Self-resetting double-sealing reverse locking composite bearing

A composite bearing and self-resetting technology, which is applied to bearing components, shafts and bearings, ball and roller bearings, etc., can solve the problems of high noise in bearing operation, mutual impact of parts, and inconvenient installation, so as to avoid internal corrosion and avoid The effect of mutual impact and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

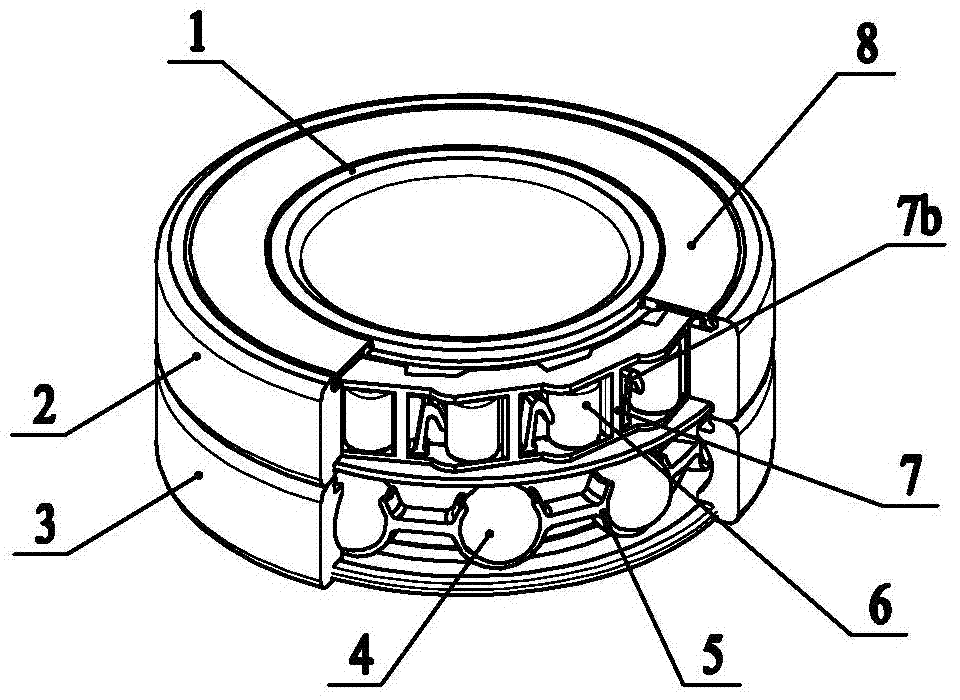

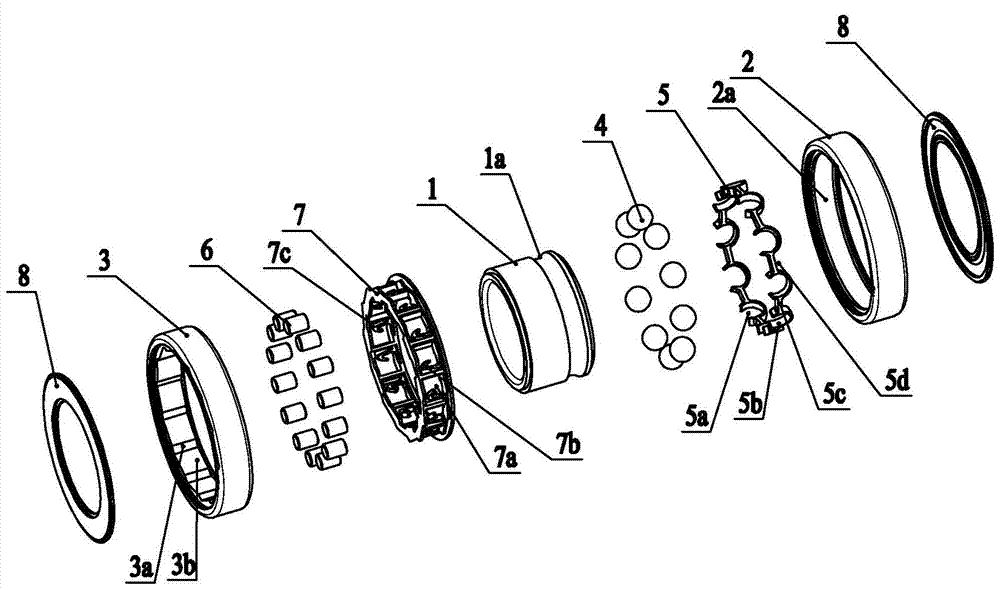

[0022] As shown in the figure: the self-resetting double-sealed reverse stop composite bearing in the embodiment is mainly composed of an inner ring 1, a first outer ring 2, a second outer ring 3, a ball 4, a wave-shaped cage 5, a roller 6, a self- It is composed of reset retainer 7, seal 8 and other components.

[0023] Such as figure 1 , figure 2 As shown, the first end of the outer peripheral surface of the inner ring 1 is provided with an inner ball groove 1a with a circular arc in cross section, and the second end is a smooth surface; the inner peripheral surface of the first outer ring 2 is provided with There is an outer ball groove 2a with a circular arc-shaped cross section; several groups of curved surfaces connected end to end are arranged on the inner peripheral surface of the second outer ring 3, one end of the curved surface is an arc segment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com