Electric fan

A technology of electric fans and fan blades, which is applied in the field of new electric fans, can solve problems such as time-consuming, unfavorable market competition, and complicated installation process, and achieve the effects of increasing air volume, improving the beauty of life, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

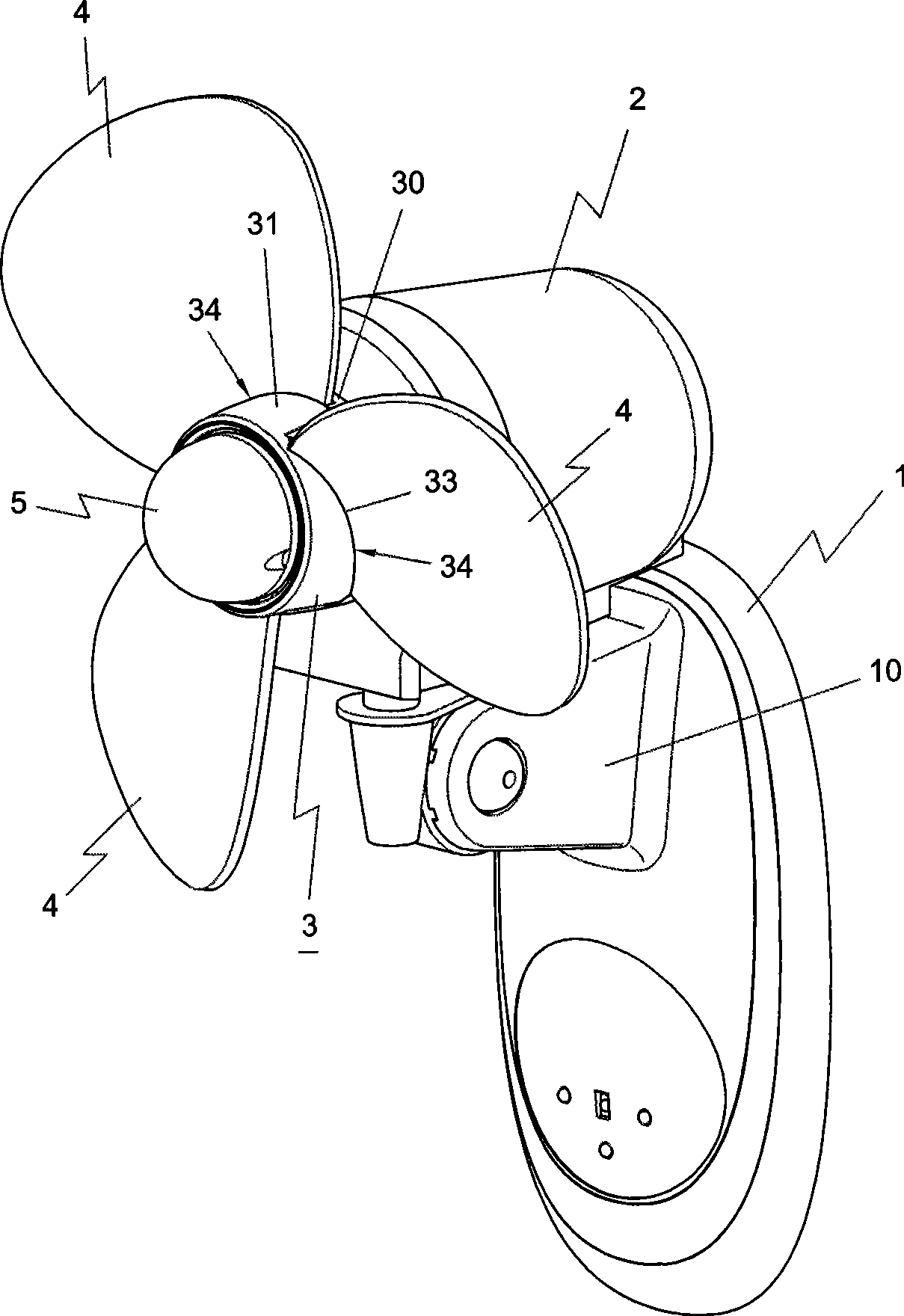

[0042] Such as figure 1 and 2 Shown, be embodiment 1 of electric fan of the present invention, embodiment 1 comprises:

