Liquid pump using elastomeric piston, piston assembly and manufacturing method thereof

a technology of elastomeric pistons and liquid pumps, which is applied in the direction of liquid fuel engines, positive displacement liquid engines, single-unit apparatuses, etc., can solve the problems of increasing equipment costs, difficulty in manufacturing and assembly, and difficulty in improving product precision, so as to facilitate automatic assembly and improve product precision and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

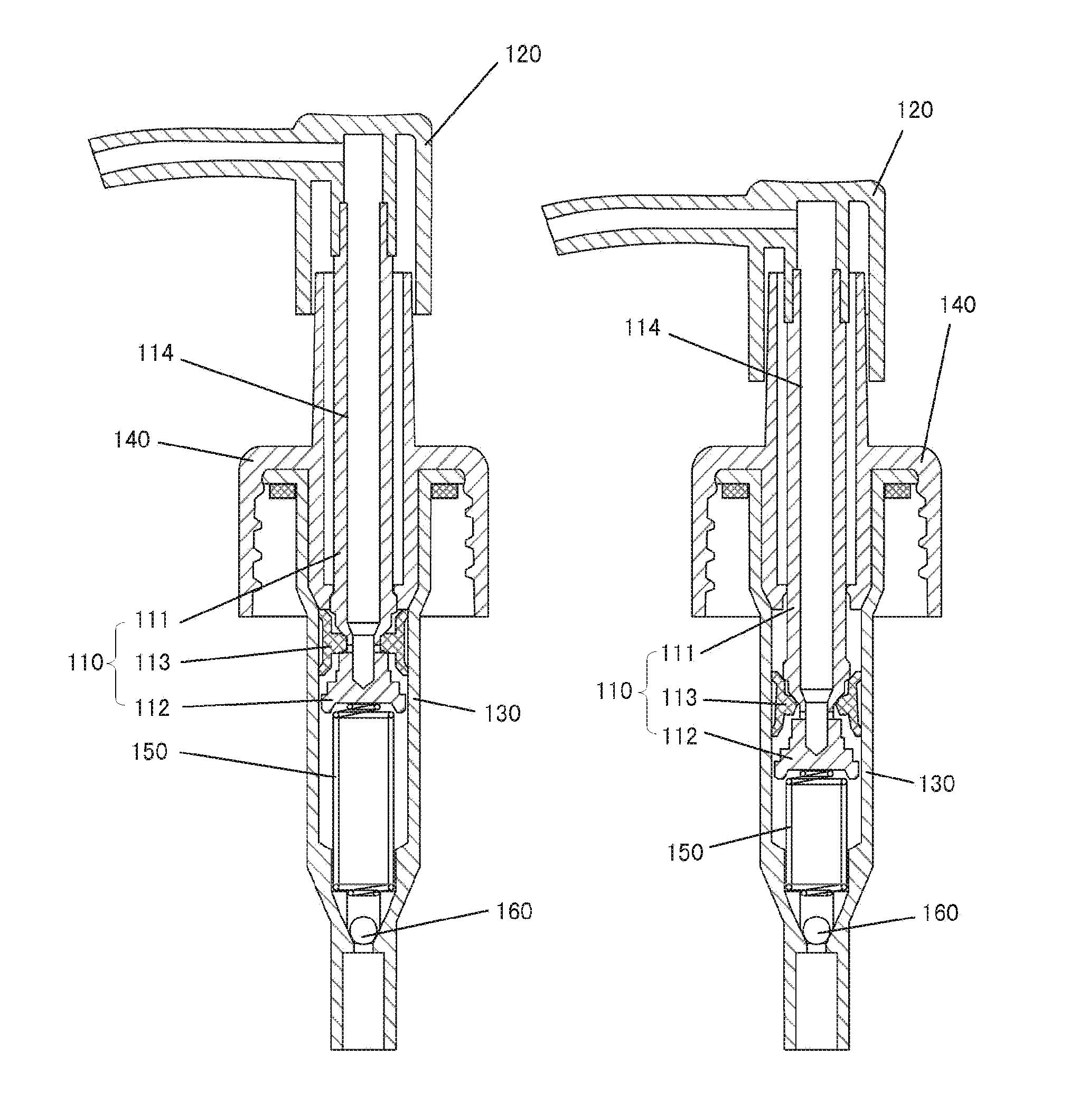

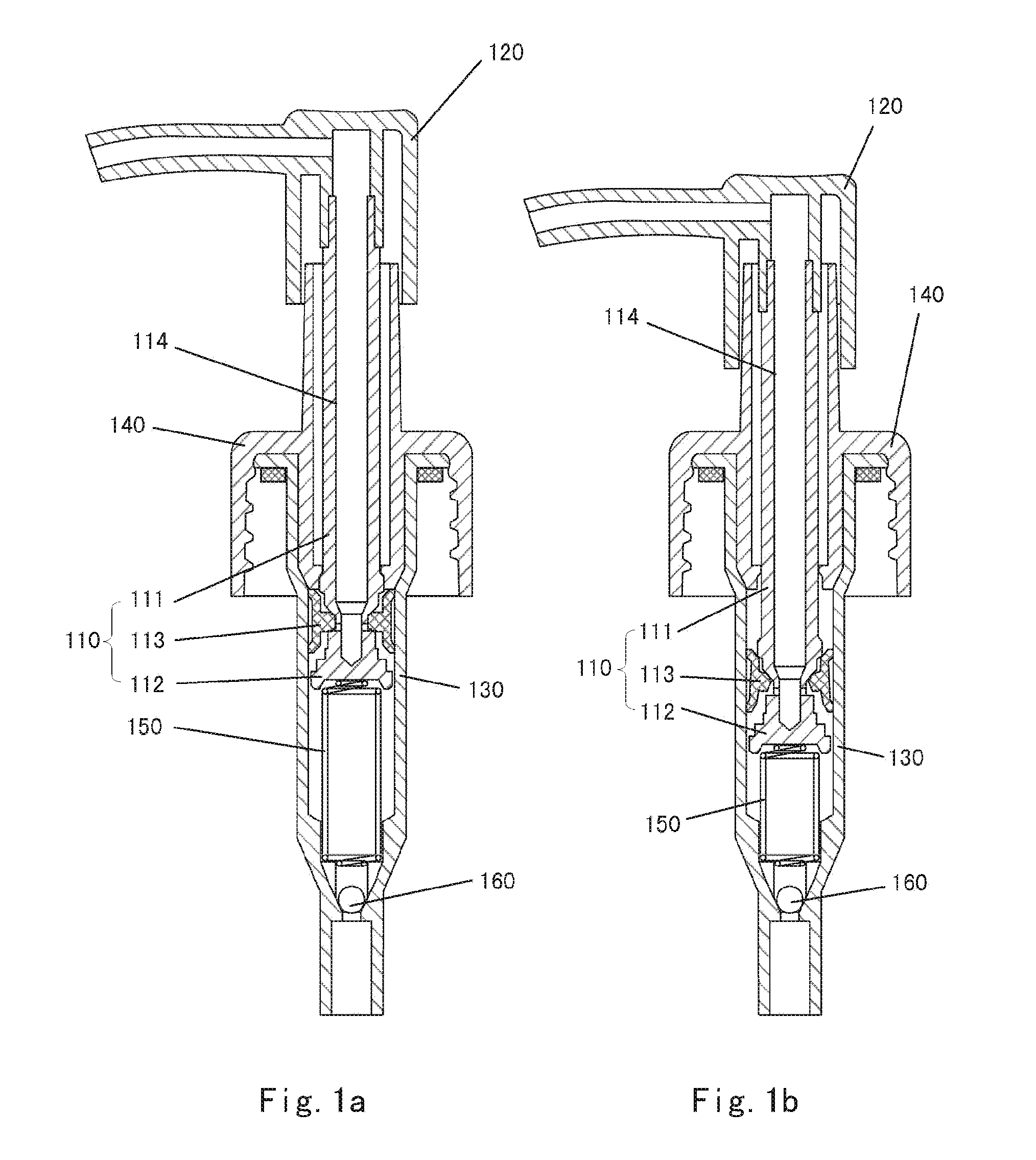

[0059]Referring to FIGS. 3-6, a liquid pump of the invention mainly comprises a piston assembly 10, a press head 20, a cylinder 30, an integrated threaded sleeve-cylinder cap 40, a spring 50 and a lower non-return ball valve 60. The liquid pump can, through its integrated threaded sleeve-cylinder cap 40, be mounted at an opening (usually an open neck) of a container (not shown) of a liquid product. Of course, the threaded sleeve and cylinder cap can also be of the separate type. As the invention focuses on the piston assembly of liquid pump, other components of the liquid pump, which may be of the conventional structures, are not described in detail in this application.

