High-frequency induction cutter welding device

A welding device and high-frequency induction technology, which is applied in the field of welding processing, can solve problems such as inconvenient clamping, low processing efficiency, and unstable welding quality, and achieve the effects of solving troublesome operation, simple structure, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

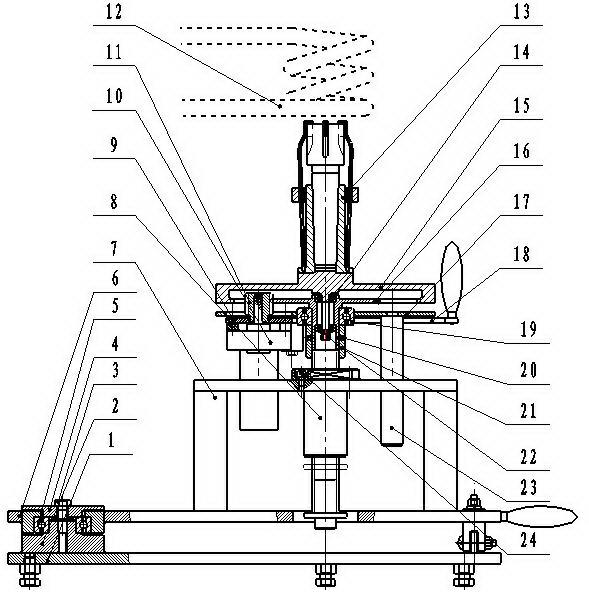

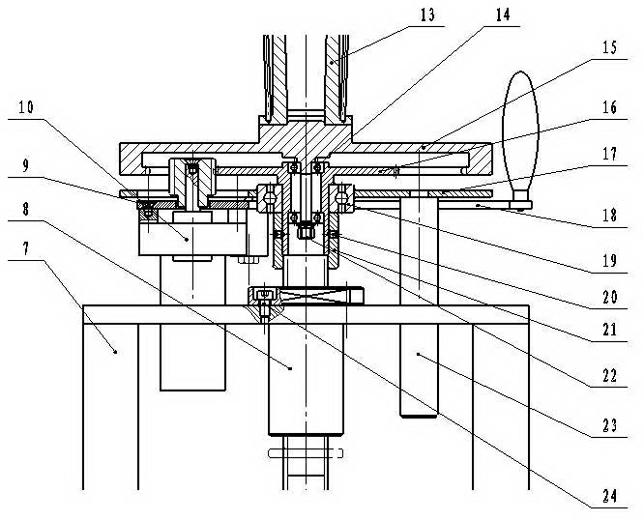

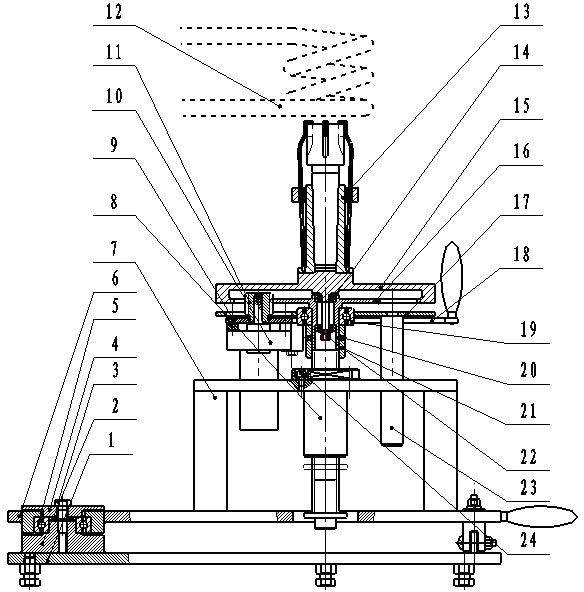

[0019] Embodiment: A high-frequency induction tool welding device of this embodiment includes: base plate 1, fixing seat 2, outer hexagon screw 3, cover plate 4, bearing A5, rotating seat 6, rotating frame 7, lifting screw nut pair 8. Screw 9, DC24V motor 10, driving gear 11, induction coil 12, clamp body 13, bearing B14, rotating table gear seat 15, lifting gear seat 16, limit plate 17, gear plate 18, bearing C19, support screw 20, coupling sleeve 21, tighten nut 22, anti-rotation rod 23, hexagon socket head cap screw 24. Bottom plate 1, fixed seat 2, nut 3, cover plate 4, bearing A5, rotating seat 6, and rotating frame 7 form the base part, wherein the outer circle of the step of fixed seat 2 is interference fit with the inner ring of bearing A, and is set in The inner hole on the rotating seat 6 is an interference fit with the outer ring of the bearing A, the bottom plate 1 and the fixed plate 2 are connected into one body by welding, the rotating frame 7 and the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com