Cleaning device for plate processing

A cleaning device and plate processing technology, which is applied in the field of plate processing and can solve problems such as inability to dry plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

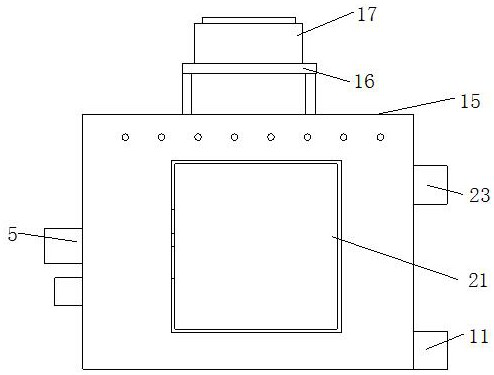

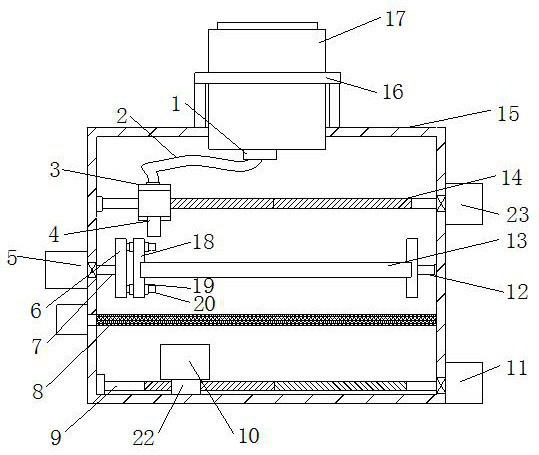

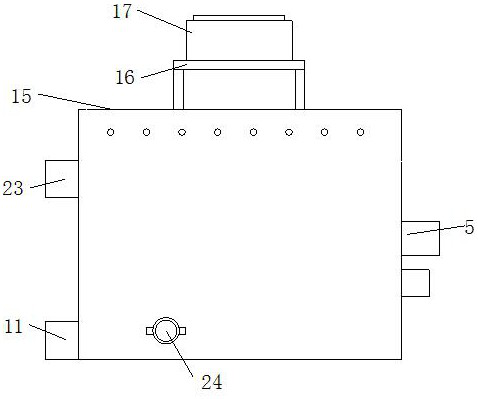

[0021] Embodiment: The present invention can be powered by commercial power, and the staff can open the transparent observation window 21, and then put the plate 13 to be processed between the two splints 18, and make the two ends of the plate 13 on the two splints 18 the inner wall of the slot, and then the staff twists the mounting nut 19 to slide the splint 18 along the direction of the mounting bolt 20, and then adjust the distance between the two splints 18, so that the two splints 18 can clamp the plate 13 fixed, then the staff drives the third motor 23 and the water pump 1, the third motor 23 works to drive the second reciprocating screw rod 14 to rotate, and then drives the water spray head 4 to move left and right through the first slider 3, and then the staff starts the water pump 1 , the water pump 1 works to spray the cleaning water in the water storage tank 17 through the connecting pipe 2 and the water spray head 4, and the sprayed cleaning water is evenly sprayed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com