Valve pressure tester for pipeline

A valve pressure and testing device technology, which is used in measuring devices, fluid tightness testing, and machine/structural component testing. The effect of recovering damage and deformation, strong flexibility, improving the quality of use and testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

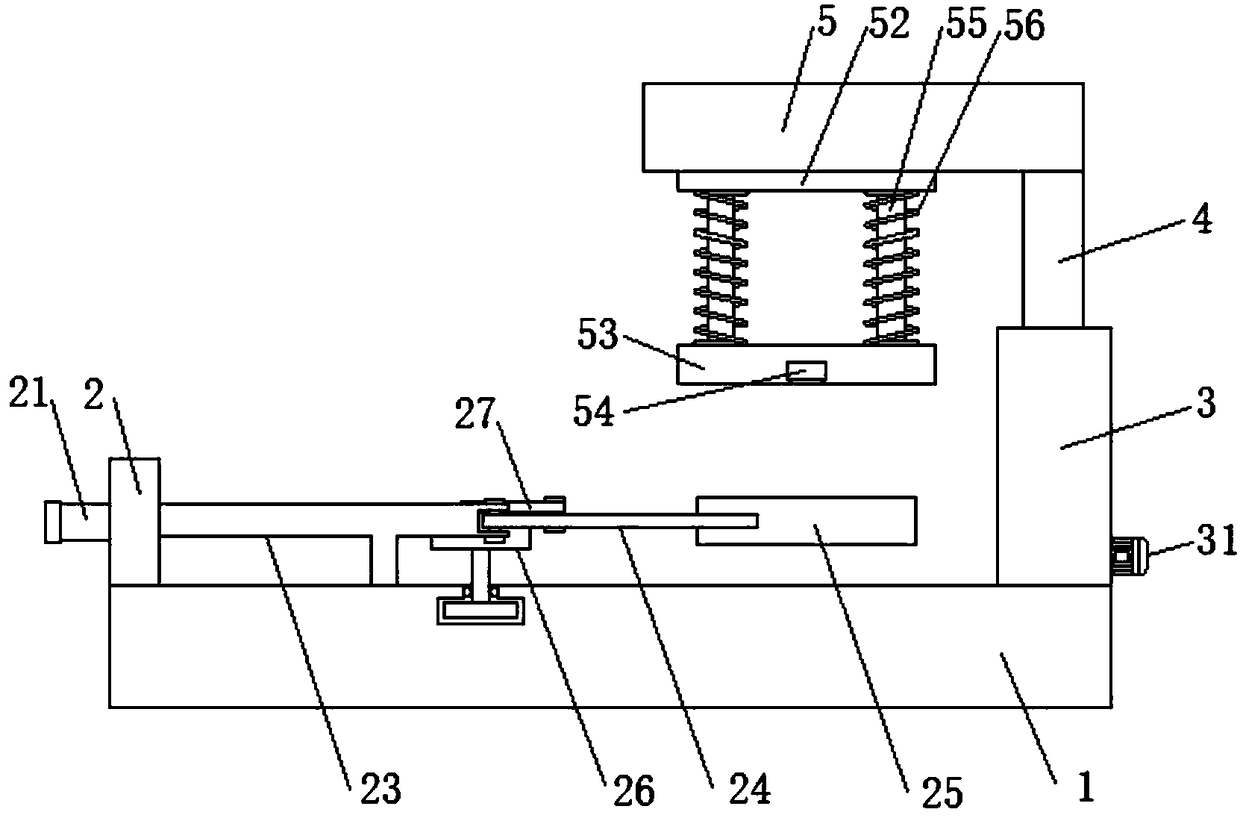

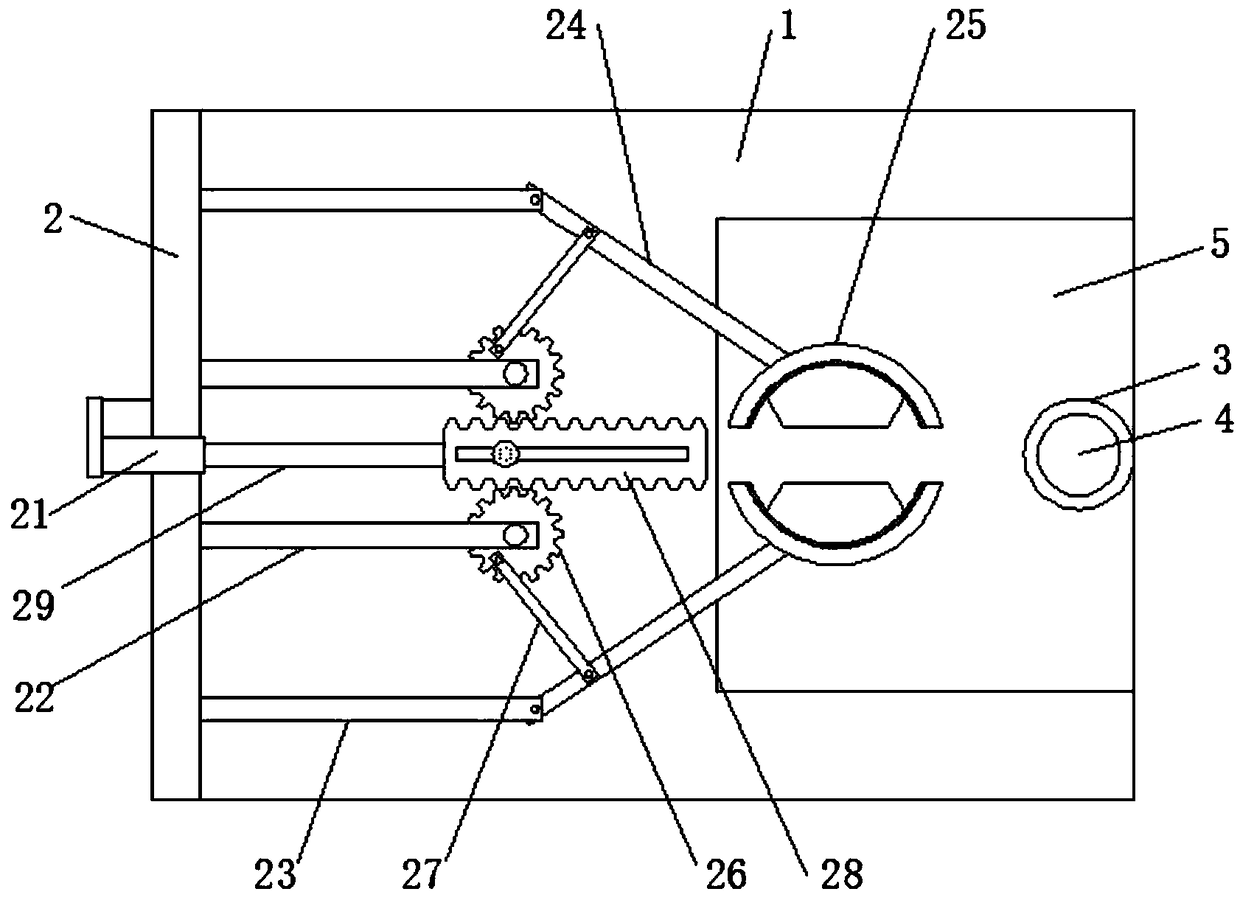

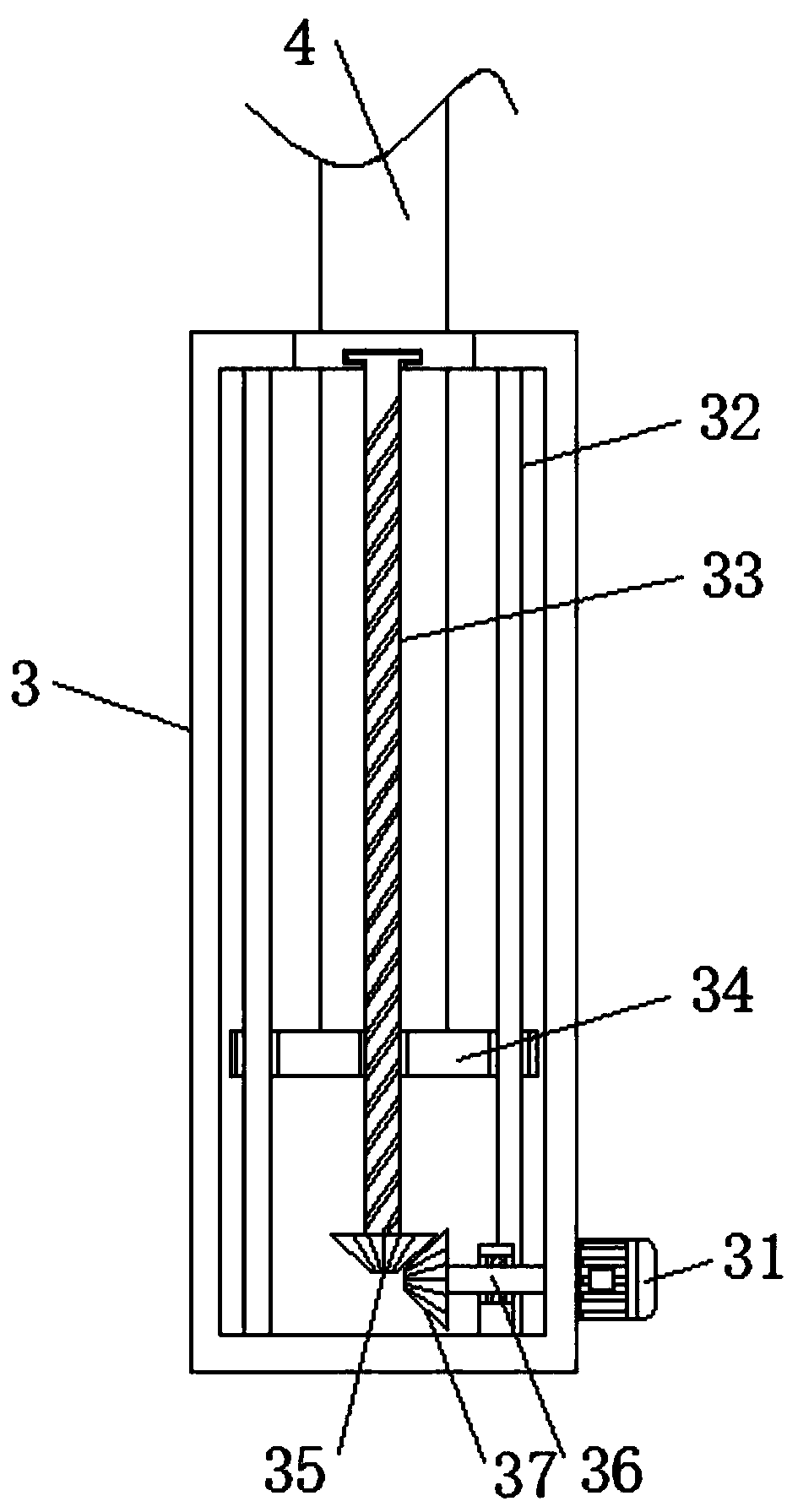

[0027] refer to Figure 1-4 , a valve pressure testing device for pipelines, including a fixed base 1, and also includes a valve fastening mechanism, a stable lifting mechanism, and a test protection mechanism that moves up and down with the stable lifting mechanism;

[0028] The valve fastening mechanism includes a positioning vertical plate 2 welded on the top side of the fixed base 1. The outer end surface of the positioning vertical plate 2 is equipped with a push rod motor 21, and the inner end surface of the positioning vertical plate 2 is respectively connected with two sets of support bars 22 and Fixed cross bar 23, two groups of supporting cross bars 22 are located between two groups of fixed cross bars 23, one end of fixed cross bar 23 is rotatably installed with adjusting long rod 24, and one end of adjusting long rod 24 is welded with valve clamping plate 25, supports One end of the cross bar 22 is rotatably equipped with a first gear 26, and the top edge of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com