Automatic feeding device of bulb of holiday lamp

A technology of automatic feeding and light bulbs, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of reducing the production rate of assembled finished products, achieve the effect of convenient automatic assembly and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

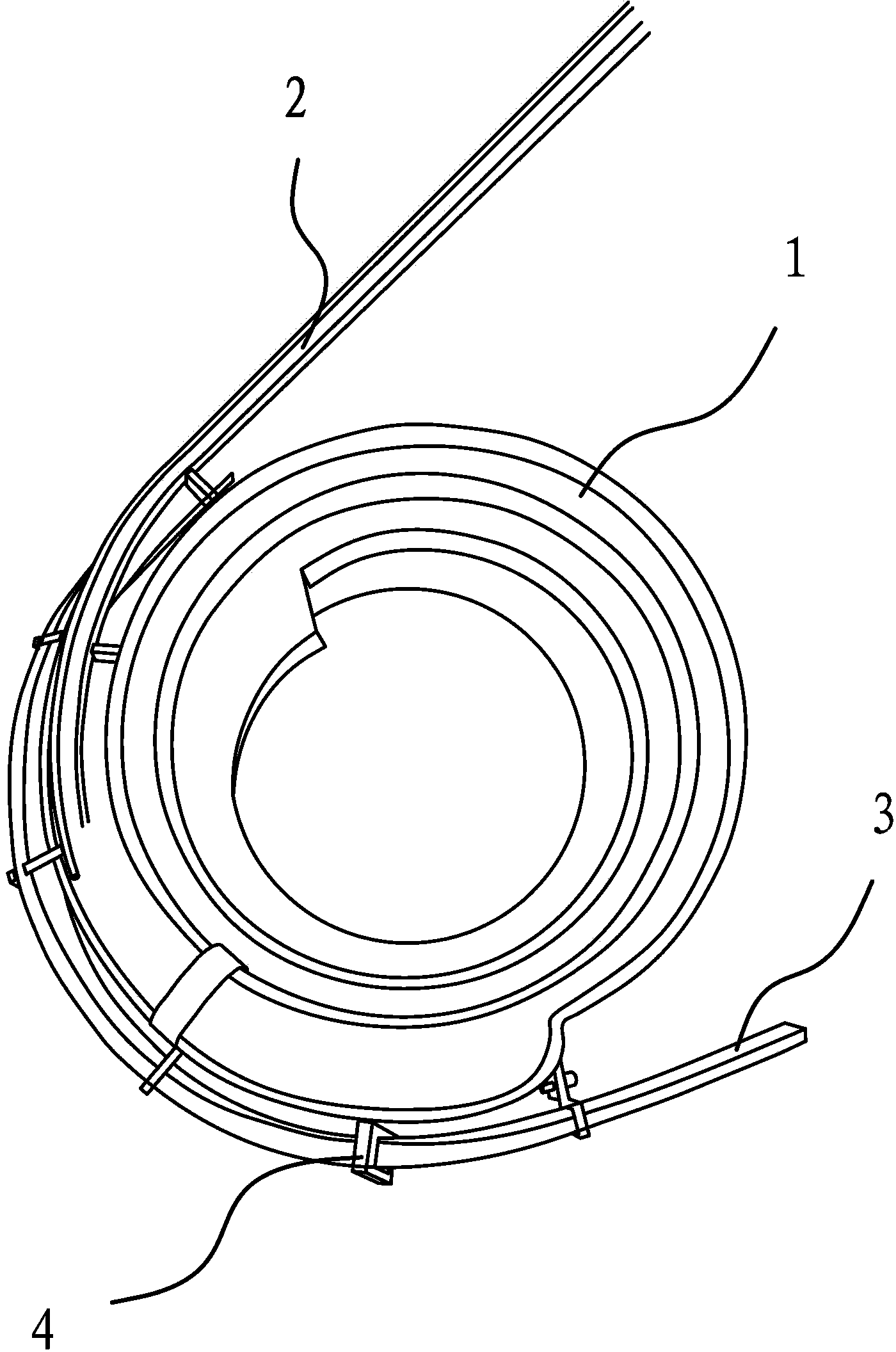

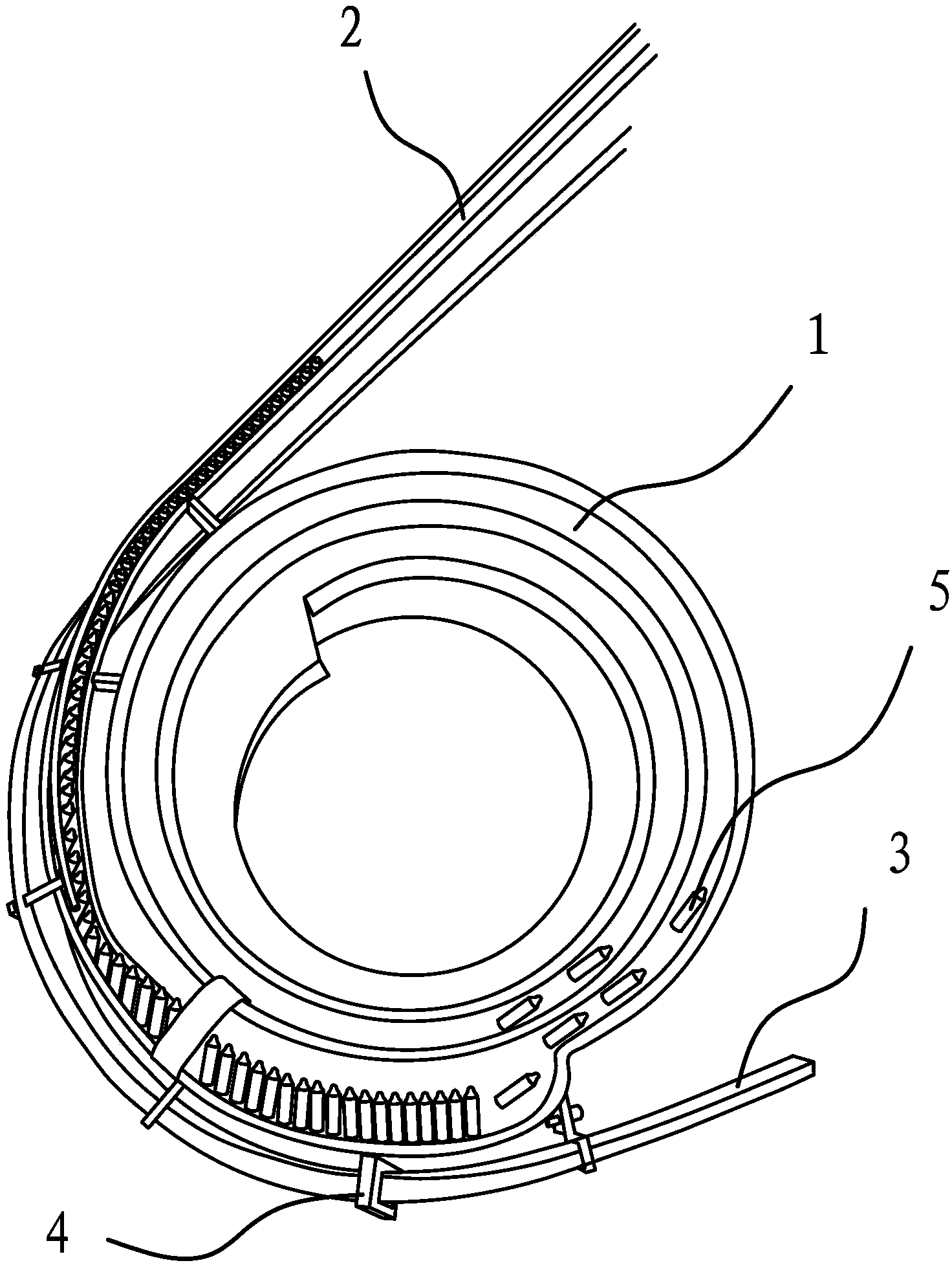

[0023] Such as figure 1 As shown, the automatic feeding device for holiday light bulbs includes a vibrating feeding tray, in which there is a hopper 1, the outlet of the hopper 1 is connected with a conveying track 2, and the outer periphery of the conveying track 2 is provided with a magnetic body 3 extending parallel to it.

[0024] The vibrating feeding tray includes a base, the top side of the base is fixedly connected with the spiral hopper 1, and a controller capable of causing the hopper 1 to vibrate is also arranged on the base. On the screw hopper 1, a connection hole is provided on the side wall of the discharge port on the top side, and a connection hole is correspondingly provided on the side wall of the feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com