Permanent-magnet generator rotor and its manufacturing method

A technology of permanent magnet generator and manufacturing method, which is applied in the direction of magnetic circuit rotating parts, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc., and can solve the problems of inability to eliminate axial magnetization component, magnetic dust blockage, magnetic Large steel volume and other issues, to achieve the effect of reducing the demagnetization effect, avoiding magnetic circuit saturation, and large effective air gap area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

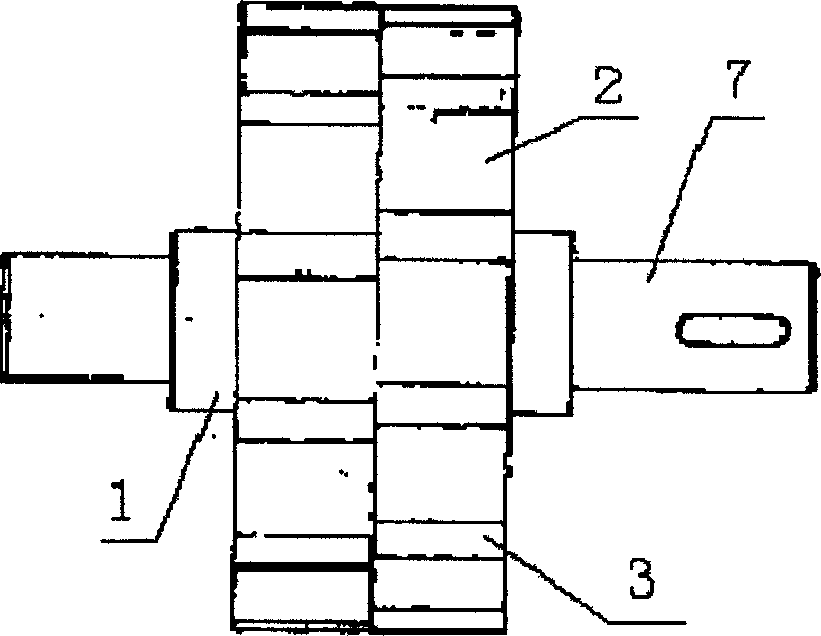

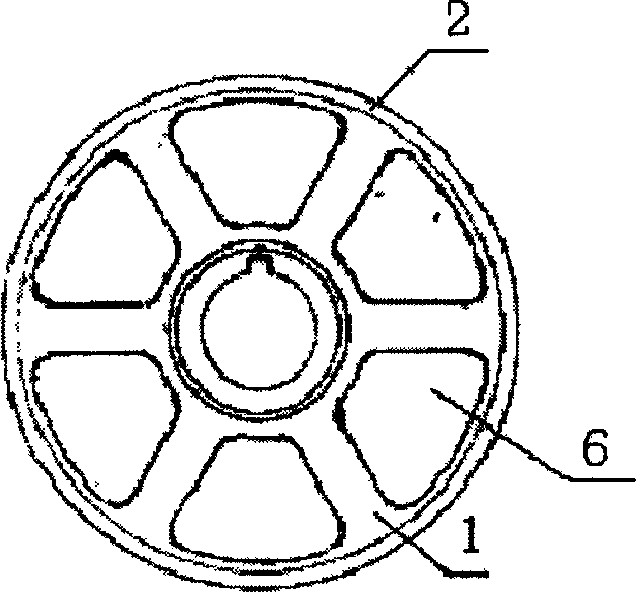

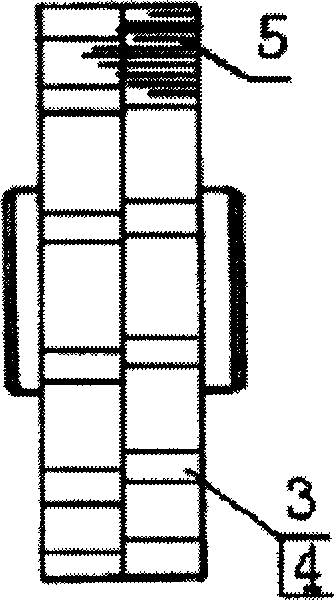

[0018] Embodiments of the present invention: as attached figure 1 or attached figure 2 As shown, it is composed of a rotating shaft (7), a rotor outer ring (2), a spoke wheel rotor body (1) and 12 straight rare earth magnets (3), and the spoke wheel rotor body (1) is mounted on the shaft On (7), the rotor outer ring (2) is press-fitted on the surface of the spoke-wheel rotor body (1), and several straight lines (5) are rolled on the surface of the spoke-wheel rotor body (1). The body (1) is provided with 6 through holes (6), as attached image 3 As shown, there are 12 dovetail-shaped straight grooves (4) on the surface of the rotor outer ring (2), and the straight grooves (4) are parallel to the axis of the rotor outer ring (2), and the straight rare earth magnets ( 3) has a dovetail-shaped cross section, and 12 straight rare-earth magnets (3) are respectively embedded in 12 dovetail-shaped straight grooves (4). Of course, as attached Figure 4 As shown, the cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com