Universal hoisting clamp for circular tube

A universal and hoisting technology, applied in the field of heavy object hoisting, can solve the problems of cumbersome and time-consuming operation process, insufficient safety performance, poor stress conditions, etc., and achieve the effect of wide application range, easy implementation and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is further explained:

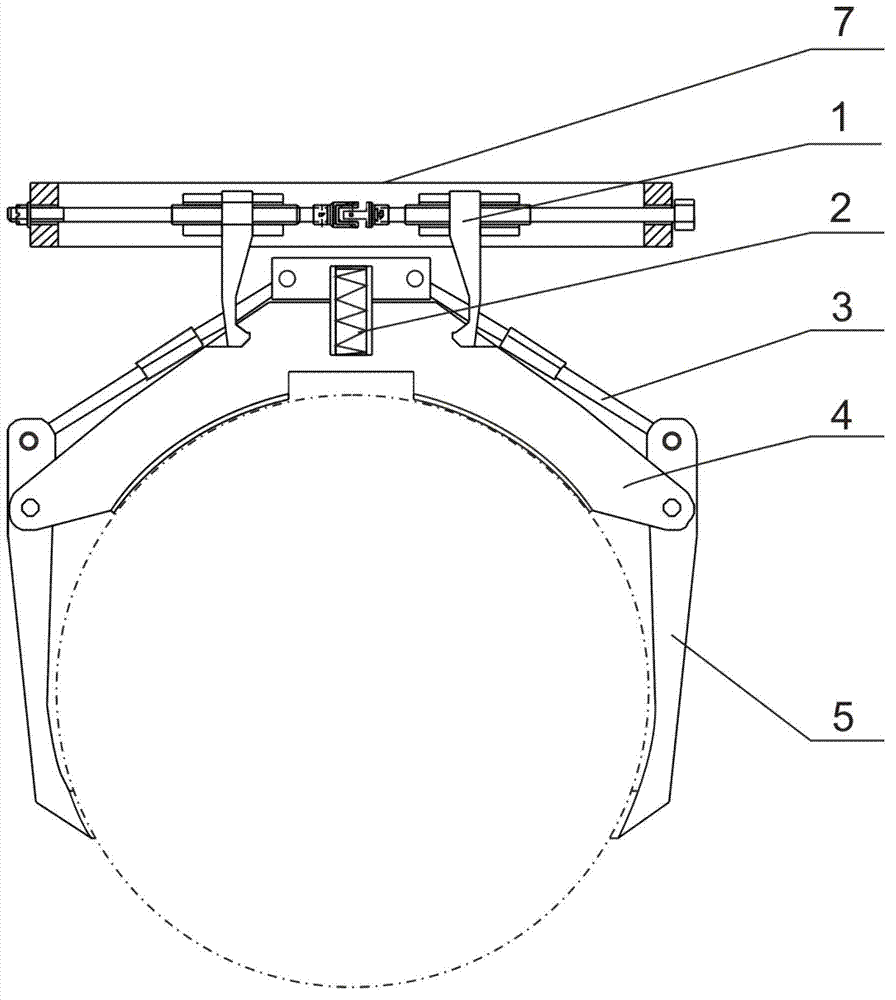

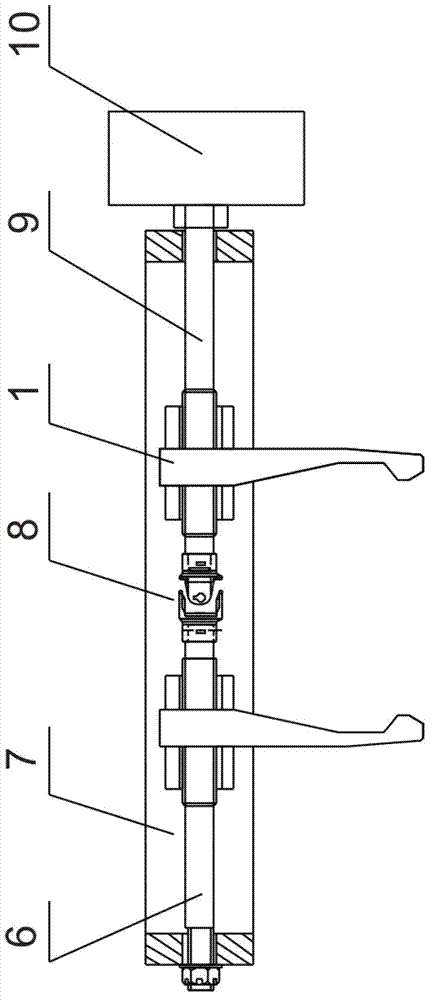

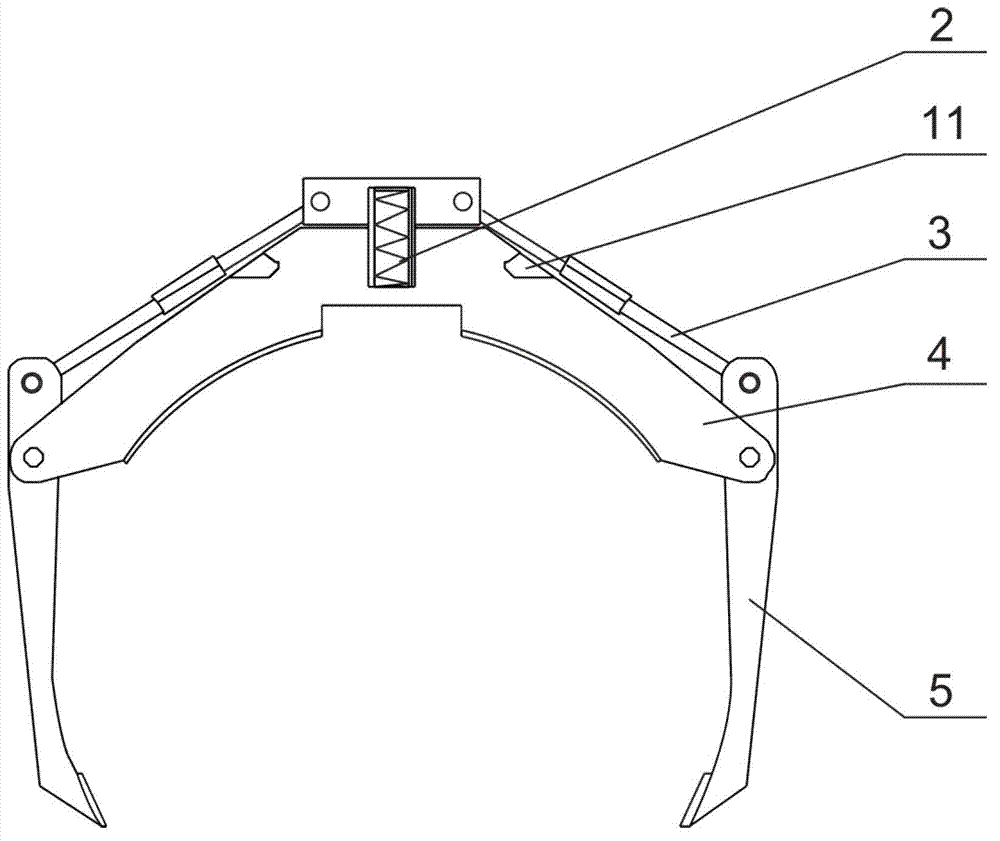

[0014] like figure 1 , 2 As shown in and 3, the round pipe universal lifting fixture provided by the present invention includes a clamp 5, a base 7, a reduction motor 10 installed on the right end of the base 7, a left screw rod 6 and a right screw rod installed in the base 7 9. The saddle 4, the left helical rod 6 and the right helical rod 9 are threaded with claws 1, and the end of the claws 1 is hook-shaped, and is articulated with the groove 11 provided on the upper part of the saddle 4. The top of the clamp 5 is hinged with a push rod 3, the top of the push rod 3 is hinged with the top of the saddle 4, the middle and upper part of the upper end of the clamp 5 is hinged with the end of the saddle 4, the length of the push rod 3 is manually adjusted, and the push is hinged on the saddle. The clamp 5 on the seat 4 controls its openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com