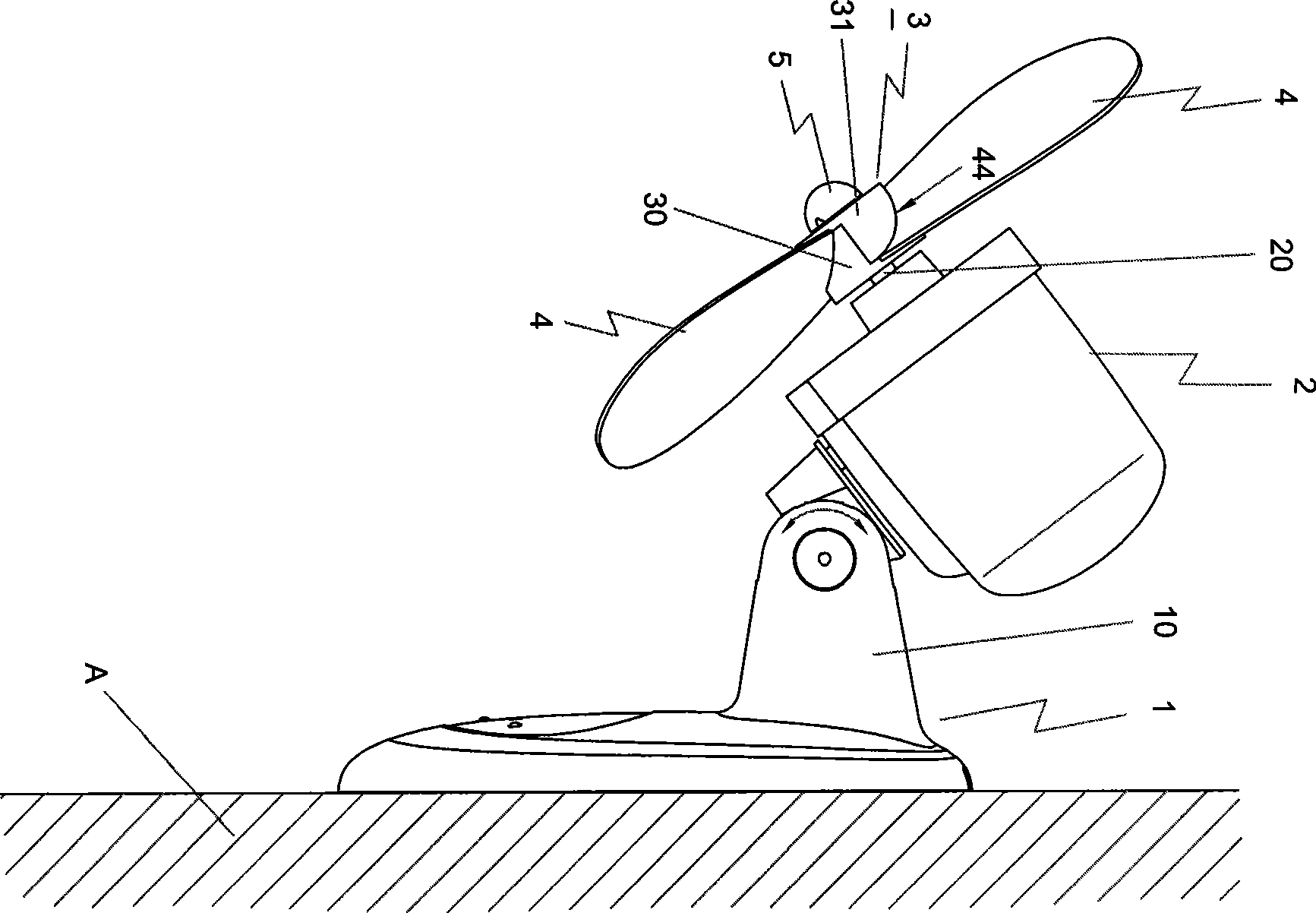

[0043] Base 1. The base 1 can be hung on the wall A or stand on the ground or on a table. A connecting seat 10 is provided on the base 1 to set the motor unit 2.

[0044] The motor unit 2, the motor unit 2 is located on the connection seat 10 of the aforementioned base 1, so that the motor unit 2 can adjust the angle up and down, as figure 2 As indicated by the R arrow, the motor unit 2 is provided with a mandrel 20 .

