Vacuum alternating-current contactor for mechanical emergency

A technology of AC contactor and emergency action, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve problems not mentioned, and achieve the effect of increasing synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

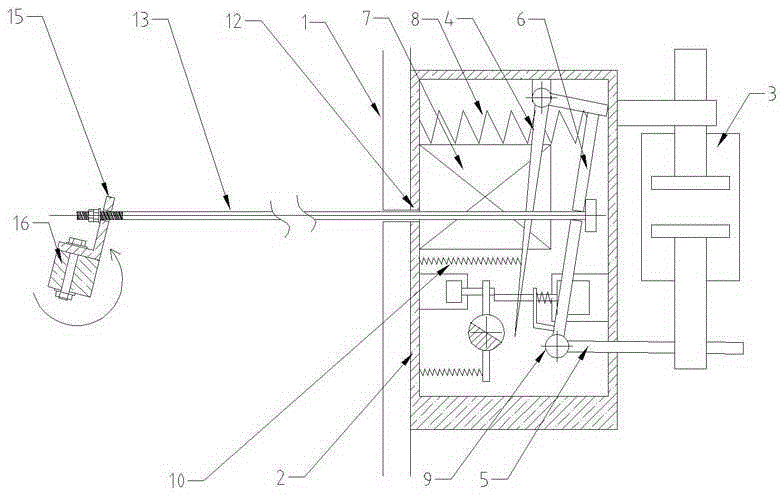

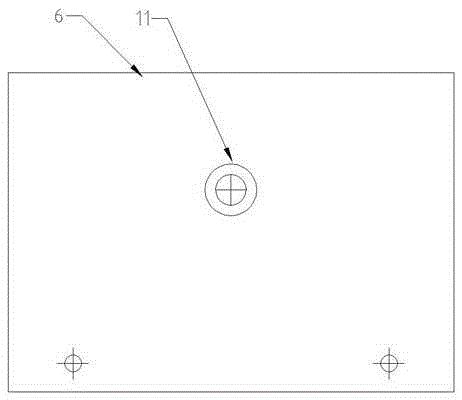

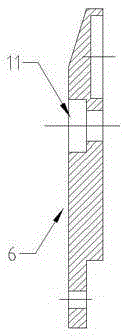

[0026] A vacuum AC contactor capable of mechanical emergency action, which is composed of an insulating frame 1, a metal rear sealing plate 2, an electromagnetic operating mechanism, a manual operating mechanism and a vacuum switch tube part 3. The electromagnetic operating mechanism has a closing and holding Buckle 4, transmission arm 5, closing armature 6, closing coil 7, opening coil and opening spring 8; wherein, the inflection point of the transmission arm 5 is installed on the closing rotating shaft 9, and one part of the transmission arm 5 The arm is the closing armature 6, and the end of the arm presses the opening spring 8 tightly, and the other arm is connected to the moving contact of the vacuum switch tube part 3; there is a closing coil 7 under the closing armature 6; there is a buckle at one end of the closing holding pin plate 4 The plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com