Dredging type silt cleaning device

A technology for cleaning equipment and silt, applied in the direction of earth mover/shovel, construction, etc., can solve problems such as threats to the life and property safety of residents, increase in river dredging construction, and poor drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] see Figure 1 to Figure 5 , the present invention provides a technical solution:

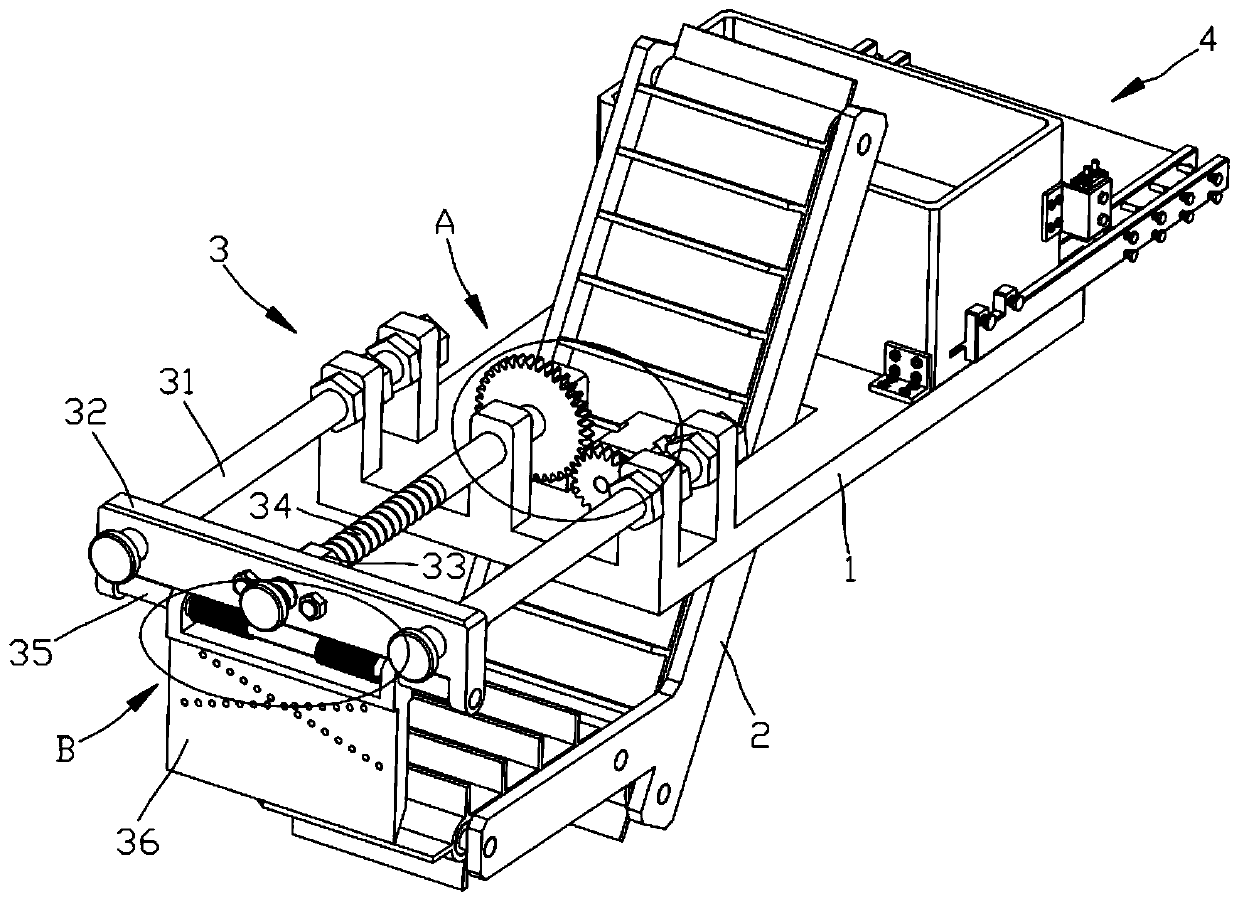

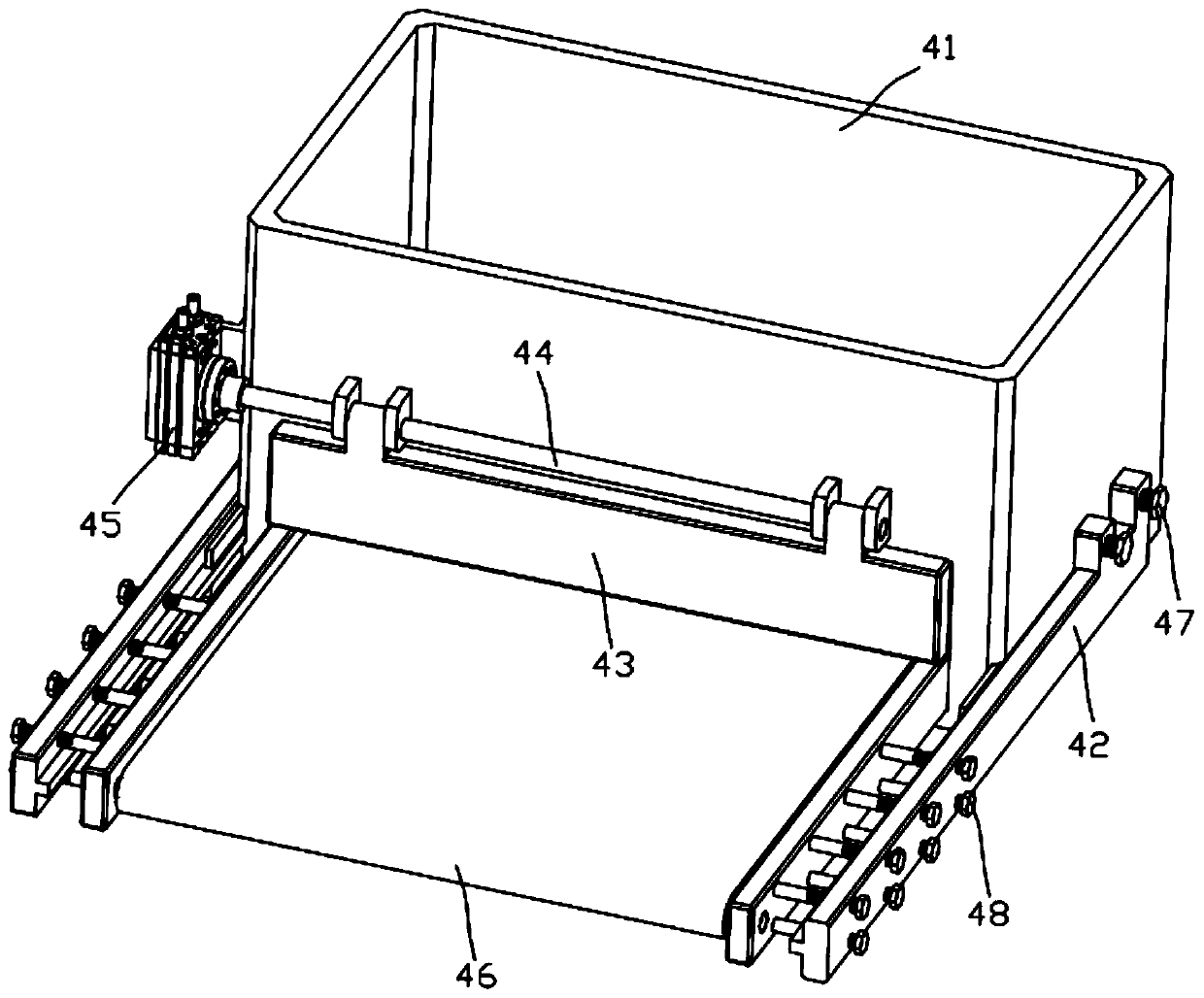

[0026] A dredging type sludge cleaning device, including a hull 1, a lifting conveyor belt 2, a dredging mechanism 3 and a transfer mechanism 4, wherein:

[0027] The conveyor belt 2 is fixedly installed on the hull 1, and the conveyor belt 2 is divided into a feed end and a discharge end, wherein the feed end of the conveyor belt 2 is located below the shovel plate 36, and the discharge end of the conveyor belt 2 is located at the receiving hopper 41 above;

