Assembling device and method for tee pipes

A technology for three-way pipe fittings and assembly equipment, which is applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of low assembly efficiency, high labor cost, and unfavorable long-term production and development of the company, and achieves convenient clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention are described in detail below:

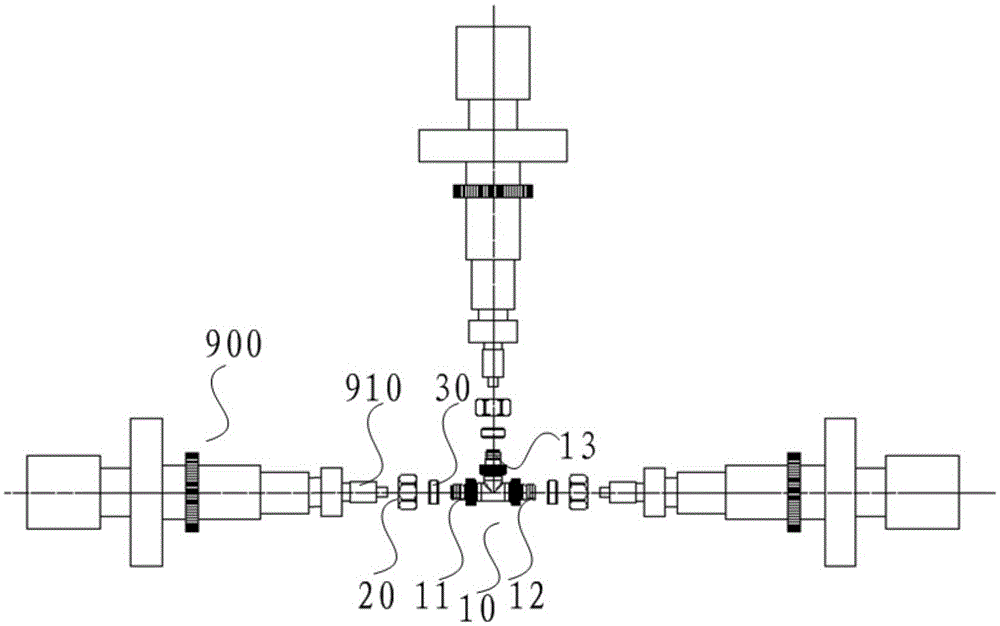

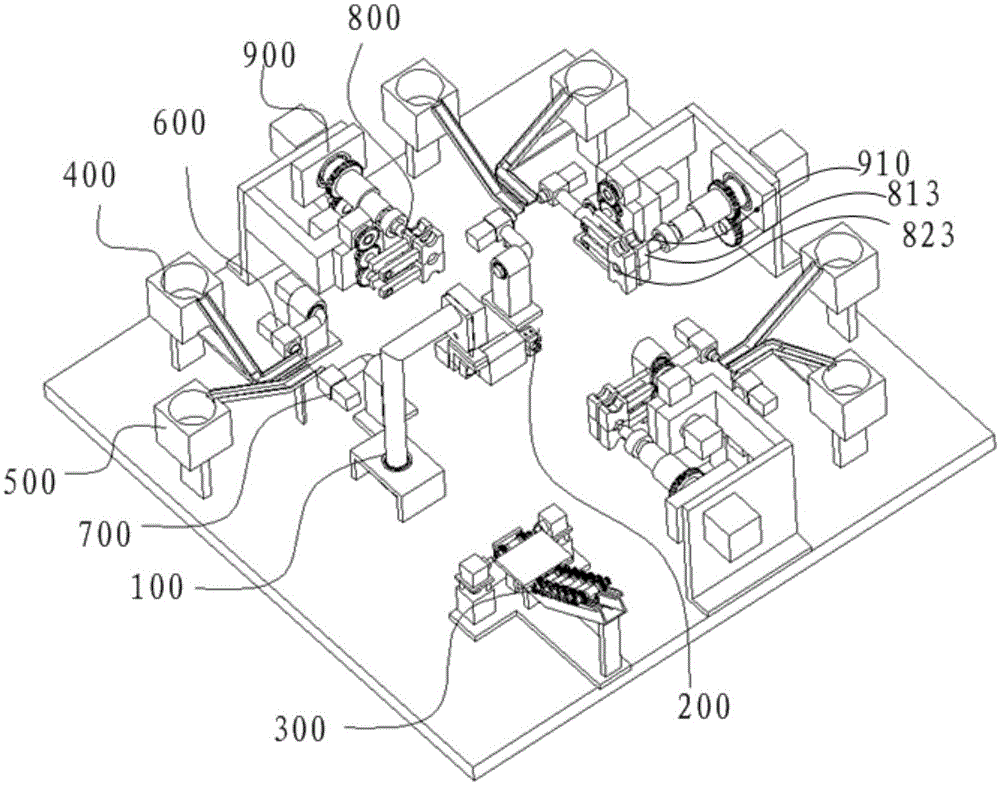

[0050] Such as Figure 1-2 As shown, a three-way pipe fitting assembly equipment, the three-way pipe fitting 10 is provided with a first joint 11, a second joint 12 and a third joint 13, the axes of the first joint 11 and the second joint 12 are located on the first straight line, The axis of the third joint 13 is located on a second straight line, and the first straight line and the second straight line intersect perpendicularly. The three-way pipe fitting assembly equipment includes a controller, a pipe fitting manipulator 100, a pipe fitting assembly location 200, and a first assembly mechanism, a second assembly mechanism, and a third assembly mechanism arranged around the pipe fitting assembly location 200. The mechanism and the third assembly mechanism are respectively used to assemble the nut 20 and the sleeve 30 to the first joint 11 , the second joint 12 and the third joint 13 of the three-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com