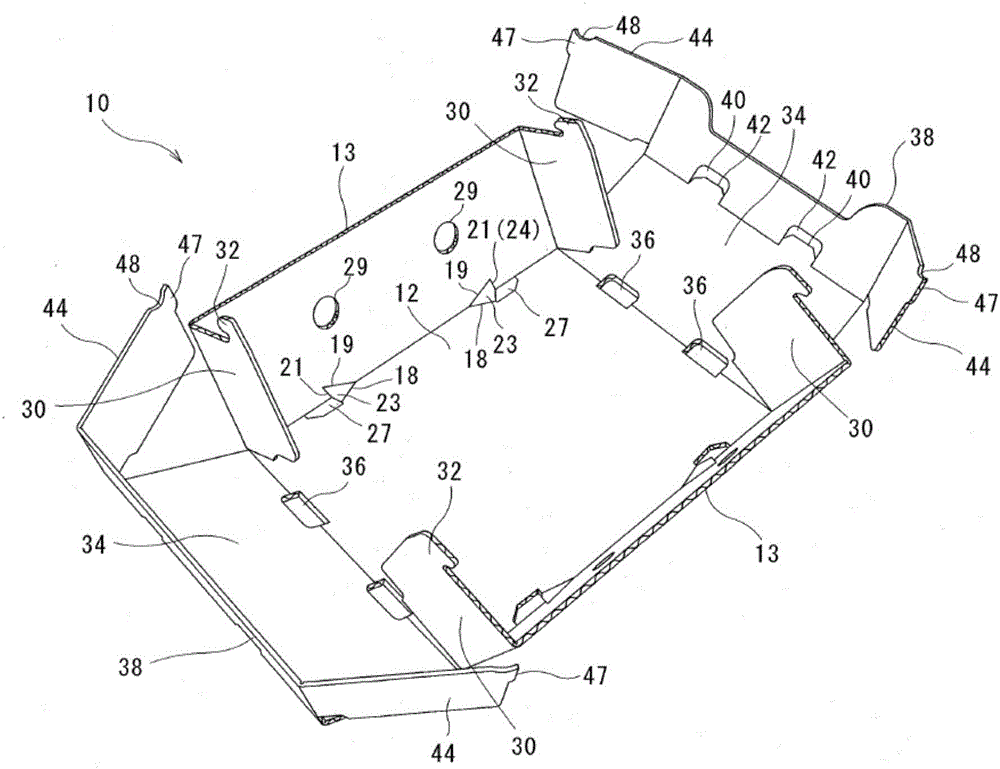

[0067] Figure 8 A file box 10 of a second embodiment is shown. Components identical to those of the document case 10 of the first embodiment are given the same reference numerals, and descriptions of these components are omitted. The file box 10 of the present embodiment differs from the file box 10 in the first embodiment in that a lock receiving portion 23 and a cut-out portion 27 are formed on each boundary portion between the side panel 13 and the folding flap 30 . In the second embodiment, the folding flap 30 corresponds to the first panel, the side panel 13 corresponds to the second panel, and the locking member 44 corresponds to the third panel. A locking recess 48 is formed on the outer end edge 45 of each locking piece 44 . In the second embodiment, the cutout portion 27 may not be formed.

[0068] In the second embodiment, the side panel 13 is folded relative to the bottom panel 12 , and the folding flap 30 is folded relative to the side panel 13 . By doing so, ...

no. 3 example

[0070] Figure 9 A file box 50 of a third embodiment is shown. In the file box 50 , side panels (second panels) 52 are connected to long sides of a bottom panel (first panel) 51 , and end panels 53 are connected to short sides of the bottom panel 51 . A lock receiving portion 55 , a cut-out portion 56 and a side panel fold line (first fold line) 54 are formed on each boundary portion between the bottom panel 51 and the side panel 52 . An end panel fold line (second fold line) 57 is formed on each boundary portion between the bottom panel 51 and the end panel 53 . A rectangular lock (third panel) 58 is attached to the outer edge of the end panel 53 . A lock piece fold line 59 is formed on each boundary portion between the lock piece 58 and the end panel 53 . A locking lug 60 protruding toward the side panel 52 is formed at an inner corner of each locking piece 58 , and a locking recess 61 is formed between the locking lug 60 and the outer end edge of the locking piece 58 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com