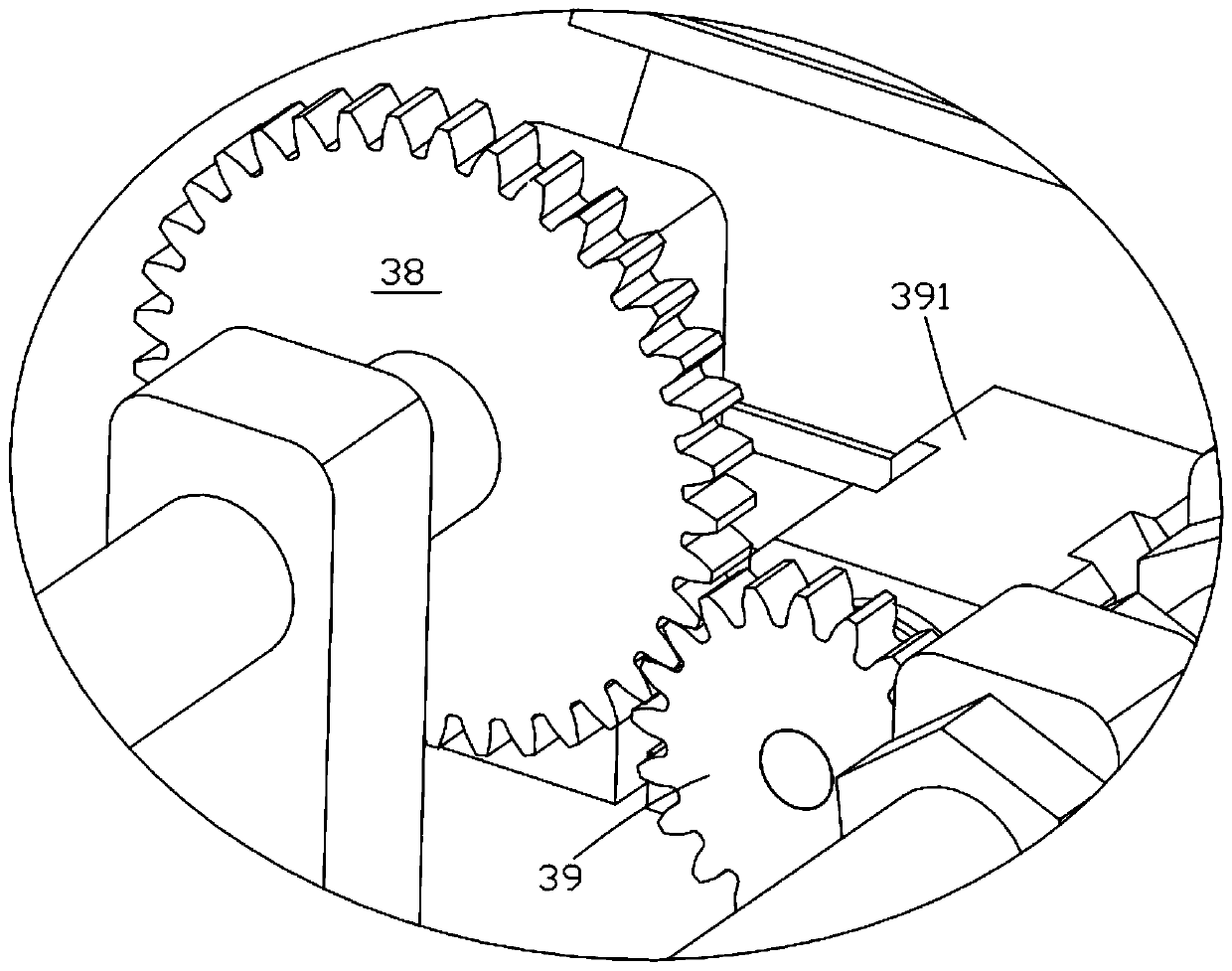

[0028] Dredging mechanism 3 comprises support rod 31, slide block 32, sleeve 33, screw mandrel 34, connecting shaft 35, shovel plate 36, torsion spring 37, bull gear 38, pinion 39 and motor 391, two support rods 31 respectively It is fixedly installed on the front support frame of the hull 1 by bolts, and the two ends and the middle of the slide block 32 are provided with round holes, wherein the round holes at the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com