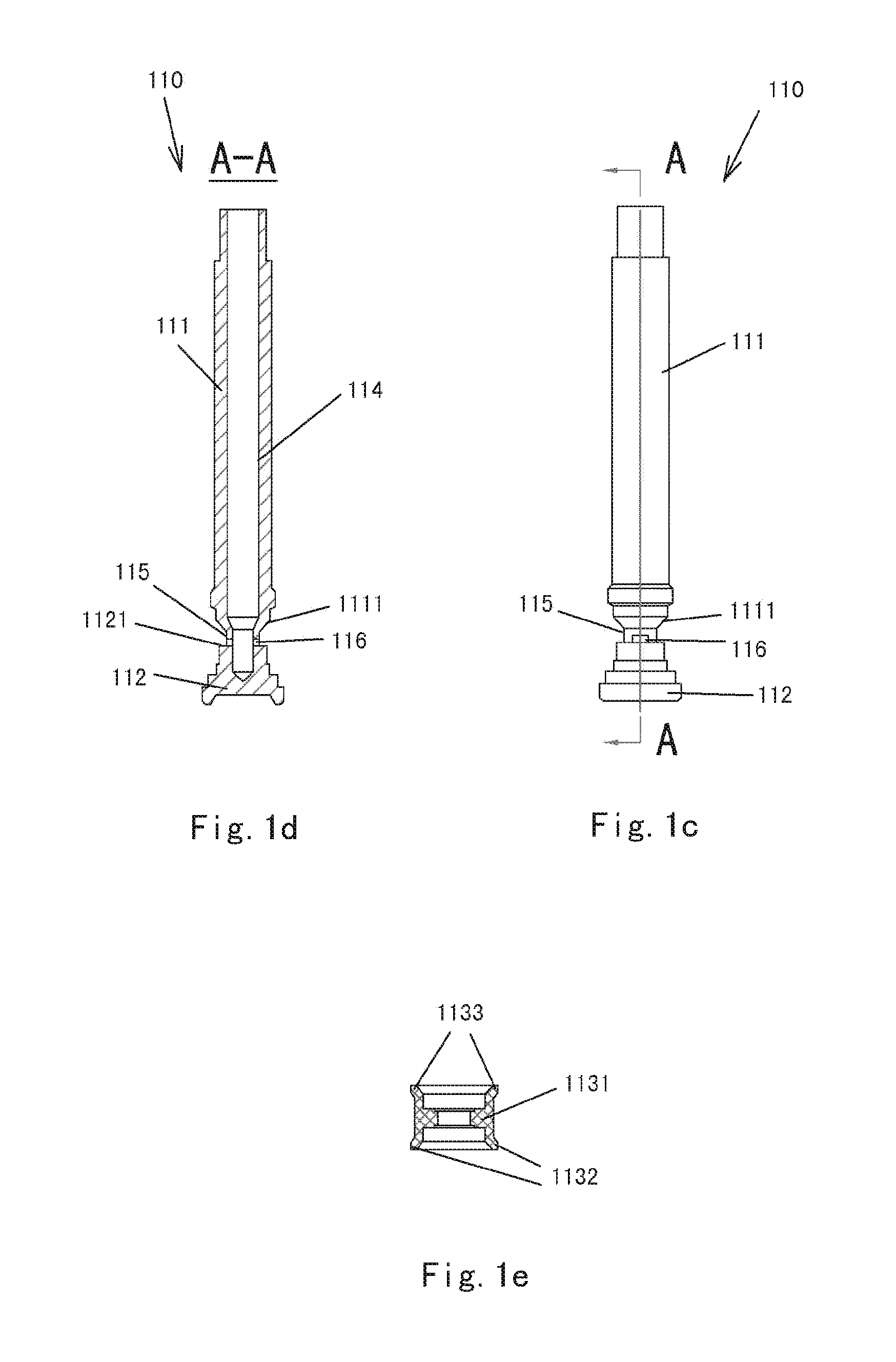

[0060]The piston assembly 10 is composed of a piston rod 11, a piston head 12 and a piston 13 fitted around a piston engaging portion 15 between the piston rod 11 and the piston head 12. Both the piston rod 11 and the piston head 12 can be made of a relatively rigid plastic material, for example, polypropylene, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| longitudinal length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com