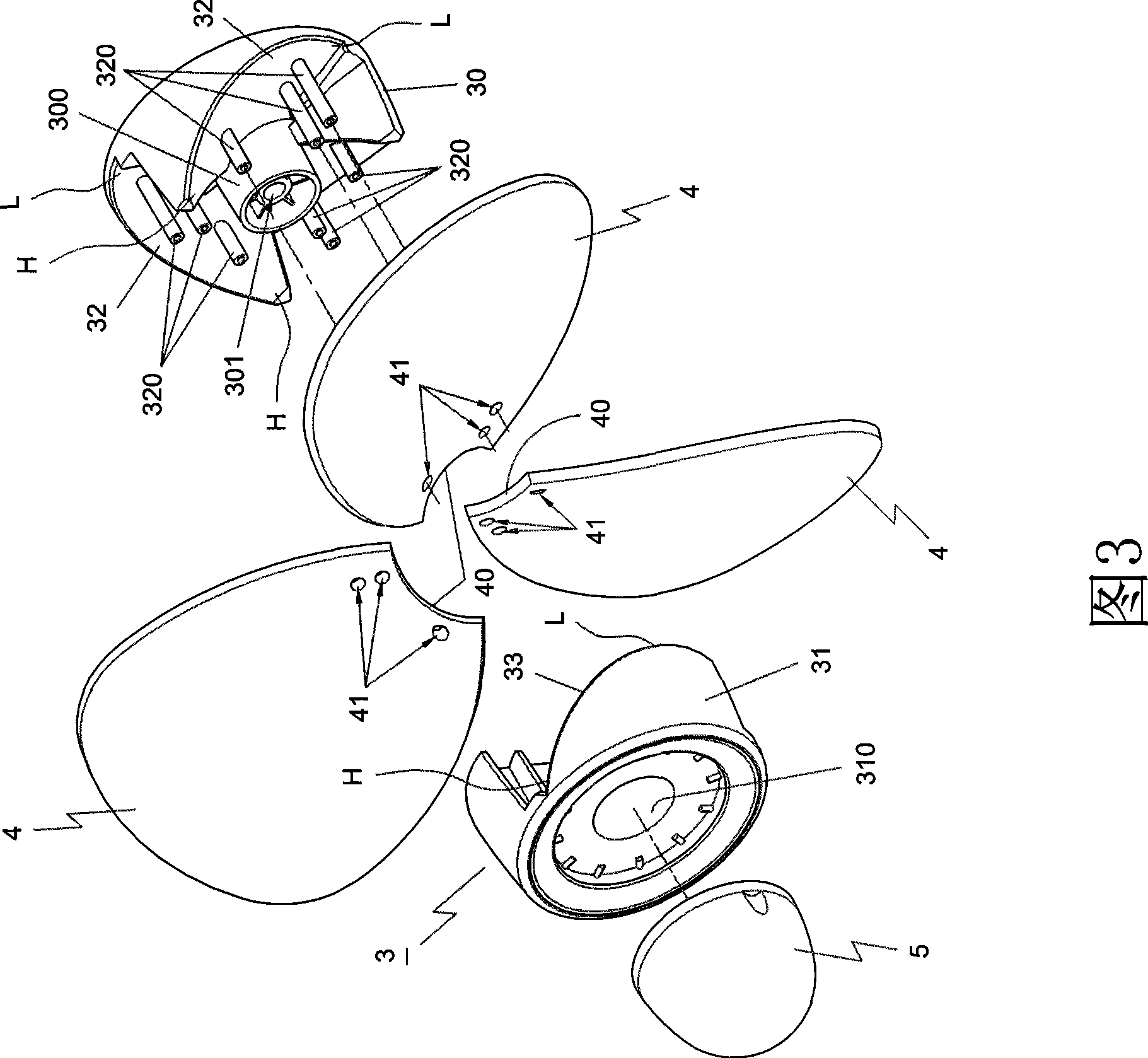

[0045] The blade seat 3, as shown in Figure 3, is provided with a first assembly 30 and a second assembly 31 corresponding to each other, the first assembly 30 is provided with a joint seat 300, the joint seat 300 is also provided with a shaft hole 301, and the second assembly 31 is provided with a joint Set 310, another example Figure 4 As shown, a plurality of curved surfaces 32, 33 are respectively provided on the first component 30 ...

Embodiment 2

[0049] Such as Figure 11 Shown, be embodiment 2 of electric fan of the present invention, embodiment 2 comprises:

[0050] The structures of the base 1 , the motor unit 2 and the fan blade 4 are the same as those of the base 1 , the motor unit 2 and the fan blade 4 in the first embodiment.

[0051] The blade seat 6 of the second embodiment is provided with a first assembly 60 and a second assembly 61 corresponding to each other, the first assembly 60 is provided with a joint seat 600, the joint seat 600 is also provided with a shaft hole 601, and the second assembly 61 is provided with a joint sleeve 610, a plurality of curved surfaces 62, 63 are respectively provided on the first component 60 and the second component 61 (this can refer to Figure 4 ), the curved surfaces 62, 63 of the first component 60 and the second component 61 are in a symmetrical shape, and form a relatively symmetrical side (refer to Figure 11 H point), gradually lowering to one side (see Figure 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com